Contents

Notes on using these operating instructions

099-008800-EW501

22.7.2022

1 Contents

1Contents .......................................................................................................................................... 3

2For your safety ............................................................................................................................... 4

2.1 Notes on using these operating instructions .......................................................................... 4

2.2 Explanation of icons ............................................................................................................... 5

2.3 Safety instructions .................................................................................................................. 6

2.4 Transport and installation ...................................................................................................... 9

3Intended use ................................................................................................................................. 11

3.1 Applications .......................................................................................................................... 11

3.2 For operation only with the following equipment ................................................................. 11

3.3 Documents which also apply ............................................................................................... 11

3.3.1 Warranty ............................................................................................................... 11

3.3.2 Declaration of Conformity ..................................................................................... 11

3.3.3 Service documents (spare parts and circuit diagrams) ........................................ 11

3.3.4 Part of the complete documentation ..................................................................... 12

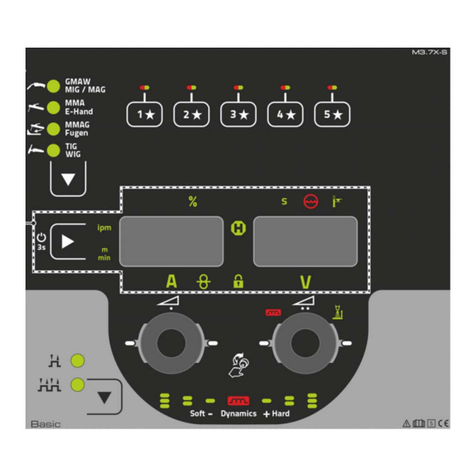

4Machine description – quick overview ...................................................................................... 13

4.1 Front view / rear view ........................................................................................................... 13

5Design and function ..................................................................................................................... 15

5.1 Assembly/disassembly ........................................................................................................ 15

5.1.1 Power source connection ..................................................................................... 16

5.2 Transport and installation .................................................................................................... 16

5.2.1 Mains connection .................................................................................................. 17

5.2.1.1 Mains configuration ............................................................................... 17

5.2.2 Ambient conditions ............................................................................................... 17

5.2.3 Machine cooling .................................................................................................... 18

5.3 Functional characteristics .................................................................................................... 18

6Maintenance, care and disposal ................................................................................................. 19

6.1 General ................................................................................................................................ 19

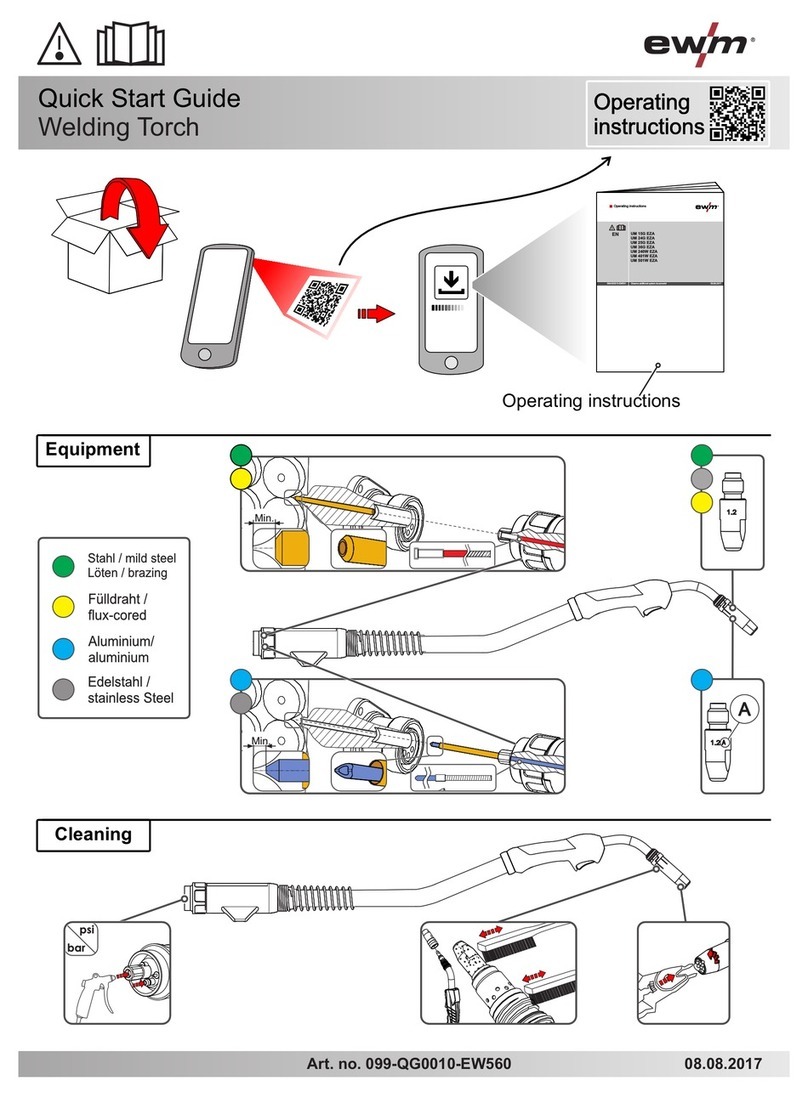

6.1.1 Cleaning ............................................................................................................... 19

6.1.2 Dirt filter ................................................................................................................ 19

6.2 Maintenance work, intervals ................................................................................................ 20

6.2.1 Daily maintenance tasks ...................................................................................... 20

6.2.2 Monthly maintenance tasks .................................................................................. 20

6.2.3 Annual test (inspection and testing during operation) .......................................... 20

6.3 Disposing of equipment ....................................................................................................... 21

7Rectifying faults ........................................................................................................................... 22

7.1 Checklist for rectifying faults ................................................................................................ 22

8Technical data .............................................................................................................................. 23

8.1 voltConverter 230/400 ......................................................................................................... 23

9Appendix ....................................................................................................................................... 24

9.1 Searching for a dealer ......................................................................................................... 24