CPC507

C P C 5 0 7 U s e r M a n u a l 1 ©2022 F a s t w e l V e r . 0 0 2

Table of Contents

Table of Contents.....................................................................................................................................................1

List of Tables............................................................................................................................................................2

List of Figures…………………………………. ........................................................................................................... 3

Conventions…………………………………………………………………………………………………………………….5

General rules of usage …...……………………………………………………………………………………….………….7

Manufacturer's warranties…………………………………………………………………………………………………….7

Transportation, Unpacking and Storage ………………………………………………………………………...………….9

1. INTRODUCTIOIN……………………………………………………………………………..………………………………11

1.1 System overview…………………………………………..…………………………………………………...………….11

1.2 General description of the module…………………………………………………………..…………………………..11

1.3 Module versions …………………………………………………………………………………………………………...11

2. GENERAL INFORMATION………………………………………………………………….………………………………12

2.1 General Features of CPC507……………………………………………...……………………………………………..12

2.2 Compatibility with the PICMG/VITA standards ……………………………………………………………......……….13

2.3 Device dimensions………………………………………………………………………………………………………...14

2.4 Delivery checklist…………………………………………………………………………………………………………..14

2.5 Operational conditions …..…………………………………………………………………………………………….....15

2.6 Product labeling ………….……………………………………………………………………………………………......16

2.7 Packaging information ……………………………………………………………..…………………………………......16

3. DESIGN AND OPERATION …….…………………………………………………..……..………………………………..17

3.1 Block diagram ………………………...……………………………………………….…………………………………..17

3.2 Specific performance features of functional nodes ………………………………………………………………..…..18

3.3 System expansion options ….…………………………………..………………………………………………………..19

3.3.1 PMC/XMC Modules……...……………………………………………………………………………………………19

3.4 Using the module in the CPCI system ……...…………………………………………..………………………………19

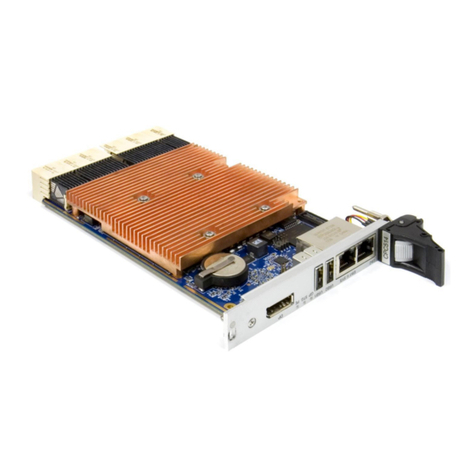

3.5 Location of main components …………………………………………………………………………………..……….20

4. INTENDED USE……....…………....…………………..…………………………………………………………………….21

4.1 Module Interfaces ………………..…………...…………………………………………………………………………..21

4.1.1 XMC interface………………………………………………………………………………………………………..21

4.1.2 PMC interface………………………………………………………………………………………………………..22

4.1.3 SATA interface………………………………………………………………………………………………………24

4.1.4 COM port…………………………………………………………………………………………………………..…25

4.1.5 Connectors on the front panel of CPC507…………………………………………………………………….…25

4.1.6 LEDs on the front panel of CPC507……………………………………………………………………………....28

4.1.7 Using the module in CompactPCI system………………………………………………………………………..28

4.1.8 Compact PCI connectors…………………………………………………………………………………………..29

4.2 Timers ………………………………………………………………...……………………………………………………36

4.2.1 Watchdog Timer…………………………………………………………………………………………………….36

4.2.2 Description of I/O registers of WDT controller…………………………………………………………………..37

4.3 SPI controller / LEDs / GPIO …...………………………………………………….…………………………………….39

4.3.1 Description of SPI controller registers…………………………………………………………………………...39

4.3.2 Programming SPI device………………………………………………………………………………………….40

4.3.3 FRAM with sequential access……………………………………………………………………………………40

4.4 Devices on the local SMBus ……………………..……………………………………………...……………………….41

4.5 Battery ……………..…………………………………………...…………………………………………………………..41

5. INSTALLATION…..…………………………………………………………………………………………….……………..42

5.1 Safety requirements …………………………………..…………………………………………………………..…..42

5.2 CPC507 installation procedure……………………………………………………………………………………….43

5.3 Board Removal Procedure……………………………………………………………………………………………44

5.4 Installing peripherals to CPC507……………………………………………………………………………………..44

5.4.1 Connecting USB devices……………………………………………………………………………………….45

5.5 Battery replacement…………………………………………………………………………………………………...45

5.6 Installing CFast Drive………………………………………………………………………………………………….45

6. SYSTEM SETUP ……………………..…………….…………………………………………..…………………………….46