Contents

iv IQS-5320

6 Taking Measurements in WDM Mode ........................................................49

Performing WDM Mode Measurements ................................................................................50

Selecting a Graph Type in WDM Mode .................................................................................52

Viewing WDM Mode Measurement Results ..........................................................................54

Viewing Trace Information ....................................................................................................56

Viewing Detailed Trace Measurements .................................................................................57

Adjusting Trace Display Resolution .......................................................................................59

7 Taking Measurements in Drift Mode .........................................................61

Performing Drift Mode Measurements .................................................................................61

Selecting a Graph Type in Drift Mode ...................................................................................63

Viewing Drift Mode Measurement Results ............................................................................65

Viewing Trace Information ....................................................................................................67

Viewing Detailed Trace Measurements .................................................................................68

Adjusting Trace Display Resolution .......................................................................................70

8 Managing Traces .........................................................................................71

Saving a Trace .......................................................................................................................72

Recalling a Trace ...................................................................................................................73

Exporting a Trace to ASCII Format ........................................................................................74

Deleting a Trace ....................................................................................................................75

Clearing a Trace from the Display .........................................................................................76

Renaming a Trace .................................................................................................................76

Defining the Default Storage Location ..................................................................................78

Defining a File Autonaming Format ......................................................................................80

Viewing Results from Existing Trace Files ..............................................................................81

9 Generating Reports .....................................................................................83

Entering Report Information .................................................................................................84

Using Report Templates ........................................................................................................87

Printing a Report ..................................................................................................................89

10 Maintenance ................................................................................................91

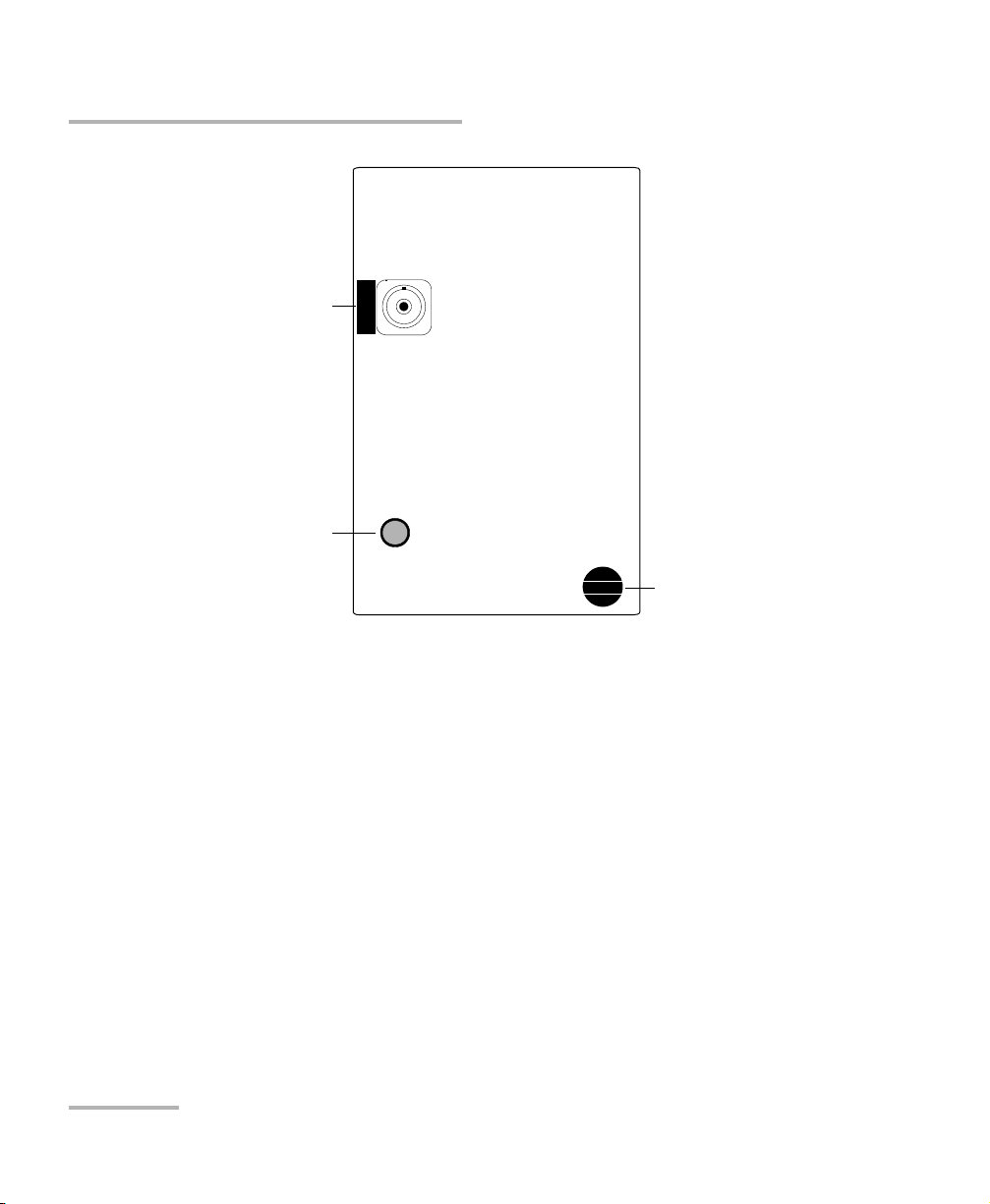

Cleaning the Front Panel .......................................................................................................91

Cleaning Fixed Connectors ....................................................................................................92

Cleaning Connectors Equipped with EUI/EUA Adapters ........................................................94

Cleaning Detector Ports ........................................................................................................98

Recalibrating the Unit ...........................................................................................................99