2

1. Declaration of conformity....................................... 3

2. WEEE-Declaration .................................................... 4

3. Important Notes....................................................... 4

4. Features ..........................................................................5

4.1. General Features...........................................................5

4.2. Technical Data...............................................................5

4.3. Scope of delivery...........................................................5

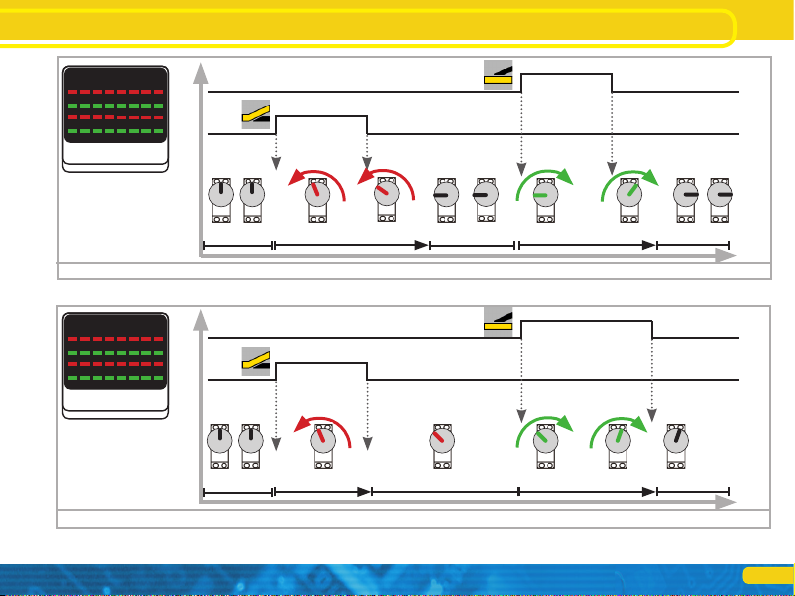

4.4. Operating modes..........................................................6

4.4.1. Digital mode..............................................................6

4.4.2. Proportional mode ...................................................6

4.5. Servo types ...................................................................8

4.5.1. Analog servos ............................................................8

4.5.2. Digital servos .............................................................8

4.5.3. ESU servo drive .........................................................8

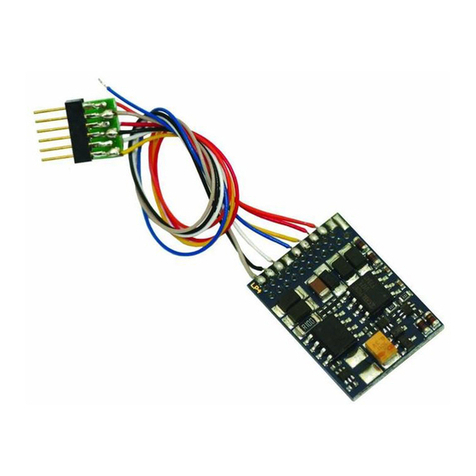

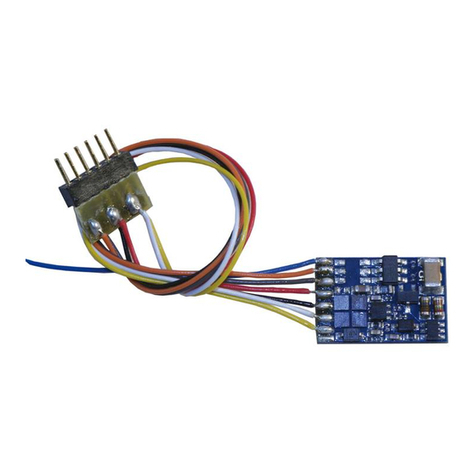

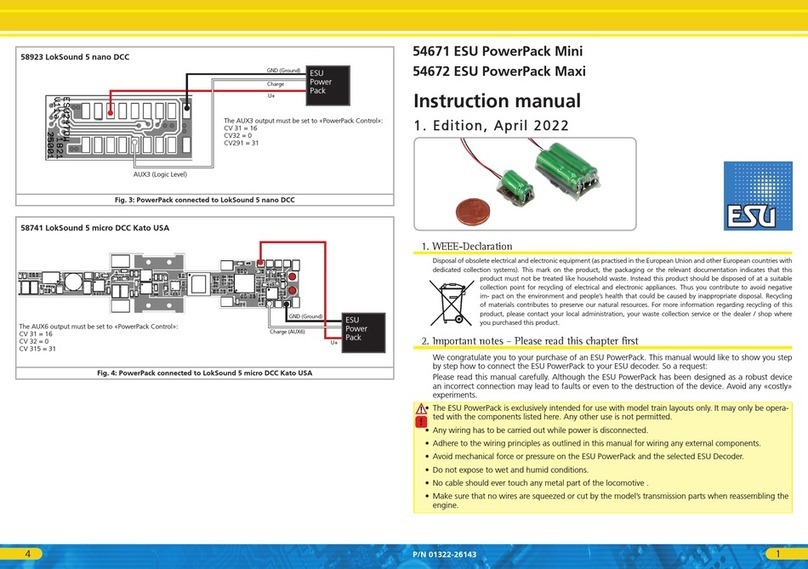

5. Connection to the digital system ........................... 9

5.1. Terminals ......................................................................9

5.2. Power supply by the digital system..............................10

5.3. External power supply ................................................10

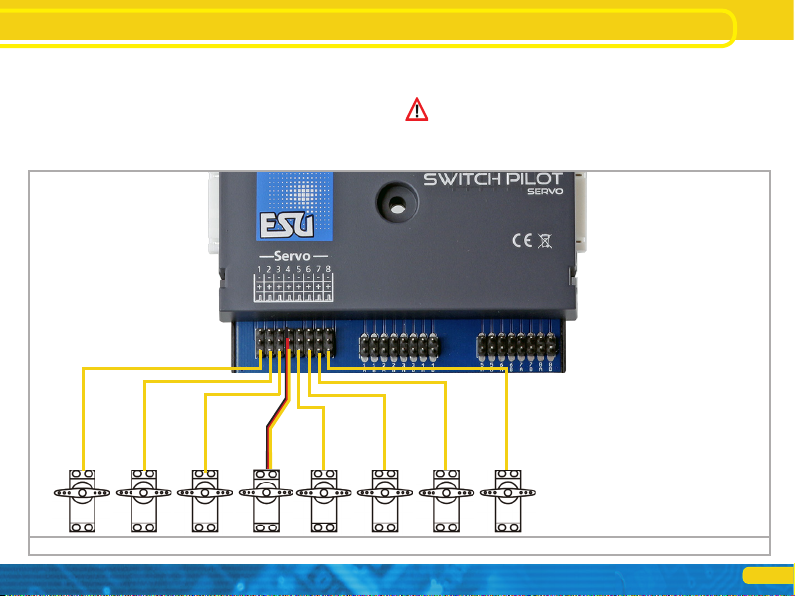

5.4. Wiring the outputs .....................................................11

5.4.1. Servo connection ....................................................11

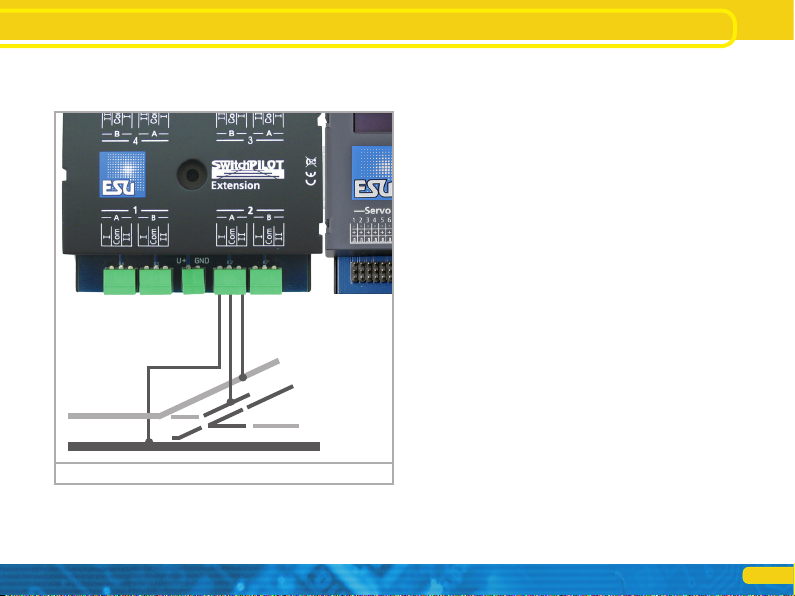

5.5. Connecting the SwitchPilot Extension .........................12

5.5.1. Relay outputs...........................................................12

5.5.2. Turnout frog polarization .........................................13

6. Configuration with OLED...................................... 14

6.1. Relationship accessory addresses / turnout numbers ...14

6.1.1. Assigning turnout numbers......................................15

6.2. Introduction to the operating structure.......................16

6.3. Address mode for ROCO® command stations ............17

6.4. Configuring outputs ...................................................17

6.4.1. Servo position und mode .........................................17

6.4.2. Servo speed and relay response time........................18

6.4.3. Servo seesaw effect (“Bouncing”)............................18

6.5. Servo pulse configuration............................................18

6.6. Function Mapping.......................................................19

Content

6.7. Status information ......................................................20

6.7.1. Display software version & track voltage ..................20

6.7.2. Displaying the status of the outputs.........................20

7. Configuration with LokProgrammer.................... 21

8. Configuration POM................................................ 22

8.1. Connection to the digital system.................................22

8.2. Reading and writing CVs with POM ...........................22

9. Configuration with the programming track........ 23

9.1. Connection to the digital system.................................23

9.2. Read & Write CVs .......................................................23

10. Learning turnout numbers from command station..23

11. RailCom® ............................................................. 24

11.1. RailCom® Configuration .........................................24

12. Direct switching with the inputs for push buttons... 24

13. Reset to factory default (decoder reset)............ 25

13.1. With the programming button..................................25

13.2. With DCC systems ....................................................25

13.3. With the display........................................................25

14. Support ................................................................. 25

15. Menu references .................................................. 26

16. Solenoid address & turnout numbers ................ 31

17. List of all supported CVs...................................... 33

18. Change history..................................................... 38

19. Warranty certificate............................................. 39