5

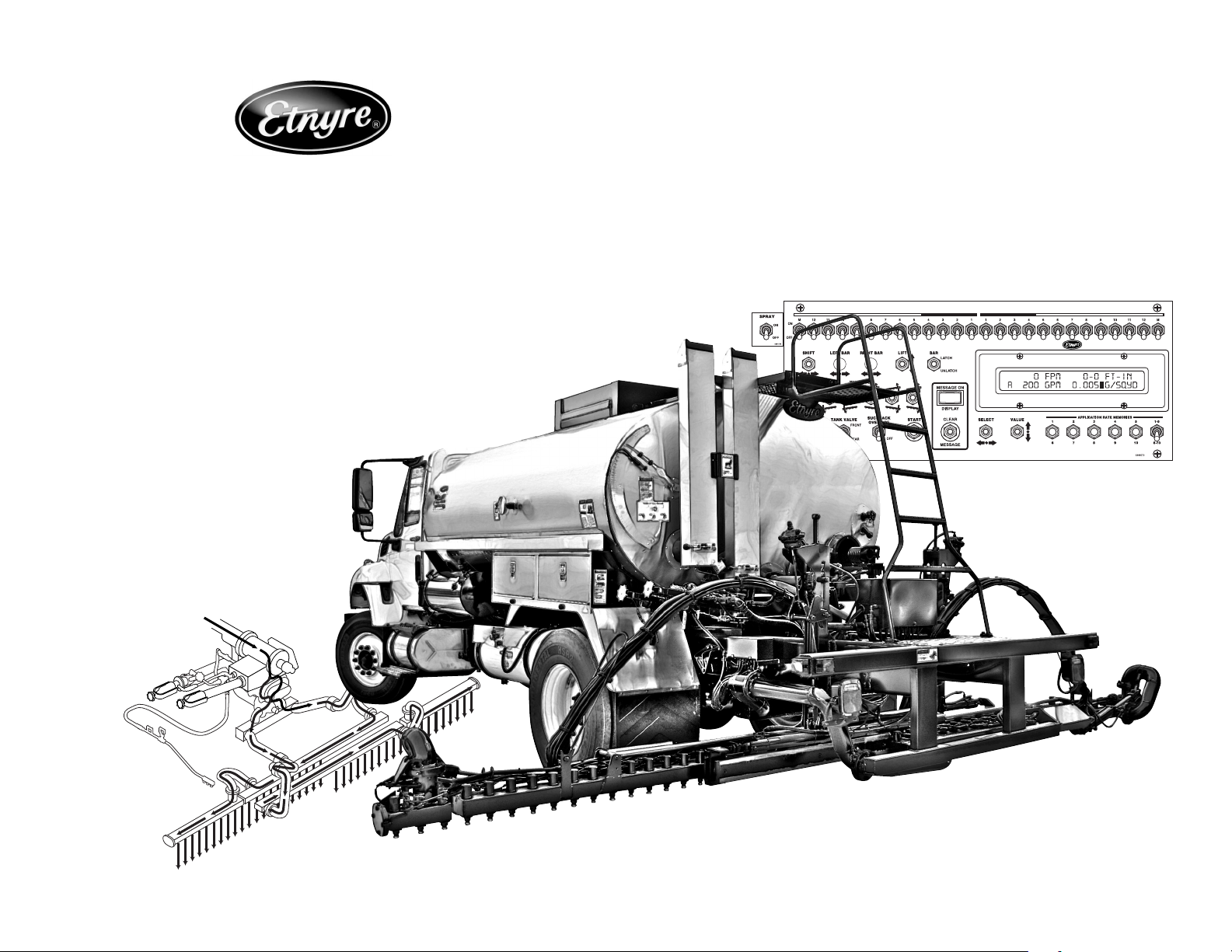

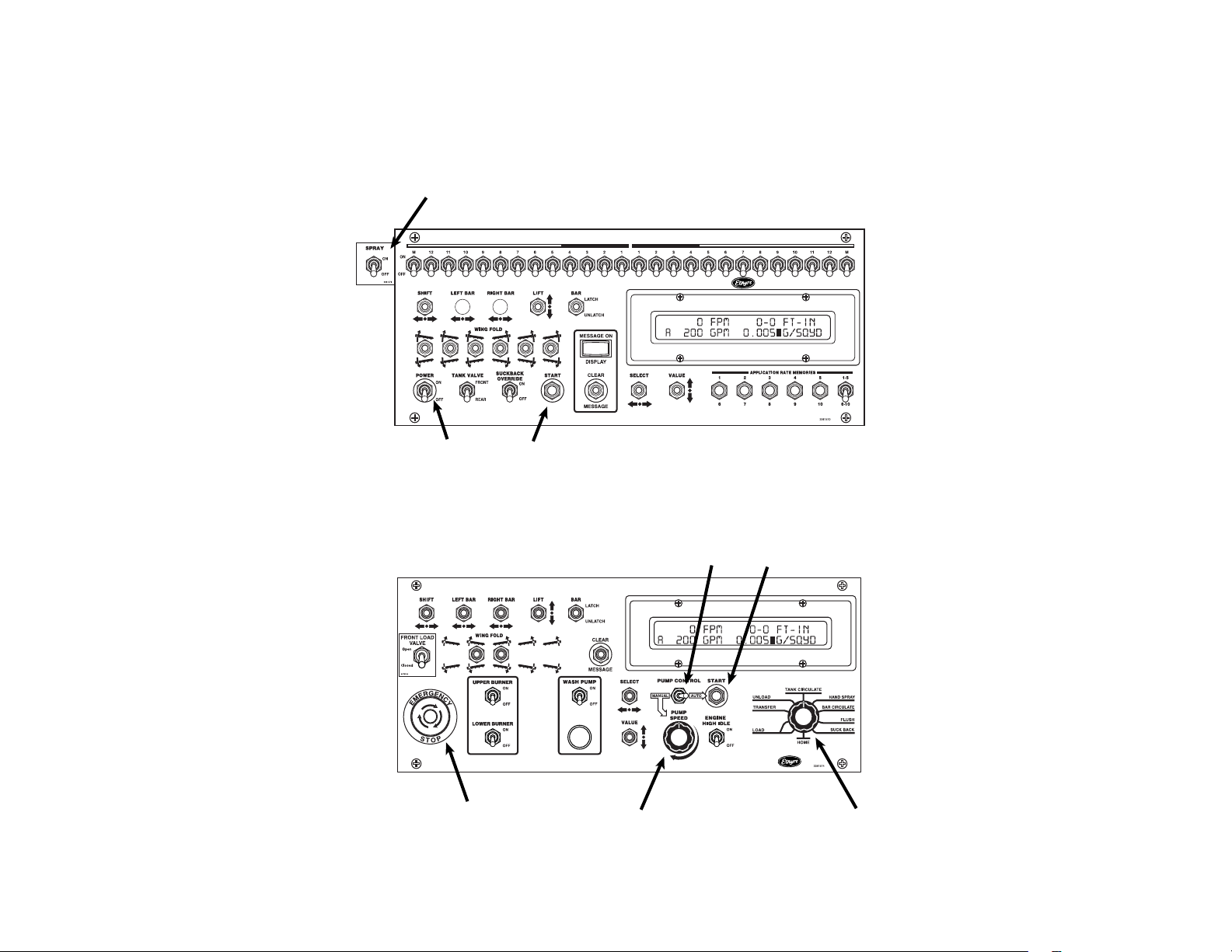

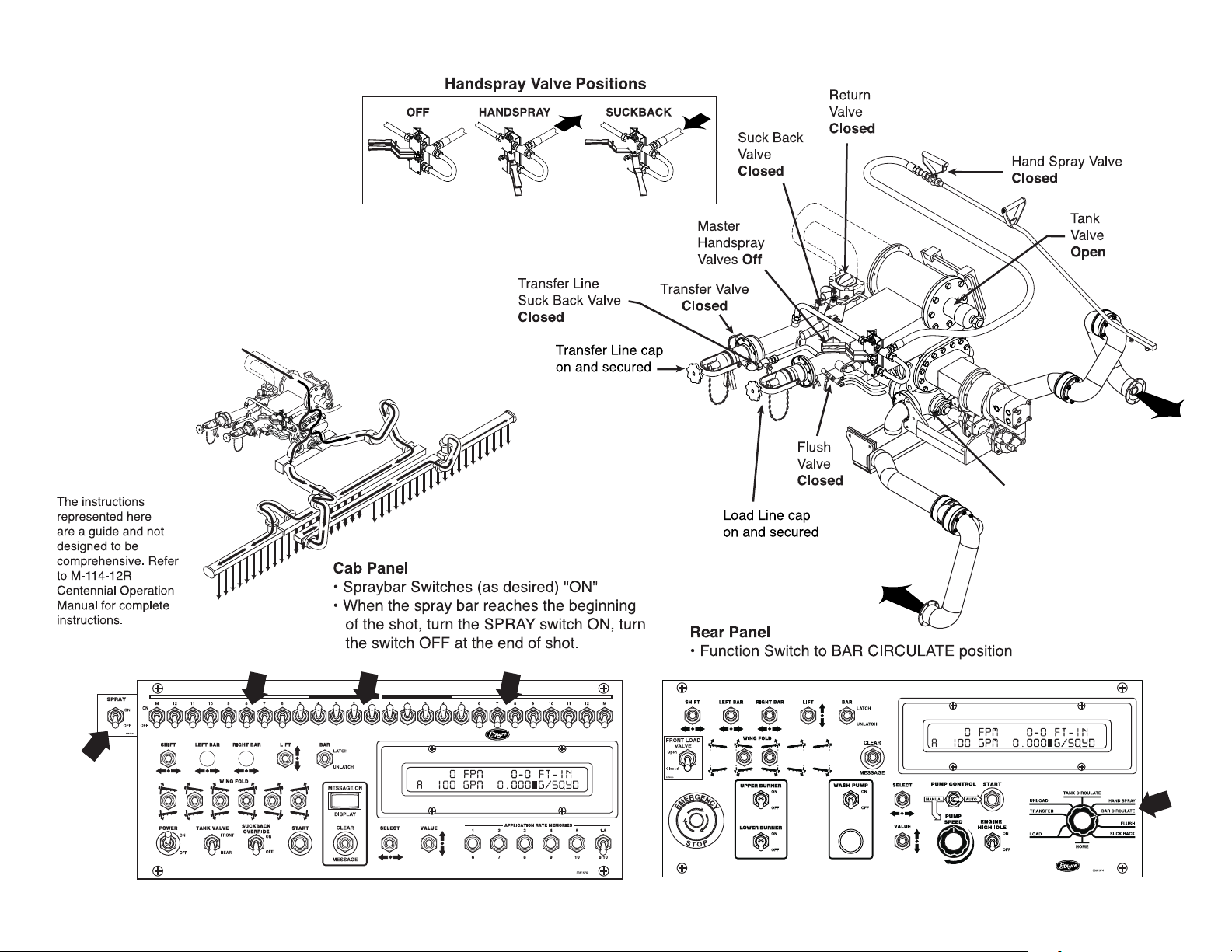

1. SPRAY Switch

Turning this switch to ON when the

Function knob (rear panel) is turned

to BAR CIRCULATE or BAR SUCK

BACK, opens all activated spray

valves.

2. START Button

Starts the asphalt pump turning at the

target pump rate or starts calibration

operations in the setup screens.

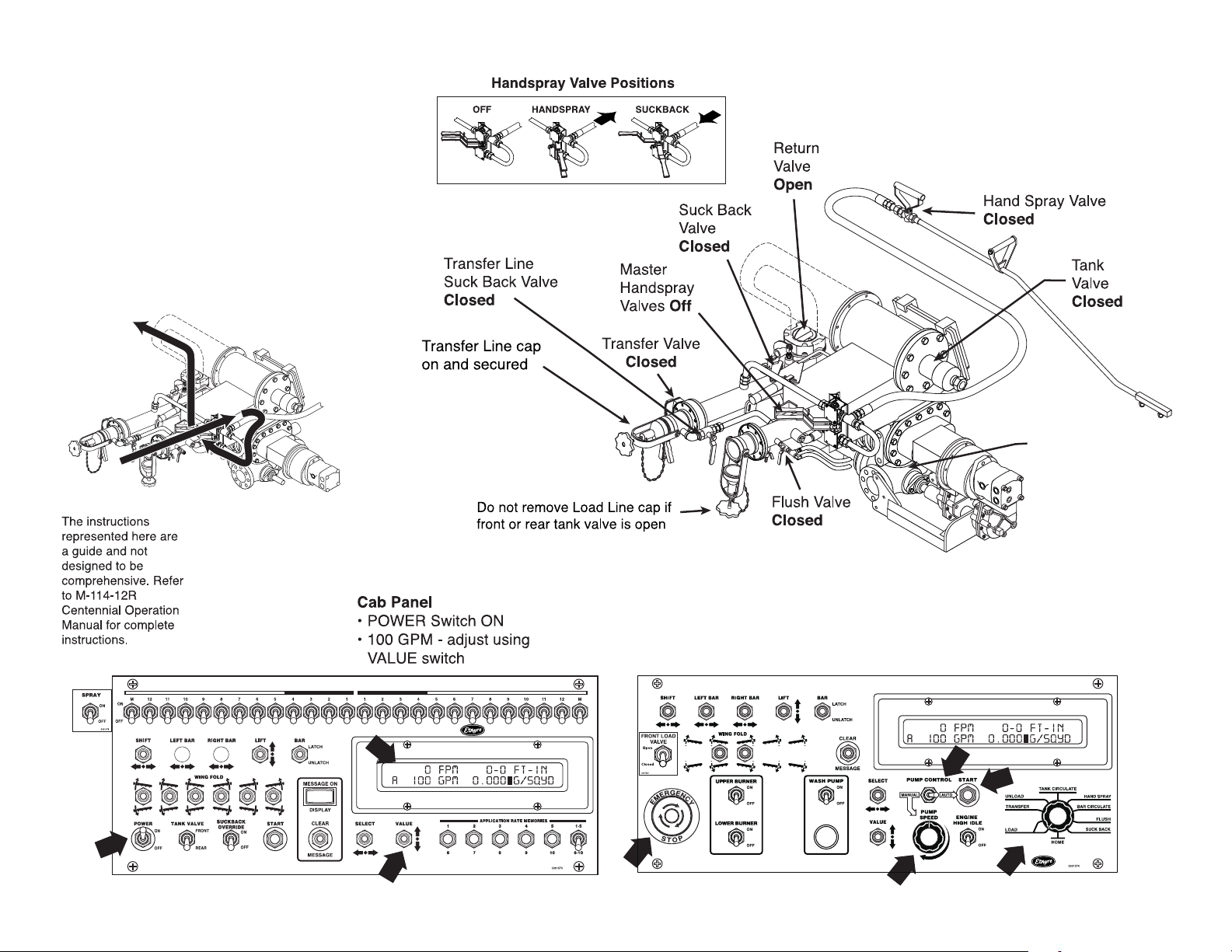

3. POWER Switch

Both POWER switches, front and rear,

must be ON for the system to be ON.

The entire system can be shut down

by turning either POWER switch to

OFF. Before turning either POWER

switch to ON be sure you know what

will automatically activate.

4. PUMP SPEED Control Knob

When MANUAL PUMP CONTROL

is selected, turning this knob to

the right (clockwise) increases the

asphalt pump speed. It is possible

to over-speed the asphalt pump in

MANUAL control since the asphalt

pump speed is also dependent on the

engine speed.

Always turn the knob back to the left

(counter-clockwise) before selecting

AUTO PUMP CONTROL or turning

ON either POWER switches (front

or rear).

5. Function knob

When the desired operation is se-

lected through this knob, the asphalt

pump stops turning if the PUMP CON-

TROL is in AUTO, and all automatic

valves (tank valve, 4-way valve, bar

suck back valves, and balance valves)

are set for the desired operation. The

asphalt pump rate is set to the stored

preset for the desired operation.

The factory pump rate presets are:

• LOAD/TRANSFER - 100 GPM

• TANK CIRCULATE - 150 GPM

• BAR SUCK BACK - 200 GPM

• BAR FLUSH - 100 GPM

• UNLOAD - 100 GPM

• HAND SPRAY - 50 GPM

When BAR CIRCULATE is selected,

the asphalt pump rate is calculated

based on the displayed spray width,

application rate, and the setting of the

%CIRC factor.

6. PUMP CONTROL Switch

With the switch turned to AUTO, the

asphalt pump speed is controlled at

the desired rate through the com-

puter.

With the switch turned to MANUAL,

the asphalt pump speed is controlled

with the PUMP SPEED control knob at

the desired rate for a specic engine

speed.

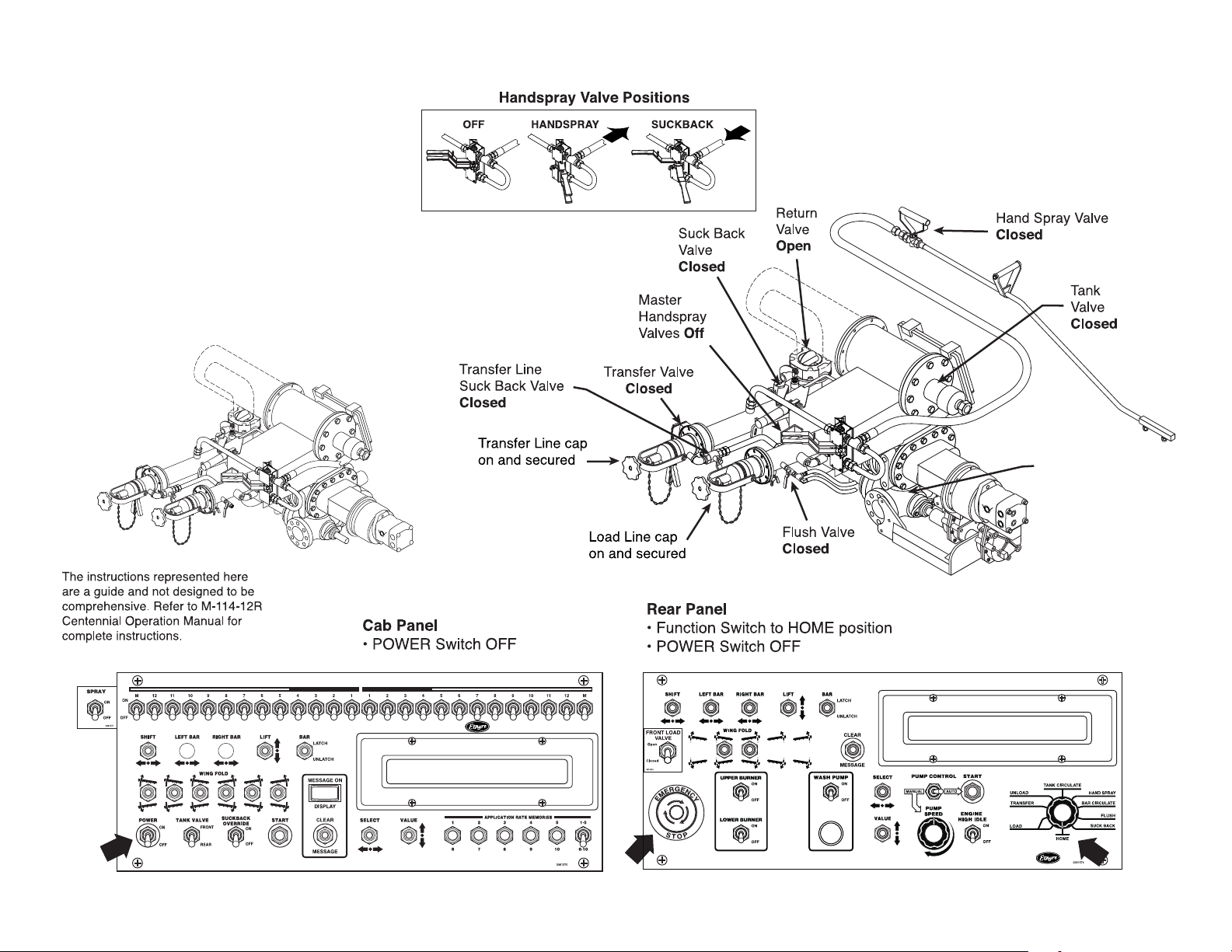

Control Panels

Cab Control Panel

Rear Control Panel