Contents

Notes on using these operating instructions

099-00T501-EW501

1.8.2022

1 Contents

1Contents .......................................................................................................................................... 3

2For your safety ............................................................................................................................... 5

2.1 Notes on using these operating instructions .......................................................................... 5

2.2 Explanation of icons ............................................................................................................... 6

2.3 Safety instructions .................................................................................................................. 7

2.4 Transport and installation .................................................................................................... 10

3Intended use ................................................................................................................................. 12

3.1 Use and operation solely with the following machines ........................................................ 12

3.2 Software version .................................................................................................................. 12

3.3 Documents which also apply ............................................................................................... 13

3.3.1 Warranty ............................................................................................................... 13

3.3.2 Declaration of Conformity ..................................................................................... 13

3.3.3 Welding in environments with increased electrical hazards ................................. 13

3.3.4 Service documents (spare parts and circuit diagrams) ........................................ 13

3.3.5 Calibration/Validation............................................................................................ 13

3.3.6 Part of the complete documentation ..................................................................... 14

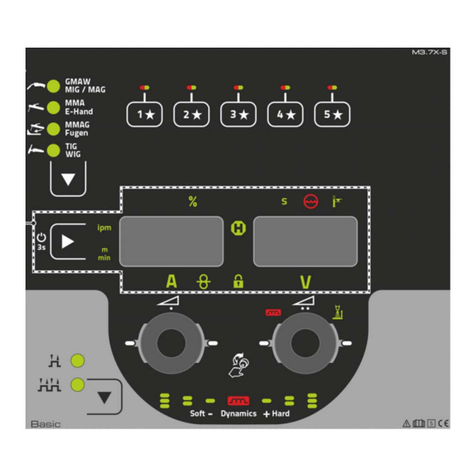

4Machine control – Operating elements ...................................................................................... 15

4.1 Overview of control sections ................................................................................................ 15

4.1.1 Control section A .................................................................................................. 16

4.1.2 Control section B .................................................................................................. 18

4.1.3 Control section C .................................................................................................. 20

4.2 Machine display ................................................................................................................... 21

4.3 Operating the machine control ............................................................................................. 21

4.3.1 Main screen .......................................................................................................... 21

4.3.2 Setting the welding current (absolute/percentage) ............................................... 21

4.3.3 Welding parameter setting in the operation sequence ......................................... 21

4.3.4 Setting advanced welding parameters (Expert menu) ......................................... 22

4.3.5 Changing basic settings (machine configuration menu) ...................................... 22

4.3.6 Lock function ........................................................................................................ 22

5Functional characteristics ........................................................................................................... 23

5.1 TIG welding .......................................................................................................................... 23

5.1.1 Setting the shielding gas volume (gas test)/rinse hose package ......................... 23

5.1.1.1 Automatic gas post-flow ........................................................................ 23

5.1.2 Welding task selection .......................................................................................... 24

5.1.3 Ignition correction ................................................................................................. 24

5.1.4 Manual ignition setting .......................................................................................... 25

5.1.4.1 Recurring welding tasks (JOB 1-100) ................................................... 26

5.1.5 Welding programs ................................................................................................ 27

5.1.5.1 Selection and adjustment ...................................................................... 27

5.1.5.2 Specifying max. no. of accessible programs ........................................ 27

5.1.6 Arc ignition ............................................................................................................ 27

5.1.6.1 HF ignition ............................................................................................. 28

5.1.6.2 Liftarc .................................................................................................... 28

5.1.6.3 Automatic cut-out .................................................................................. 28

5.1.7 Operating modes (functional sequences)............................................................. 29

5.1.7.1 Explanation of symbols ......................................................................... 29

5.1.7.2 Non-latched mode ................................................................................. 30

5.1.7.3 Latched mode ....................................................................................... 31

5.1.7.4 spotArc .................................................................................................. 32

5.1.7.5 spotmatic ............................................................................................... 33

5.1.7.6 Non-latched operation, version C ......................................................... 34

5.1.8 TIG activArc welding ............................................................................................. 35

5.1.9 TIG antistick .......................................................................................................... 35

5.1.10 Pulse welding ....................................................................................................... 36

5.1.10.1 Average value pulse welding ................................................................ 36

5.1.10.2 Thermal pulsing ..................................................................................... 37

5.1.10.3 Automated pulses ................................................................................. 37

5.1.10.4 Pulsing in an upslope/downslope .......................................................... 38