MNP37M03GBV00 Date: 24-11 Rev. 0

Page 4of 79

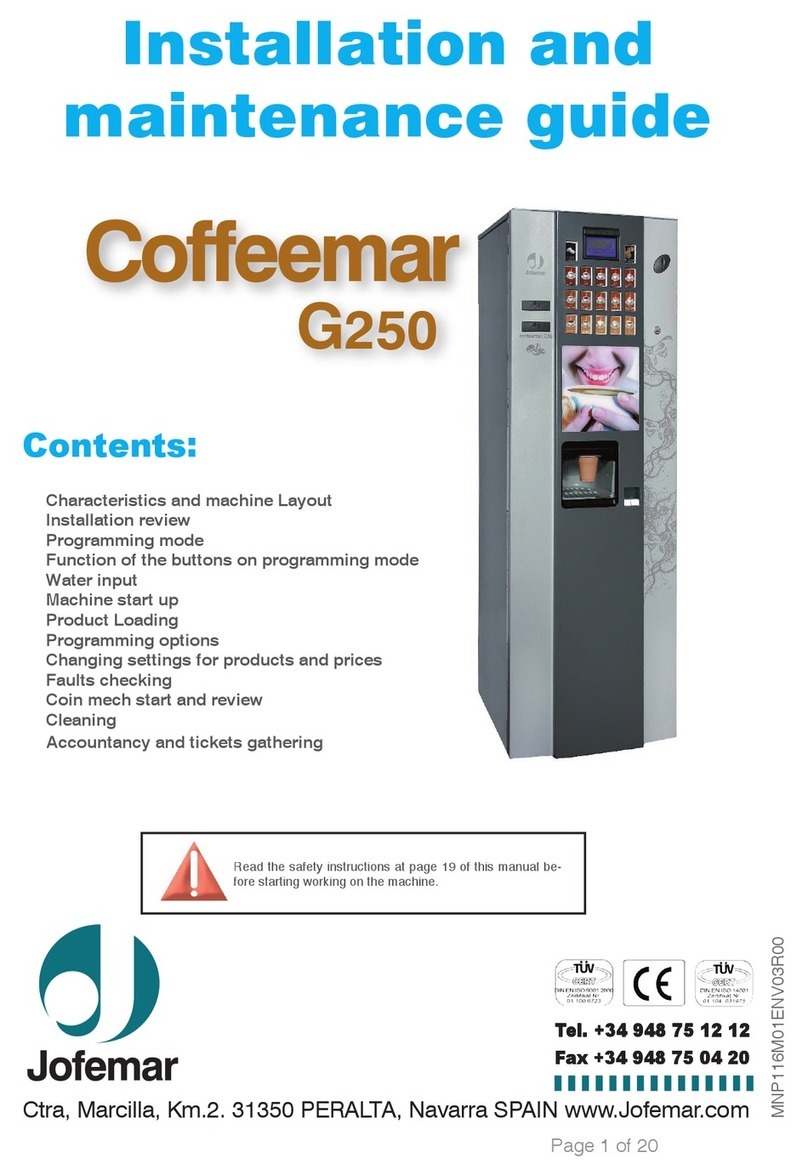

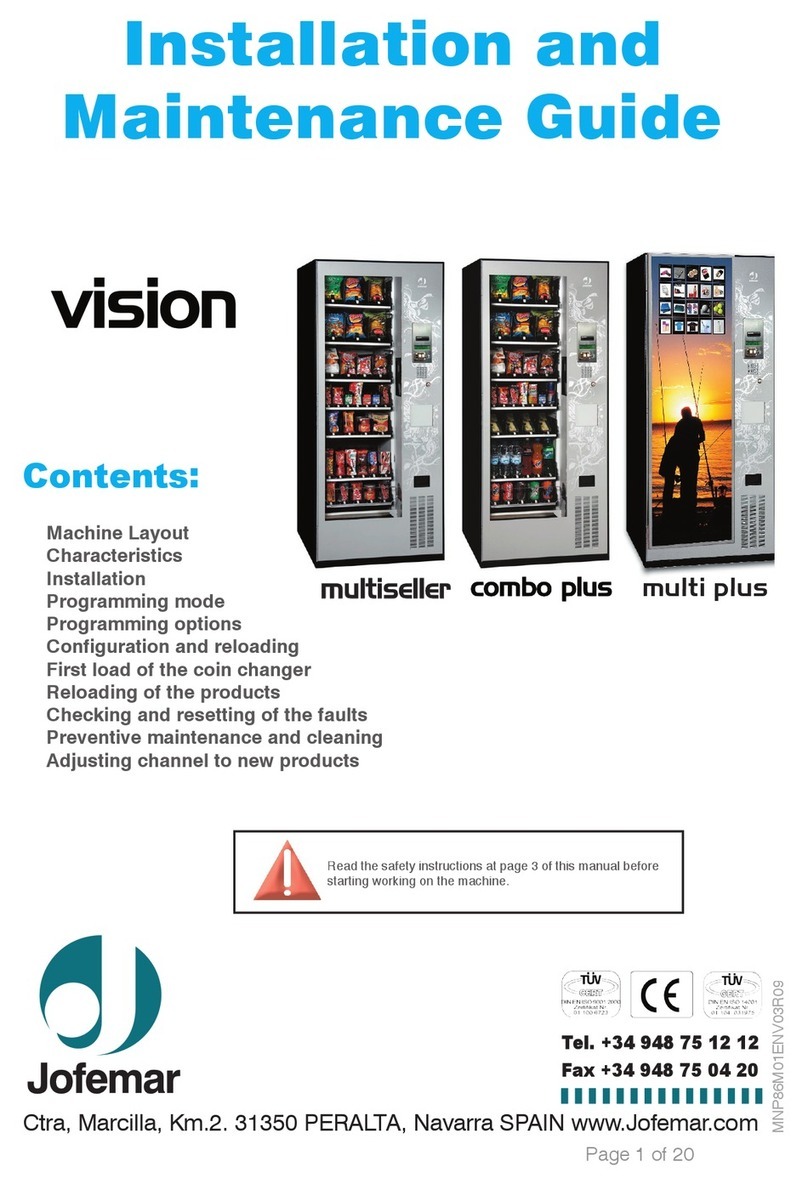

Table of Contents

1.-Symbols used in this document................................................................................6

2.-Description of the machine.......................................................................................7

2.1.-Construction......................................................................................................8

2.1.1.-Advertising panels.....................................................................................8

3.-Technical specifications. ..........................................................................................9

3.1.-Initial electrical installation.................................................................................9

4. -Installation and start up...........................................................................................9

4.1. –Installation.......................................................................................................9

4.2. -Start up..........................................................................................................10

4.2.1. -Connection to water mains. ....................................................................11

4.2.2.-Connection to mains................................................................................12

4.2.3.-Safety switch...........................................................................................13

5.-Preliminary operations............................................................................................14

5.1.-Cup loading.....................................................................................................14

5.2.-Spoon loading.................................................................................................15

5.3. -Filling the water circuit....................................................................................16

5.4.-Disinfection and washing of beaters and water circuits....................................18

5.5.-Loading sugar, soluble products and coffee beans..........................................22

6. -Basic machine operation concepts........................................................................23

6.1. -Safety systems. .............................................................................................23

6.2. -Water circuit...................................................................................................24

6.3. -Electrical drawings.........................................................................................26

6.4. -Air-break.......................................................................................................28

6.5. -Pressure boiler...............................................................................................29

6.6.-Coffee mil –doser assembly...........................................................................31

6.7.-Coffee brewing assembly................................................................................32

6.8.-Soluble container assembly and beater assembly...........................................35

6.9. -Cup dispensing assembly..............................................................................36

6.10.-Sugar and stir-stick dispensing assembly......................................................39

6.11. -Rotating arm................................................................................................40

6.12. -Kits available as an option............................................................................41

6.12.1. -Water intake pump................................................................................41

6.12.2.-Water softener.......................................................................................43

6.12.3 Flavour filter for hot drinks .......................................................................48

6.12.4 Jofemar BT-10 banknote reader kit..........................................................49

6.12.5 Coffeemar Modem Kit..............................................................................51

7.-Machine cleaning and maintenance. ......................................................................53

7.1.-Daily cleaning. ................................................................................................54

7.2.-Weekly cleaning..............................................................................................55

7.3.-Monthly cleaning.............................................................................................56

7.4.-Yearly cleaning...............................................................................................56

8. -Version names......................................................................................................56

8.1. -Coffeemar G-500 with 3 beaters and 4 containers. ........................................56

9.-Compliance with regulations...................................................................................57

10.-Products which can be dispensed from the machine............................................58

11. -Programming mode.............................................................................................58

11.1. -Programming options...................................................................................58

11.1.0. –OP_0 price options. ..............................................................................61

11.1.1 OP_1 money accounting. (only MDB machines)......................................62

11.1.2 –OP_2. product accounting......................................................................62