2

Introduction

Safe-Air Testers are designed to provide a quick and easy method for carrying out accurate periodic

testing of breathing-air supplies. From the touch screen display the appropriate breathing-air standard

can be selected for your test.

The F6001, is designed specifically to test high pressure air breathing air cylinders and high pressure

charging systems up to 300bar.

It is supplied in a hard weatherproof case with storage provision for a wide range of accessories and

equipment.

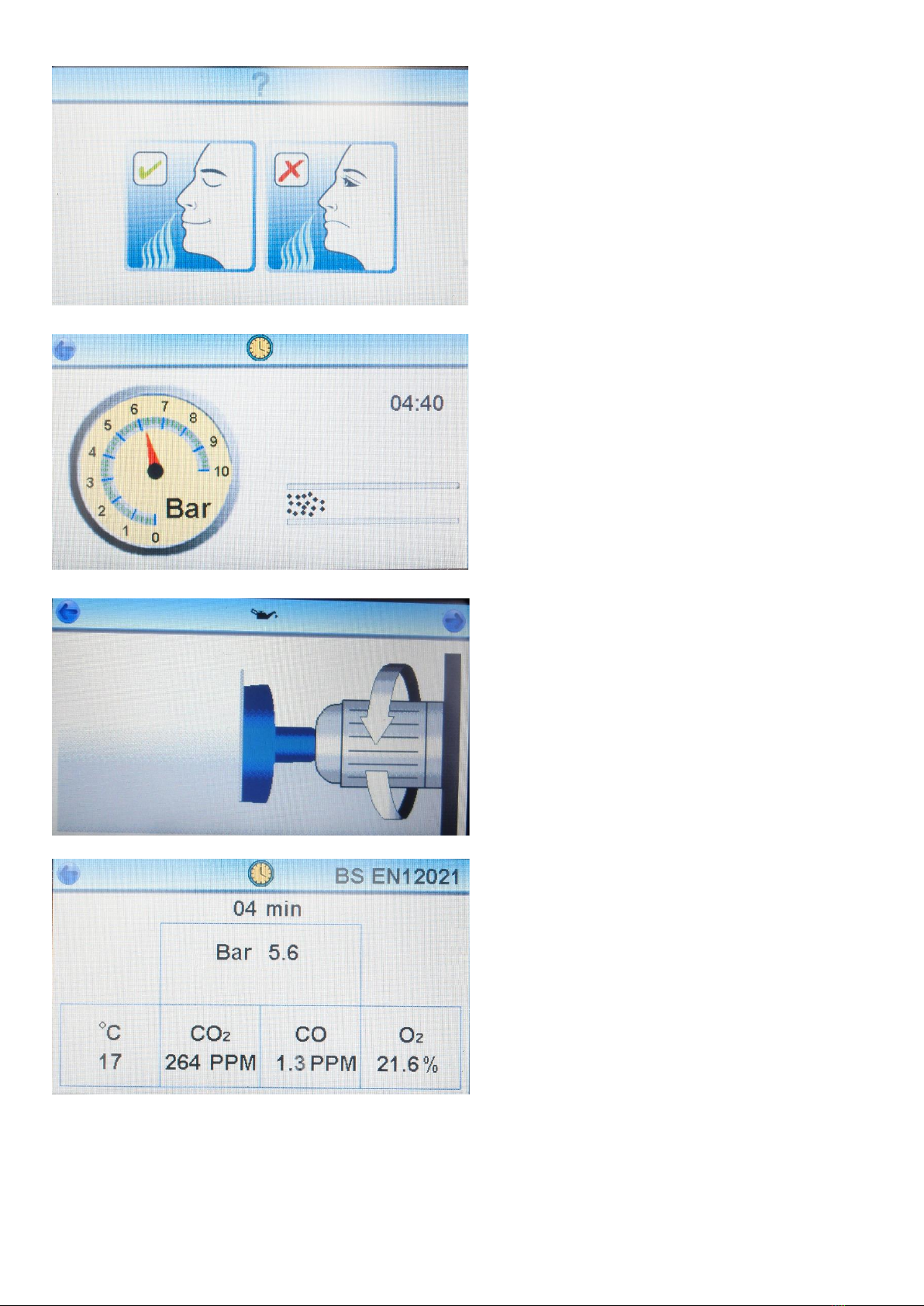

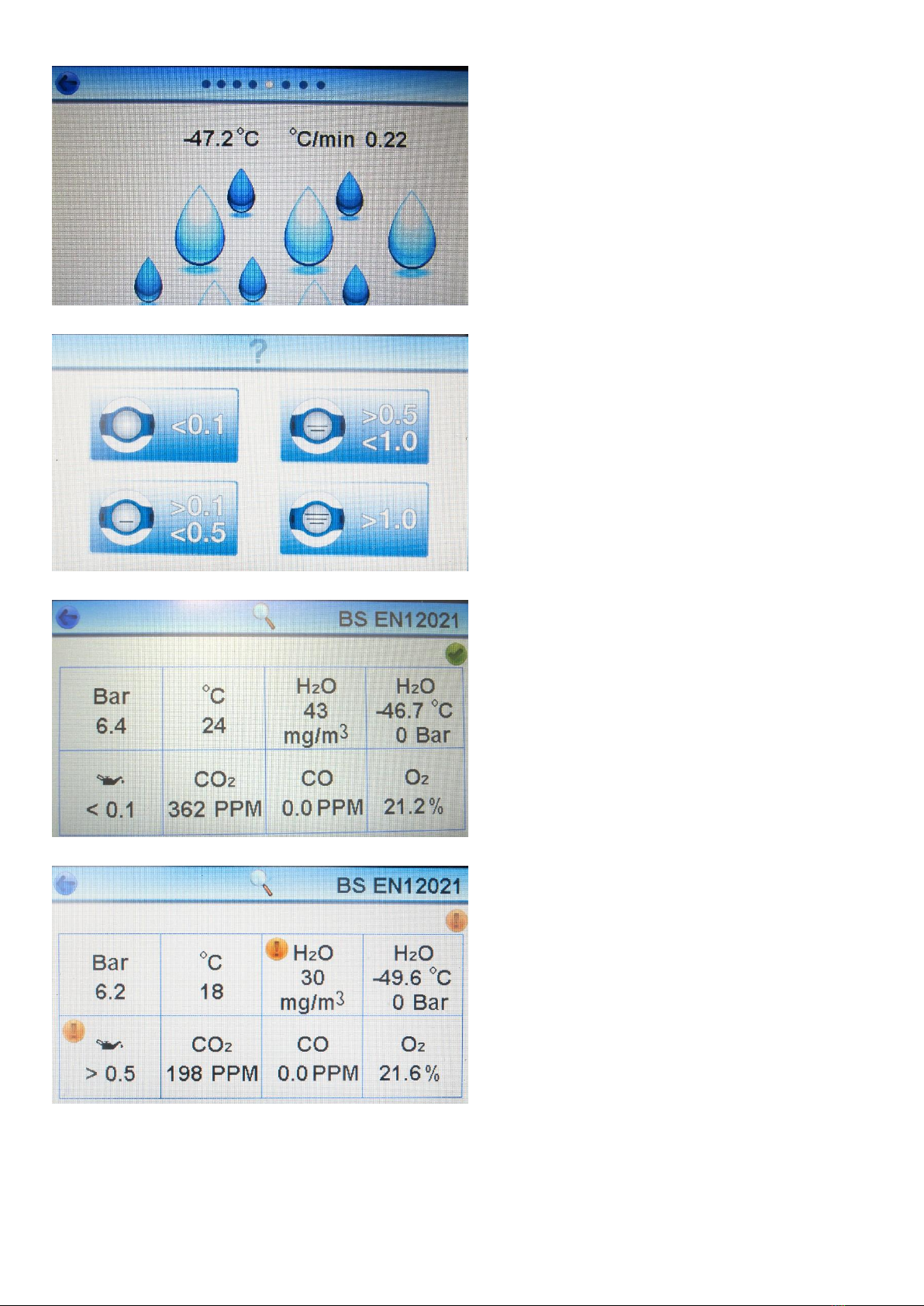

The test is carried out using built in electrochemical cells for carbon monoxide and the oxygen and an

infrared LED sensor for the carbon dioxide. The moisture is measured with an electronic dewpoint

meter and the instrument also records test pressure and ambient temperature. For measuring oil

aerosols Draeger Impactors are connected through a test port and this can also be used for testing a

number of other Draeger chemical reagent tubes detailed below. The Draeger Impactors are supplied

in packs of 10 and show the degree of oil contamination on a screen.

Calibration and Warranty

Safe-Air Testers leave our factory with a 12-month warranty and calibration certificate. Our standard

turnaround on annual calibration is 10-15 working days providing there is no major damage that

requires an extensive rebuild. Note:- Please download all stored data before returning the Tester to

Factair.

Temperature Parameters

Storage: -10/+50°C Operating Range: +5/+35°C

This tester is calibrated for the following approved reagent tubes/Impactor.

The tester can also be used with the old type Draeger reagent tube for oil, ref.6728371. (Refer to

Appendix 2 at the rear of the manual for instructions.)

IMPORTANT –IT IS RECOMMENDED THAT YOUR SAFE-AIR TESTER IS RETURNED FOR

RECALIBRATION AND SERVICING WITHIN 12 MONTHS FROM THE ISSUE DATE OF ITS CALIBRATION

CERTIFICATE