9

EEC-declaration of concurrence.

We, Hadewe Neopost BV.,

De Tijen 3

9201 BX Drachten

The Netherlands

declare, entirely under our own responsibility, that

the products described in this manual, to which this

declaration relates, conform the standards of

EN 291-1, EN 292-2

EN 60950

EN 55022, EN 50081-1

EN 60555-2 and EN 60555-3

EN 294

in accordance with

The Machine Directive 89/392/EEC, modified by

the directives 91/368/EEC, 93/44/EEC and 93/

68/EEC,

The low voltage Directive 73/23/EEC, modified by

the directive 93/68/EEC,

and the EMC Directive 89/336/EEC, modified by

the directives 92/31/EEC and 93/68/EEC.

It is forbidden to put the product into use

before the equipment to which it is

connected, declared to be in accordance with

the stipulations of the Machine Directive.

9. SPECIFICATIONS

This operator manual refers to machines as from machine number 98 BZ-5049

Machine specifications

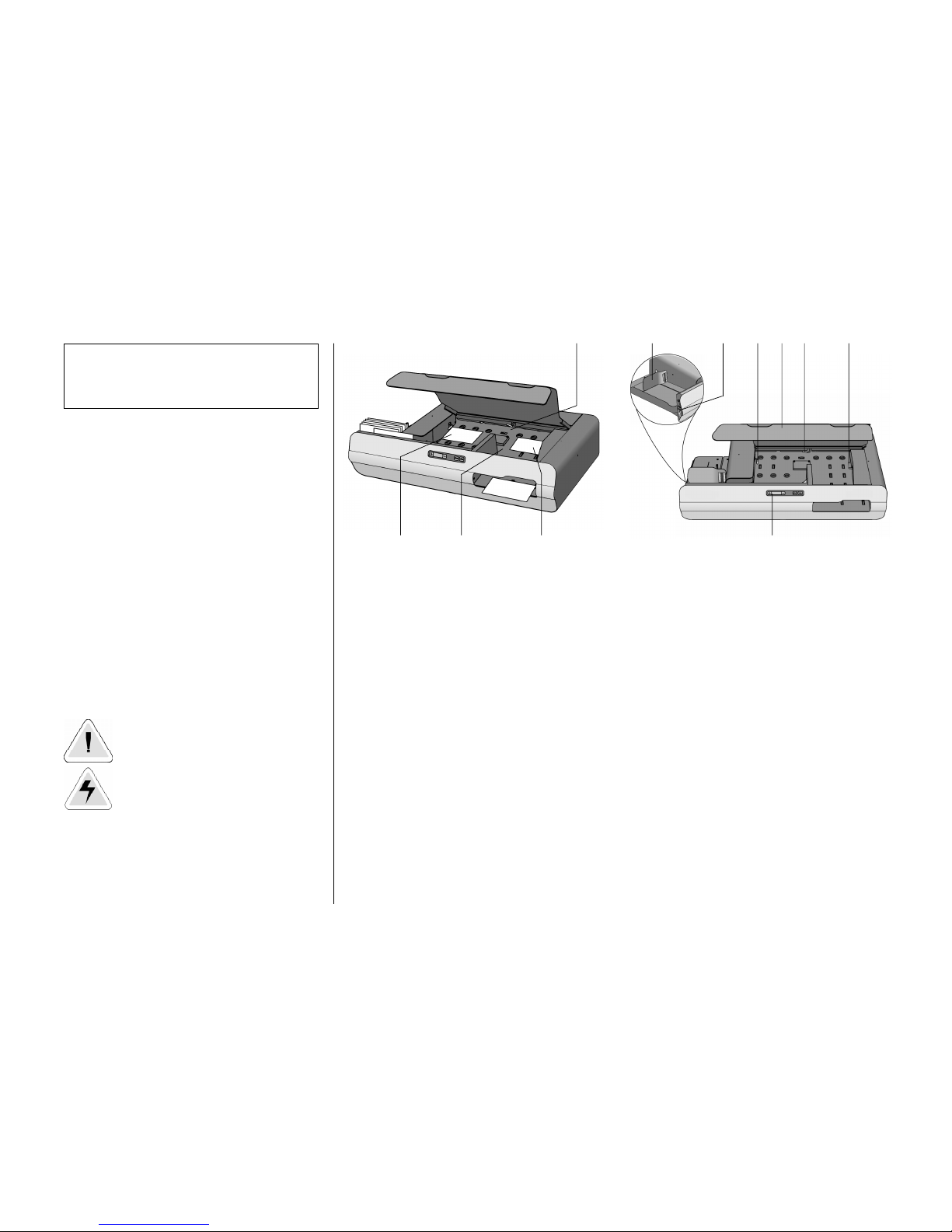

Model : LO-1 (IM 30)

Type : letter opening device for medium office use.

Overall dimensions : height 321 mm (12,6 inch)

: width 566 mm (22,3 inch)

: length 997 mm (39,3 inch)

Weight : 66 kg

Noise level : ± 68 dB(A) following DIN 45635 part 19

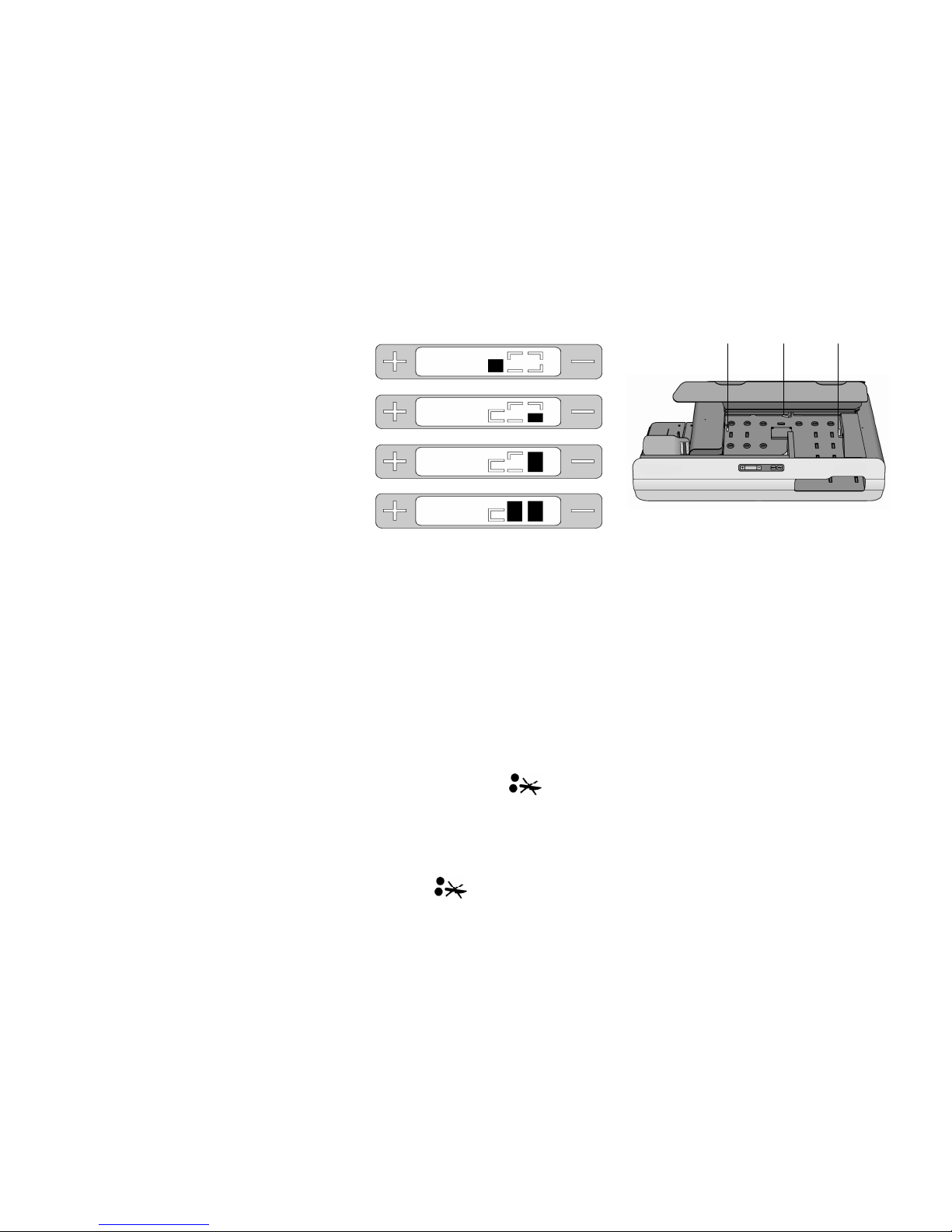

Theoretical max. speed : 2400 envelopes per hour, depending on mode of operation

Operating temperature : 10 - 40°C (50 - 122°F)

Humidity : 10 - 90%

Power consumption : 100 - 120 V AC / 50/60 Hz / 2.3 -3.0 Amps

220 - 240 V AC / 50 Hz / 1.2 -1.5 Amps

Approvals : conforms to IEC 950 and derivatives

UL listed ITE, File E153801

BS EN60950, File SM11322

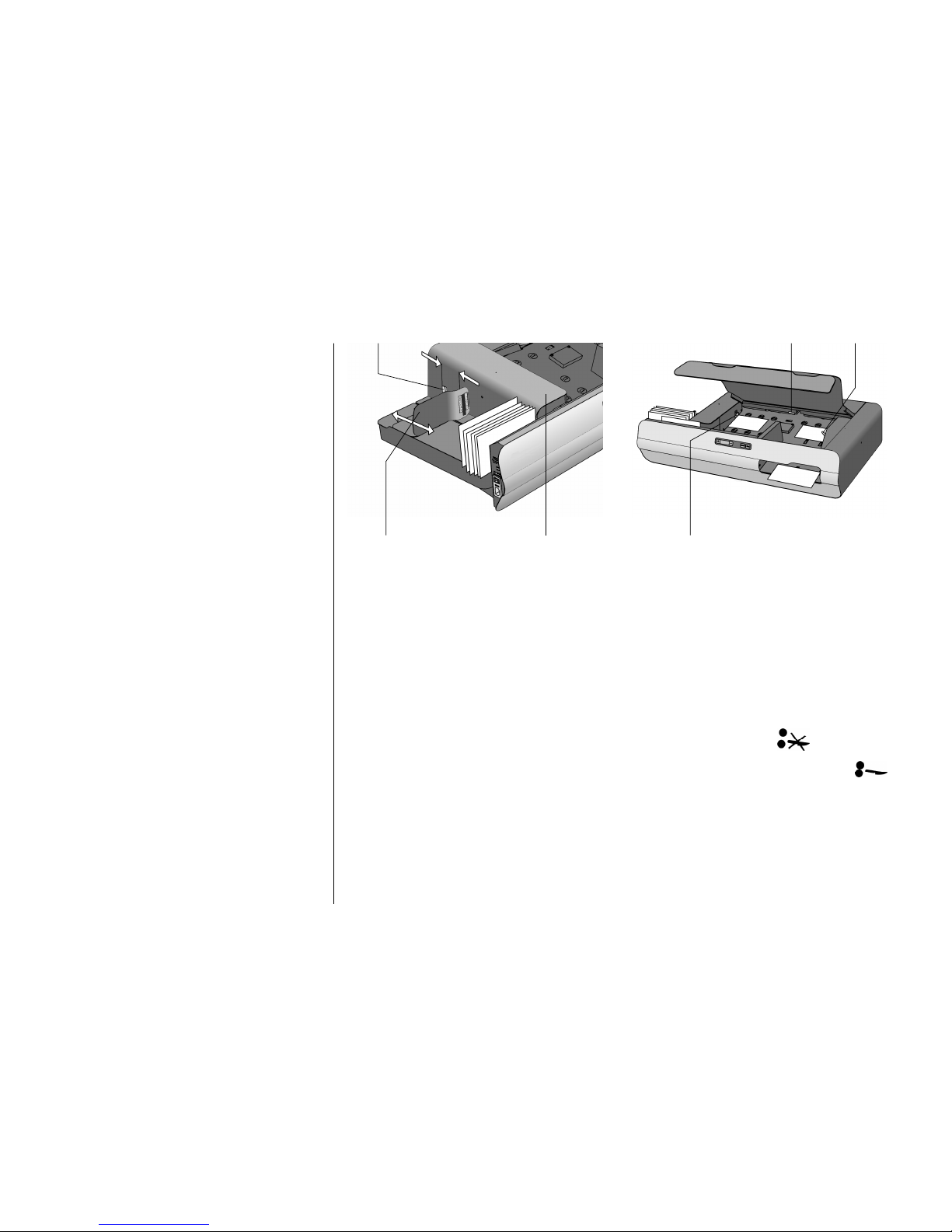

Envelope specifications minimum maximum

width : 140 mm (5.5 inch) 260 mm (10.2 inch)

length : 85 mm (3.3 inch) 175 mm ( 6.9 inch)

thickness : - 4 mm ( 0.16 inch)

In mixed mail applications the minimum width is 180 mm (7.1 inch)

Envelope quality : 50 g/m2200 g/m2

(13 lb Bond) (120 lb Book)

Note: this equipment has been tested and found to comply with the limits for class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with this instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

HADEWE Neopost BV, De Tijen 3,

9201 BX DRACHTEN, The Netherlands

89.38.96 index - 09/98 Specifications and design are subject to change without prior notice