27

RX OP/CL

TX OP/CL

SAFE

+

+

OPEN

B

A

OPEN

OP

CL

Fig. 34

Fig. 35

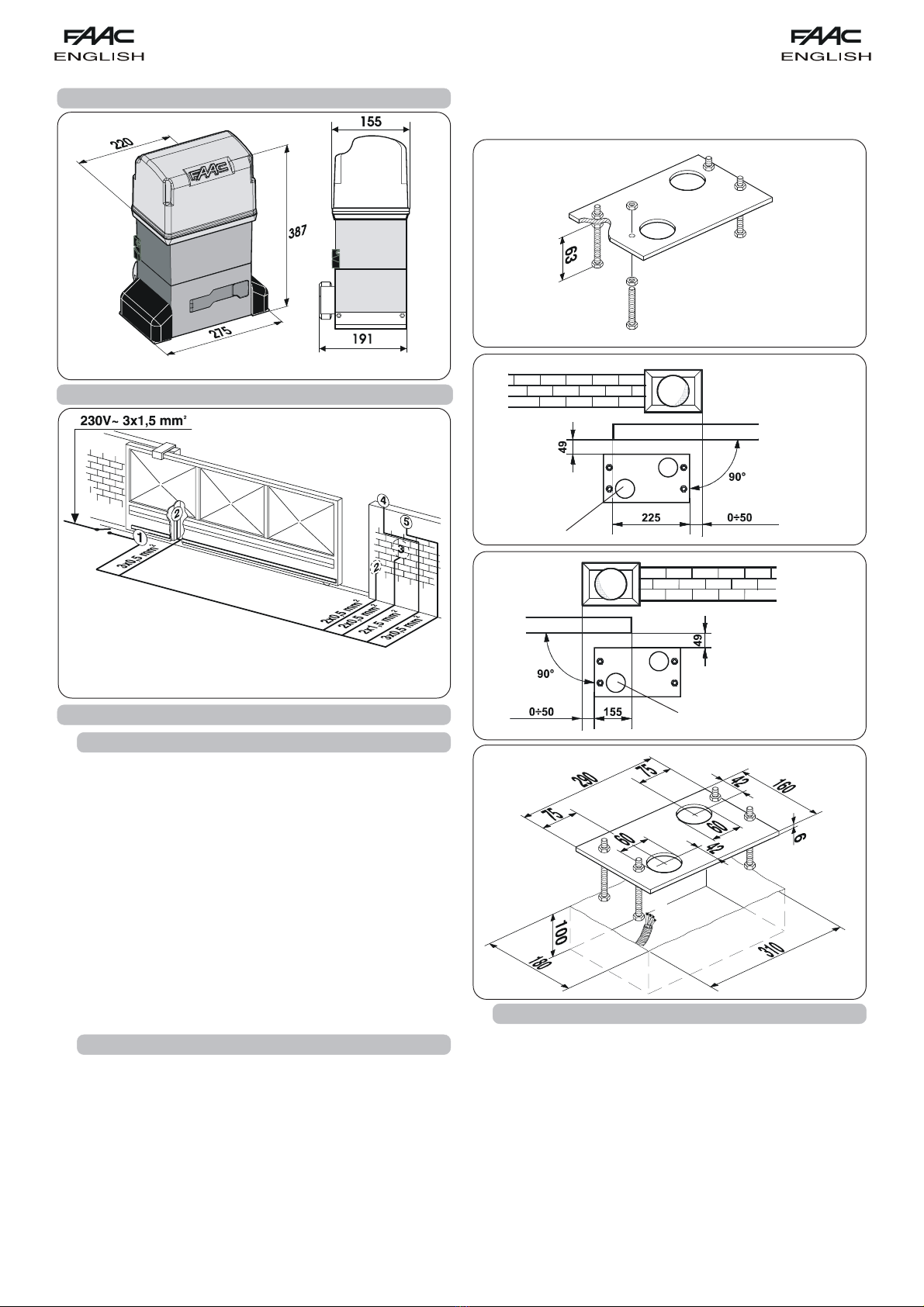

5.4.2. J7 Terminal board - Power supply (fig. 23)

POWER SUPPLY (terminals PE-N-L):

PE: Earth connection

N:Power supply ( Neutral )

L:Power supply ( Line )

NB.: For correct operation, the board must be connected to

the earth conductor in the system. Install an adequate

differential thermal breaker upstream of the system.

To install several partial opening pulse generators,

connect the N.O. contacts in parallel (fig.35).

FSW OP - Opening safety devices contact (terminal 3): The

purpose of the opening safety devices is to protect the

leaf movement area during opening. During opening, in

the A-AP-S-E-EP logics the safety devices reverse the

movementof the gate,or stop and restart the movement

when it is released (see advanced programming in

Chpt. 5.5.2). During the opening cycle in logicsthe B, C

and B/C, they interrupt movement. They never operate

during the closing cycle.

If the Opening safety devices are engaged when the

gate is closed, they prevent the opening movement.

To install several safety devices, connect the N.C.

contacts in series (fig.25).

NB.: If no opening safety devices are connected, jumper

connect inputs FSW OP and -TX FSW (fig. 26).

FSW CL - Closing safety devices contact (terminal 4): The

purpose of the closing safety devices is to protect the

gate movement area during closing. During closing, in

the A-AP-S-E-EP logics, the safety devices reverse the

movement of the gate, or stop and reverse the

movement when it is released (see advanced

programming in Chpt. 5.5.2). During the closing cycle in

logics B, C and B/C, they interrupt movement. They

never operate during the opening cycle. If the Closing

safety devices are engaged when the gate is open,

they prevent the closing movement.

To install several safety devices, connect the N.C.

contacts in series (fig.25).

NB.: If no closing safety devices are connected, jumper

connect terminals FSW CL and -TX FSW

(fig. 26).

STOP - STOP contact (terminal 5): any device (e.g. a push-

button) which, by opening a contact, stops gate

movement.

To install several STOP devices, connect the N.C.

contacts in series (fig. 25).

NB.: If STOP devices are not connected, jumper

connect the STOP and -terminals.

SAFE - EDGE safety device contact (terminal 6): The purpose of

the "edge" safety device is to protect the leaf movement

areaduring opening/closing. In all logics, during opening

and closing, the safety device reverses gate movement

for 2 seconds. If the safety devices operate again during

the 2-seconds reversing time, it stops movement (STOP)

without any reversing.

If the Edge safety device is engaged while the gate is

closed or open, it prevents movement.

To install several safety devices, connect the N.C.

contacts in series (fig.25).

NB.: If edge safety devices are not connected, jumper

connect the SAFE and - inputs (fig. 26).

–

Negative for power supply to accessories (terminals 7

and 8)

+ 24 Vdc - Positive for power supply to accessories

(terminals 9 and 10)

Important: Accessories max. load is 500 mA. To calculate

absorption values, refer to the instructions for individual

accessories.

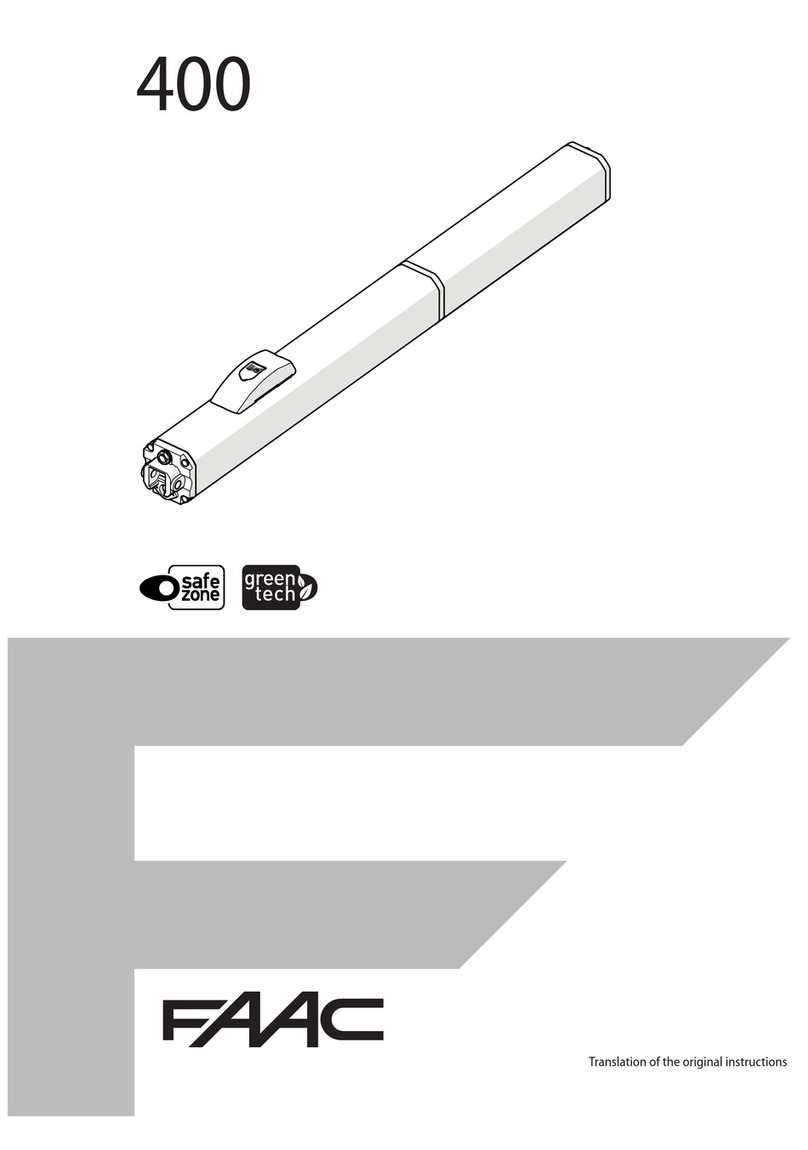

Connection of a pair of closing photocells and a pair of

opening/closing photocells

Connection of two N.O. contacts in parallel

(e.g. Open A, Open B)

5.4.3. J6 Terminal board - Motors and flashing lamp

(fig. 23)

MOTOR - (terminals MOT-C, MOT-1, MOT-2): Motor connection

(see Par. 6.5).

LAMP - (terminals LAMP L, LAMP N): Flashing lamp output 230Vac

max 60W.

5.4.4. J1 Terminal board - Accessories (fig. 23)

Consult the relevant tables for a detailed description of

operation in the different logics

OPEN A - “Total Opening” command (terminal 1): any pulse

generator (push-button, detector, etc.) which, by

closing a contact, commands total opening and/or

closing of the gate leaf.

To install several total opening pulse generators,

connect the N.O. contacts in parallel (fig. 35).

OPEN B - “Partial opening” or “Closing” command (terminal 2):

any pulse generator (push-button, detector, etc.)

which, by closing a contact, commands partial

opening and/or closing of the gate leaf. In the B, C

and B/C logics, it always commands gate closure.