6

Installation Instructions

Note: The following installation instructions

assume you are fully capable of installing a gate

operator. This manual does not instruct you in

designing a gate, installing a gate, or basic

electrical wiring. The installation tasks

discussed in this manual are tasks particular to

the 885 Operator.

Before you install the 885 Operator, make sure that the

gate rolls smoothly, without binding throughout it’s

entire travel. Lubricate, adjust, or replace any gate parts

or rollers to achieve this.

WARNING! A gate that does not roll smooth

at start up or anywhere in it’s travel is a

potential safety hazard. The entrapment

protection feature of the 885 can only work

properly if the pulling force needed to move the

gate is consistent throughout the entire travel.

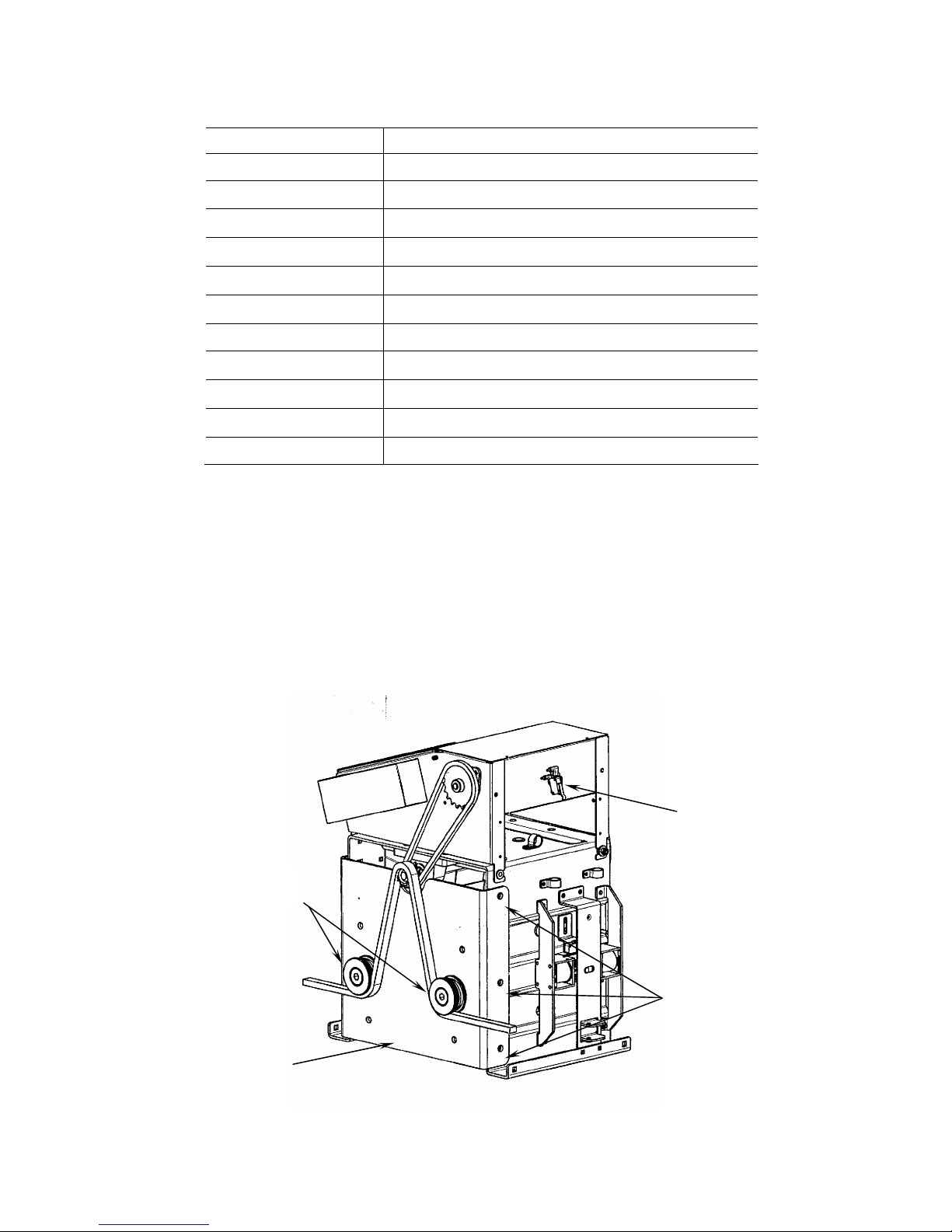

Mounting the Operator

Before the 885 Operator can be mounted, you must have

a footing that is at least 16” x 24” and at least 18” deep.

If you are in an area with a frost line to consider, be sure

that you get below it. Figure 2 shows an example of a

footing that is flush with the edge of the driveway. The

footing could be placed further away from the driveway

if necessary for your installation.

Before pouring the footing, you must terminate the

electrical conduit for main power and any accessories in

the proper location. Figure 2 shows an area (within the

dashed line, inside the operator) where the conduit can

be stubbed up. If you are able to be more precise, the

shaded areas show the ideal locations for high voltage

(main power) and low voltage (accessory devices)

conduit.

Once the footing has been poured, and had a reasonable

amount of time to set up, the operator can be set in place.

Adjust the operator so that it sits the right distance from

the gate, considering the chain mounting brackets that

will be used. The center of the main sprocket and idlers

of the operator should be in line with the chain mounting

holes (or slots) of the chain mounting brackets. As

shown in figure 2, if you are using the brackets provided

by FAAC, this will place the center of the drive gears

anywhere from 1 ¼” to 2 ½” from the face of the gate.

Once the operator is in place, mark the concrete through

the mounting holes of the operator. Remove the operator

and use a ½” masonry bit to drill holes the appropriate

depth for your concrete anchors. Use ½” concrete

anchors that are at least 3” long. Once the holes are

drilled and blown out, pound the anchors in to place.

Set the operator back in place and adjust the distance

from the center of the sprocket to the gate face, if

necessary. Install the nuts and washers on to the anchors

and tighten.

Attach the Chain

CAUTION! Attach the chain with the gate at

its midpoint (half open). The 885 Operator is

sent to you with the limit adjustments set at the

center position. Failure to attach the chain with

the gate half open can seriously damage the

limit assembly.

If you have a round gate frame (chain link), and plan to

use the chain mounting kit provided with the operator,

attach the “L” shaped plates to the gate as shown in

Figure 2. Use the “U” bolts (muffler clamps) to attach

them so that the slot for mounting the chain is at the

same height as the bottom of the idler sprockets.

If you are using another bracket or have something

prefabricated to the gate, be sure that the hole for the

chain mounting tension bolt is close to the same height

as the bottom of the idler sprockets. If necessary, the

idlers can be mounted in one of three positions to

accommodate a height difference.

Assemble the 10’ chain sections with the master links

that are provided. If necessary, use a chain break to cut

the chain to the appropriate size. Attach the chain

tension bolts to either end of the chain with the master

links. Screw one of the nuts and slide one lock washer

on to each tension bolt before putting it through the hole

(or slot) in the chain-mounting bracket. Screw the

second nut on to the tension bolt after it is installed in the

mounting bracket. Use the second (outer) nut to adjust

the chain tension and then lock down the adjustment with

the inner nut and lock washer.

Mount the chain to the gate on one end; then run it under

the first idler, over the main sprocket, and under the

other idler. See Figure 1. Then mount the chain to the

gate on the other end.

To properly adjust the chain mounting and tension, you

must first roll the gate opened and closed to insure

proper alignment.

WARNING! Moving the gate manually before

making a preliminary limit adjustment, can

seriously damage the limit assembly. Please see

the next section before finalizing your chain

mounting.