21

ENGLISH

ENGLISH

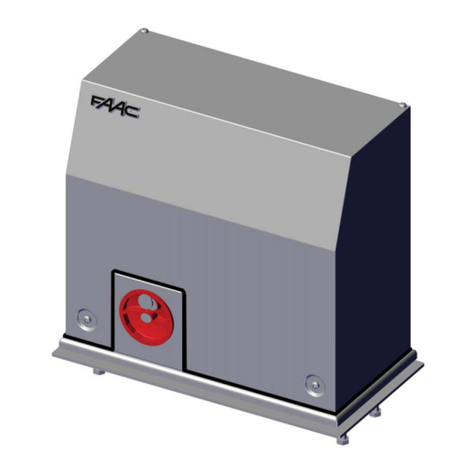

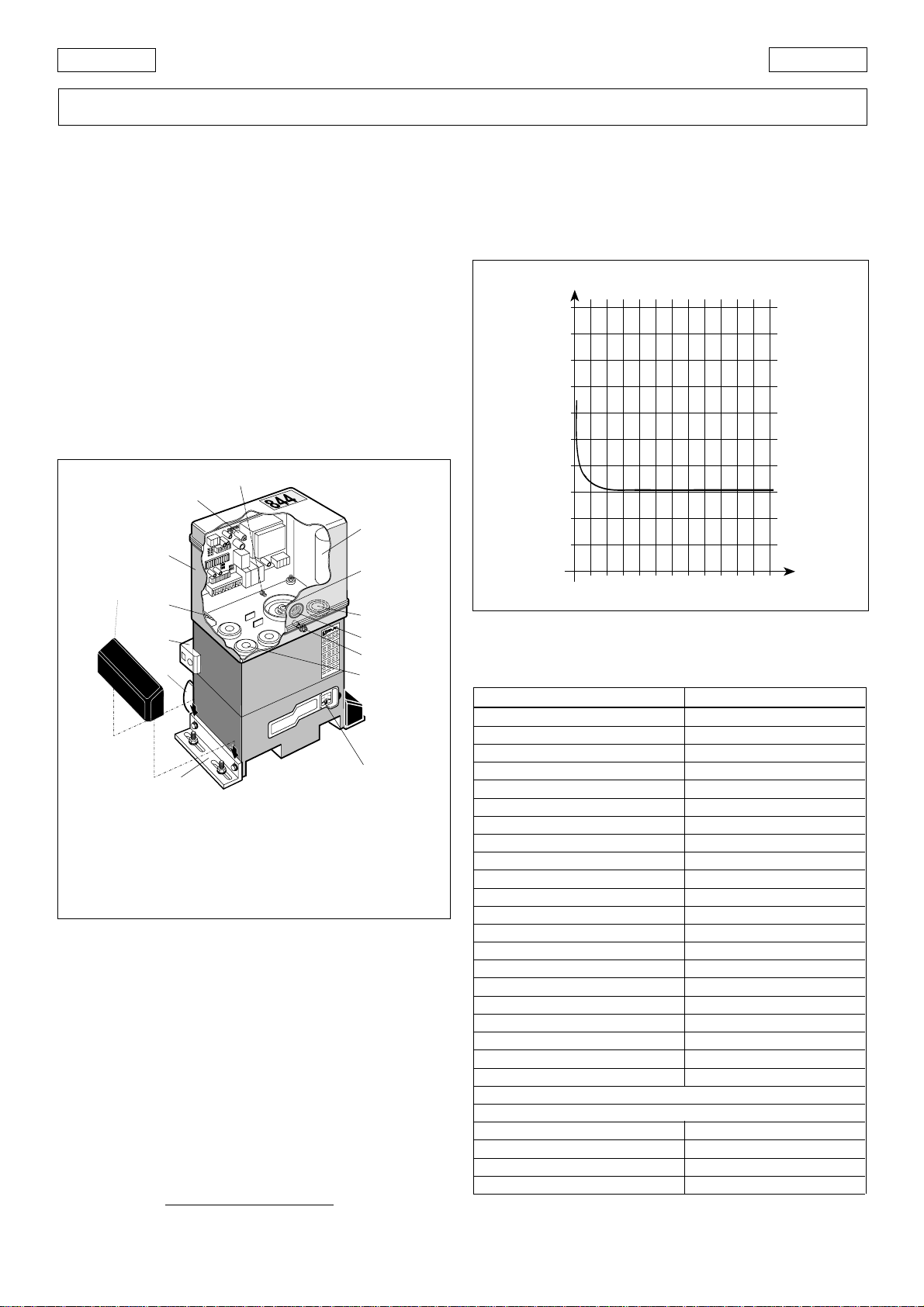

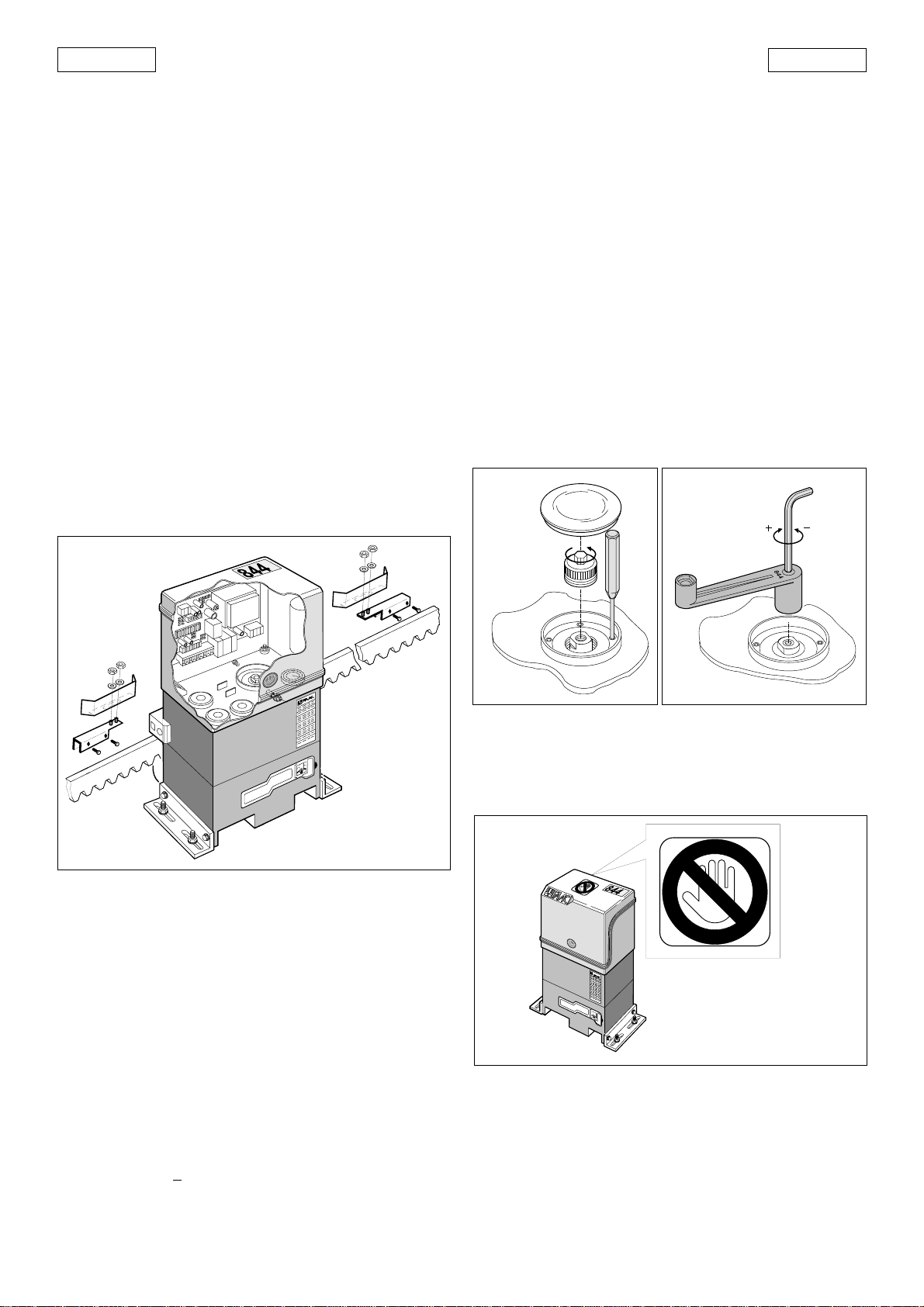

Fig. 34

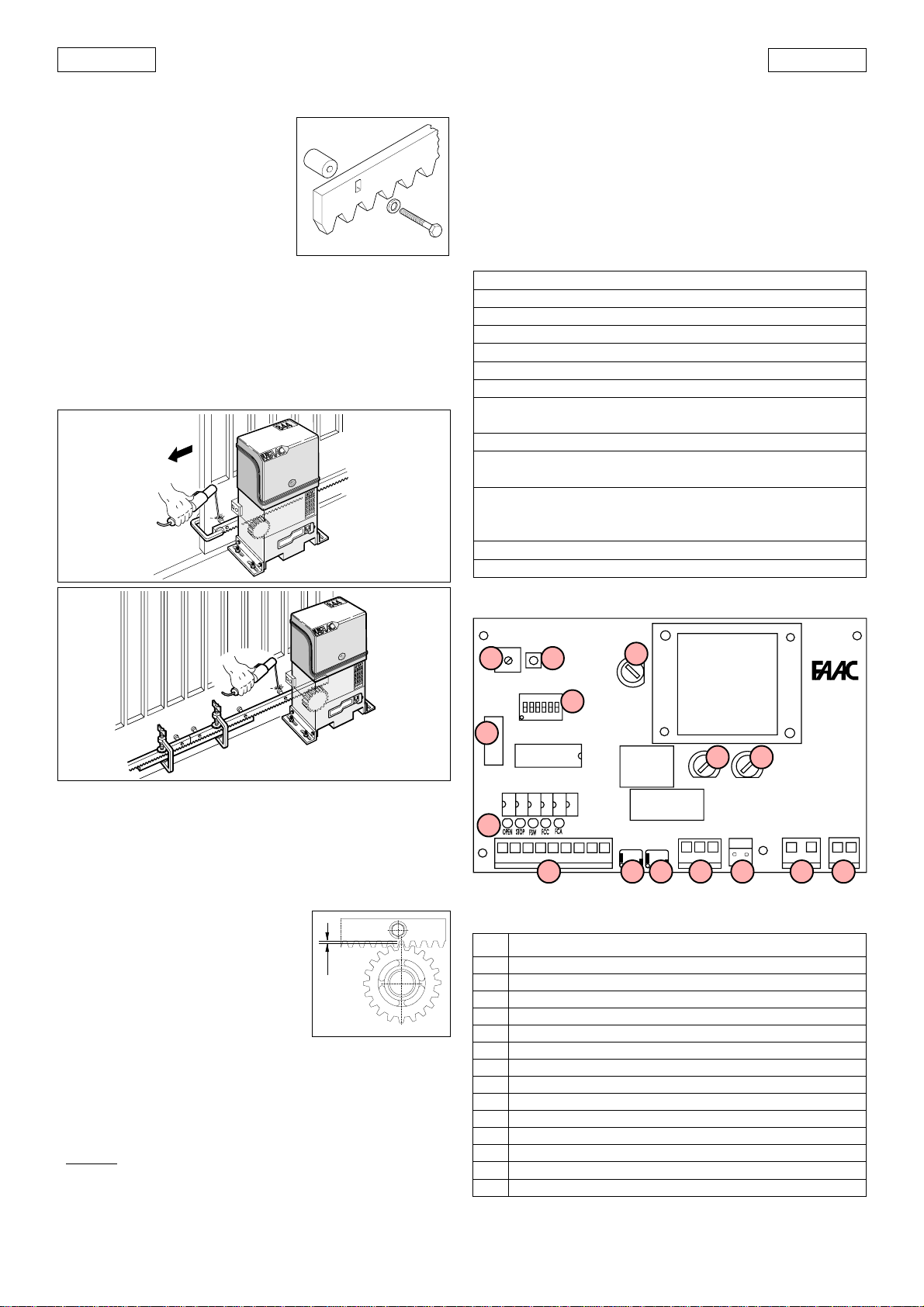

5.7. TORQUE ADJUSTMENT

The 844 MC-R automation system is equipped with an anti-

crushing mechanical clutch which stops the opening/closing

movement when the gate encounters an obstacle.

Whentheobstacleisremoved,thegateresumesitsmovement

until the relevant limit switch trips or the safety time (TIME OUT)

is exceeded.

This torque limiter must be set in compliance with current

standards.

Toadjustthe thresholdoftheanti-crushingsystem, proceedas

follows:

1) Switch off the power supply.

2) Remove the cover of the relevant bore (Fig. 1- ref. 9), and

unscrew the cap of the clutch adjusting screw (Fig. 32).

3) Keepthe drivingshaft in positionby means ofthe supplied

lever, and adjust the clutch as shown in Fig. 33.

To increase torque, turn the screw clockwise.

To decrease torque, turn the screw counterclockwise.

the operator is supplied with the clutch set to maximum

torque. Initially, the working torque of the system must be

decreased.

4) Switch on the power supply and check whether the anti-

crushing system trips correctly.

Fig. 32 Fig. 33

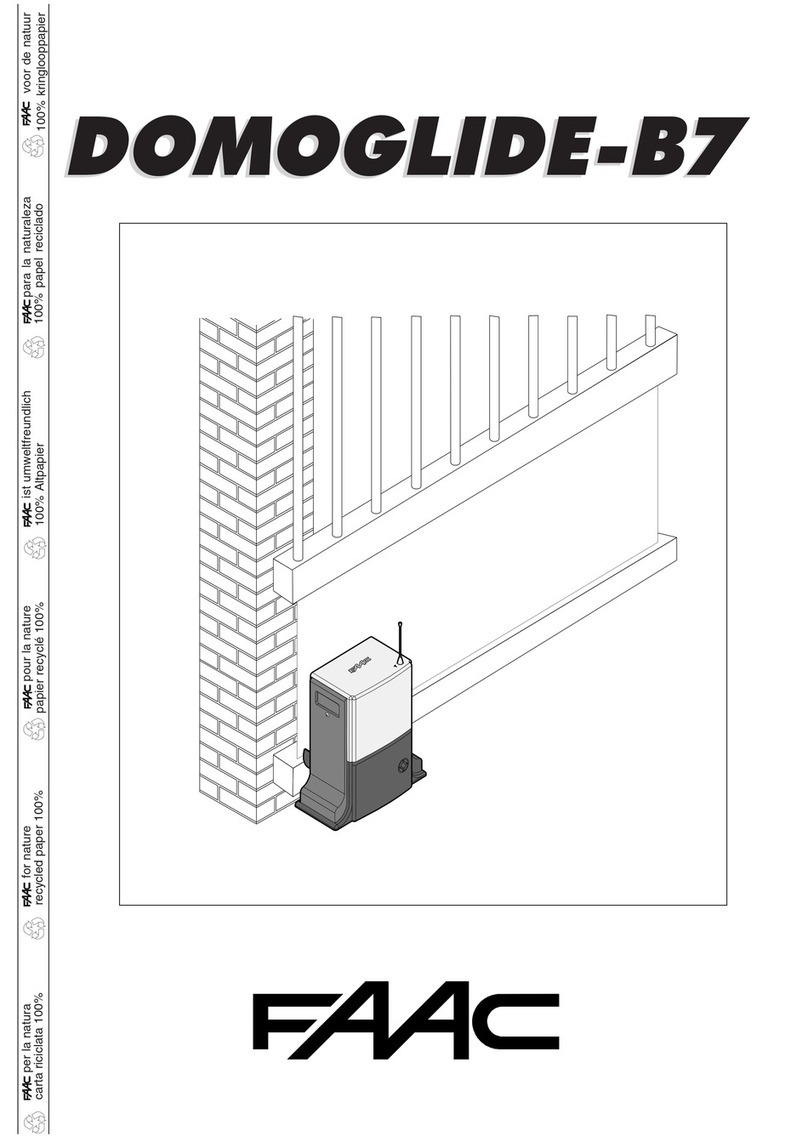

6. TESTING THE AUTOMATION

When installation is complete, affix the danger warning label

to the top of the casing (Fig. 34).

Press fit the covers over the operator fixing bars (Fig. 35).

Thoroughly check operation of the automation and all

connected accessories.

Checktheclosurestoppositionofthegateandcheckthatthe

lock plate is in the correct position. If necessary, change its

position and recheck operation by performing a few gate

movement cycles. When you are sure that the position is

correct, fix the lock plate with screws or by welding.

alarmhasbeeneliminatedandtheRESETbuttonhasbeen

pressed (or the power supply has been momentarily inter-

rupted).

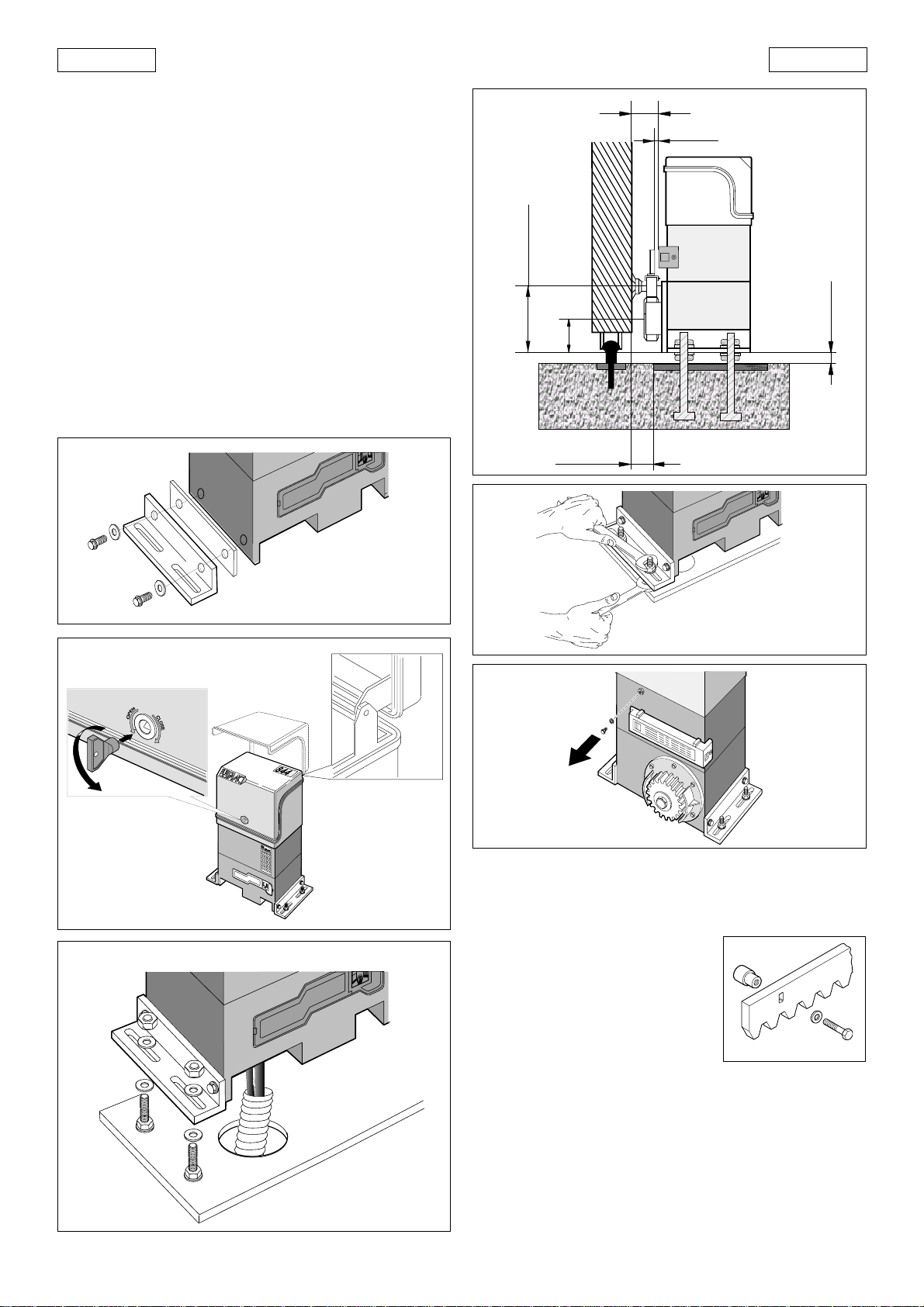

5.6. POSITIONING THE TRAVEL STOP PLATE

The 844 MC-R operator is fitted with an inductive proximity limit

switch (Fig.1 - ref.3). When the latter detects the passage of a

plate fastened to the top of the rack, it stops the movement of

the gate.

To position the two travel stop plates correctly, proceed as

follows:

1) Connect the limit switch connector to the 844MPSR con-

trol unit in accordance with the direction of gate closure

(paragraph 5.2.3. and Figs. 24/25).

2) Assemble the limit switch, positioning the stop plate cen-

trallyrelative to thethreaded studs of thebracket (Fig.31).

3) Switch on the power supply.

4) Move the gate by hand towards it closed position, stop-

ping approximately 2 cm from the physical stop of the

gate.

5) Set brake-adjusting trimmer TR1 approximately to its cen-

tral position (Fig. 19 - ref. TR1).

6) Slide the travel stop plate on the rack in the opening

direction. When the LED of the opening travel limit switch

(FCA)in the 844MPSR electronic control unit(Fig. 28) goes

out, advance the travel stop plate by approximately 45

mm, and fix it to the rack by tightening the screws.

7) Move the gate by hand towards its closed position, stop-

ping approximately 2 cm from the physical stop of the

gate.

8) Slide the travel stop plate on the rack in the closing direc-

tion. When the LED of the closing travel end limit switch

(FCC) in the 844 MPSR electronic control unit goes out

(Fig.28), advance the travel stop plate by approximately

45 mm, and fix it to the rack by tightening the screws.

9) Re-lock the system (see paragraph 5).

10) Run a complete cycle of the gate, to check whether the

limit switch trips correctly. To adjust the limit switch posi-

tions, operate brake trimmer TR1: when the trimmer is

rotated clockwise, the braking space is decreased; when

thetrimmerisrotatedcounterclockwise,thebrakingspace

is increased.

Notes on positioning the travel stop plates

• The distance between the limit switch and the travel stop

plate must be < 5mm (Fig.11).

• To avoid damaging the operator and/or interruptions to

service,leaveadistanceofatleast2cmfromthephysical

stops of the gate.

Fig. 31