Evoca Group Snakky SL User manual

INSTALLATION, USE AND MAINTENANCE MANUAL

UK English

Snakky SL

DOC. NO. H 204U 00

EDITION 1 2003-03

Italiano Si dichiara che la macchina, descritta nella targhetta di identicazione, è

conforme alle disposizioni legislative delle Direttive Europee elencate a lato e suc-

cessive modiche ed integrazioni.

English The machine described in the identication plate conforms to the legisla-

tive directions of the European directives listed at side and further amendments and

integrations

English The harmonised standards or technical specications (designations) which

comply with good engineering practice in safety matters in force within the EU have

been applied are:

Français La machine décrite sur la plaquette d’identication est conforme aux

dispositions légales des directives européennes énoncées ci-contre et modications

et intégrations successives

Español Se declara que la máquina, descrita en la etiqueta de identicación, cum-

ple con las disposiciones legislativas de las Directrices Europeas listadas al margen

y de sus sucesivas modicaciones e integraciones

Português Declara-se que a máquina, descrita na placa de identicação está con-

forme as disposições legislativas das Diretrizes Européias elencadas aqui ao lado e

sucessivas modicações e integrações

Deutsch Das auf dem Typenschild beschriebene Gerät entspricht den rechts aufge-

führten gesetzlichen Europäischen Richtlinien, sowie anschließenden Änderungen

und Ergänzungen

Nederlands De machine beschreven op het identicatieplaatje is conform de

wetsbepalingen van de Europese Richtlijnen die hiernaast vermeld worden en latere

amendementen en aanvullingen

Italiano Le norme armonizzate o le speciche tecniche (designazioni) che sono

state applicate in accordo con le regole della buona arte in materia di sicurezza in

vigore nella UE sono:

Français Les normes harmonisées ou les spécications techniques (désignations)

qui ont été appliquées conformément aux règles de la bonne pratique en matière de

sécurité en vigueur dans l’UE sont :

Deutsch Die harmonisierten Standards oder technischen Spezikationen (Bestim-

mungen), die den Regeln der Kunst hinsichtlich den in der EU geltenden Sicherheits-

normen entsprechen, sind:

Español Las normas armonizadas o las especicaciones técnicas (designaciones)

que han sido aplicadas de acuerdo con las reglas de la buena práctica en materia de

seguridad vigentes en la UE son:

Português As normas harmonizadas ou as especicações técnicas (designações)

que foram aplicadas de acordo com boas regras de engenharia em matéria de seg-

urança em vigor na UE são:

Nederlands De geharmoniseerde normen of technische specicaties (aanwijzingen)

die toegepast werden volgens de in de EU van kracht zijnde eisen van goed vakman-

schap inzake veiligheid zijn de volgende:

DICHIARAZIONE DI CONFORMITA’

DECLARATION OF CONFORMITY

DÉCLARATION DE CONFORMITÉ

KONFORMITÄTSERKLÄRUNG

DECLARACIÓN DE CONFORMIDAD

DECLARAÇÃO DE CONFORMIDADE

VERKLARING VAN OVEREENSTEMMING

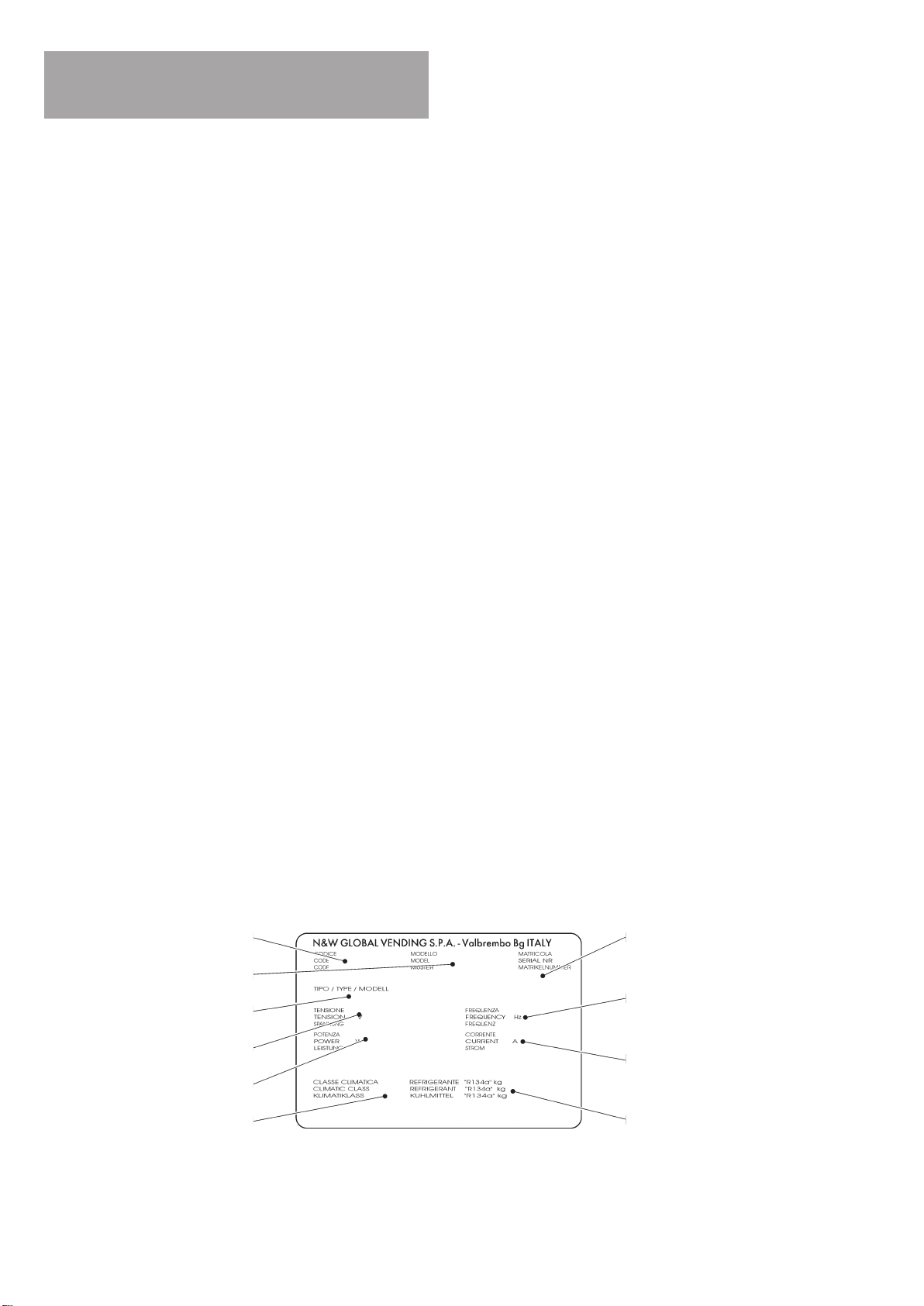

Targhetta di identicazione

Identication label

Valbrembo, 01/01/2012

ANDREA ZOCCHI

C.E.O

Direttive europee

European directives

Sostituita da

Repealed by

2006/42/EC

73/23/EC + 93/68/CE 2006/95/CE

89/336/EC + 92/31/CE +

93/68/CE

2004/108/EC

90/128/EC 2002/72/CE

80/590/EEC and 89/109/

EEC

EC 1935/2004

EC 10/2011

2002/96/EC

Norme armonizzate /

Speciche tecniche

Harmonised standards

Technical specica-

tions

EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006

+ A2:2006+ A13:2008

EN 60335-2-75:2004 + A1:2005 + A11:2006 +

A2:2008 + A12:2010

EN 62233:2008

EN 55014-1: 2006 + A1: 2009

EN 55014-2: 1997 + A1: 2001 + A2: 2008

EN 61000-3-2: 2006 + A1: 2009 + A2: 2009

EN 61000-3-3: 2008

EN 61000-4-2: 2009

EN 61000-4-3: 2006 + A1: 2008

EN 61000-4-4: 2004

EN 61000-4-5: 2006

EN 61000-4-6: 2009

EN 61000-4-11: 2004

Il fascicolo tecnico è costituito presso:

The technical le is compiled at:

N&W GLOBAL VENDING S.p.A.

Declaration of conformity

The declaration of conformity with the European Direc-

tives and Standards provided for by the laws in force

is supplied by the rst page of this manual, which is an

integral part of the machine.

It is declared that the machine described by

the identication plate is in compliance with the

provisions of the European Directives, its sub-

sequent amendments and integrations as well as with

the harmonised standards or technical specications

(designations) applied in compliance with the safety

rules of good practice enforced in the EU and listed on

the same page.

Warnings

f o r u s e

The machine can be used by children and by people

having reduced physical, sensorial or mental skills under

the supervision of people responsible for their safety or

specically trained on the use of the machine. Children

shall be prevented from playing with the machine by the

people in charge of their supervision.

f o r s c r a p p i n g

The symbol shows that the machine can not

be disposed of as common waste, but it must

be disposed of as it is established by the

2002/96/CE (Waste Electrical and Electronics

Equipments - WEEE) European Directive and

by the national laws arising out of it in order to prevent

any negative consequence for environment and human

health.

The dierentiated collection of the machine at the end of

its life is organised and managed by the manufacturer.

For the correct disposal of the machine contact the sales

point where you have purchased the machine or our

after-sales service.

The unlawful disposal of the machine implies the appli-

cation of the administrative sanctions provided for by the

rules in force.

Attention!

If the machine is equipped with a cooling system, the

cooling unit contains HFC-R134a uoridised greenhouse

eect gas ruled by the Kyoto protocol, the total heating

potential of which is equal to 1300.

1

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

TABLE OF CONTENTS

INTRODUCTION PAGE 2

IDENTIFICATION OF THE VENDING MACHINE PAGE 2

IN CASE OF FAILURE PAGE 2

TRANSPORT AND STORAGE PAGE 2

USING THE VENDING MACHINE PAGE 3

POSITIONING THE VENDING MACHINE PAGE 3

WARNING FOR INSTALLATION PAGE 3

PRECAUTIONS IN USING THE MACHINE PAGE 3

WARNING FOR SCRAPPING PAGE 4

TECHNICAL SPECIFICATIONS PAGE 4

ACCESSORIES PAGE 4

POWER CONSUMPTION PAGE 4

VARIABLE COMBINATION LOCK PAGE 5

LOADING AND CLEANING PAGE 6

MAIN SWITCH PAGE 6

CONFIGURING THE SPIRALS PAGE 6

HYGIENE AND MAINTENANCE PAGE 7

LOADING PRODUCTS PAGE 8

INSTALLATION PAGE 9

UNPACKING THE VENDING MACHINE PAGE 9

MASTER/SLAVE BANK PAGE 9

CONNECTING THE VENDING MACHINES PAGE 10

CONNECTING THE NUMERIC KEYPAD PAGE 10

ASSEMBLING THE VENDING MACHINE PAGE 11

CONNECTING TOTHE POWER SUPPLY PAGE 11

CONTROLS AND INFORMATION PAGE 12

INTERNAL COMPONENTS PAGE 12

MAIN SWITCH PAGE 12

BANK CONFIGURATION PAGE 12

OPERATING MODES PAGE 13

USER INTERFACE PAGE 13

NORMAL OPERATING MODE PAGE 13

FILLER MENU PAGE 13

STATISTICS PAGE 14

PRICES FOR SINGLE SELECTIONS PAGE 14

SPECIAL SELECTIONS PAGE 14

TEST PAGE 15

EVADTS TRANSFER PAGE 15

TECHNICIAN MENU PAGE 16

PRESENT FAILURES PAGE 17

PROGRAMMING PARAMETERS PAGE 18

SPIRALS/SELECTIONS PAGE 18

PHOTOCELLS PAGE 19

DISPENSING COMPARTMENT LOCK PAGE 19

REFRIGERATION PARAMETERS PAGE 19

DISPLAY PAGE 19

MISCELLANEOUS PAGE 19

STATISTICS PAGE 20

TEST PAGE 20

MACHINE INFORMATION PAGE 21

EVADTS CODES PAGE 21

INITIALISING PAGE 21

MAINTENANCE PAGE 22

PRINTED BOARD FUNCTIONS

AND INDICATOR LIGHTS PAGE 22

SOFTWARE UPDATE PAGE 22

CONFIGURINGTHETRAYS PAGE 23

PRODUCT SPACERS PAGE 23

PRODUCT EJECTOR PAGE 23

REPLACING THE SPIRALS PAGE 23

REMOVING THE TRAYS PAGE 23

CHANGING THE NUMBER OF TRAYS PAGE 24

CHANGING THE TRAY CONFIGURATION PAGE 24

POWER SUPPLY UNIT PAGE 25

ACCESS TO THE COOLING UNIT PAGE 25

MENU SUMMARY PAGE 26

WIRING DIAGRAM PAGE 49

INTRODUCTION

This technical documentation is part and parcel of

the machine and must always follow the machine in

case it is moved or ownership is transferred, so as

to allow consultation by dierent operators.

Before starting installation and using the machine, it is

rst necessary to carefully read and understand the in-

structions contained in this manual, as they oer impor-

tant information on installation safety, operating instruc-

tions and maintenance.

Th i s m a n u a l i s d i v i d e d i n T o T h r e e c h a p T e r s .

The rst chapter describes the loading and routine

maintenance operations which are carried out in areas of

the machine accessible with simple use of the door key,

without using any other tools.

The second chapter contains the instructions for cor-

rect installation and all information necessary for opti-

mum use of the machine.

The third chapter describes maintenance operations

which involve the use of tools to access potentially dan-

gerous areas.

The operations described in the second and third chap-

ters must be carried out only by personnel who have the

specic knowledge of the machine functioning from a

point of view of electrical safety and health regulations.

IDENTIFICATION OF THE VENDING

MACHINE AND ITS CHARACTERISTICS

Every machine is identied by its own serial number,

indicated on the rating plate attached inside the cabinet

on the right side.

This plate (see g. 1) is the only one acknowledged by

the manufacturer as the identication of the apparatus,

and carries all the data which readily and safely give

technical information supplied by the manufacturer. It

also assists in the spare parts management.

IN CASE OF FAILURE

In most cases, any technical problems are corrected by

small repair operations; however, before contacting the

manufacturer we recommend that this manual be read

carefully.

Should there be serious failures or malfunctions, contact

the following:

N&W GLOBAL VENDING S.p.A.

Via Roma 24

24030 Valbrembo

Italy - Tel. +39 - 035606111

TRANSPORT AND STORAGE

To prevent any damage, special care should be taken

when loading or unloading the machine.

The machine can be lifted by a motor-driven or manual

forklift truck, and the forks are to be placed underneath

the machine from the side clearly indicated by the sym-

bol on the cardboard package.

Do not:

overturn the vending machine;-

drag the vending machine with ropes or similar;-

lift the vending machine by its sides;-

lift the vending machine with slings or ropes;-

shake the vending machine.-

The machine should be stored in a dry room where the

temperature remains between 0° C and 40 °C.

Avoid stacking machines one on top of the other and

always keep it upright as indicated by the arrows on the

packing.

Refrigeration system class

Absorbed power

Operating voltage

Model

Product code

Type and amount of refrigerant gas

Current

Frequency

Serial number

Type

3

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

USING THE VENDING MACHINE FOR

PACKAGED PRODUCTS

The machine can operate only as “slave”, which means

thatithas to be connected to a “master” machine thatcan

control its functions, since the reduced electronics does

notpermitautonomousoperationofthisvendingmachine.

Thevariousfunctionsareprogrammedthroughtheselec-

tionkeypadof the“master”machine,whichmustbeofthe

numeric combination type.

Allmodels are equipped with variableconfiguration trays,

addingorremovingdividers,spiralsandratiomotors;there-

fore the machine can be easily suited to specific needs.

All trays are preset for the operation of up to 6 selections

(maximum setting).

Thecompartmentsareequippedwithindependentmotors

and spirals; each selection will continue its operation

autonomously even if the other selections are discon-

nected.

POSITIONING THE VENDING MACHINE

The vending machine is not suitable for outdoor installa-

tion.Itmustbepositionedinadryroomwherethetempera-

tureremainsbetween2°Cand32°C,andnotwherewater

jets are used for cleaning (e.g. in large kitchens, etc.).

The machine can be used only in a bank with another

machine that can control the “master/slave” function.

The same “master” machine can control a bank with two

machines operating as “slave”.

Theventilationsystemallowsthebackpanel tobeleaned

against the wall, thus saving space, as air is drawn from

under the machine and exhausted through a grille on the

right-hand side. However, the grille must be completely

free without obstructions to the airflow for at least 40 cm.

If this were not possible, the spacer supplied with the

machine must be fitted to ensure the required distance

from the wall (see Fig. 2).

Warning!

Incorrectventilationmaycompromisetheproperfunc-

tioning of the cooling unit.

The machine should be positioned with a maximum incli-

nation of 2°.

Ifnecessaryprovideproperlevellingbywayoftheadjust-

able feet included.

WARNING FOR INSTALLATION

The machine installation and the following mainte-

nance operations should be carried out by qualified

personnel only, who are trained in the correct use of

the machine according to the standards in force.

The machine is sold to be connected to a “master” ma-

chine.

The composition of the bank of machines and assembly

must be carried out only in accordance with the manufac-

turer’s instructions, where necessary using the approved

kits.

The integrity of the machine and compliance with the

standardsoftherelevantsystemsmustbecheckedat

least once a year by qualified personnel.

PRECAUTIONS IN USING THE MACHINE

The following precautions will assist in protecting the

environment:

- use biodegradable products only to clean the machine;

- adequately dispose of all containers of the products

used for loading and cleaning the machine;

- keep the machine away from heat sources;

- regularly check the condition of the door seal to limit

any heat dispersion;

- limit as much as possible door opening time during

loading operations to avoid temperature increase

inside the cabinet and subsequent power consumption.

Fig. 2

1 - Securing holes

2 - Spacer

3 - Fastening screws

4 - Can-bus connection cable

4

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

WARNING FOR SCRAPPING

Wheneverthemachineistobescrapped,thelawsinforce

regarding environment protection should be strictly ob-

served. More specifically:

- ferrous and plastic materials and the like are to be

disposed of in authorized areas only;

- insulating materials should be recovered by qualified

companies.

- the gas inside the cooling unit, regardless of the type

(see the identification plate), should be recovered by

qualified companies by means of special equipment.

TECHNICAL SPECIFICATIONS

Power supply voltage 230 V~

Power supply frequency 50 Hz

Absorbed power 345 W

Max. operating conditions:

Ambienttemperature 32 °C

Relative humidity 65 %

Refrigeration system:

Compressor’s refrigeration output 320 W

Fan-forced evaporator

Programmable defrosting cycle

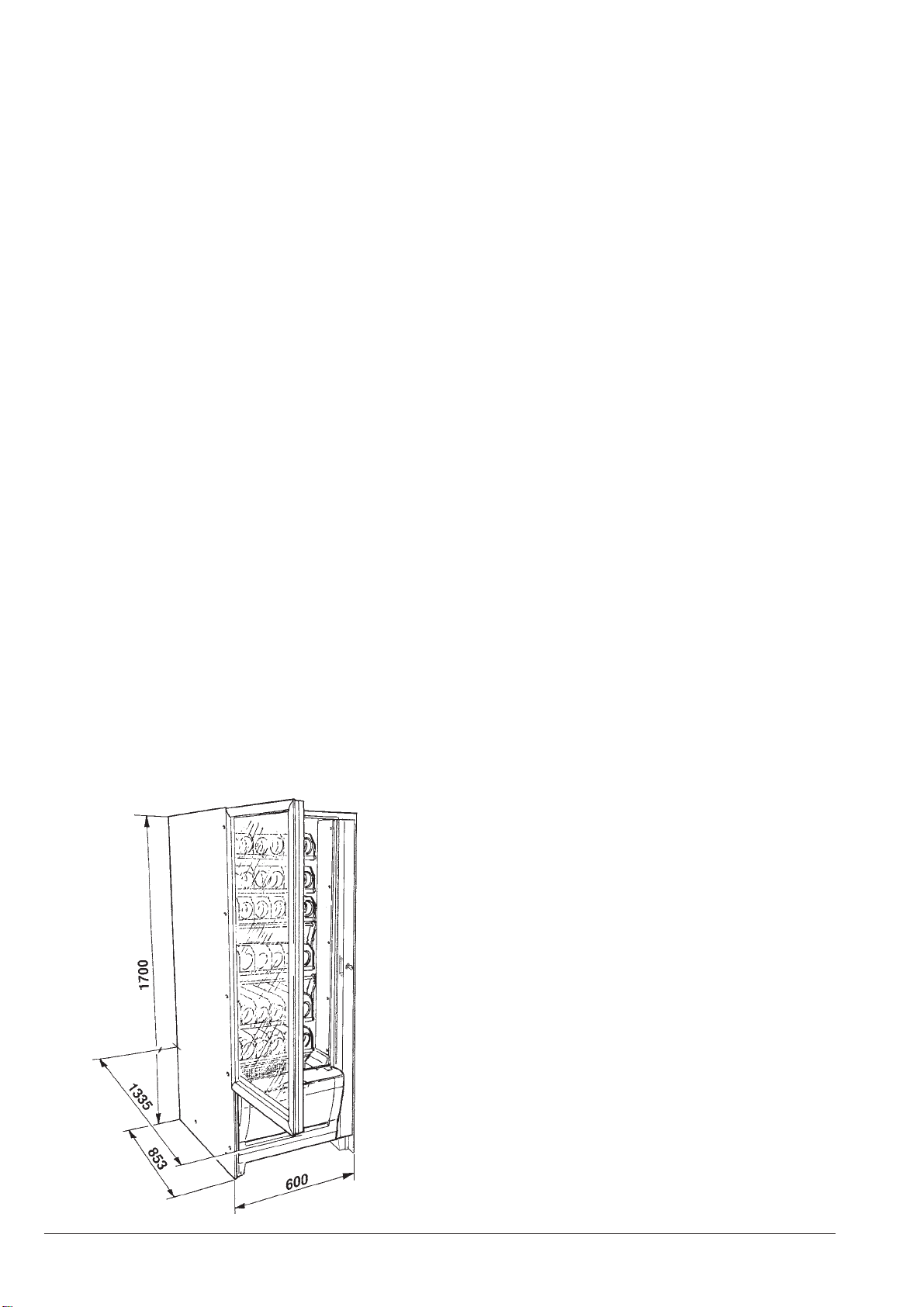

DIMENSIONS

Height 1700 mm

Width 600 mm

Depth 854 mm

Overall depth with door open 1335 mm

Weight 165 Kg

CONTROLS AND SAFETY DEVICES

- Main switch

- Timeout for power supply to dispensing motors

- Compressor overheating protection

- Line fuses

- Fuses on transformer primary and secondary windings

ACCESSORIES

A wide range of accessories can be installed on the

machine, to vary its performance.

Theinstallationkitsaresuppliedwiththeirowninstallation

and test instructions, which must be strictly observed to

ensure the machine safety.

Installationandthefollowingtestingoperationsmust

be carried out exclusively by personnel who have a

specific knowledge of the machine functions from a

point of view of electrical safety and health regula-

tions.

POWER CONSUMPTION

The machine power consumption depends on many fac-

tors, such as temperature and ventilation of the room

where it is installed, temperature of loaded products,

internal temperature of the refrigerated box.

Under average conditions, and namely:

- ambient temperature: 20 °C

- refrigerated box temperature: 8 °C

- temperature of loaded products

(machine completely empty) 20 °C

the following power consumption levels resulted:

- hourly stand-by power consumption 151 Wh

The above power consumption calculated from average

data should only be taken as an indication.

Fig. 3

5

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

CHANGEABLE COMBINATION LOCK

Some machine models are fitted with a changeable com-

bination lock.

Thelock is supplied with twosilvercolour keys to be used

for normal opening and closing.

The lock can be customised by using a kit, available as

accessory,whichpermitsthecombinationofthelocktobe

changed.

This kit includes a change key (black) for the current lock

combination as well as the change (gold) and use (silver)

keys for the new combination.

Setsof change and usekeyswithother combinations can

be supplied on request.

Additional sets of use keys (silver) may be requested,

indicating the combination stamped on the keys.

Generally, only the use key (silver) is used, while the

combination change keys (gold) can be kept as spares.

Do not use the change key for normal opening, as it

may damage the lock.

Fig. 4

To change combination do as follows:

- open the machine door to avoid forcing the rotation;

- lightly lubricate the inside of the lock with a spray;

- insert the current change key (black) and rotate to the

change position (reference notch at 120°);

- remove the current change key and insert the change

key (gold) with the new combination;

- rotate to the close position (0°) and remove the change

key.

The lock will now have the new combination.

Thekeys withthe old combinationcannot beused for

the new combination.

6

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

Chapter 1

LOADING AND CLEANING

MAIN SWITCH

Byopeningthesidedoor,accesscanbegainedtothemain

switch (see Fig. 5) that disconnects the power from the

machine electrical system to allow the loading and clean-

ing operations in full safety.

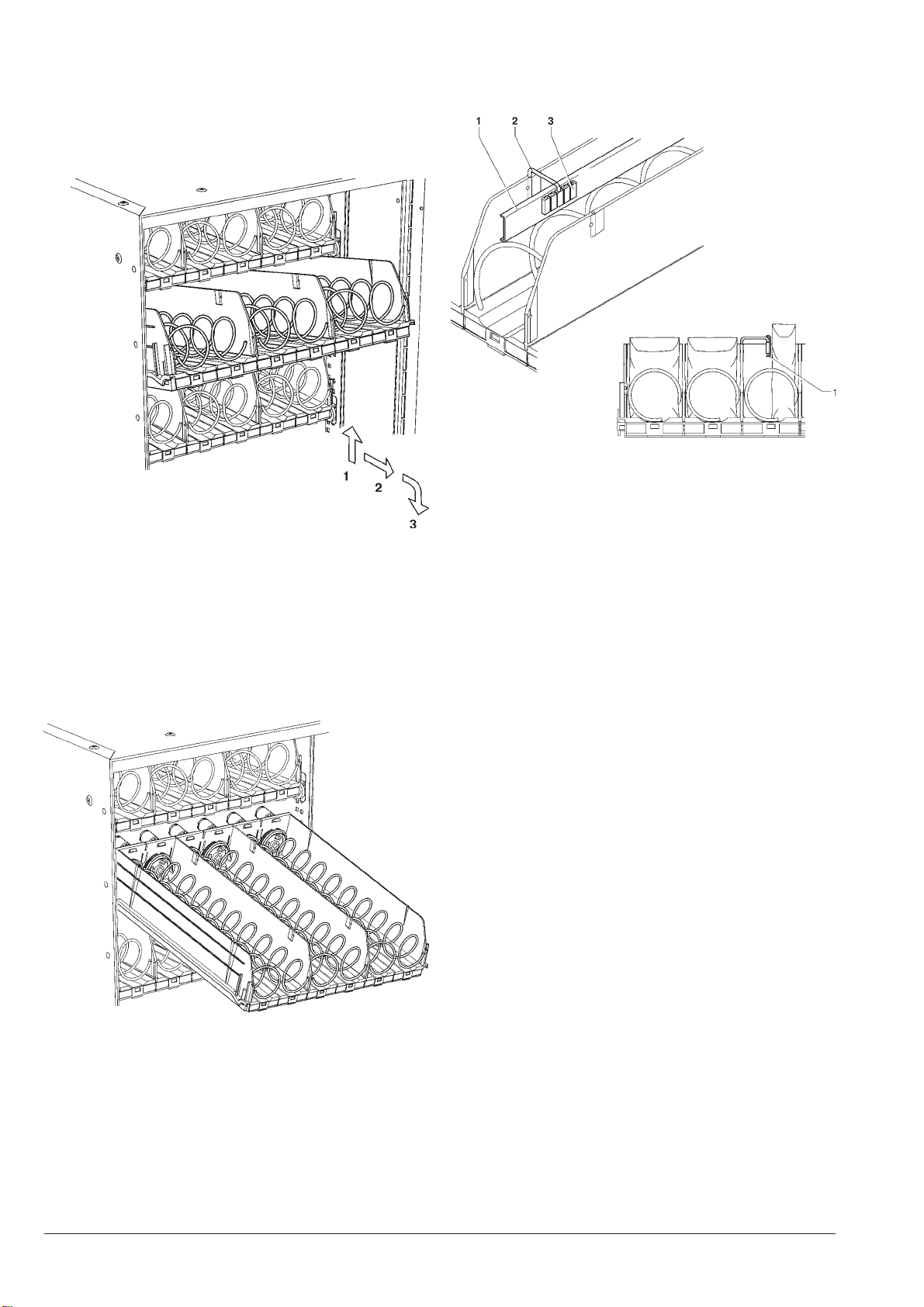

Fig. 7

1 - 180° rotation spiral

2 - Divider

A - Spiral pitch

B - Maximum product size

CONFIGURING THE SPIRALS

Accordingtothesizeoftheproductstobedispensed,each

machine can be fitted with a variable number of trays

(maximum6),productcompartmentsandwithdispensing

spirals of different pitch.

Fig. 5

1 - Door opening grip

2 - Trays

3 - Lock

4 - Product passage photocells (optional)

5 - Product dispensing compartment

6 - Main switch

Fig. 6

1 - Tray

2 - Mobile walls

3 - Right-hand spiral

4 - Left-hand spiral

Thisvendingmachineshouldonlybeusedtoselland

dispensepackaged productsthat do not need refrig-

eration to be preserved.

Strictlycomplytotheproducer’sspecificationsregarding

storage method and expiry date for each product.

Any other use is unsuitable and thus potentially

dangerous.

Thespiralscanbehousedeitherin152mmcompartments

(two spirals, right-hand and left-hand, in each compart-

ment)forlargesizeproducts,orinto75mmcompartments

(oneright-handspiral ineachcompartment)forsmallsize

products.

Whendispensingsticksofcandiesorsimilarproducts,itis

possibleto settherotation of thespiralsto 180°insteadof

360° for the 75 mm compartments and use a special right

hand spiral fitted with a divider (see Fig. 7), doubling the

capacity of the compartments.

7

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

Itisalsopossible toinserta dividerinthe alreadyinstalled

spirals (see Fig. 8). The spirals can be positioned with 22,5 degree steps by

pulling them towards the front and rotating them in the

direction of ejection.

Normally, the products can be dispensed without any

problems when the spiral end is in the lower centre posi-

tion.

The maximum size (see Fig. 6) and the number of prod-

ucts,thepitchandthedirectionofrotationofthespiralsare

shown in the following table.

The machine is supplied with a table indicating the opti-

mum setting for the different product types.

Theconfigurationcanbechangedfollowingtheindications

of the relevant chapter.

HYGIENE AND MAINTENANCE

According to current health and safety regulations, the

operator of vending machines is responsible for their

hygiene and cleaning.

It is advisable to use sanitising products (chlorine based

detergent or similar) to clean all surfaces even if not in

direct contact with food.

Some parts of the machine can be damaged by strong

detergents.

The manufacturer declines all responsibility for damage

caused

by non-compliance with the above instructions or by the

use of strong or toxic chemical agents.

Under no circumstances should sprayed water be

used.

Before any maintenance operation always switch the

machine off.

Asstandardfeatureorusingspecialkits,themachinecan

be equipped with small compartments, suitable for dis-

pensing cans, plastic bottles up to 69 mm dia., 0.2 litre

Tetra-Paks.

The compartments equipped in this way can be recog-

nisedbytheshapeoftheproductsupportbracket(seeFig.

9).

Some bottle types can be dispensed without using the

supports.

Most bottles can be dispensed without using any special

accessories, loading the bottles up side down, so that the

cap slides in the compartment channel.

Fig. 8

1 - Spiral

2 - Divider

A.mm B.mm °N

08676

46067

45058

642401

046311

430331

036241

420291

)°081(420291+91

Fig. 9

1 - Compartment’s channel

2 - Product raised support

8

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

LOADING PRODUCTS

- Remove one tray at a time, lifting it and pulling it past

the retaining slide. The upper trays will tilt downwards

to facilitate loading.

Fig. 11

Fig. 10

- Load all products starting at the front, without inserting

products with a temperature above 30°C, ensuring that

all spaces are filled. The bottom of the product must

rest at the bottom of the compartment with the label

facing the window so that it can be identified.

Allproductsshouldloadeasily,donotinsertproducts

which are too large for the space.

- Push in the trays completely, ensuring that they go

past the retaining slide.

The sealed end of bags may be caught under the spiral,

preventing the free fall of the product.

Fold the seal towards the front of the unit and upwards

before inserting the product in the spiral.

More fragile products must be placed on the lower

trays to prevent damage when they drop.

Verythinproductscanbedispensedonlyusingthespecial

spacer.

NOISE LEVEL

The continuous, weighted equivalent acoustic pressure

level is below 70 dB.

START-UP

Each time the machine is started, the number of trays

connected to the system are checked by the electronic

controls.

Also the number of actually connected compartments is

checked.

OPERATING TEMPERATURE

The machine can operate only where the ambient tem-

perature is between 2°C and 32°C.

The cabinet temperature can be adjusted between 8°C

and 20°C.

Fig. 12

1 - Product spacer

2 - Brackets

3 - Adjustment notches

9

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

Chapter 2

INSTALLATION

The machine installation and the following mainte-

nance operations should be carried out by qualified

personnel only, who are trained in the correct use of

themachineandareawareofthespecificrisksofsuch

operations.

Themachineis notsuitable foroutdoorinstallation, it

mustbeinstalledinadryroomwherethetemperature

remains between 2°C and 32°C.

It cannot be positioned where water jets are used for

cleaning (e.g. in large kitchens, etc.).

The machine should be positioned with a maximum

inclination of 2°.

The relative humidity must not exceed 65%.

UNPACKING THE VENDING MACHINE

After removing the packing, ensure that the machine is

intact.

If the vending machine is found to be damaged, immedi-

ately inform the carrier and do not use the machine.

No packing elements (i.e. plastic bags, polystyrene

foam, nails, etc.) should be left within the reach of

children, as they are potentially dangerous.

Packing materials must be disposed of in authorised

containersandtherecyclableonesmustberecoveredby

qualifiedcompanies.

If the vending machine had been laid down during

transport,allowatleastone hour beforeconnectingit

to the mains.

MASTER/SLAVE BANK

Since the machine does not have its own user interface,

itmustbeconnectedtoanothervendingmachinethathas

master functions.

Themastermachinemusthaveanumerickeypadtoallow

programming operations and vending for the bank of

machines.

It is also possible to configure as master those vending

machines that have direct selection buttons, using the

numeric keypad supplied with the machine.

Thebankcanbecomposedofthreevendingmachines,of

which one is master and two are slave; in this case the

selectionnumbersofthetwoslave machinesmustbeset

with three digits.

The typical configurations are therefore as follows:

A - Master with direct buttons (adding the numeric

keypad) + slave without interface; all components

required for this configuration are supplied with the

machine.

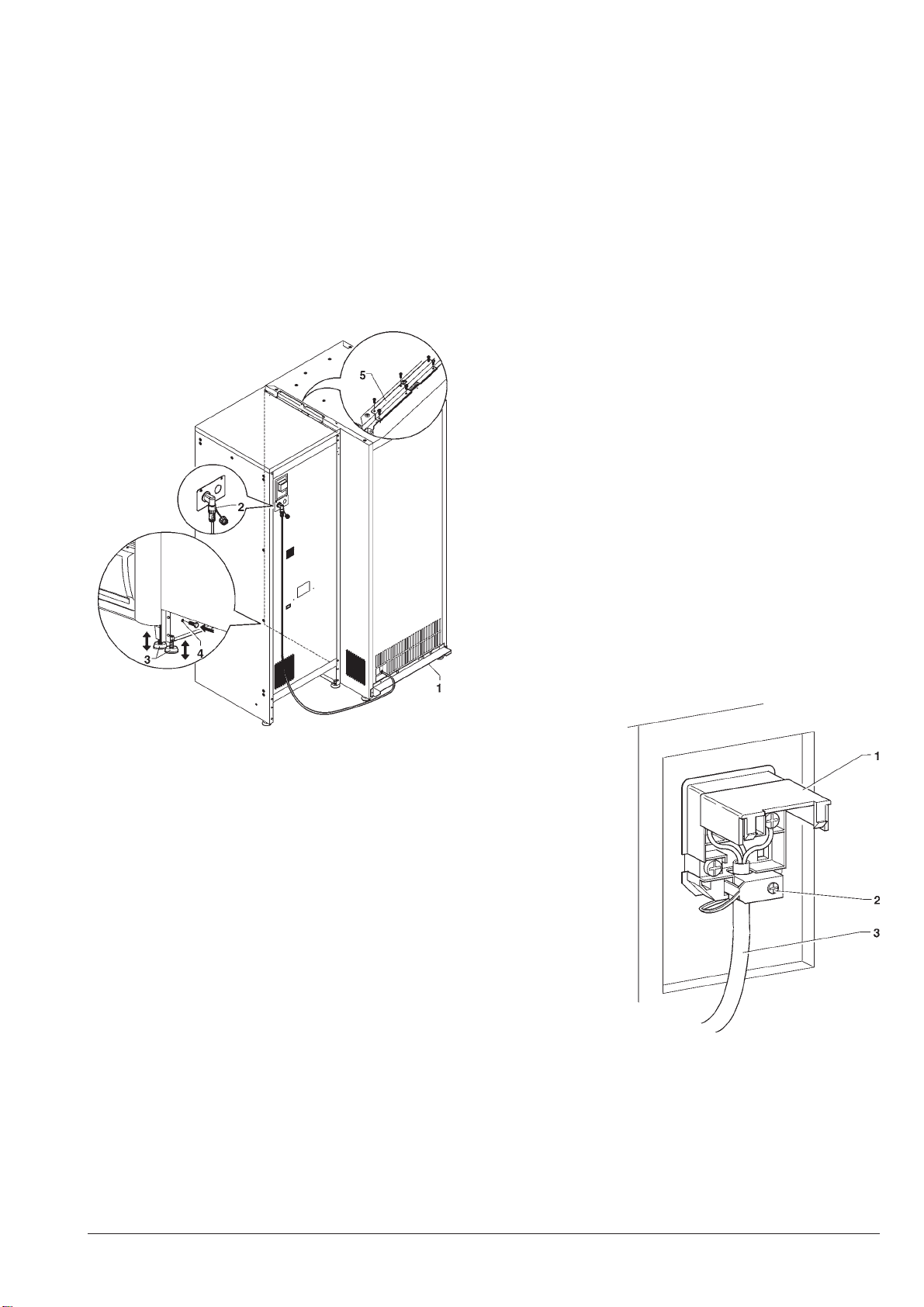

Fig. 13

1 - Vending machine without interface

2 - Vending machine with direct buttons

3 - Vending machine with numeric keypad

4 - Additional numeric keypad

10

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

Fig. 14

1 - Pre-cut section

2 - Can-bus connector

3 - Connector’s holder plate

4 - Machine securing hole

5 - Power supply unit cover

6 - Actuation board

7 - C.P.U. Board

8 - Keypad cable

9 - Numeric keypad

10 - Slot for keypad flat cable

Using special kits also the following configurations are

possible:

B - Master with numeric keypad + slave without inter-

face

B - Master with direct buttons (adding the numeric

keypad) + 2 slaves without interface

B - Master with numeric keypad + slave with direct

buttons + slave without interface

Important notice!

When assembling the bank of machines the ventila-

tion grilles of the cooling units must be taken into

account.

Shouldthegrillesbecovered,thespacersuppliedwiththe

machine must be fitted (see Fig. 2).

Specifickitsareavailableforthedifferentmodelstoclose

the empty space between cabinet and wall.

Warning!

Do not move the vending machines when already

assembled.

It is not possible to lift them or push them and slide them

along the floor, nor can they be transported, without

separating the various machines.

CONNECTING THE VENDING MACHINES

Ensure that the master vending machine is connected to

the power supply.

- Remove the pre-cut section of the external back panel

and eliminate any burrs on the sheeting.

- Insert the can-bus cable inside the cabinet and secure

connector’s holder plate to the back panel with 2

screws.

- From the front of the vending machine, drill a 10-mm

diameter hole on the left side of the cabinet.

- Remove the cover from the power supply unit and

connect the can-bus cable terminal to connector “J4”

or “J6” on the actuation board. Secure the cable and

replace the parts that were removed.

CONNECTING THE NUMERIC KEYPAD

If the master machine is of the type with direct selection

buttons, the numeric keypad (see Fig. 18) must be in-

stalled as follows:

- by removing the pre-cut section make a hole on the

door for the numeric keypad wiring.

- attach the keypad, taking care not to leave any air

bubbles.

- connect the keypad cable to connector J16 on the

C.P.U. board

11

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

CONNECTING THE MACHINE

TO THE POWER SUPPLY

Themachineisdesignedtooperateunderasingle-phase

230 V~ voltage and is protected by T6.3 A fuses.

Apowersupplyoutletmustbeprovidedforeachmachine

of the bank.

Itisnotpossibletoconnectmorethanonemachineto

the same power outlet.

Before making the connection, ensure that the rating of

each machine corresponds to that of the power grid, and

more specifically:

- the supply voltage rating must be within the range

recommended for the connection points;

- the main switches should be capable of withstanding

the peak load required, and at the same time ensure

proper omnipolar disconnection from the power grid

with an opening gap of the contacts of at least 3 mm.

Theswitches,thepoweroutletsandtheplugsmustbe

located in an easily accessible position.

Theelectricalsafetyofthemachineisensuredonlywhen

itis correctlyearthedaccording tothesafety standardsin

force.

This fundamental safety requirement must be duly

verified, and if in doubt the system must be carefully

tested by qualified technicians.

Thepowersupplycableisofthetypewithafixedplug.Any

replacement of the power cable (see Fig. 16) should be

made by qualified and suitably trained personnel only

using cables type HO5 RN - F or HO5 V V-F or H07 RN-

F with a 3x1-1.5 mm2section.

ASSEMBLING THE VENDING MACHINES

To assemble master and slave vending machines do as

follows:

- Check that side ventilation grilles of the machines

equipped with a cooling unit are completely free.

Should the ventilation grilles be covered, even partially,

due to the layout to be adopted, it will be necessary to

fit the spacer (see Fig. 15) supplied with the machine.

Important notice!

Thebankofmachinesshouldinanycasebeatleast4cm

from the wall so that correct ventilation may be ensured.

- Ensure that the inclination of the machines does not

exceed 2°; If necessary provide proper levelling by

way of the adjustable feet included; the feet must be

adjusted to keep the machines side by side at the

same height.

- Secure the clamping bracket to the left side of the

master machine and position it next to the vending

machine; connect the connectors of the external can-

bus cable.

- Line up the front of the two vending machines, taking

care not to pull the external can-bus cable and not to

damage the cabinet with the protruding clamping

bracket.

- Secure the clamping bracket to the top panel of the

slave machine. Secure the two vending machines with

the screw at the base.

Fig. 15

1 - Spacer

2 - Can-bus cable connectors

3 - Adjustable feet

4 - Securing hole (to be drilled)

5 - Machine clamping bracket

Fig. 16

1 - Lift cover

2 - Cable clamp

3 - Power supply cable

Do not use adapters, multiple sockets and/or exten-

sions.

THE MANUFACTURER DECLINES ALL RESPONSI-

BILITY FOR ANY DAMAGE CAUSED BY NON-COM-

PLIANCE WITH THE ABOVE MENTIONED PRECAU-

TIONS.

12

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

Fig. 17

1 - Product dispensing compartment housing

2 - Cooling unit condenser

3 - Cooling unit evaporator

4 - Cold airflow grilles

5 - Removable grille cover

6 - Tray guides

7 - Product passage photocells

8 - C.P.U. board

9 - Transformer fuses

10 - Mains fuses

11 - Main switch

CONTROLS AND INFORMATION

The machine can be used only as slave, therefore the

control functions are handled by the master machine.

Themainswitch,whichisofthemanualtype,disconnects

the machine in the event of maintenance operations.

The information for the user (sales price and selection

number)isindicated on self-adhesive labels to be placed

in front of the spirals during installation.

INTERNAL COMPONENTS

The evaporator assembly mounted on the cabinet shelf

comprises two fans, the evaporator, the air duct and a

water retaining tray placed under the evaporator.

The C.P.U. board (central processing unit) located in the

lower right section inside the vending machine controls

thedifferentfunctions andcommunicateswiththeC.P.U.

board of the master machine.

Thecoolingunitislocatedinthelower partof thecabinet.

Whenremovingthecoverofthelastventilationgrille(see

Fig.17) the air circulationensuresauniform temperature

inside the refrigerated box, between 9°C and 12°C.

When covering the ventilation grille, the temperature

inside the refrigerated box is differentiated between the

upperthreetrays(12°-16°C)andthelowerthreetrays(8°-

10°C).

Thecoolingunitis defrostedautomaticallyevery 6hours.

However, the timing is programmable.

Thepowersupplyunit,mountedinthelowersectionofthe

cabinet, contains the relay card which activates the com-

pressor, the protection fuses, the main switch, the trans-

former and the C.P.U. board.

MAIN SWITCH

Thepowersupplyunit(seeFig.27)isfittedwithamanual

switch that disconnects the power from the machine

electrical system,

except from the terminal board supporting the line

cable, the line fuses and from the same switch area.

Beforeremovingthecoverfromtheseparts(indicated

witha specific plate) it is necessary to disconnect the

external switch.

All operations which require the machine to be ener-

gised with the door open must be carried out by

qualifiedpersonnelwhoareawareofthespecificrisks

of such condition.

BANK CONFIGURATION

The machines are initially configured for operation in a

bank of machines, therefore the software must be set for

the necessary options.

After completing the connection between the machines

and to the power supply, switch on only the master

machine.

Access the master/slave function in the technician menu

andselect the type ofslave to define thenumber of digits

indicating the selection.

Two digits (XX) are advisable if the bank has only one

machine with numeric selection.

If there are two slaves, it is advisable to use three digits

(0XX, 9XX) for identifying the selection groups.

When switching on the slave regarding the choice made,

the master will communicate if the procedure was suc-

cessful.

If necessary, repeat the procedure to configure the sec-

ond slave, making sure not to configure two slaves the

same way.

The configuration must be defined every time the master

machine is initialised.

Should the configuration of a slave need to be changed,

accessthemasterfunctionthatindicatestheswitchedon

slaves as not configured.

After the configuration, it will be possible to access the

filler and technician menus of the slave from the master

machine.

When pressing the programming button on the master,

thesoftwarewillasktheusertoselectthetypeofvending

machine to be accessed.

13

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

Fig. 18

OPERATING MODES

Themachinecontrolsoftwarehasthreedifferentfunction

levels, which are:

- normal operation;

- filler menu;

- technician menu.

Accordingto theoperatingmode, thedisplayand keypad

functions of the master machine change as described in

the following paragraphs.

USER INTERFACE

The interaction between system and operator happens

through the following components located on the master

machine:

- Liquid crystal display (LCD) (the number of lines and of

characters depend on the type of master).

- External keypad configured via software with numeric

keys from 0 to 9, having with the following functions in

the in the filler and technician menus:

Numeric keys

1to 7 are used toselect directly a menu itemby keying in

the corresponding number shown in the summary tables

included in the appendix to this manual.

Next menu key :

“” is used to move to the next menu option.

In the case of command management it varies the status

ofLogicalDatawhere required, or in the case of Numeric

Data it writes the value 0.

Previous menu key :

“” is used to move to the previous menu option.

In the case of command management it varies the status

ofLogicalDatawhere required, or in the case of Numeric

Data it writes the value 8.

Enter key :

“”isusedtomovefromamenutoasub-menuortoenter

a command.

InthecaseofLogicalDataitentersthestatusthatappears

on the display.

Exit key :

“” is used to move from a sub-menu to the higher level

menu, or to exit from the current command.

NORMAL OPERATING MODE

The machine is preset to normal operating mode when

connected to the power supply with the main switch on.

The lighting is switched on and the messages for the

customer are indicated on the display of the master.

FILLER MENU

The machine is preset to “filler” mode when pressing the

menuaccessbuttononthemastermachineandselecting

on which machine to operate.

The “ ” and “ ” keys scroll through the filler menu which

permits:

“Statistics” Data reading and display

“Single Prices” Changing the price for one

selection

“Special selections” Virtual selections

Return of virtual price

Two-motor selections

Photocellparameters

“Test” Test selection

Motor test

Autotest

“EVADTS” Connection

Ifamenuisnotenabledduringprogramming,atitleis

displayed in the list but it cannot be accessed.

Price key

Key is used to access directly the price/selection

combinationoftimeband0,ifthefunctionisenabledinthe

“Technician” menu.

14

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

STATISTICS

Data on the machine operations is stored in both general

countersandrelativecounters,whichcanberesetwithout

losing total data.

PRINT

Connect an RS232 serial printer having a Baud rate of

9600, 8 data bit, no parity, 1 stop bit to the serial port

located on the push-button board to print all of the statis-

tics, and namely:

Total

- counter by single selection

- counter by time bands

- failure counter

- photocell errors

- motor errors

- dispensing compartment lock errors

Relative

- counter by single selection

- counter by time bands

- failure counter

- photocell errors

- motor errors

- dispensing compartment lock errors

Thehardcopyprintoutwillalsocontainthemachineinfor-

mation, and namely:

- date/time of print

- machine name

- software version

- operator code

- machine code

- Installation date.

To connect the printer, do as follows:

- press the confirm print key “ ”, displaying the mes-

sage “Confirm?”;

- connect the printer before confirming;

- press the confirm key “ ” to start printing.

DISPLAY

When pressing the confirm key “ ” the data described in

the paragraph “Printing the statistics” is sequentially dis-

played.

RESETTING THE RELATIVE STATISTICS

Statistics can be reset for relative counters globally (all

types of data) or selectively for:

- selections

- failures

- photocell errors

- motor errors

- dispensing compartment lock errors

Press the confirm key “ ”, and the message “Confirm?”

starts blinking.

Press the confirm key “ ”, the message “Working” is

displayed for a few seconds and all statistics are reset.

PRICES FOR SINGLE SELECTIONS

This function is used to change the sales price for each

selection according to the time band.

Key is used to access directly the price/selection

combination settings, if the function is enabled in the

“Technician” menu.

SPECIAL SELECTIONS

VIRTUAL SELECTIONS

Thisfunctionisusedtodefineapairofselectionsthatcan

be sold at a price different from the sum of the two

selections, using a single selection number. 10 virtual

selections can be programmed (70 to 79).

RETURN OF VIRTUAL PRICE

Thisfunctionisusedtodefine,intheeventoffailedsecond

dispensinginavirtualselection,nottocashthepriceofthe

second selection (only if an MDB payment system or

validatorareused).Withotherpaymentsystems,itcanbe

decided whether or not return the entire amount.

SELECTIONS WITH TWO MOTORS

Themachinecanbesetuptodispenselongproducts,and

dividerscanbefittedsothattwomotorsareusedforeach

single selection.

With this function the operation of two motors can be

combined,specifyingtheselectionnumberofthesecond

motor.

Thefirstmotornumberwillbetheselectionnumber,while

the selection number of the associated motor will remain

disabled.

Important notice!

After a failure to the motors of these selections, the

machineconfigurationprocedureinthe“Spiral/Selec-

tion” menu must be followed.

DISPENSING DETECTION

Thevendingmachinecanbefitted(asstandardfeatureor

as optional according to the model) with a device that, by

means of photocells, detects the passage of dispensed

products.

Thisdevice permits, in the eventof failed detection of the

dispensed product:

- set a rotation time for the spiral beyond the limit switch,

to overcome any jamming;

- return or not the paid amount;

- block further selections for the involved spiral.

15

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

TEST

SELECTIONS

Thisfunctionisusedtosimulatethenormaldispensingof

products without inserting any money to check the func-

tioningofthespiralrotationbypressingtheselectionkeys.

MOTOR TEST

It activates all motors in a sequence, indicating on the

display the number of the involved selection.

AUTOTEST

A function to check, in a semiautomatic manner, the

correct operation of some devices is implemented in the

software.

Somechecksoccurautomatically,othersneedthemanual

operationofthemonitoredcomponent;presskey“ ”togo

to the next check.

The monitored devices are:

“Temperature”

The value of temperature detected by the probe is dis-

played.

Intheeventofdisconnectionthevalue-11.0isdisplayed.

In the event of a short-circuit the value 41.0 is displayed.

Press “ ” to advance.

“Buzzer”

A series of sounds is emitted.

“Compressor”

The compressor is activated/deactivated using the “ ”

and “ ” keys.

“Selections”

All selections are activated in a sequence.

“Photocells”

If the product detection device is present, the light beam

reading and interruption are checked.

“Disp compt lock”

If the device for locking the dispensing compartment

opening, use the “ ” and “ ” keys to lock and unlock the

compartmentopening.

EVADTS TRANSFER

When activating this function, the machine awaits the

connection with a device to acquire the EVADTS statis-

tics.

16

© by NECTA VENDING SOLUTIONS SpA 0303 204-00

TECHNICIAN MENU

Using the programming procedures described in this

section, it is possible to set all variables regarding ma-

chineconfiguration.

Toaccessitisnecessarytopresstheprogrammingbutton

on the master machine and enter the information for the

machine that will be set to “filler menu” mode. Press key

from the filler menu.

N.B. By pressing again the key from the technician

menu, the machine will return to “filler” mode.

The “ ” and “ ” keys scroll through the technician menu

items, which include:

Failures Read Failures

Reset failures

Motor errors

Motors status

Reset motor errors

Program parameters Cash Prices

Master/Slave

Decimal point

Bonus

Spirals/selections Configuration

Virtual selections

Return of virtual price

Two-motor selections

Product code

Photocells Spiral settling time

Money return

Empty spiral control

Disp compt lock Operating mode

Unlock time

Out of service time

Out of serv. if open

Cold parameters

Temperature

Defrosting

Cooling unit

Display Language

Personalised strings

Miscellaneous Password

Energy saving

Menu masking

Statistics Display partial

total

Cancel partial

total

Display relat. partial

total

Cancel relat. partial

total

Print relative partial

total

Cancel partial

total

Test Complete selections

Motor test

Autotest

Miscellaneous Machine info Installationdate

Machine code

Operator code

Initialising

EVADTS Pass code

Security code

Connection

Table of contents

Popular Vending Machine manuals by other brands

Automatic Products

Automatic Products SNACKSHOP 113 instruction manual

Rowe

Rowe 4900JR SERIES Field service manual

Royal Vendors

Royal Vendors TDV Helpful hints

Dixie Narco

Dixie Narco 55 Series Technical manual

BIANCHI VENDING

BIANCHI VENDING ANE23BL Installation and maintenance manual

Westomatic

Westomatic Primo Compact Cleaning manual

Intelligent Vending

Intelligent Vending MULTI-6 installation instructions

Jofemar

Jofemar Vision Easy Combo Hardware installation and maintenance guide

Multiplex

Multiplex FreshBlender FAQ & Troubleshooting

Westomatic

Westomatic EVOLVE FITTING PLINTHS

Necta Vending Solutions SpA

Necta Vending Solutions SpA Sfera Installation, use and maintenance manual

Jofemar

Jofemar Vision ES-PLUS Technical manual