To be handed to the workshop!

Operating instructions for the

Electric Angle Grinder type MSfe

649-1

b

with electronic speed control

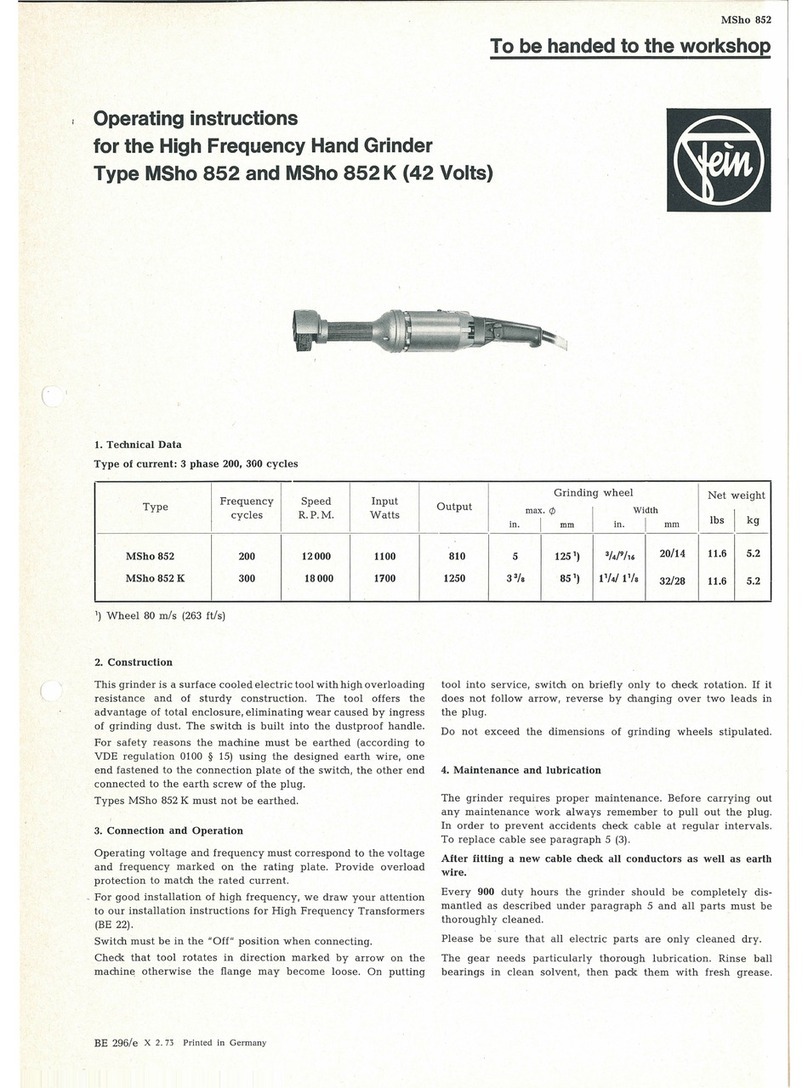

1. Technical

data

Current:

"'

(single

phase

AC)

Double

insulated

without

earth

wire

according

to

the

VDE

regulations

0740

Radio

suppressed

in

accordance

with

radio

interference

degree

VDE

0875

Out-

Net

weight

elastic

disc

Polishing

tool

Thr

ead

Type

Speed

Input

put

max.

(/)

max.

(/)

of

R.P.M.

Watts

Watts

lbs

MSfe

649-1b

HOO-

750 480 7.7

4000

2.

Mode

of

Operation

Always

make

sure

that

tool

is

switched

off

before

plugging.

Main

voltage

must

correspond

to

the

operating

voltage

mark

ed

on

the

rating

plate

.

The

speed

can

be

changed

at

the

control

button

of

the

inter

-

mediate

piece

between

motor

housing

and

handle

stepless

from

1400

to

4000

rotations

per

minute.

The

speed

can

be

changed

at

stand-still

or

during

operation

of

the

machin

e.

Clockwise

rotation

:

increasing

speed;

ant

i-cloc

kwise

rotation:

diminishing

speed.

The

angle

grinder

is

equipped

with

a

motor

protecti

ve

plug.

When

overloaded

,

it

disconnects

the

machine.

When

the

motor

protective

plug

is

released,

it

can

again

be

connected

after

20

or

30

seconds.

Switch

must

be

in

the

"Off"

position,

before

connecting

again

the

motor

protective

plug.

To

pr

eve

nt

the

overbridging

of

the

insulation

no

add

ition

al

ma

rk

ing

plates

and

signs

must

be

riv

eted

or

screwed

on

th

e

housing.

We

recommend

the

use

of

transfers

only.

Only

us

e

grinding

wheels

with

the

approved

specifications

and

for

the

approved

peripheral

speed

according

to

the

table

.

3.

Maintenance

and

lubrication

Before

carrying

out

any

ma

int

e

nanc

e

wo

rk

alwa

ys

remember

to

pull

out

the

plug.

BE 418/e X 5. 13

Printed

in

Germany

I

kg

in.

I

mm

in

. I

mm

spindle

3.5 63

/4

170 I

I

97

/s

250 M

14

After

100

duty

hours

clean

cool

air

openings

on

the

motor

housing

. Bl

ow

out

motor

with

pneumatic

air.

After

300

duty

hours

renew

the

gear

grease.

Use

on

ly

the

F

ein

special

gear

grease

FG

9.

Do

not

mix

with

ot

her

greases;

for

this

purpose

grease

also

th

e

anti-friction

b

ea

r

ing

in

the

gear

head

with

FG

9.

Pay

attention

to

the

gi

ve

n

quantities

of

grease.

No

claims

can

be

entertained

for

damage

due

to

negligent

main-

tenance

and

inadequate

lu

brica

tion.

Typ

e

Quan-

Order

Contents

T

ype

of

t

ity

refe

re

nc

e

abo

ut

grease

For

gears:

MSfe

649-1 b I

FG

9 I 3.2

oz

90 g IMZ60-4/

FG9

I6.4

oz

180

g

For

ball

bearings

:

MSfe

649-1 b I

FK

5 I

MZ

60-5/

FK

5 0.2 oz 5 g

for

ball

about

one

b

ea

rin

g thi

rd

of

th

e

part

74

MSfe

649

-1

b.

FG

9

space

bet

-

MZ60

-3/

FG9

3.2 oz 90 g

ween

i

nner

for

ant

i-

and

outer

friction

bearings

1

ring

I

parts

37,

45, 55

After

900

working

hours

the

g

rind

er

must

be

thoroug

hl

y

cleaned.

Wash

th

e

ball

bearings

in

clean

solvent

and

pack

them

with

fr

e

sh

grease.

Quantit

y a

nd

ty

pe

of

grease

according

to

the

tabl

e.

For

dismantling

see

§ 4.