MSho

852

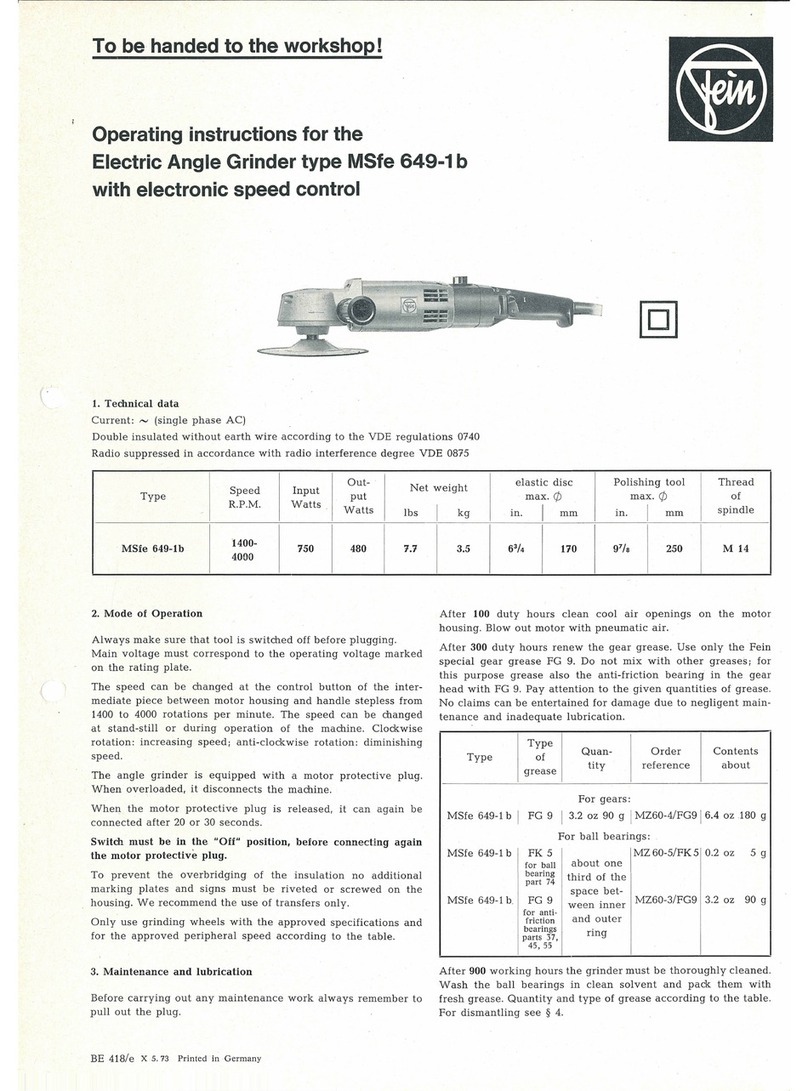

To be handed to the workshop

Operating instructions

for the High Frequency Hand Grinder

Type MSho

852

and MSho

852

K

{42

Volts)

1.

Technical

Data

Type

of

current:

3

phase

200, 300

cycles

Frequency

Speed

Input

Type

cycles

R.P.M.

Watts

MSho

852 200 12000 1100

MSho852K

300 18000 1700

1)

Wheel

80 m/s (263 ft/s)

2.

Construction

This

grinder

is a

surface

cooled

electric

tool

with

high

overloading

resistance

and

of

sturdy

construction.

The

tool

offers

the

advantage

of

total

enclosure,

eliminating

wear

caused

by

ingress

of

grinding

dust.

The

switch

is

built

into

the

dustproof

handle

.

For

safety

reasons

the

machine

must

be

earthed

(according

to

VDE

regulation

0100 §

15)

using

the

designed

earth

wire,

one

end

fastened

to

the

connection

plate

of

the

switch,

the

other

end

connected

to

the

earth

screw

of

the

plug.

Types

MSho

852 K

must

not

be

earthed

.

3.

Connection

and

Operation

Operating

voltage

and

frequency

must

correspond

to

the

voltage

and

frequency

marked

on

the

rating

plate.

Provide

overload

protection

to

match

the

rated

current.

.

For

good

installation

of

high

frequency,

we

draw

your

attention

to

our

installation

instructions

for

High

Frequency

Transformers

(BE

22)

.

Switch

must

be

in

the

"Off"

position

when

connecting.

Check

that

tool

rotates

in

direction

marked

by

arrow

on

the

machine

otherwise

the

flange

may

become

loose

.

On

putting

BE

296/e X 2.

73

Print

ed

in

German

y

Grinding

wheel

Net

weight

Output

max.

rp

I

Width

I

in. I

mm

in. I

mm

lbs

kg

---

810 5 125 1) 3

/4f9h6

20/14 11.6 5.2

1250 3 3/s 85 1) 11

/4/

11/s 32/28 11.6 5.2

tool

into

service,

switch

on

briefly

only

to

check

rotation

.

If

it

does

not

follow

arrow,

reverse

by

changing

over

two

leads

in

the

plug.

Do

not

exceed

the

dimensions

of

grinding

wheels

stipulated.

4.

Maintenance

and

lubrication

The

grinder

requires

proper

maintenance.

Before

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

In

order

to

prevent

accidents

check

cable

at

regular

intervals.

To

replace

cable

see

paragraph

5

(3).

After

fitting

a

new

cable

check

all

conductors

as

well

as

earth

wire.

Every

900

duty

hours

the

grinder

should

be

completely

dis-

mantled

as

described

under

paragraph

5

and

all

parts

must

be

thoroughly

cleaned.

Please

be

sure

that

all

electric

parts

are

only

cleaned

dry.

The

gear

needs

particularly

thorough

lubrication

.

Rinse

ball

bearings

in

clean

solvent,

then

pack

them

with

fresh

grease.