(

MSho

840-2

To

be handed to the workshop

Operating instructions

for the High Frequency Hand Grinder

Type MSho

840-2

and MSho

840-2

K

(42

Volts)

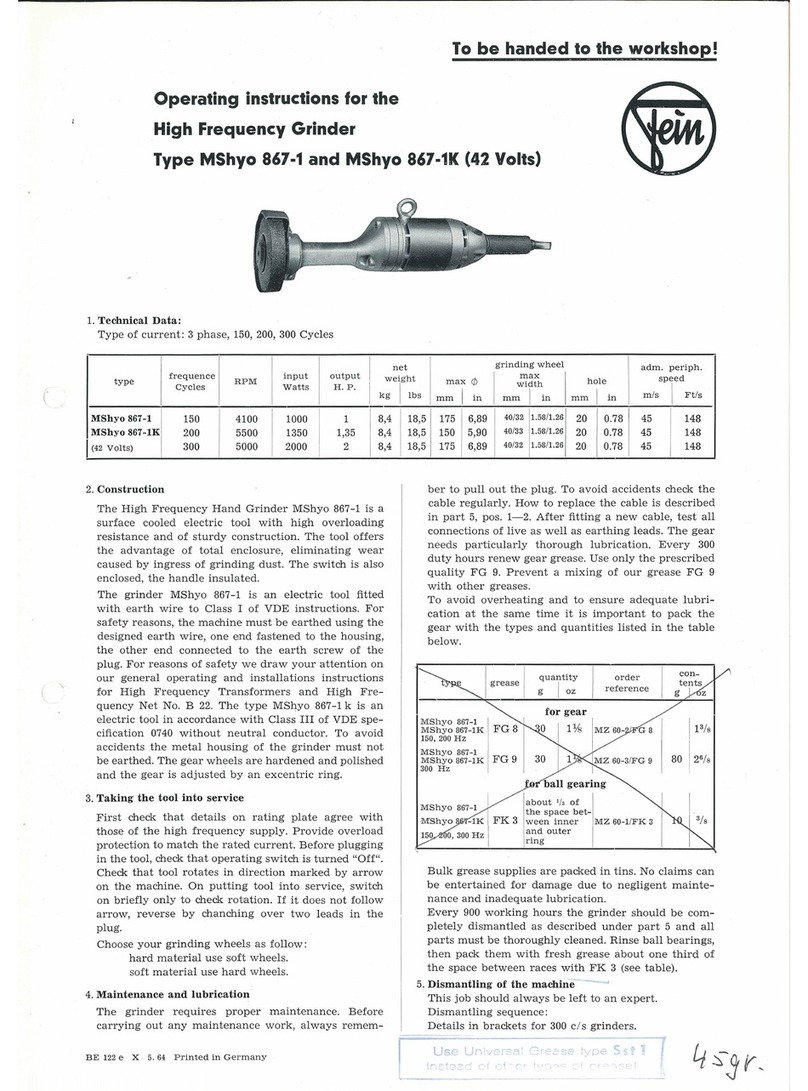

1.

Technical

Data

Type

of

current:

3

phase

150,

200,

300

cycles

Collet

C/J

Type

Fr

e

quency

Spe

ed

Input

Cycles I R.

P.M

.

Watts

in.

mm

150

,,4

6')

I

9000

190

MSho

840-2

'/4

200

6')

12000

250

MSho

840-2K

300

,,4

6')

I

18000

360

1)

On

demand

with

collet

8

mm

(approx.

5

/,/

' )

2.

Construction

This

grinder

is

a

surface

coo

led

e

lectric

tool

with

high

over-

lo

ad

ing

resistance

and

of

sturdy

construction.

The

tool

offers

the

advantage

of

total

enclos

ur

e,

eliminating

wear

caused

by

ingress

of

grinding

dust.

The

switch

is

built

into

the

dustproof

plastic

handle.

For

safety

reasons

the

machine

must

be

earthed

(according

to

VDE

regulations

0100 12.

65

§ 5 N

and

6

N)

using

the

(green-

yellow)

designed

earth

wire,

one

end

fastened

to

the

metal

cas

ing,

the

other

end

connected

to

the

earth

screw

of

the

plug.

For

reasons

of

safety

we

draw

your

att

e

ntion

on

our

general

operating

and

installation

instructions

for

High

Frequency

Transformers

and

High

Frequency

Net

(BE

22).

Type

MSho

840-2 K

(42

Volts)

must

not

be

ea

rthed.

3.

Connection

and

Operation

Op

e

rating

voltage

and

frequ

e

ncy

must

correspond

to

th

e

voltage

a

nd

frequency

marked

on

the

rating

plate.

Provide

ov

erload

protection

to

match

the

rated

current.

Switch

must

be

in

the

"Off"

position

when

connecting

.

Check

that

tool

rotates

in

direction

marked

by

arrow

on

the

machine,

o

therwis

e

the

collet

ma

y b

ecome

loos

e.

On

putting

BE

325/e

GW

2. 73

Printed

in

German

y

Out-

Max.

¢

of

gr

indin

g

wheel

for

admi

ss

ibl

e

Net

put

p

er

iph

e

ral

spee

d

Weight

30 m/s (99

ftfs)

145

m/s

(148 ft/s) I 80

m/s

(263f

t!s)

HP

in. I

mm

in. I mm in. I

mm

Lbs

I

kg

110

2x

3

/4

50x20

2x

3/s

50x10

21/2x3

/s

63x10

4.6 2.1

150 11/2x3

/4

40x20

2x

3/s

50x10

21

/2x

3

/s

63x10

4.6 2.1

220

11/4x3

/4

30x20

2x

3

/s

50x10

21/2x3

/s

63x10

4.6 2.1

tool

in

to

se

rvic

e,

swit

ch

on

briefly

onl

y

to

ch

eck

rotation.

If

it

do

es

no

t

follow

arrow,

reverse

by

changing

over

t

wo

l

eads

in

th

e

plug.

The

grinder

is

us

ed

for

grinding

out

and

polishing

dies,

cas

t

ings

and

press

moulds.

For

the

required

rotary

tools

and

for

the

hard

metal

milling

cutters

,

which

are

used

for

milling

jn

hard

metal,

see

our

leaflet

MSho

.

When

grinding

with

th

e

grinder

pay

attention

to

your

local

safety

regulations

.

4.

Maintenance

and

Lubrication

The

grinder

requires

prop

er

ma

intenance

.

In

order

to

prevent

accidents

check

cable

at

reg

u

lar

intervals.

To

replace

cable

(9)

,

unscre

w

screws

(17)

and

(18)

and

remove

h

andle

top.

Clamp

off

cable

from

sw

itch

(7)

and

earth

screw

(1

5

).

Lo

os

en

clamp

(11)

a

nd

draw

out

cabl

e.

After

fitting

a

new

cable,

check

all

conductors

as

well

as

earth

wire.

Every

900

duty

hours

the

gri

nder

should

be

completely

dis-

mantl

ed

as

described

und

er

paragraph

5

and

all

pa

rts

must

be

thoroug

hly

cleaned.

Rinse

ball

bearings

in

cl

ea

n

solv

e

nt

a

nd