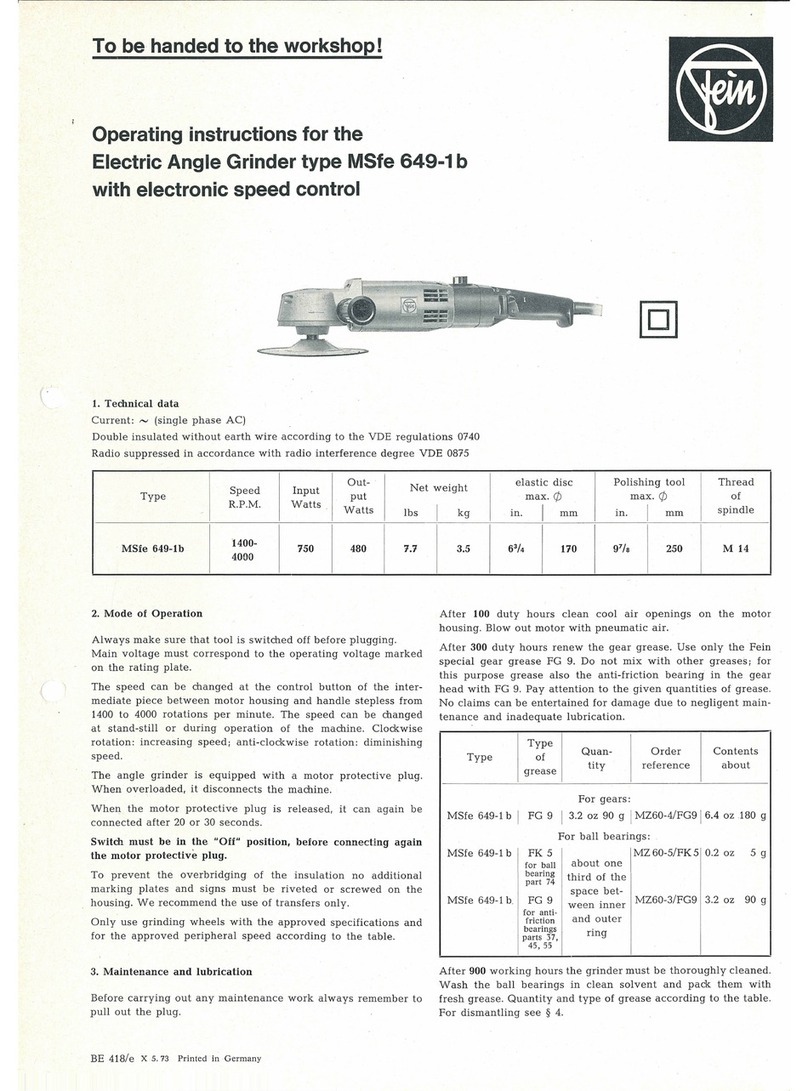

To be handed to the workshop

Operating instructions

for the Hand Grinder type MShy

664

and type MShy

764

{42 Volts)

1.

Technical

Data

Type

of

current:

~

(A.C.

single

phase)

Double

insulation

without

earth

wire

in

accordance

with

VDE 0740.

Radio

suppressed

in

accordance

with

VDE

0875.

Speed

Capacity

Type

RPM

Input

I

Output

Watts Watts

MShy

664 } 6900 1400 920

MShy

764

1)

Grinding

wheel

for

147 ft./s

max.

2.

Operation

Switch

in

"Off"

position.

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate

.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed.

We

re-

commend

the

use

of

transfers.

Grinding

wheels:

Only

use

grinding

wheels

with

the

admissible

peripheral

speed.

In

any

case

pay

attention

to

your

local

safety

regulations

on

the

use

of

grinding

wheels.

3.

Maintenance

and

lubrication

Pull

out

the

plug

before

carrying

out

any

maintenance

work.

After

100

working

hours

clean

air

openings

of

the

motor

hous-

ing.

Blow

out

motor

with

dry

pneumatic

air.

Clean

electric

parts

only

dry.

Replace

carbon

brushes

when

they

have

worn

down

to

7

mm

(0.28 in).

To

replace

brushes

see

paragraph

4,

section

4.

Only

use

"Fein"

carbon

brushes.

After

fitting

new

brushes,

run

tool

unloaded

for

about

15

min.

BE 417/e X 5.73

Grinding

wheel

hole

Net

weight

max

.

Cf;

I

ma

x.

width

I I

mm

I in.

mm

I in.

mm

in.

kg

lbs

125 1) 5 32/26 11

/4

20 25/32 4.5 9.91

Check

cable

at

regular

intervals.

To

exchange

cable,

see

para-

graph

4,

section

4.

After

300

working

hours

renew

the

gear

grease.

Quantity

of

grease:

75 g.

Order

Reference

for

tube

of

approximately

90 g:

MZ

60-3/Sst

1.

Only

use

Fein

special

grease

Sst

1. A

mixing

of

this

grease

with

other

greases

endangers

the

greasing

capaci-

ties.

After

900

working

hours

clean

machine

thoroughly.

Rinse

ball

bearings

in

clean

solvent

and

pack

with

fresh

grease

Sst

1.

Only

the

anti-friction

bearing

(54)

must

be

greased

with

grease

FK

5.

Order

Reference

for

the

tube

of

5 g:

MZ

60-5/FK 5.

Fill

space

between

inner

and

outer

ring

only

one

third

with

grease.

For

good

and

adequate

lubrication

and

in

order

to

avoid

over-

heating

it

is

important

to

pack

the

gearing

with

the

grades

and

quantities

of

grease

given.

Dismantling

see

paragraph

4.

No

claims

can

be

entertained

for

damage

due

to

negligent

main-

tenance

and

lubrication.

4.

Dismantling

The

work

should

always

be

left

to

an

expert.

1.

Unscrew

screws

(55).

take

off

outer

bearing

(30).