7

Instrument Setup

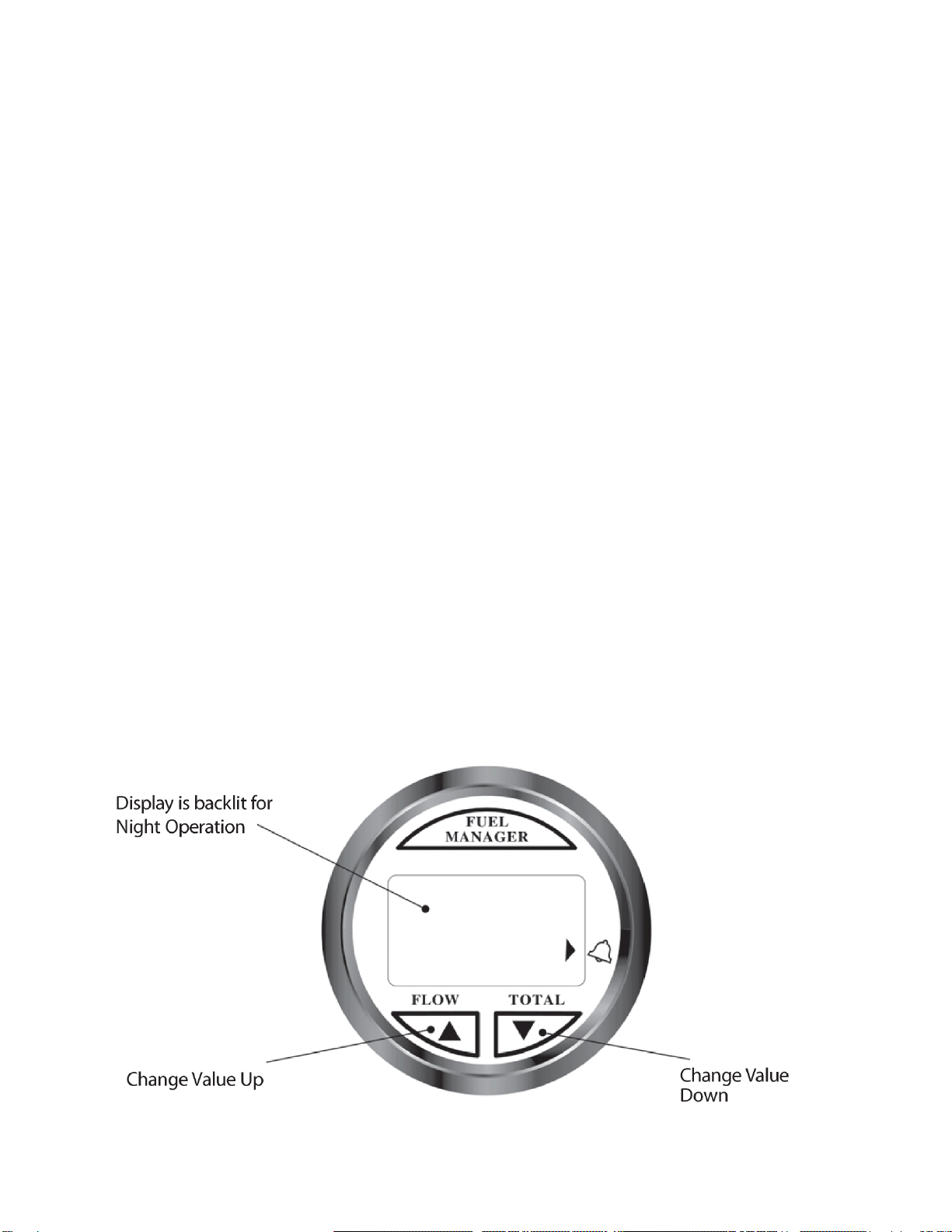

Select units of measure

The Fuel Management fuel flow meter can

display fuel values in US gallons, Liters or

Imperial gallons. To change the current

display setting, perform the following steps.

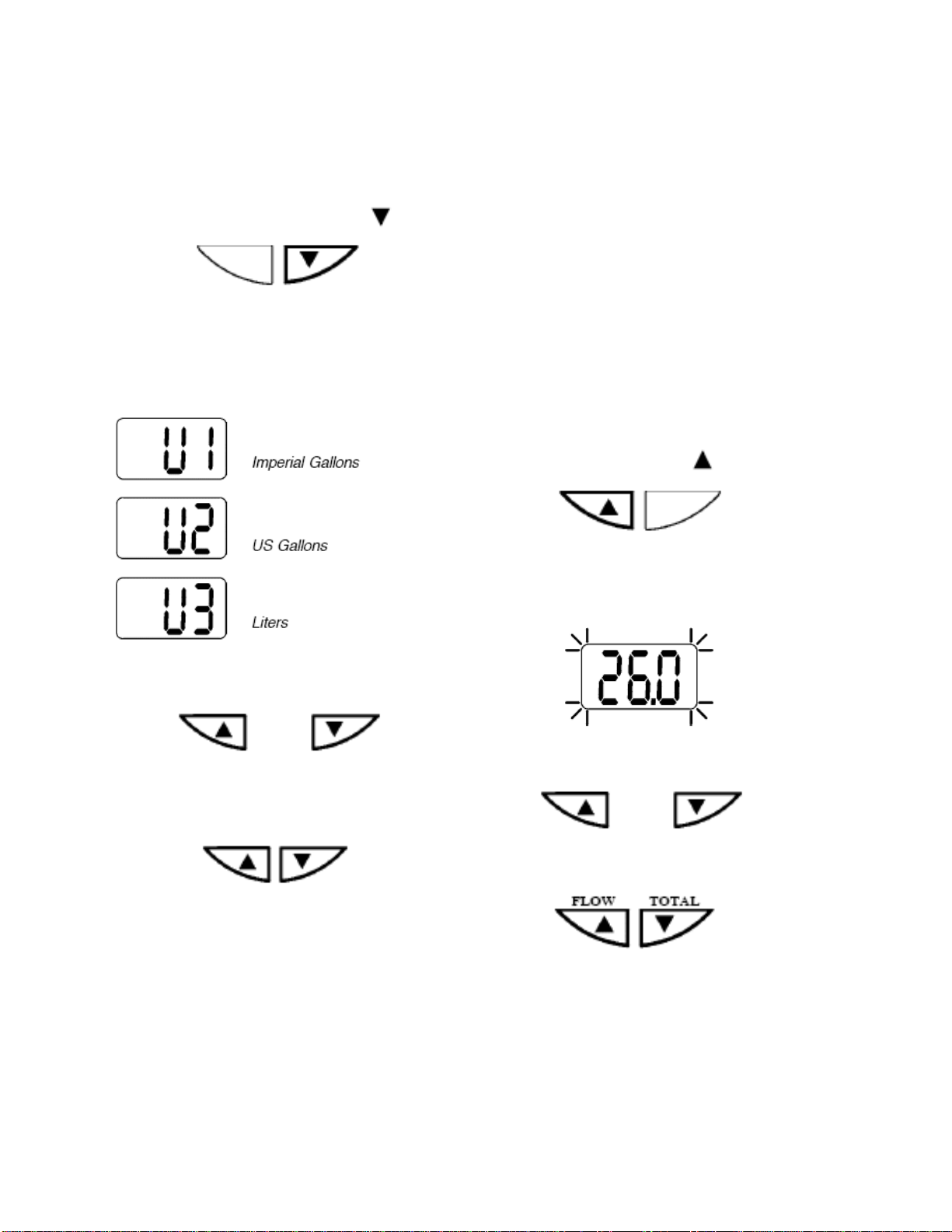

1. Power up the unit while holding key.

Press and hold during power up

2. Once the unit is on, release the key.

The current display setting is indicated as

pictured below:

3. To select another display setting, use the

up or down keys to change the value.

or

4. To save the change and exit this mode,

press and hold both keys simultaneously

for one second.

Press and hold for one second

The fuel values are now displayed using the

new setting.

Calibration

The fuel transducer supplied with the fuel

flow meter will provide readings at better

than 5% accuracy. Individual calibration

will increase this level of accuracy to better

than 2% over a fuel flow range of 2 to 32 US

gallons per hour.

While a properly calibrated unit should

provide accuracy within the published limits,

the user should also have a level sender o

fuel level gauge installed in the boat. This is

necessary due to possible operator induced

errors such as forgetting to reset the fuel

used when filling the tank, or other operato

controlled actions that may render the device

inaccurate. Perform the following steps to

calibrate your fuel flow meter:

1. Reset the total log value to zero(see pg 9)

2. Use a known amount of fuel. The larger

the amount the more accurate the

calibration will be.

3. Take note of the actual volume of fuel

used and the fuel used indicated by the

total log. If these two totals are different,

the instrument may require calibration.

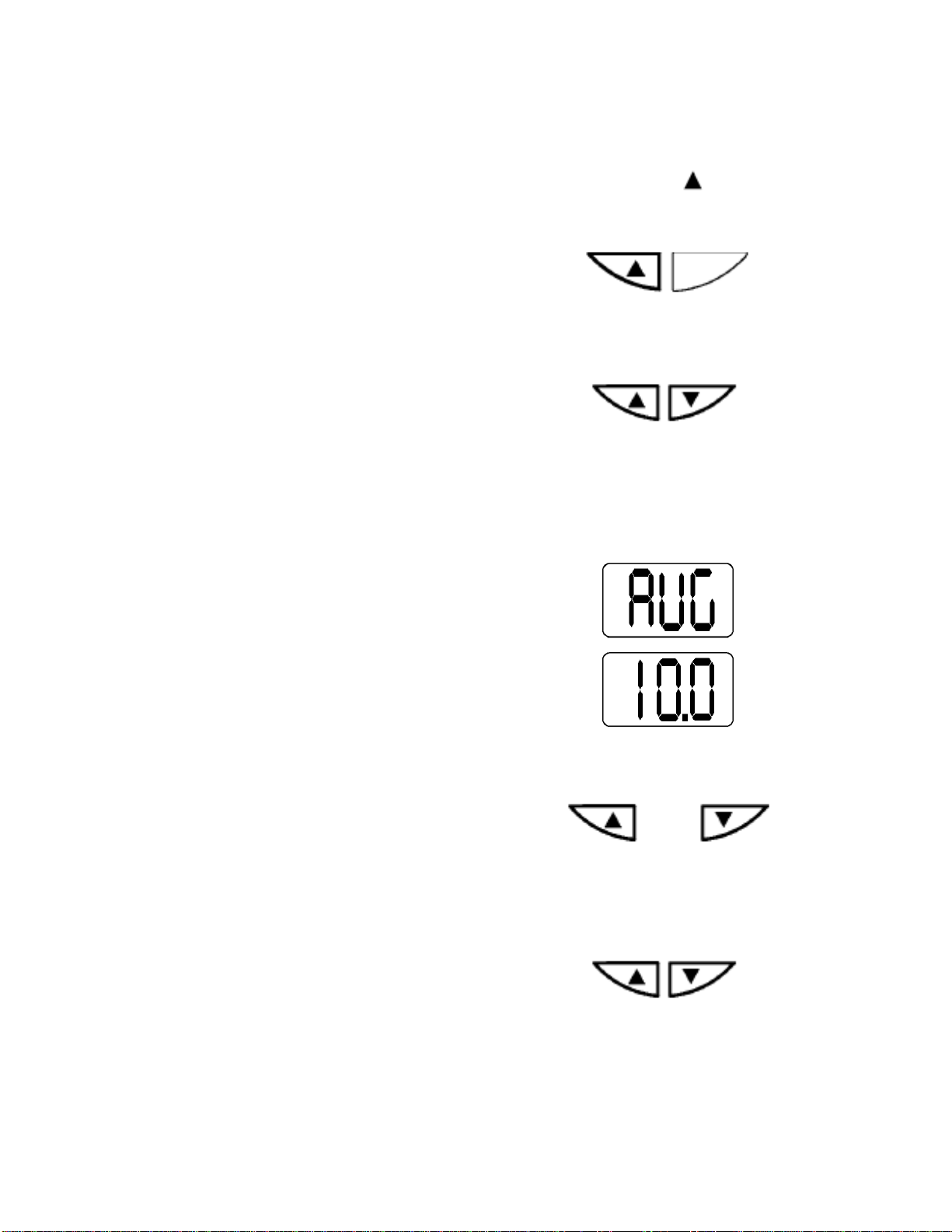

4. Apply power while holding key.

Press and hold while applying power

5. Release the key. The display flashes the

current total log value.

6. Use the up or down key to change the

display and indicate the actual volume of

fuel used.

or

7. Press both keys simultaneously and hold

for 2 seconds to exit.

Press and hold for 2 seconds

The fuel flow meter is now calibrated.

AVG (which shows as AUG) is displayed.

To skip this function and return to normal

mode, hold both keys simultaneously fo

another 2 seconds