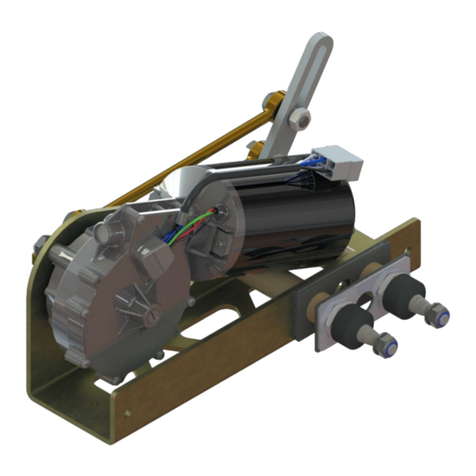

2 Technical data

2.1 General

• Product ........................................ Exalto windshield wiper

• Types............................................ 232BD –12 and 24 Volt

• Cataloguenumbers12V ....................... 2157.30/32/35/40/45/50

• Cataloguenumbers24V ....................... 2158.30/32/35/40/45/50

2.2 Electrical data 12 Volt

• Torque(max.).....................................................32Nm

• Voltage...........................................................12 Volt

• Current.............................................................3.0 A

• Powerconsumption(max.)..........................................36 W

• Numberofrevolutions ......................... Low 38 rpm, high 56 rpm

• Recommendedcable .................5 wires, 1½ (16 g) or 2½ mm2(14 g)

.....................................................up to 10 m long

• Recommendedfuse .......................................6 A slow blow

• Grounding ........................................Insulatedearthreturn

Electrical data 24 Volt

• Torque(max.)....................................................32Nm

• Voltage.......................................................... 24 Volt

• Current............................................................ 1.5 A

• Powerconsumption(max.)......................................... 36 W

• Numberofrevolutions ......................... Low 38 rpm, high 56 rpm

• Recommendedcable ................ 5 wires, 1½ (16 g) or 2½ mm2(14 g)

.....................................................up to 10 m long

• Recommendedfuse ...................................... 4 A slow blow

• Grounding .........................................Insulatedearthreturn

2.3 Mechanical data

• Dimensions............................... l x w x h = 196 x 104 x 119 mm

• Shaftdiameters................. Drive shaft Ø 20 / support shaft Ø 8 mm

• Mounting ....................................Through glass or bullkhead

• Bearing..................................Bronze housing, self-lubricating

• Wiperarms...................................... Model PU up to 750 mm

• Wiperblades .............................................. Up to 800 mm

• Wipearc...........................Wipe arc disc 40°-90° adjustable per 5°

• Weight ................................................... approx. 2.5 kg

6