9

USER’S GUIDE

541 3ph AUTOMATED SYSTEMS

Readtheinstructionscarefullybeforeusingtheproductandstore

themforfutureuse.

GENERAL SAFETY REGULATIONS

Ifcorrectlyinstalledandused,5413phautomatedsystemsensure

ahighdegreeofsafety.

Somesimplerulesonbehaviourcanpreventaccidentaltrouble:

-Donot,underanycircumstances,standunderthesectionaldoor.

-Donotallowchildren,personsorthingstostandneartheautoma-

tedsystems,especiallywhiletheyareoperating.

-Keepremote-controls,orotherpulsegeneratorsthatcouldopen

thedoor,wellawayfromchildren.

-Donotallowchildrentoplaywiththeautomatedsystem.

-Donotwillinglyobstructdoormovement.

-Preventanybranchesorshrubsfrominterferingwithdoormove-

ment.

-Keepwarning-lightsefficientandeasytosee.

-Donotattempttoactivate the doorbyhandunlessyouhave

released it.

-Make surethat therearenopersons,animalorthingsnear the

doorbeforereleasingthedoor.

- In the event of malfunctions, manually activate or release the

doortoallowaccessandwaitforqualifiedtechnicalpersonnel

todothenecessarywork.

-Whentheoperatorisreleased,beforerestoringmotorisedopera-

tion,makesurethatthesystemisnotpowered.

- Do not in any way modify the components of the automated

system.

-Donotattemptanykindofrepairofdirectactionwhateverand

contactqualifiedFAACpersonnelonly.

-Atleasteverysixmonths:arrangeforqualifiedpersonneltocheck

efficiency of the automated system, safety devices and earth

connection.

-Arrangeforqualifiedpersonneltocheckthedoorattheintervals

recommendedbythemanufacturer,addressingspecialattention

tothesafetysystemsandbalancing.

- Transit under the door is permitted only when the automated

systemisidle.

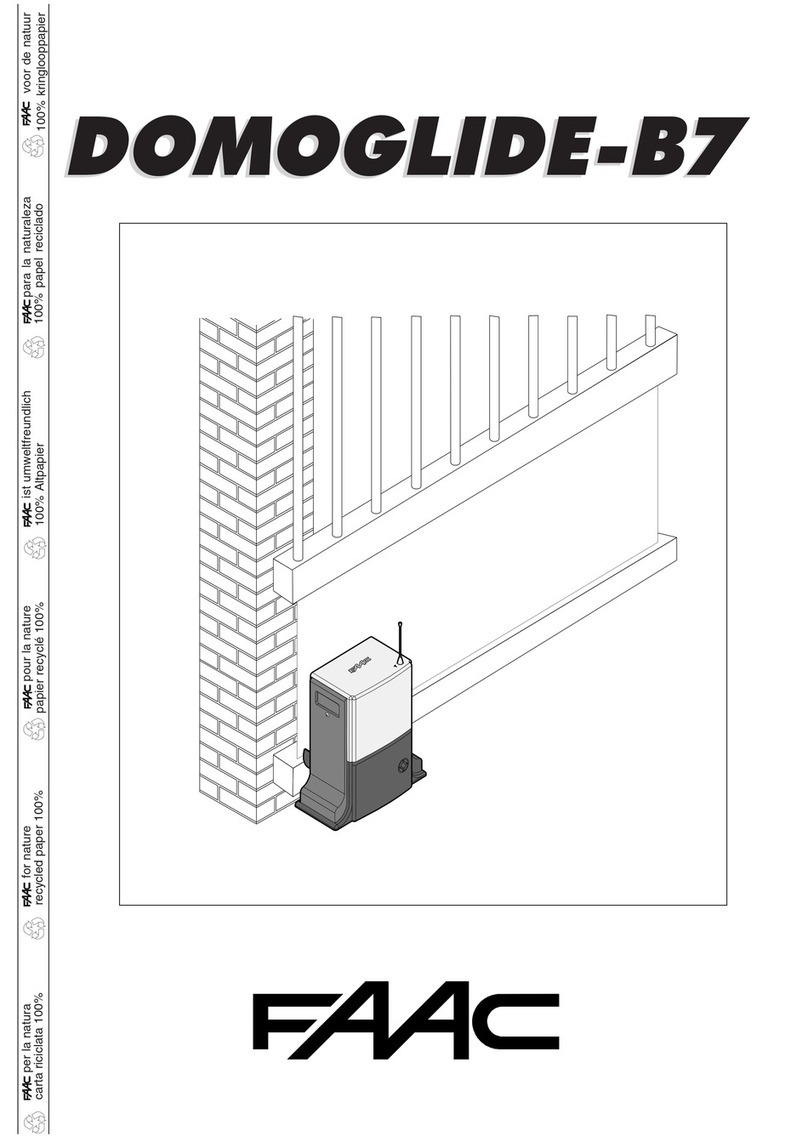

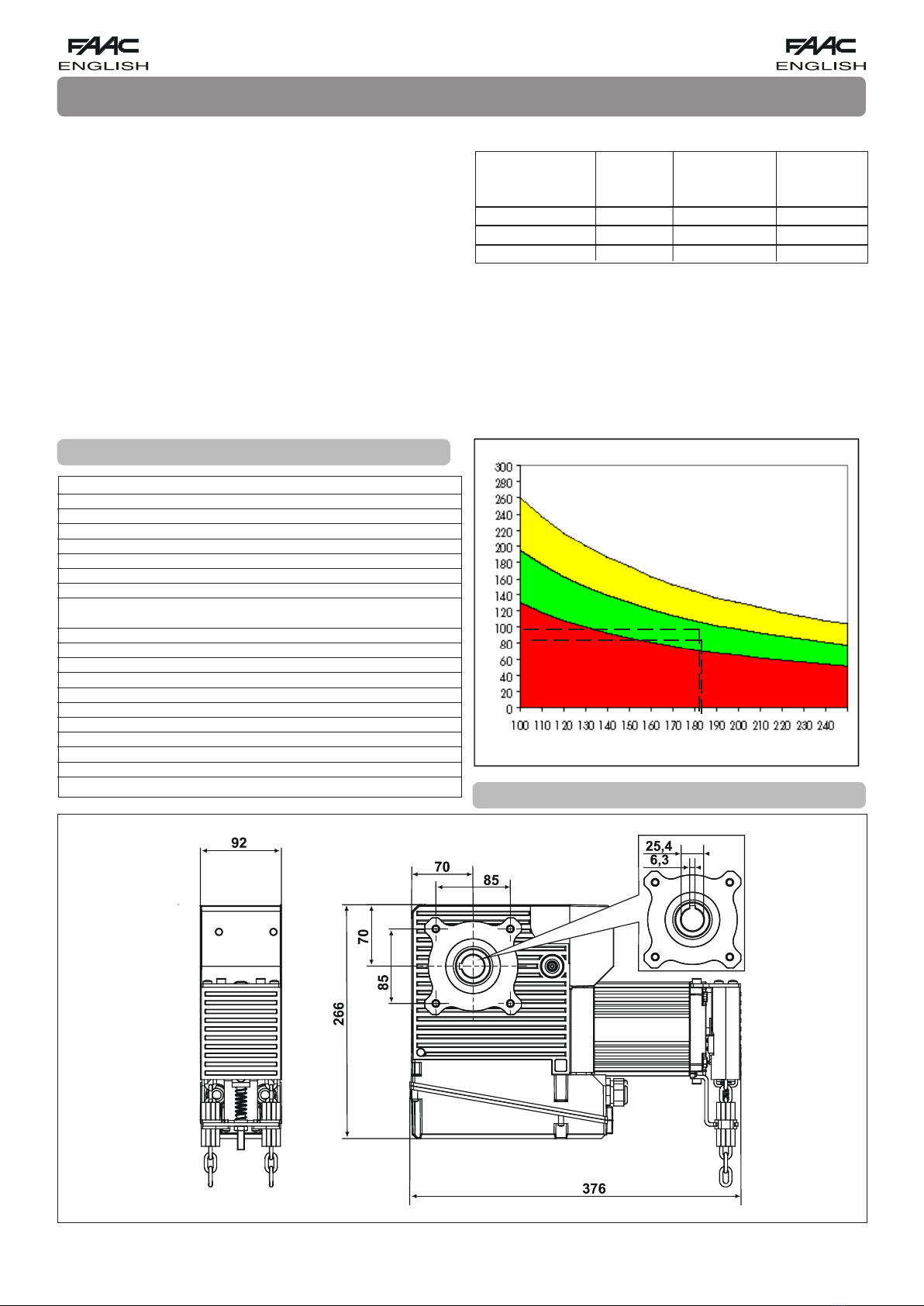

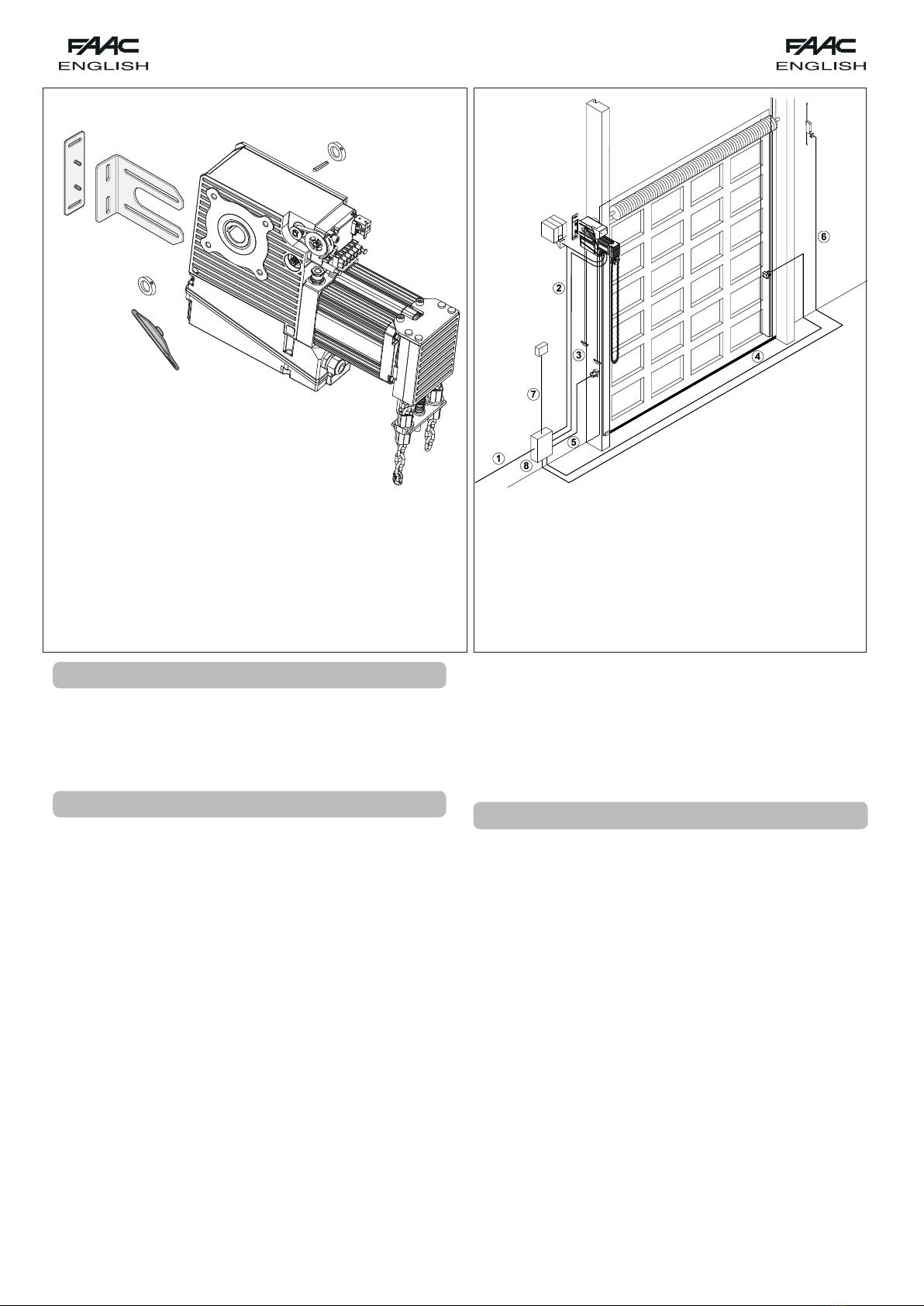

DESCRIPTION

The5413phautomatedsystemsareidealforactivatingbalanced

industrialsectionaldoors.

They consist of an electro-mechanical operator and remote

electronic control equipment. The non-reversing system ensures

mechanicallockingofthedoorwhenthemotorisnotoperating

and,therefore,nolockneedstobeinstalled.Operatorreleaseand

amanualmanoeuvringsystem(thelatterisonlysuppliedonthe

modelsforwhichitisspecified),makethedoormanoeuvrablein

theeventofapowercutormalfunction.

The door is normally closed; when opening is commanded, the

equipmentactivatestheelectricmotorwhichdrivesthedoorto

opening position to permit access. In “dead-man” systems, the

commandpush-buttonmustbekeptpressedforthewholeduration

oftheopeningorclosingmanoeuvre.

Intheautomaticallyoperatingsystems:

-Iftheautomaticlogicwasset,thedoorclosesafterpausetime

haselapsed.

-Ifthesemi-automaticlogicwasset,asecondpulsemustbesent

toclosethedoor.

-Astoppulse(ifsupplied)alwaysstopsmovement.

Forfulldetails on thebehaviour oftheautomated systemin the

differentlogics,consulttheinstallationTechnician.

Automatedsystemsmayincludesafetydevices(sensitiveedges,

photocells)thatpreventthedoorfromclosingand/oropeningwhen

thereisanobstacleintheareatheyprotect.Emergencymanual

openingispossiblebyusingthereleasesystem.

Manualcommandispossiblebyactivatingthechain-operated

winch(formodelswithwhichitissupplied).

Electriccommandisdisabledduringthemanualmanoeuvreor

whentheoperatorisreleased.

Thewarning-light,wheresupplied,indicatesthatthedooriscur-

rentlymoving.

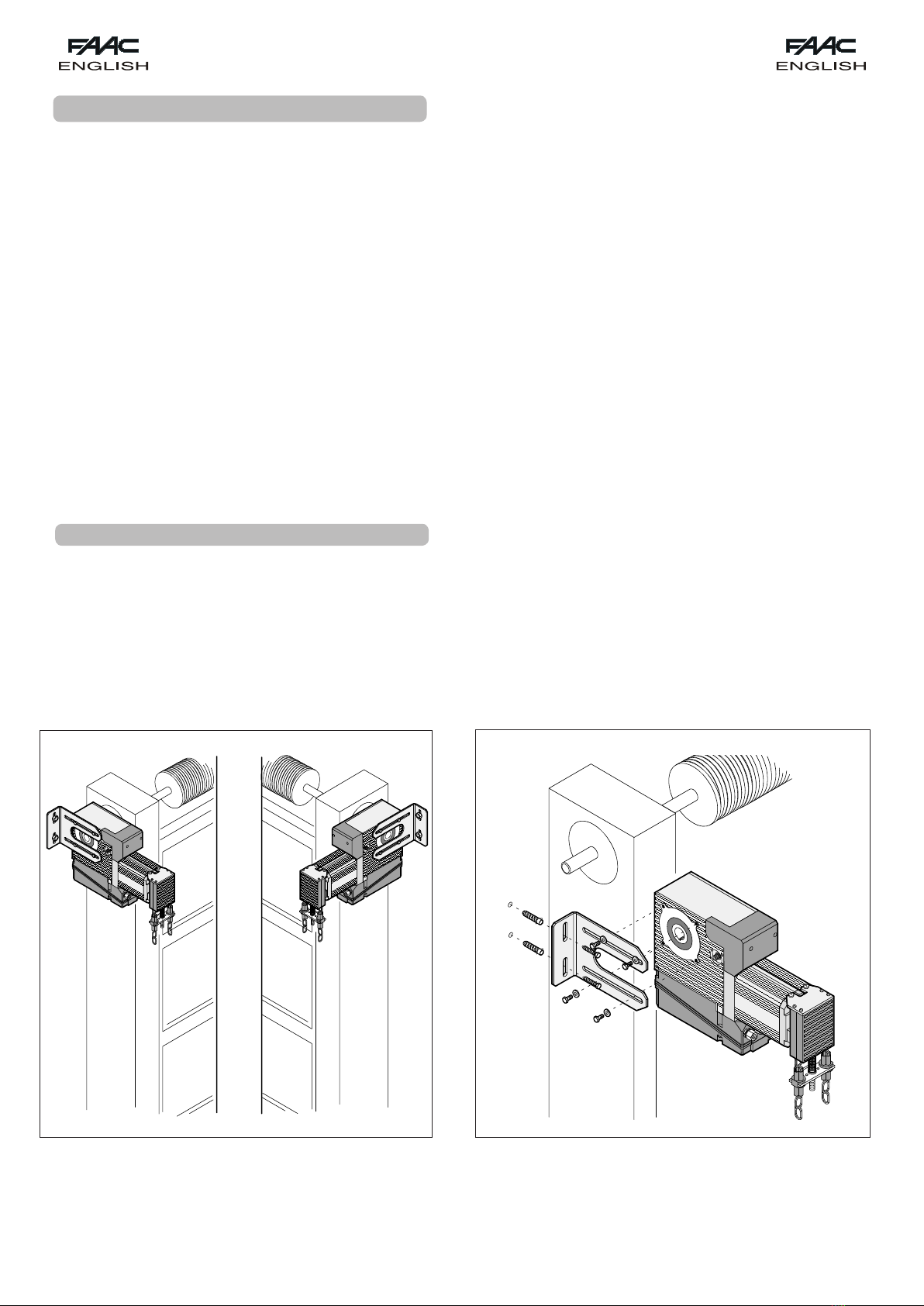

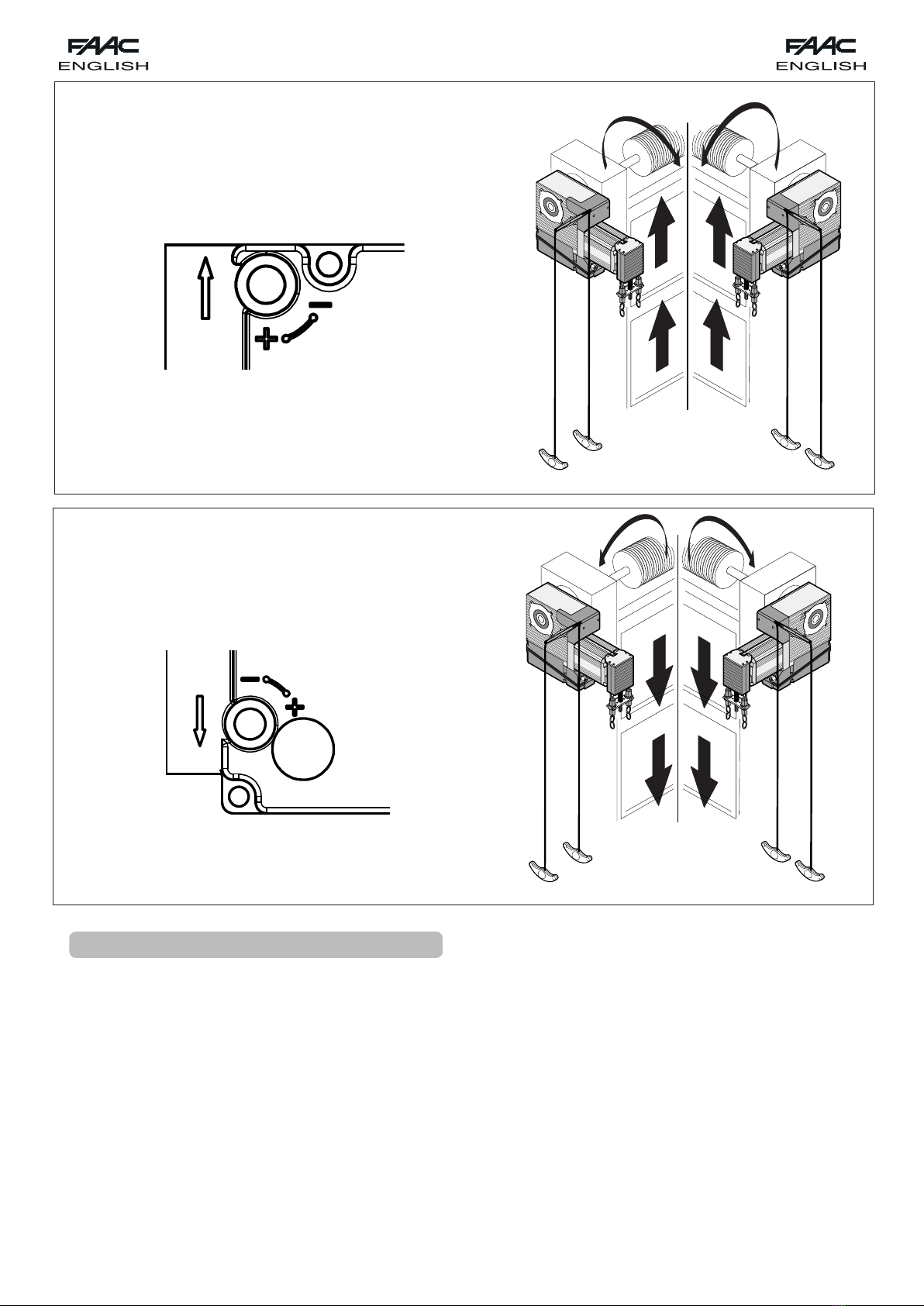

MANUAL OPERATION (541 3ph with winch)

If the door has to be activated and the automated system is

inactiveduetoapower-cutormalfunction,thedooropeningand

closingmanoeuvrescanbedonebyhand,byusingthechain-

operatedwinch.Checktheindicatorsigntoseewhichbranchof

thechainhastobeactivatedtoperformtherequiredmanoeuvre.

Pulldownwardonlythebranchinvolved.

Ifnoindicatorsignispresent,pulloneofthechainbrancheswi-

thoutforcingandcheckifthedoortendstomoveintherequired

direction.Ifnot,activatetheotherbranch.

Whilethewinch isoperating,theoperator’selectrical controlis

disabled.

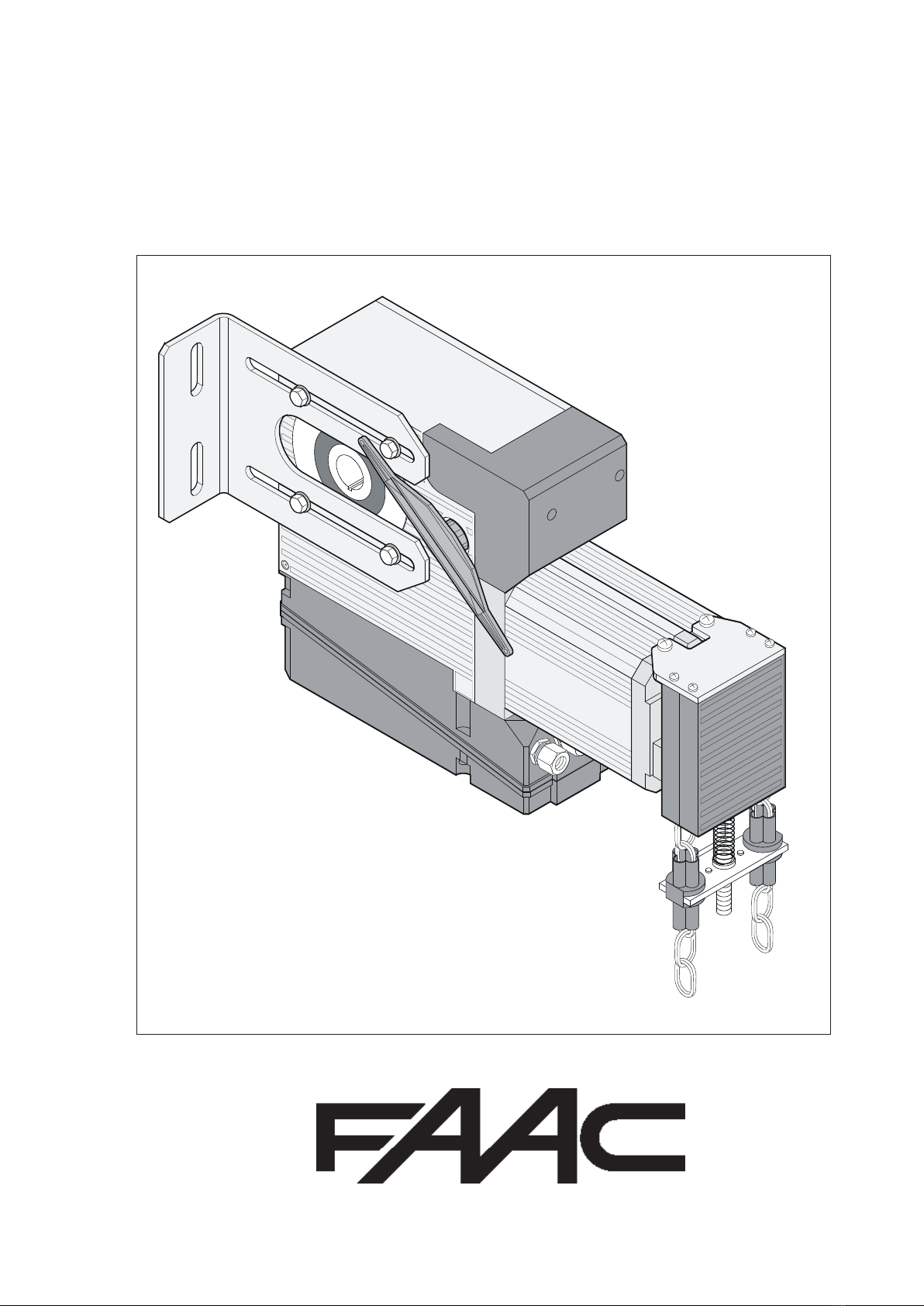

RELEASING THE OPERATOR AND RESTORING AUTO-

MATIC OPERATION

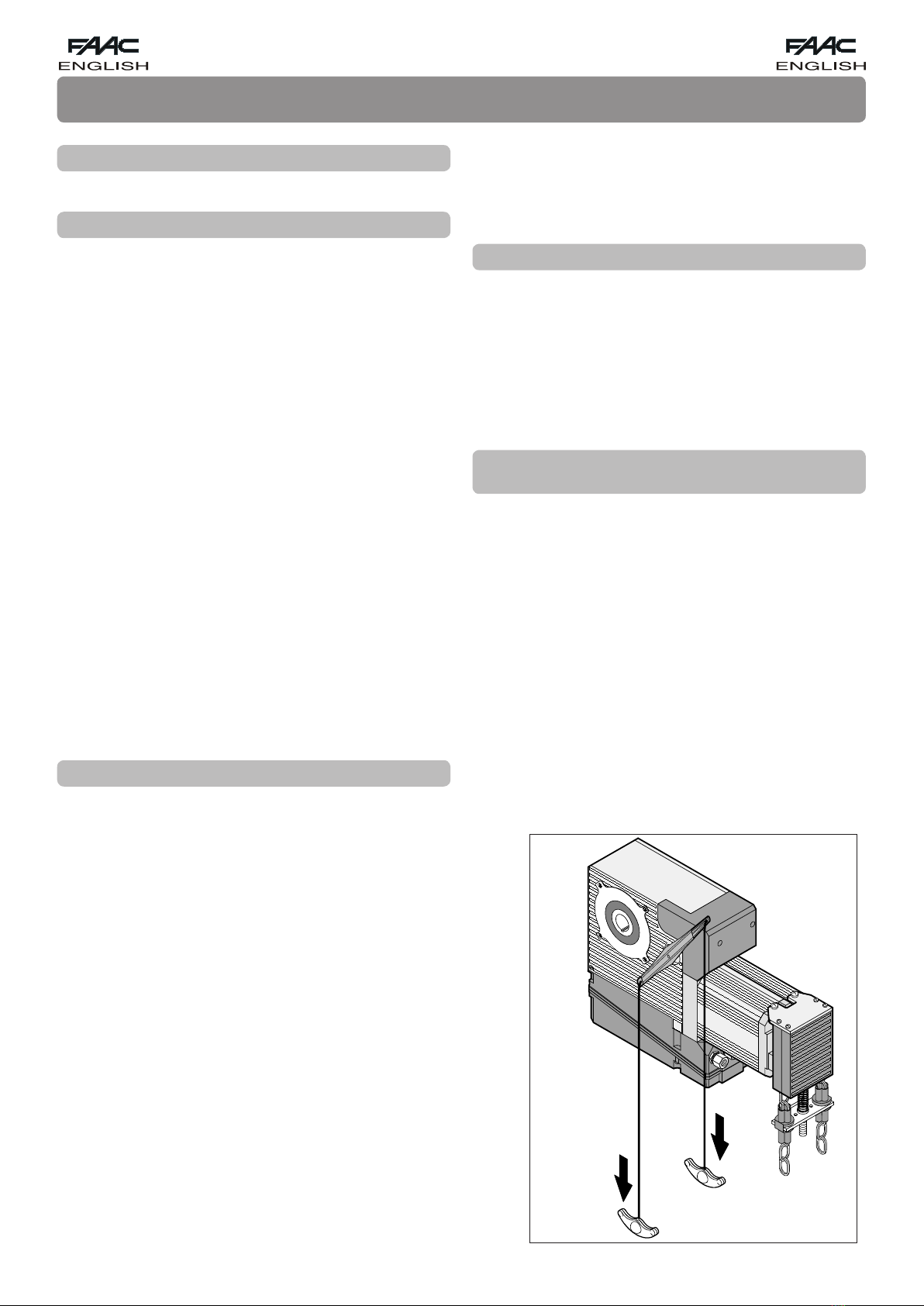

The5413phoperatorsareprovidedwithanemergencysystem

whichcanbeactivatedfromtheinside.

Theoperatorreleaseoperationmust be effectedwiththedoor

closedifpossible.Inanyevent,thepresenceofpersons,animals

andobjectsintheimmediatevicinityoftheoperatorisabsolutely

forbidden.

Ifthedoorhastobemovedmanuallyduetoapowercutormal-

functionoftheautomatedsystem,cutoutpowertothesystemand

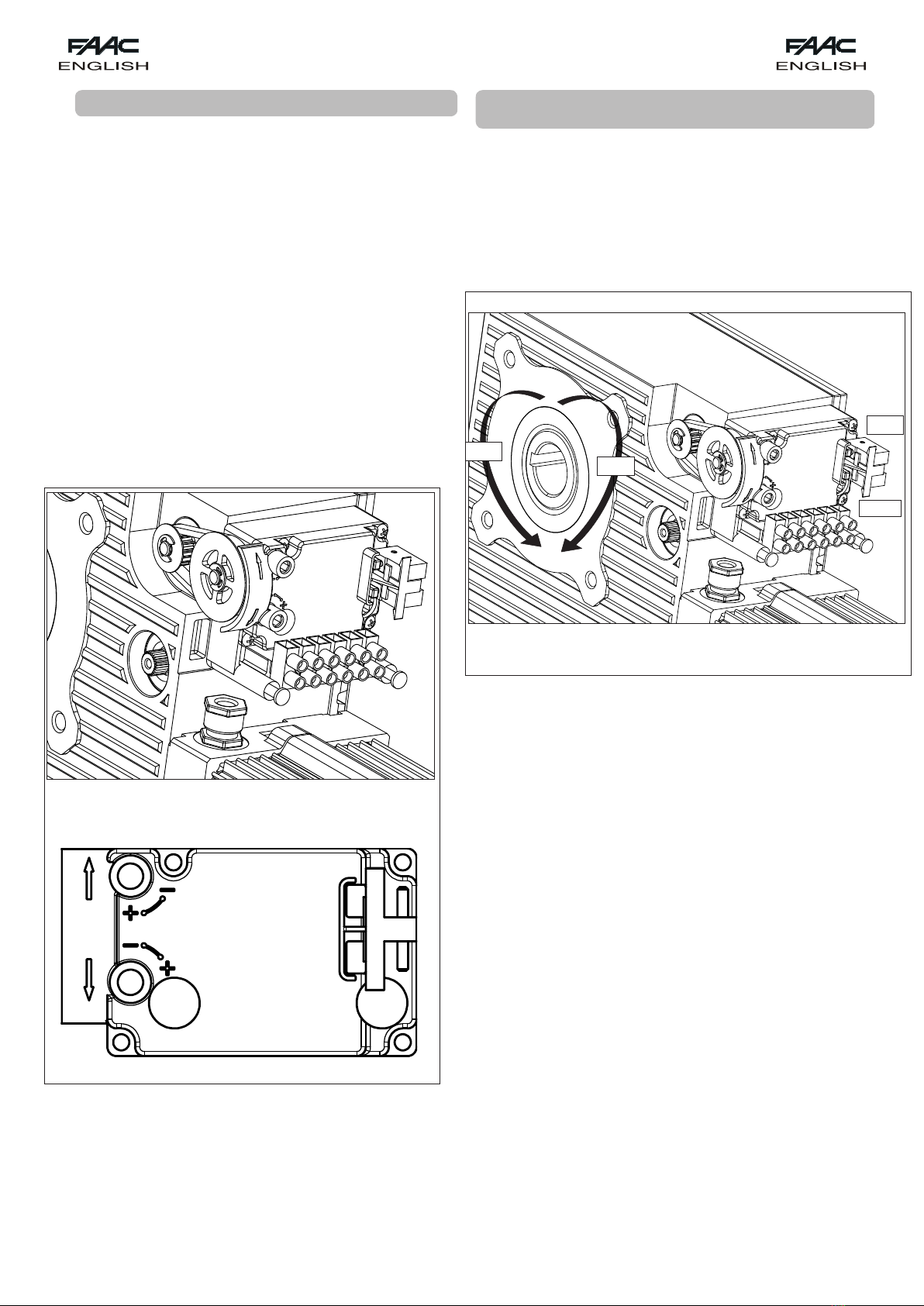

usethereleasedeviceasfollows:releasetheoperatorbypulling

theropewiththeredknob(seefigure1)downwarduntilthelever

reachesthetravel-limitstop.Torestoreautomaticoperation,fully

closethedoorandpulltheropewiththegreenknobuntilthelever

returnstoitsoriginalposition.

Fig. 1