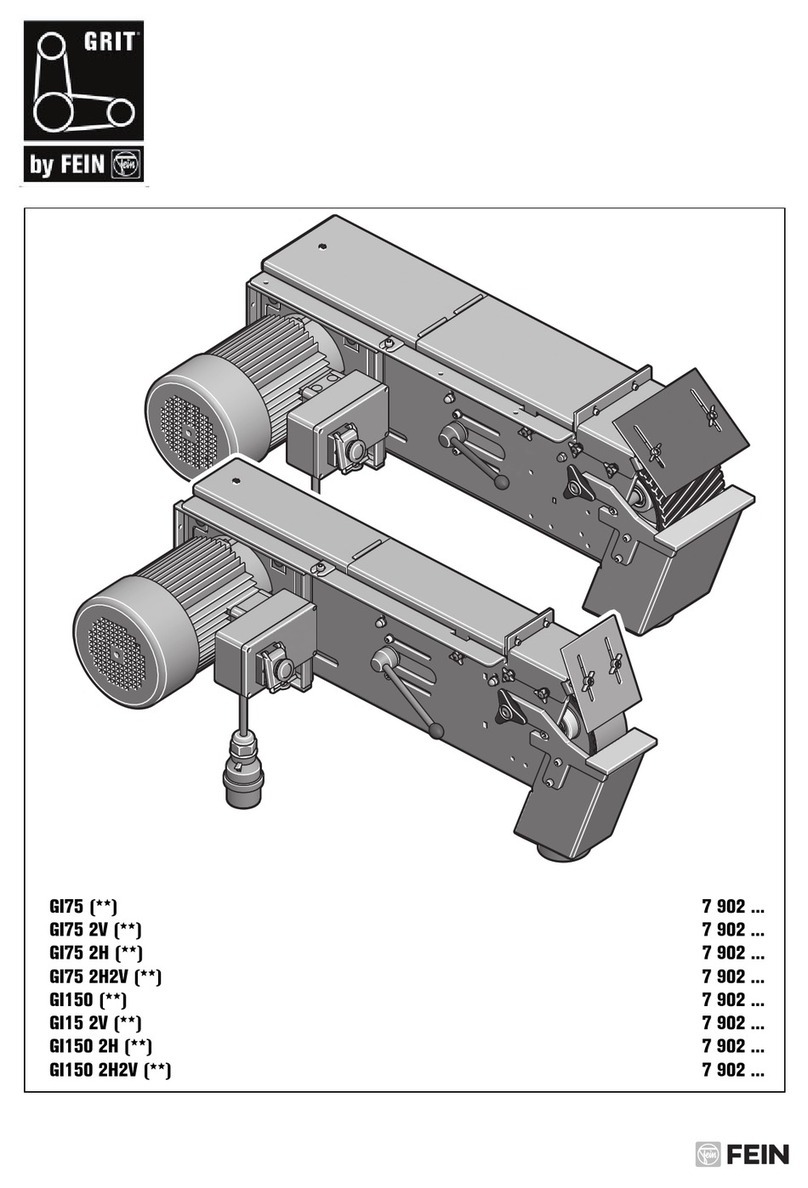

Component

Parts

0

z

Order

c Description+-' Reference

0'

....

oj

0

z

Order

>-

Descri

ption

+-' Reference

<Y

....

oj

Po<

Po<

1-6

MK

3-76-2 I 1

motor

housing,

assembled

60

RJ

27

a-

40x21

,5 1 Nilos

rin

g

1

MK

3-76 1

motor

housing

61

PT

11-48 1 end cover

2a SR 9-M5x7 1 grubscrew 62

LK6-26

1 needle bearing

3

state

type

1 stator, assembled 63 RJ 30i-24x1,2 1 Seeger-V-securing ring

and

vo

lta

ge w

ith

winding

64

RJ 19-5 1 sealing ring

4 SR 11-M6x12 2 grubscrew 65

PT

19-42 1

be

aring

plate

5

SR

20-37 1

thr

eaded sleeve 66 RJ 24-27 1 washer

6 SR 27-15 1 ring eyelet

67

LK

11-5 1 ball bearing

68

RJ

27a-40x

21

,5 1 Nilos

rin

g

7-27

GH7-34-4

1

fan

housing,

assembled

with

switch

69

PT

16-36 1 end cover

70

SR 5-M4x15 1 countersu

nk

screw

7

GH7-34

1

fan

housing

8

BF

29-112 1 angle

9

BF

9-3x10

AL

4 countersunk rivet

71

WB6-62

1 drive

shaft

72

ZR

14-99*) 1 bevel g

ear

wheel, 32 teeth,

200 cycles

10

EZ

1-54 1 switch, 25 A

11

DJ

5-25 1

rubber

cap

12

SR6-M4x8

3 fillis

ter

screw

ZR

14-97*) 1 bevel gear wheel, 36 teeth,

300 cycles

73

BF

21-5x5x16 1 fitting key

( 13

SA

5-38 1 switch lever

14

DJ

1-46 1 felt

ring

15

SR3-M4x6

1 fillister screw

16 SR

3-M4

x8 1

earth

screw

74

RJ 29a-16x0,6 1 circlip Seeger

75

PT5d-M5

4 spring washer for bearing plate

76 SR 33-M5x15 4

I

hexagon socket screw

77

JS 20-20 1 protecting cap

78 MZ 35-28 1

FEIN

pl

ate

17-23

GH

4-60-1 1

handle,

assembled

Parts

for

MSfo

880-lc

(6500 R.P.M.)

17

GH

4-60 1

handle

18

JS

4-76 1 ins

ulatin

g washer

19 JS 13-75 1 cable protecting sleeve

20 RJ 7-35 1 retaining

ring

21

SR6-M4x6

2 fillister countersunk screw

22

JSt6-15

1

rubber

sleeve

23

EZ

6-59 1 cable, assembled

50

I

ZR

13

-60*) 1 bevel pinion, 18 teeth, 200 cycles

ZR

13-58

*)

1 bevel pinion,

15

teeth, 300 cycles

72

ZR

14-98*) 1

be

vel gear wheel,

33

teeth,

I

200 cycles

ZR

14-96*) 1 bevel gear wheel,

41

teeth,

300 cycles

Parts

for

low

tension

(42

Volts)

24

PT

31-23 1 clamping clip

24a

PT

31-29 1 clamping piece

24b

BF

9-4x15

AL

2 countersunk rivet

1-

6

MK

3-76-1 1

motor

housing,

assembled

7-27

GH

7-36-4 1

fan

housing,

ass

e

mbled

with

switch

25

PT

31-21 1 clamping clip

26

PT6-.M3

,5 2 spring washer

27 SR 3-M3,5x25 2 fillist

er

screw

7

GH

7-36 1 fan housing

8

BF

29-109 1 angle

10

EZ

1-42 1

sw

itch, 60 A

30

WL

2-32-1 1

rotor

12 SR 6-M5x10 4 fillis

ter

countersunk screw

32 BF

21

-3x3x40 1 fitting

key

13

SA5-39

1 switch lever

34

JS

4-64 1 washer

35

LK

16-2 1 groove

ball

bearing

wit

h sealing 14

D)

5-24 1 rubber

rin

g

15 SR 3-

M6

x10 1 fillister screw

37

BF

21-3x3x10 1 fitting

ke

y

38 FL 1-100 1

fan

wheel, 200 cycles

FL 1-106 1

fan

wheel, 300 cycles

24

PT

31-2 1 clamping

brid

ge

24a

PT

31-28 1 cable clamping

pie

ce

25 SR 3k-M4x25 2 fillister

sc

rew

40

PT6-M8

1 spring washer

41

MR

1-

M8

1 hexagon

nut

42

DJ

5-10 1

rubb

er

sealing

43 BU 1-186 1 cover

44 SR 33-M5x50 4 hexagon socket screw

45 SR

33

-M

6x

15

1 hexagon socket screw

46 SR 33-M6x55 2 hexag

on

socket

sc

rew

17-28

GH

4-61-2 1

handle,

assembled

17 GH 4-61 1 ha

nd

le

23 EZ 6-60 1 cabl

e,

assembled, 5 m (16 ft) long

28

DJ

5-

27 1 rubber sealing

46 SR 33-M6x90 2 hexag

on

socket screw

47

SR 33-M5x25 4 hexagon socket

sc

rew

Accessories

48

MR

19-1 1

nut

49

PT

1-M8 1 disc

50

ZR

13-61*) 1 bevel pinion,

23

teeth, 200 cycles

ZR

13-59*) bevel

pin

ion, 17 teeth, 300 cycles

51

BF

21-5x5x16 1 fitting

key

52 RJ 24-13 washers

of

different thickne

ss

53

RJ 27i-17x35,7 1

Ni

los

rin

g

Z 7-

SW

17 1 single e

nd

spanner

z 10-7 1 hexagon so

ck

et spanner 4

mm

(5

132

")

z 10-8 1 hexagon socket spanner 5

mm

(3116")

z 13-22 1 peg spa

nner

MZ

19-32 1 2nd

han

dle, assembled

M8

-65 1

fl

ange of grinding wheel

54-78

GH

6-52-1 1

gear

housing,

assembled

M8-52

1

fl

ange

of

grinding wheel

54

GH6-52

1 gear housing

MZ6

0-3/FG

9 1 tube

of

gear grease

57

LK

1-10 1 groove ball bearing

58 SR 5-M4x15 3 countersunk screw

59

PT

16-44 1 e

nd

cover

wheel guard, assembled

IM 10-70-1 for MSfo 880

-1d

M 10-71-1 for MSfo 8

80

-1c

,,.)

Parts 50

and

72 are la

pped

.

Only

to

be supplied as pa

ir

s.