Page | 6

EP104 – First Steps

Step 1

First navigate to C999 and change the value to “0” (this allows display of all registers).

Ensure that Photo/Safe/Stop/24V are all illuminated Green. To check motor rotation and encoders, we first put the

EP104 into Service Mode. In this mode only the internal Open/Stop/Close buttons are functional. It should come

default in this mode.

Set C033 = 5

Step 2 – Main Power Settings

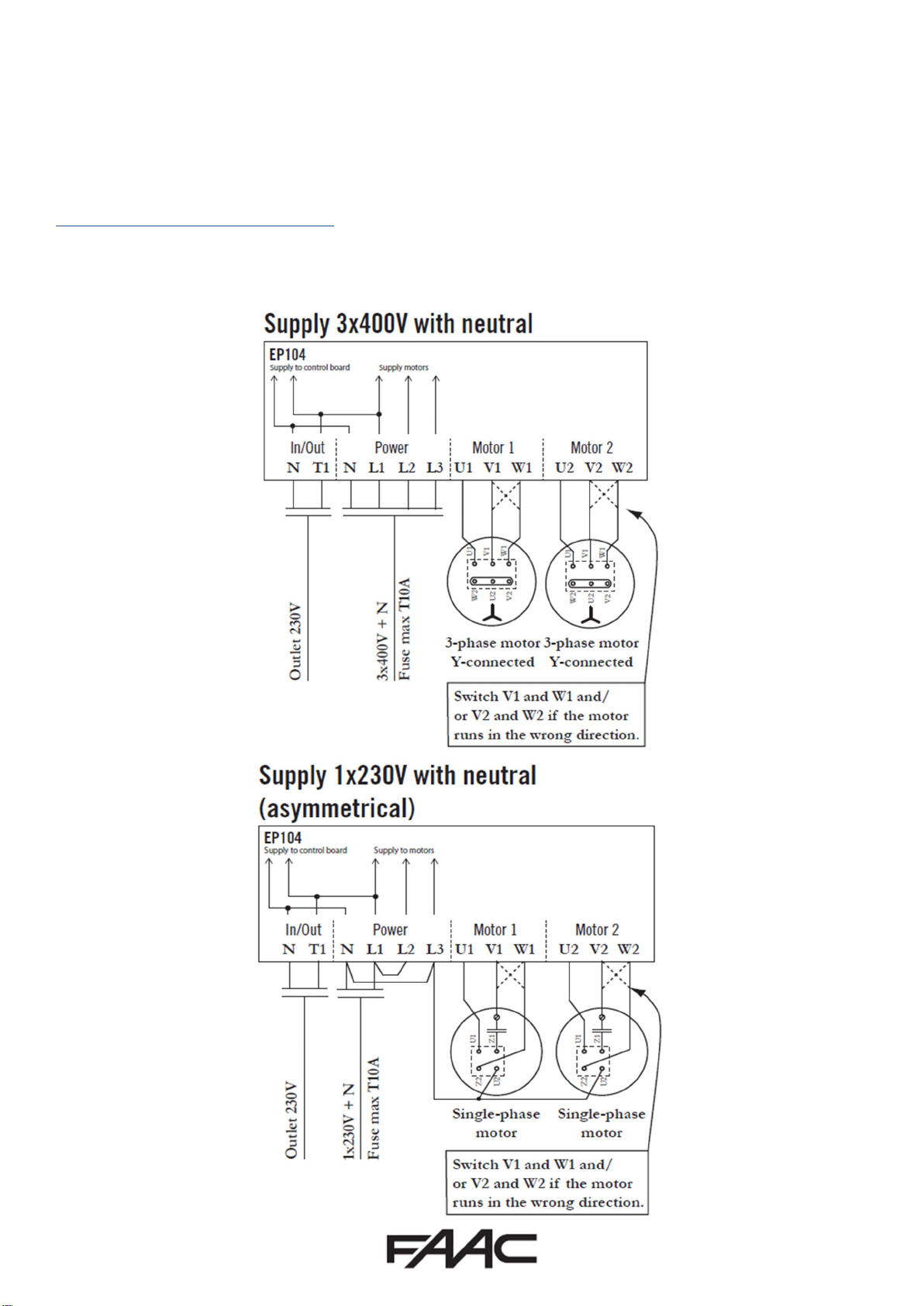

Set Power type in C202 to “0” for 3-Phase 400V with Neutral, or “2” for Single Phase with Neutral (Asymmetric).

Step 3 – Checking Motor Direction

To test the operation of the motor as we are in Service Mode, set L001 = 4 and set L002 = 0, this will allow

movement of only Motor 1. If you are using an EP104-1, please disregard L002.

At this point you should be able to use the Dead-Man Controls on the board itself (The three buttons below the

display, 1st Black is the Open, 2nd Black is Close) to move the gate in the desired direction. If the gate moves in the

opposite direction to the button being pressed, you need to switch the motor polarity as shown in the Power and

Motor Connections section above or double check L110 = 1 (Motor 1 on the left as viewed from inside) or 2 (Motor 1

on the right as viewed from inside). If you are using an EP104-2, repeat the process but set L001 = 0 and set L002 = 4

and perform the same test but now double check L120 = 1 (Motor 2 on the left as viewed from inside) or 2 (Motor 2

on the right as viewed from inside). Please only press the button for a second or so to check movement as otherwise

it is most likely that an Error will be generated, as have not yet set the power readings.

If it does not move, something is not wired correctly, check incoming voltage, motor connections first.

Step 4 – Motor Power and Encoder Settings

We can now adjust the power and encoder settings of the EP104. If you have a Single Leaf system, please skip to

(14). At this stage, the gates can be in any position, ideally halfway to start and engaged to the operator.

1. Set L001 = 0 and L002 = 4

2. Set C240 = 0.0

3. C241 (Motor Power Readout), it should say 0.00 with the gate stopped. Press and hold the Open Button on

the board and make a note of the value when the gate is moving and then press the Close Button on the

board and make a note of the value when gate is moving

4. Set C242 = average value recorded from C241 when opening plus 0.3

5. Set C243 = average value recorded from C241 when closing plus 0.3

6. C261 (Motor Current Readout), it should say 0.00 with the gate stopped. Press and hold the Open Button on

the board and make a note of the value when the gate is moving and then press the Close Button on the

board and make a note of the value when gate is moving

7. Set C262 = average value recorded from C261 when opening

8. Set C263 = average value recorded from C261 when closing

9. Set L002 = 1

10. Check L120 is set to either “1” if Motor 2 is on the Left or “2” if on the right (viewed from motor side)

11. L121 (Position Readout Motor 2). Press and hold the Open Button on the board until the gate is fully open

and make a note of the value. Now press the Close Button on the board and make a note of the value

12. Set L122 = value recorded from L121 when fully open

13. Set L123 = value recorded from L121 when fully closed

14. Set L002 = 0 and L001 = 4

15. Set C230 = 0.0