1.

2.

3.

4.

5.

04

Tough, exible, cost-effective

In short: GRIT GX

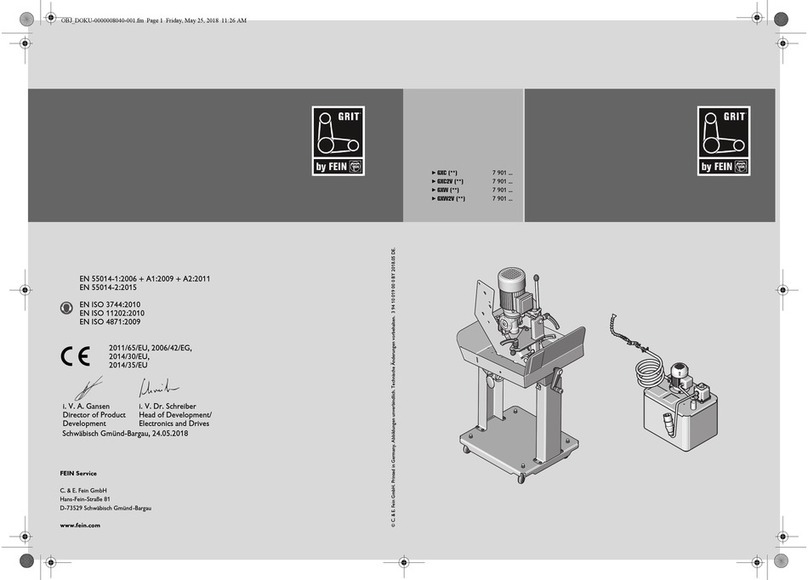

If you work on steel or stainless steel every day, then GRIT GX belt grinders are

the right choice. Twenty-ve years of experience and know-how have evolved into

GRIT – evident by the highly exible design and machine reliability; the GX Grinders

have the ability to easily adapt to various materials and applications – from rough

grinding to mirror polishing.

The GRIT GX functions according to the building-block principle. The belt grinder

is the foundation of the system. By simply adding modules, the spectrum of perfor-

mance is highly enhanced. i.e. having the ability to notch pipe and tubing. The modular

system is highly cost effective, saving both time and money. Grind efciently and

effectively with the GRIT GX system.

Powerful belt sander in single-

or two-speed models – the

heart of the modular GX pro-

gram. Highly productive and

economical as a stand alone

grinding center.

Add-on module for quick and

efcient radius grinding or

notching. Radius grinding

applications include: pipe,

square/rectangular tubing, bar

stock and proles.

Add-on module for nishing and

polishing applications on round,

ferrous and non-ferrous stock –

from rough grinding to mirror

polish.

Independent of the GX program,

the GXE machine utilizes durable

steel brushes for deburring steel

and stainless steel workpieces.

Available with optional pedestal

base and steel or stainless steel

brushes.

Accessories for the GX belt

grinders range from superior

performing grinding belts to

a cooling unit module.

BeltGrinderGX75/GX752H

RadiusGrindingModuleGXR

CylindricalGrindingModuleGXC

DeburringMachineGXE

Accessories