ASs

636-1

b

To be handed to the workshop

Operating instructions

for the double insulated and interference-suppressed

Electric Screw-Driver Type ASs 636-1 b

and ASs 736-1 b

(42

Volts)

1.

Specifications

Type

of

current:

(single-phase

A.C.)

double

insulation

in

accordance

with

VDE 0740

Interference-suppress

ed

to

VDE 0875

Self

drilling

screws

Speed

rpm

Square

Net

weight

Ty

pe

up

to

Input

Watts

in. I

mm

full

load

ASs

636-1 b

3f,6

4,2 2150

ASs

736-1 b

2.

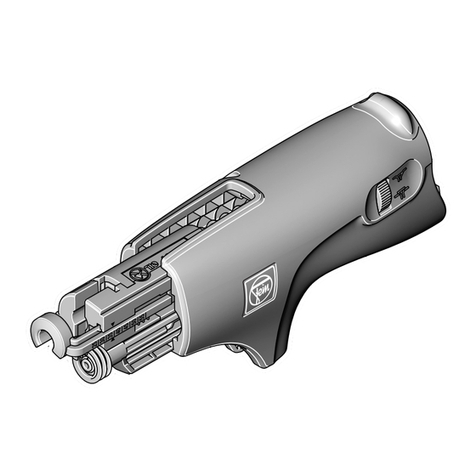

Construction

This

screw-driver

is

an

electric

tool

of

Class

II

with

protective

insulation

without

earthing

con

ductor

and

is

in

accordance

with

the

VDE

regulations

0740.

The

protecti

ve

insul

a

tion

is

attained

by

the

shock-proofed

motor

housing

made

of

Polyamide

and

by

insulating

the

armature

against

the

pinion.

The

protective

insulation

is

tested

with

the

prescribed

test

voltage

of

4000 V.

The

machine

is

radio-screened

in

accordance

with

radio

inter-

ference

degree

N.

It

is

supplied

with

a

two-core

cab

le

without

earthing

cond

uctor

and

must

not

be

earthed.

Type

ASs

736-1 b

for

low

tension

(42 V)

is

of

th

e

same

design,

but

without

double

insulation

and

not

radio-screened.

The

machine

is

provided

with

a

reversing

switch

for

clockwise

and

anticlockwise

rotation.

It

must

not

be

operated

when

the

machine

is

running.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screw

ed

on

the

housin

g.

We

recommend

the

use

of

transfers

only.

3.

Connection

Before

plugging

in

the

tool

check

that

voltage

stated

on

the

rating

plate

is

in

accordance

with

the

voltage

of

the

mains

supply.

Switch

must

be

in

the

"Off"

position

when

connecting.

BE 370/e

XEW

10.12

Printed

in

Germany

drive

I

no

load

lbs.

I

kg

1/4,

3450 230 h

exagon

3,5 1,6

socket

4.

Adjustment

of

the

torque

The

machine

is

provided

with

a

positive

clutch.

The

torqu

e is

adjus

ted

by

changing

the

position

of

the

clutch

claws;

the

deeper

the

gripping

of

the

claws,

th

e

high

er

the

torque.

In

order

to

adjust

the

claws,

turn

screw

(46)

after

having

screwed

off

bearing

sleeve

(48

)

and

loosed

grub

screw

(47)

.

Moreover

,

the

torque

is

dependent

on

the

pressur

e

of

the

driver

against

the

screw.

5.

Setting

of

the

depth

stop

With

ad

justing

sleeve

(102)

you

can

set

in

the

screwing

depth.

A

turn

of

90o

corresponds

of

25

mm

(1

")

screwing

depth

. A

deeper

stop

results

from

right

turning.

In

order

to

change

the

blades,

loosen

screw

(105),

re

move

depth

stop,

cha

nge

the

blade

and

r

emove

plaster

dust.

Push

depth

stop

on

t

he

machin

e

up

to

str

i

king

and

pull

on

screw

(105).

6.

Maintenance

Before

carrying

out

any

maintenance

work

always

remember

to

pull

out

the

plug.

To

guarantee

the

securi

ty

provided

by

the

double

in

s

ulation

clean

the

machine

regularl

y

every

300

duty

hours.

Th

is

is

done

with

a

brus

h

or

by

blowing

out

the

carbon

holders

a

nd

the

insulated

parts

with

dry

pneuma

t

ic

air.

Aft

er

checking

the

carbon

brushes

make

sure

to

ref

it

them

in

their

original

position

and

check

that

they

mo

ve

easi

ly

in

their

hold

er.