Fast DP9D User manual

DP9D / DP13D / DP14D - 40' / 60'

OWNERS MANUAL DRY DURAPLACER

OWNERS MANUAL – 2023

Dry DuraPlacer DP9D / DP13D / DP14D Page i

Table of Contents

Section

Page

Table of Contents.................................................................................................................................................... i

Warranty Registraon.......................................................................................................................................... vii

Warranty Inspecon Report .................................................................................................................................... vii

Inspecons ........................................................................................................................................................... ix

Pre-Delivery .............................................................................................................................................................. ix

Delivery ..................................................................................................................................................................... x

Aer-Sale.................................................................................................................................................................. xi

Owner Register .................................................................................................................................................... xii

Foreword to the Owner ...................................................................................................................................... xiii

INTRODUCTION ..................................................................................................................................................... 1

SAFETY................................................................................................................................................................... 2

Safety Alert Symbols and Signal Words .....................................................................................................................2

General Safety ...........................................................................................................................................................3

Prepare for Emergencies.......................................................................................................................................3

Wear Protecve Clothing ......................................................................................................................................3

Protect Against Noise............................................................................................................................................3

Pracce Safe Maintenance....................................................................................................................................3

Support Raised Equipment ...................................................................................................................................4

Avoid Heang Near Pressurized Fluid Lines ..........................................................................................................4

Avoid High-Pressure Fluids....................................................................................................................................4

Inspect Li Circuit Hoses.......................................................................................................................................5

Store Aachments Safely ......................................................................................................................................5

Electrical................................................................................................................................................................5

Service Tires Safely................................................................................................................................................5

Dispose of Waste Properly ....................................................................................................................................6

Handle Agricultural Chemicals Safely....................................................................................................................6

Reduce risk of exposure and injury:......................................................................................................................6

Handle Chemical Products Safely..........................................................................................................................7

Operate Hydraulics Safely .....................................................................................................................................7

Use Safety Lights and Devices ...............................................................................................................................8

Keep Riders O Machine.......................................................................................................................................8

Observe Maximum Transport Speed ....................................................................................................................8

EC Compliance Nocaon...................................................................................................................................9

Use a Signal Person ...............................................................................................................................................9

Use a Safety Chain.................................................................................................................................................9

Tow Loads Safely ...................................................................................................................................................9

Dry DuraPlacer DP9D / DP13D / DP14D Page ii

Avoid Overhead Power Lines ..............................................................................................................................10

Prepare for Transport..........................................................................................................................................10

Transport Safely ..................................................................................................................................................11

Park Safely...........................................................................................................................................................11

Replace Safety Signs................................................................................................................................................12

Hitch....................................................................................................................................................................12

Wing....................................................................................................................................................................13

Main Frame.........................................................................................................................................................14

Wheel and Tracks ................................................................................................................................................14

Safety Features........................................................................................................................................................15

Sign-O Form ..........................................................................................................................................................16

SPECIFICATIONS ................................................................................................................................................... 17

Tractor Power, Size Recommendaon .....................................................................................................................17

Hydraulic System Requirements ..............................................................................................................................17

Machine Dimensions & Specicaons.....................................................................................................................18

PREPARING THE MACHINE ................................................................................................................................... 19

Use the Tractor Operator’s Manual.........................................................................................................................19

Pre-Operaon Checklist...........................................................................................................................................19

AXLES, TIRES, and TRACKS ................................................................................................................................... 20

Seng Axle Width...................................................................................................................................................20

Axle Width Chart – Singles ..................................................................................................................................21

Axle Width Chart – Tracks ...................................................................................................................................22

Checking Tire Pressure ............................................................................................................................................23

Checking Wheel Nuts ..............................................................................................................................................23

Track Use .................................................................................................................................................................24

General Guidelines..............................................................................................................................................24

Maximizing Track Life ..........................................................................................................................................24

Track System Break-In .........................................................................................................................................25

Track Wear & Trash Buildup ....................................................................................................................................26

Undercarriage Inspecon and Maintenance...........................................................................................................26

Track Service............................................................................................................................................................27

Mid-Wheel, Wedges, Idler, and Mid-Roller Cap Screws......................................................................................27

Check Track Alignment........................................................................................................................................28

Track Alignment Procedure.................................................................................................................................29

ATTACHING and DETACHING ................................................................................................................................ 30

Aach the Machine Safely.......................................................................................................................................30

Aach the Machine to the Tractor ..........................................................................................................................30

Aach Safety Chain to Tractor.................................................................................................................................31

Dry DuraPlacer DP9D / DP13D / DP14D Page iii

Aach Warning Light Plug.......................................................................................................................................31

Connect Rate Controller or Nutrient Applicator System Wiring ..............................................................................31

Make Proper Hose Connecons...............................................................................................................................32

SCV Idencaon Chart...........................................................................................................................................33

Detach Machine from Tractor .................................................................................................................................34

Adjust Hitch Height..................................................................................................................................................34

TRANSPORTING ................................................................................................................................................... 35

Following Safe Transport Procedures ......................................................................................................................35

Preparing the Machine for Transport......................................................................................................................35

Fold Toolbar for Transport...................................................................................................................................35

Transport Notes and Checks ...............................................................................................................................36

Transporng the Machine .......................................................................................................................................36

Using Warning Lights ..........................................................................................................................................36

Keep Riders O the Machine ..............................................................................................................................36

Cauon for All Machines .........................................................................................................................................37

Unfolding/Extending the Toolbar ............................................................................................................................37

HYDRAULIC FLOW ................................................................................................................................................ 39

Regulang Hydraulic Flow to the Pump ..................................................................................................................39

Load Sensing Closed Center System (LS Closed) .................................................................................................39

Pressure Compensang Closed-Center System (PC Closed) ...............................................................................39

Open Center System (Open) ...............................................................................................................................40

Tractor SCV Funcons..............................................................................................................................................40

Down Pressure (Kick) Orice Adjustment ................................................................................................................42

ADJUST DEPTH CONTROL..................................................................................................................................... 43

Adjust Applicaon Depth.........................................................................................................................................43

Adjust Gauge Wheels ..............................................................................................................................................43

Adjust Row Unit Height ...........................................................................................................................................43

ADJUST GROUND SPEED ...................................................................................................................................... 44

PREPARING THE HOPPER SYSTEM ........................................................................................................................ 45

Manufacturer-specic Documentaon ...................................................................................................................45

Prepare the Tank .....................................................................................................................................................45

FILLING THE HOPPER TANK (BIN) ......................................................................................................................... 46

Filling the Tank ........................................................................................................................................................46

Air Pressure Adjustment ..........................................................................................................................................47

LUBRICATION and MAINTENANCE ....................................................................................................................... 48

Dry DuraPlacer DP9D / DP13D / DP14D Page iv

Lubricang and Maintaining the Machine Safely ...................................................................................................48

Lubricant Storage ....................................................................................................................................................48

Grease .....................................................................................................................................................................48

Greases for Air Temperature Ranges...................................................................................................................48

Alternave and Synthec Lubricants ..................................................................................................................48

Lubricaon and Maintenance Intervals...................................................................................................................49

Each 10 hours or Daily.........................................................................................................................................49

Each 50 Hours or Weekly ....................................................................................................................................50

Before and Aer Each Season .............................................................................................................................50

As Required .........................................................................................................................................................50

SERVICE ............................................................................................................................................................... 51

Pracce Safe Maintenance......................................................................................................................................51

Work in a Clean Area...............................................................................................................................................51

Service Machines Safely ..........................................................................................................................................51

Support the Machine Properly ................................................................................................................................52

Avoid High-Pressure Fluids ......................................................................................................................................52

Prevenng Hydraulic System Contaminaon ..........................................................................................................52

Replace Hydraulic Hoses .........................................................................................................................................53

Tightening Hardware ..............................................................................................................................................53

PREPARING FOR STORAGE ................................................................................................................................... 54

Removing from Storage...........................................................................................................................................54

TIGHTENING HARDWARE ..................................................................................................................................... 55

Metric Bolt and Screw Torque Values ......................................................................................................................55

Unied Inch Bolt and Screw Torque Values .............................................................................................................56

Face Seal Fings Assembly & Installaon - All Pressure Applicaons ....................................................................57

Face Seal O-Ring to Stud End Installaon ...........................................................................................................57

Face Seal Adjustable Stud End O-Ring Installaon..............................................................................................57

Face Seal Straight Stud End O-Ring Installaon ..................................................................................................57

Fing Installaon ...............................................................................................................................................57

Assembly Torque.................................................................................................................................................57

SAE Face Seal and O-Ring Stud End Fing Torque Chart ........................................................................................58

Dry DuraPlacer DP9D / DP13D / DP14D Page vi

Limited Warranty

Fast Ag Solutions warrants to the buyer that the new machinery is free from defects in material

and workmanship.

This warranty is only effective as to any new machinery which has not been altered, changed,

repaired or treated since its delivery to the buyer, other than by Fast Ag Solutions or its authorized

dealers or employees, and does not apply to accessories, attachments, tools or parts, sold or

operated with the new machinery, if they have not been manufactured by Fast Ag Solutions.

Fast Ag Solutions shall only be liable for defects in the materials or workmanship attributable to

faulty material or bad workmanship that can be proved by the buyer, and specifically excludes

liability for repairs arising as a result of normal wear and tear of the new machinery or in any other

manner whatsoever, and without limiting the generality of the foregoing, excludes application or

installation of parts not completed in accordance with this Operator’s Manual, specifications, or

printed instructions.

Written notice shall be given by registered mail, to the Manufacturer within seven (7) days after

the defect shall have become apparent or the repairs shall have become necessary, addressed

as follows:

Fast Ag Solutions

4130 Commerce Boulevard

Windom, MN 56101

This warranty shall expire one (1) year after the date of delivery of the new machinery.

If these conditions are fulfilled, Fast Ag Solutions shall at its own cost and at its own option either

repair or replace any defective parts provided that the buyer shall be responsible for all expenses

incurred as a result of repairs, labor, parts, transportation or any other work, unless Fast Ag

Solutions has authorized such expenses in advance.

The warranty shall not extend to any repairs, changes, alterations, or replacements made to the

new equipment other than by Fast Ag Solutions or its authorized dealers or employees.

This warranty extends only to the original owner of the new equipment.

Rubber parts (including tires, hoses, grommets) are not warrantied.

This warranty is limited to the terms stated herein and is in lieu of any other warranties whether

express or implied, and without limiting the generality of the foregoing, excluded all warranties,

express or implied or conditions whether statutory or otherwise as to quality and fitness for any

purpose of the new equipment. The Manufacturer disclaims all liability for incidental or

consequential damages.

This Dry DuraPlacer is subject to design changes and Fast Ag Solutions shall not be required to

retrofit or exchange items on previously sold units except at its own option.

Warranty void if not registered.

Dry DuraPlacer DP9D / DP13D / DP14D Page vii

FAST

DRY DURAPLACER

Warranty Registration

This form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery.

Customer Name

Address

City

State

Zip

Phone

Dealer Name

Address

City

State

Zip

DuraPlacer Model

Serial Number

Delivery Date

Warranty Inspection Report

DEALER INSPECTION REPORT

SAFETY

____All Fasteners Tight

____ Safety Chain Installed

____Wheel Bolts Torqued

____ All Guards Installed

____Hydraulic Hoses and Fittings Free and Tight

____ All Safety Signs Installed

____Fertilizer Hoses and Fittings Free and Tight

____ Reflectors, SMV, and Lights Clean

____Wheel Drive Turns Freely

____ Review Operating and

____Lubricate Machine

____ Safety Instructions

____Check Tire Pressure

____Frame and Wings Level

____Monitors and Controllers Function

____Wiring Harness Connected

I have thoroughly instructed the buyer on the above-described equipment which review included the Operator’s Manual

content, equipment care, adjustments, safe operation, and applicable warranty policy.

Date_____________________

Dealer’s Rep. Signature___________________________________________________

The above equipment and Operator’s Manual have been received by me, and I have been thoroughly instructed as to

care, adjustments, safe operation, and applicable warranty policy.

Date_____________________

Owner’s Signature________________________________________________________

White - FAST

Yellow - Dealer

Pink – Customer

Dry DuraPlacer DP9D / DP13D / DP14D Page viii

FAST DP9D / DP13D / DP14D Series DuraPlacer

DURAPLACER SERIAL NUMBER _______________________________

DATE PURCHASED ______________/_____/__________

BIN MANUFACTURER (CIRCLE ONE) MONTAG LYNX

NUMBER OF ROW UNITS ___________________________________

TONNAGE (CIRCLE ONE)

9T Single Bin

13T Dual Bin

14T Single Bin

Dry DuraPlacer DP9D / DP13D / DP14D Page ix

Inspections

Pre-Delivery

After the machine has been completely assembled, inspect it to be sure it is in good running order

before delivering it to the customer. Ensure each item is found satisfactory or proper adjustment

to the item(s) is made.

The following checklist is a reminder of points to inspect. It is neither an exclusive nor an

exhaustive list of points to inspect. See the Warranty Inspection Report for a formal list.

oSMV emblem is installed, protective shipping tape is removed from reflectors, and lights

are installed.

oAll grease fittings are lubricated (see LUBRICATION and MAINTENANCE section in this

Manual.)

oInspect to be sure all nuts are tightened to proper torque and all cotter pins are spread.

oThe tires are properly inflated (see SPECIFICATIONS).

oWheel bolts are tightened to their specified torque(s).

oFertilizer row units are properly adjusted.

oWarning lights are properly installed and operational.

oAll customer-ordered attachments are installed or are available for delivery.

oAny parts scratched in shipment are touched up with paint.

oAll shipping decals are removed.

oTransport pins are inserted in the transport holes.

This machine has been thoroughly checked and to the best of my knowledge is ready for delivery

to the customer.

Signed: _________________________

Date: _________________________

Dry DuraPlacer DP9D / DP13D / DP14D Page x

Delivery

The following checklist is a reminder of information which should be conveyed directly to the

customer at the time the machine is delivered.

Check off each item as it is fully relayed to the customer.

oTell the customer to use proper tools.

oExplain to the customer that the life expectancy of this or any other machine depends on

regular lubrication as directed in Operator's Manual.

oMake the customer aware of all safety precautions that must be followed while using this

machine.

oWhen the machine is transported on a road or highway at night or during the day,

accessory lights and devices should be used for adequate warning to Operators of other

vehicles. For this matter, tell the customer to check local governmental regulations.

oGive the Operator's Manual to the customer and explain all operating adjustments.

To the best of my knowledge, this machine has been delivered ready for field use, and the

customer has been fully informed as to its proper care and operation.

Signed: _________________________

Date: ________________________

Dry DuraPlacer DP9D / DP13D / DP14D Page xi

After-Sale

The following is a suggested list of items to be checked at a dealer-customer mutually agreeable

time during the first operating season.

oCheck with the customer as to performance of machine. Make certain proper operating

adjustments are understood.

oIf possible, operate the machine to see that it is functioning properly.

oAcquaint the customer with any special attachment which will help do a better job.

oGo over the entire machine for loose or missing hardware.

oCheck for broken or damaged parts.

oAsk the customer if recommended periodic lubrication has been performed.

oReview the Operator's Manual with the customer and stress the importance of proper

lubrication and safety precautions.

Signed: _________________________

Date: _________________________

Dry DuraPlacer DP9D / DP13D / DP14D Page xiii

Foreword to the Owner

READ THIS MANUAL carefully to learn how to operate and service your machine correctly. Failure

to do so could result in personal injury or equipment damage. This Manual and safety signs on

your machine may also be available in other languages.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your machine and should

remain with the machine when you sell it.

MEASUREMENTS in this Manual are given in both metric and customary U.S. unit equivalents.

Use only correct replacement parts and fasteners. Metric and inch fasteners may require a

specific metric or inch wrench.

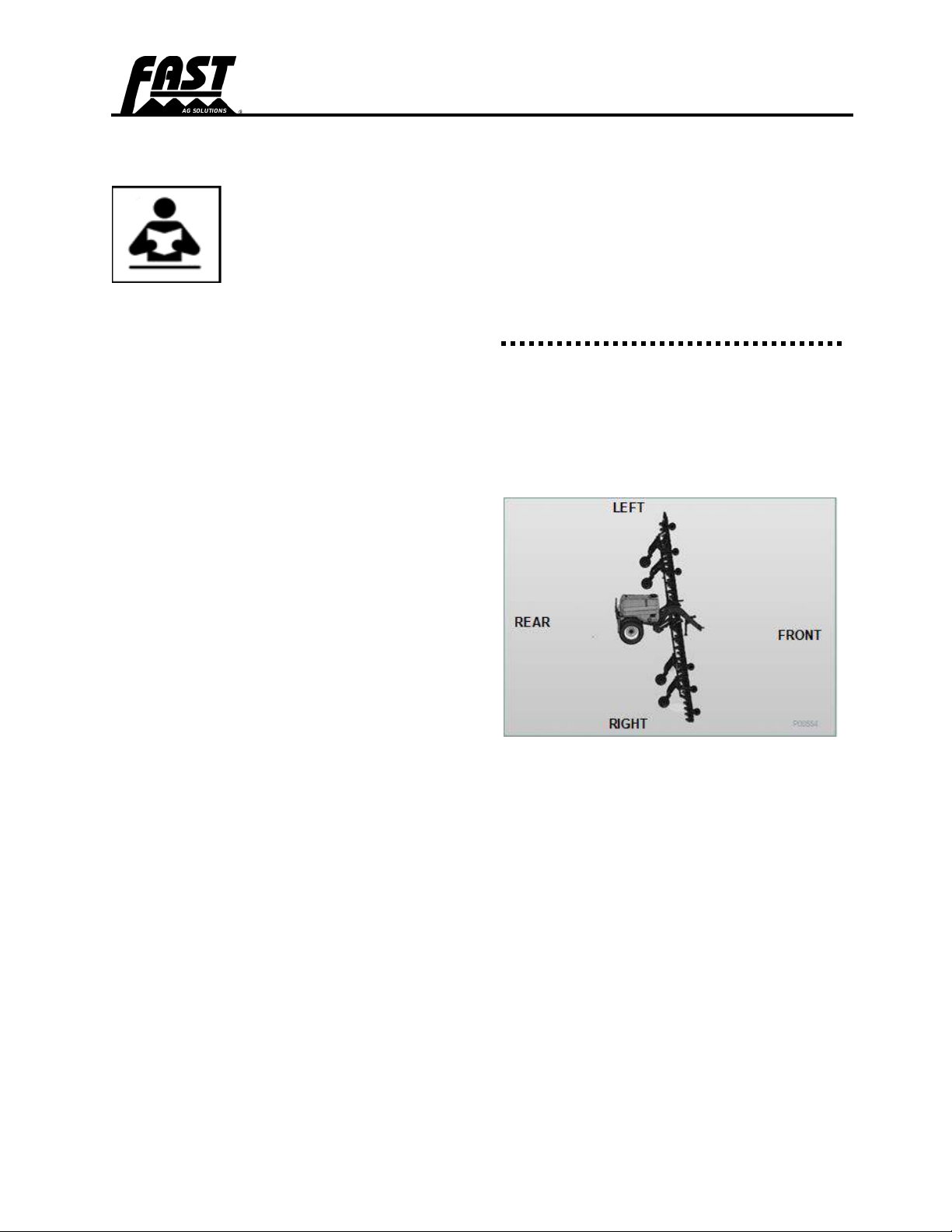

RIGHT-HAND AND LEFT-HAND sides are determined by facing in direction that the implement

will travel when going forward.

WRITE PRODUCT IDENTIFICATION NUMBERS (P.I.N.) in the Specification section and in the

Owner Register. Accurately record all numbers to help in tracing your machine should it be stolen.

Your dealer also needs these numbers when you order parts. File identification numbers in a safe

place off-machine.

BEFORE DELIVERING THIS MACHINE, your dealer performed a pre-delivery inspection.

THIS DRY DURAPLACER IS DESIGNED SOLELY for use in customary agricultural or similar

operations for the purpose of strip freshening row crops (“Intended Use”). Use in any other way

is considered as contrary to the Intended Use. The manufacturer accepts no liability for damage

or injury resulting from this misuse, and these risks must be borne solely by the user. Compliance

with and strict adherence to the conditions of operation, service, and repair as specified by the

manufacturer also constitute essential elements for the Intended Use.

Dry DuraPlacer DP9D / DP13D / DP14D Page xiv

THIS DRY DURAPLACER SHOULD BE OPERATED, serviced, and repaired only by persons

familiar with all its particular characteristics and acquainted with the relevant safety rules (Accident

Prevention). The Accident Prevention regulations, all other generally recognized regulations on

safety and occupational medicine and the road traffic regulations must be observed at all times.

Any arbitrary modifications carried out on this Dry DuraPlacer will relieve the manufacturer of all

liability for any resulting damage or injury.

THIS DOCUMENT outlines the specific design and performance requirements for the use of a

Fast Ag Solutions Dry DuraPlacer assembly. The word “must” in this document indicates a

mandatory requirement. The use of “should” indicates a recommendation of that which is advised

but not required.

WARRANTY is provided as part of Fast Ag Solutions' support program for customers who operate

and maintain their equipment as described in this Manual. The warranty is explained on the

warranty certificate which you should have received from your dealer.

This warranty provides you with assurance that Fast Ag Solutions will back its products where

defects appear within the warranty period. In some circumstances, Fast Ag Solutions also

provides field improvements, often without charge to the customer, even if the product is out of

warranty. Should equipment be abused or modified to change its performance beyond original

factory specifications, the warranty will become void and field improvements may be denied.

TIRE MANUFACTURER'S warranty applicable to your machine may not apply outside U.S.

If you are not the original owner of this machine, it is in your interest to contact your local Fast Ag

Solutions dealer to inform them of this unit's serial number. This will help Fast Ag Solutions notify

you of any issues or product improvements.

INTRODUCTION

INTRODUCTION Dry DuraPlacer 9 / 13 / 14 Ton - 40' / 60' Page 1

INTRODUCTION

Read this Manual carefully

before operating your FAST

equipment. The information

presented will prepare you

to safely operate and service

your machine.

All Operators are required to read this

Manual carefully and be acquainted with all

the operating and adjustment procedures

before attempting to operate. Failure to

follow the information in this Manual and on

decals may result in personal injury or

equipment damage.

This Manual should be considered a

permanent part of this equipment and should

remain with the equipment when you sell it.

Replacement manuals can be obtained from

your Fast Ag Solutions dealer.

This equipment has been engineered and

manufactured to provide dependable and

satisfactory use. Like all mechanical

products, it will require cleaning and upkeep.

Inspect your equipment before putting it into

service. Your authorized Fast Ag Solutions

dealer has trained mechanics, genuine FAST

service parts, and the necessary tools and

equipment when service is needed. Use only

genuine FAST parts for service or repairs.

Substitute parts will void the warranty and

may not meet standards for safe and

satisfactory operation.

Warranty is provided as part of Fast Ag

Solutions’ support program for customers

who operate and maintain their equipment as

described in this Manual. The warranty is

explained on the warranty certificate you

should have received from your dealer. This

warranty provides you with the assurance

that Fast Ag Solutions will back its products

where defects appear within the warranty

period. Should the equipment be abused or

modified to change its performance beyond

the original factory specifications, the

warranty will become void.

These instructions have been compiled from

field experience and engineering data. Some

information may be general in nature due to

unknown and varying operating conditions.

However, through experience and these

instructions, you should be able to develop

procedures suitable to your particular

situation.

The illustrations and data used in this Manual

were current at the time of printing. However,

due to possible in-line production changes,

your machine may vary slightly in detail. We

reserve the right to redesign and change the

machines as necessary without notification.

Figure 1: Orientation is viewed from behind the

machine.

SAFETY

SAFETY Dry DuraPlacer 9 / 13 / 14 Ton - 40' / 60' Page 2

SAFETY

The most important safety device on this

equipment is a safe Operator. It is the

Operator’s responsibility to read and

understand and follow all safety and

operating instructions in this Manual.

As the Operator, you are responsible for the

safe operation and maintenance of this

equipment. You must ensure that you and

anyone else who is going to operate,

maintain or work around the machine is

familiar with the operating and maintenance

procedures and related safety information

contained in this Manual.

You are the key to safety. Good safety

practices protect you and the people around

you. Be certain that everyone operating this

equipment is familiar with the recommended

operating and maintenance procedures and

follows all safety precautions. Do not risk

injury or death by ignoring good safety

practices.

Safety Alert Symbols and Signal

Words

This is a Safety Alert Symbol. When you see

this symbol on your machine or in this

Manual, be alert to the potential for personal

injury.

Follow recommended precautions and safe

operating practices.

Understand Signal Words

Throughout this Manual, the terms

CAUTION, WARNING, and DANGER are

used along with the Safety Alert Symbol to

indicate the degree of personal safety

hazard. The term IMPORTANT is used to

indicate that failure to observe the hazard

can cause damage to the equipment.

DANGER identifies the most serious

hazards. DANGER or WARNING safety

signs are located near specific hazards.

General precautions are listed on CAUTION

safety signs. CAUTION also calls attention to

safety messages in this Manual.

Follow Safety Instructions

Carefully read all safety messages in this

Manual and on your machine’s safety signs.

Keep safety signs in good condition.

Replace missing or damaged safety signs.

Be sure new equipment components and

repair parts include the current safety signs.

Replacement safety signs are available from

your Fast Ag Solutions dealer. There can be

additional safety information contained on

parts and components sourced from

suppliers that is not reproduced in this

Operator's Manual.

Learn how to operate the machine and how

to use controls properly. Do not let anyone

operate without instruction.

Keep your machine in proper working

condition. Unauthorized modifications to the

machine may impair the function and/or

safety and affect machine life.

If you do not understand any part of this

Manual and need assistance, contact your

Fast Ag Solutions dealer.

SAFETY

SAFETY Dry DuraPlacer 9 / 13 / 14 Ton - 40' / 60' Page 3

General Safety

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher

handy.

Keep emergency numbers for the poison

control center, doctors, ambulance service,

hospital, and fire department near your

telephone.

Wear Protective Clothing

Wear close-fitting clothing and safety

equipment appropriate to the job.

Operating equipment safely requires the full

attention of the Operator. Do not wear radio

or music headphones while operating the

machine.

Protect Against Noise

Prolonged exposure to loud noise can cause

impairment or loss of hearing.

Wear a suitable hearing protective device

such as earmuffs or earplugs to protect

against objectionable or uncomfortable loud

noises.

Practice Safe Maintenance

Understand service procedures before doing

work. Keep the area clean and dry.

Never lubricate, service, or adjust the

machine while it is moving. Keep hands, feet,

and clothing away from power-driven parts.

Disengage all power and operate controls to

relieve pressure. Lower equipment to the

ground. Stop the engine. Remove the key.

Allow machine to cool. Securely support any

SAFETY

SAFETY Dry DuraPlacer 9 / 13 / 14 Ton - 40' / 60' Page 4

machine elements that must be raised for

service work.

Keep all parts in good condition and properly

installed. Fix any damage immediately.

Replace worn or broken parts. Remove any

buildup of grease, oil, or debris.

On self-propelled equipment, disconnect the

battery ground cable (-) before making any

adjustments on electrical systems or welding

on the machine.

On towed implements, disconnect wiring

harnesses from tractor before servicing

electrical system components or welding on

the machine.

Support Raised Equipment

Always use a safety support when working

on, under, or around the machine. Transport/

Service locks can be used for this purpose.

Shut off the tractor’s engine and remove the

key when working on the machine.

If air has been allowed to enter hydraulic

hoses or cylinders, bleed the hydraulic

system before use. If there is a failure in the

hydraulic system, unsupported or raised

equipment could suddenly lower, causing

serious personal injury or death.

If support is not available, completely lower

wings and frame, relieve hydraulic pressure

and disconnect hoses from tractor.

Avoid Heating Near Pressurized Fluid

Lines

Flammable spray can be generated by

heating near pressurized fluid lines, resulting

in severe burns to yourself and bystanders.

Do not heat by welding, soldering, or using a

torch near pressurized fluid lines or other

flammable materials. Pressurized lines can

accidentally burst when heat goes beyond

the immediate flame area.

Avoid High-Pressure Fluids

Inspect hydraulic hoses periodically – at

least once per year – for leakage, kinking,

cuts, cracks, abrasion, blisters, corrosion,

exposed wire braid, or any other signs of

wear or damage.

Replace worn or damaged hose assemblies

immediately with Fast Ag Solutions approved

replacement parts.

Escaping fluid under pressure can penetrate

the skin causing serious injury.

Avoid the hazard by relieving pressure

before disconnecting hydraulic or other lines.

Tighten all connections before applying

pressure.

This manual suits for next models

2

Table of contents

Other Fast Farm Equipment manuals