CPC507

C P C 5 0 7 U s e r M a n u a l 1 ©2021 F a s t w e l V e r . 0 0 1

Table of Contents

Table of Contents.....................................................................................................................................................1

List of Tables............................................................................................................................................................2

List of Figures…………………………………. ........................................................................................................... 3

Conventions…………………………………………………………………………………………………………………….5

General rules of usage …...……………………………………………………………………………………….………….7

Manufacturer's warranties…………………………………………………………………………………………………….7

Transportation, Unpacking and Storage ………………………………………………………………………...………….9

1. INTRODUCTIOIN……………………………………………………………………………..………………………………11

1.1 System overview…………………………………………..…………………………………………………...………….11

1.2 General description of the module…………………………………………………………..…………………………..11

2. GENERAL INFORMATION………………………………………………………………….………………………………12

2.1 General Features of CPC507……………………………………………...……………………………………………..12

2.2 Compatibility with the PICMG/VITA standards………………………………………………………………......……..14

2.3 Module versions …………………………………………………………………………………………………………...14

2.4 Delivery checklist…………………………………………………………………………………………………………..15

2.5 Packaging information………………………………………………………………………………………………….....15

2.6 System expansion options……………………………………………………………………………………………......15

2.7 System information……………………………………………………………………………………………………......15

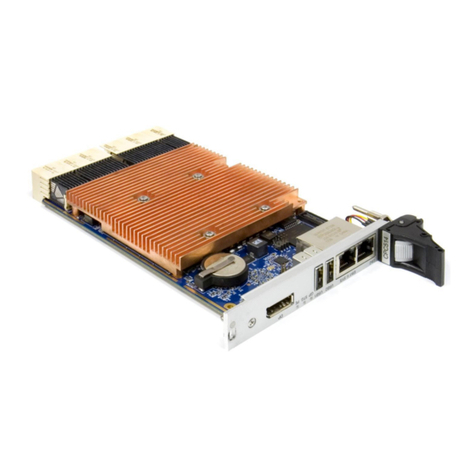

2.8 External view and location of the main elements………………………………………………………………………16

3. FUNCTIONAL DESCRIPTION…………………………………………………..…………………………………………..20

3.1 Specific performance features of functional nodes………………………...…………………………………………..20

3.2 Module Interfaces……………………………………………………………………...…………………………………..21

3.3 Timers……………………………………………………………..………………………………………………………..39

3.4 SPI controller / LEDs / GPIO……………………………………………………………..………………………………42

3.5 Devices on the local SMBus……………………………………………………………………………………..……….44

3.6 Battery………………………………….…………………………………………………………………………………...44

3.7 NAND drive………………………………………...……………………………………………………………………….44

4. INSTALLATION…...…………....…………………………………………………………………………………………….45

4.1 Safety requirements…………………………...…………………………………………………………………………..45

4.2 CPC507 installation procedure……………………………………...……………………………………………………46

4.3 Board removal procedure…...…………………………………………………………………………………………….47

4.4 Installing peripherals to CPC507……………………..………………………………………………………………….47

4.5 Battery replacement…………………………………………...…………………………………………………………..48

4.6 Installing CFast Drive…………...…………………………………………………………………………………………48

5. SYSTEM SETUP……………………………………………………………………………………………….……………..49

5.1 Resetting the BIOS Setup settings…………………………………………………………………………………..…..49

6. AMI APTIO BIOS SETUP………………………….…………………………………………..…………………………….50

6.1 Starting and Updating BIOS Setup…………………………………………………………………………......……….50

6.2 Advanced …………………………………………………………………………………………………………………..52

7. TROUBLESHOOTING………………………………………………..………………………………………………………53

8. POWER CONSUMPTION……………………………………………………..……………………………………………..54

9. INFLUENCE OF EXTERNAL FACTORS…………………………………….…………………………….....…………...55

9.1 CPC507 operating conditions and MTBF…………………………………………………………………………......…..55

ANNEX A: TERMS, ACRONYMS AND ABBREVIATIONS …………………….……………………………………………..56

ANNEX B: DICSLAIMER…………………………………………………………………………………………………..……….58