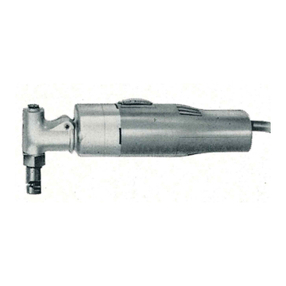

QSz

636

To

be

handed

to

the

workshop

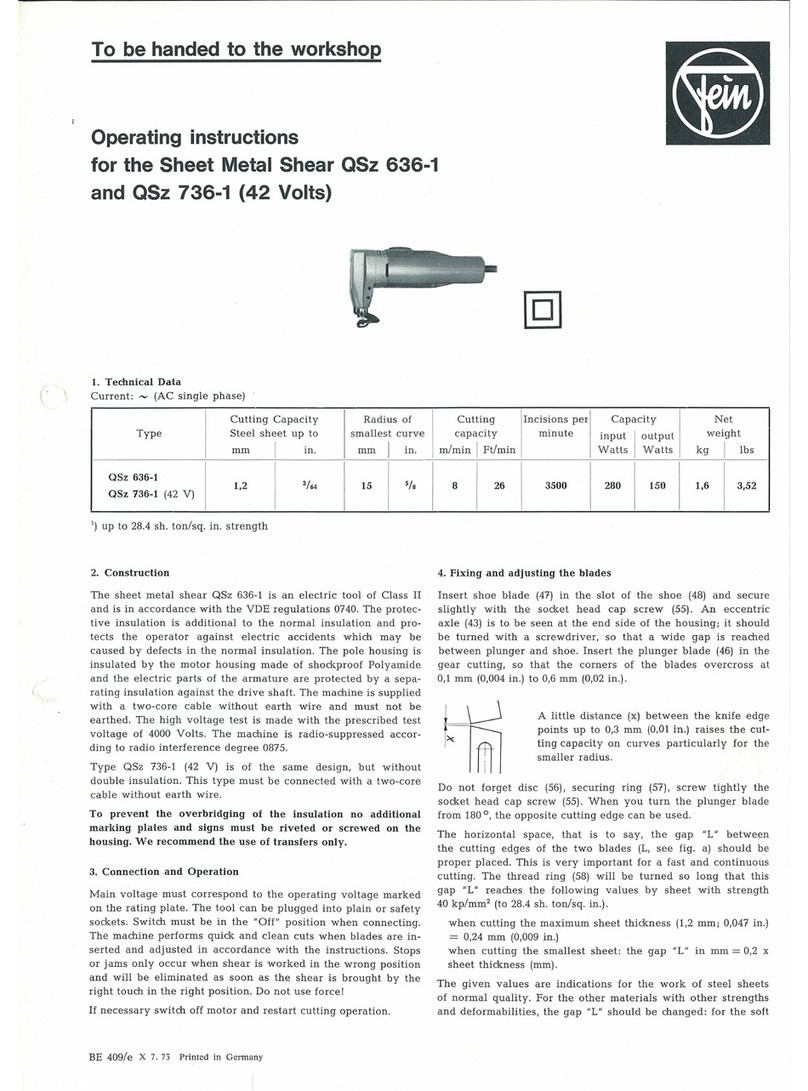

Operating

instructions

for

the

double

insulated

and

radio

suppressed

Sheet

Metal

Shear

QSz

636,

and

type

QSz

736

(42

Volts)

1.

Technical

Data

Current:

~

(AC

single

phase)

for

sheet

metal

up

to

Radius

of

Cutting

Incisions

per

Capacity

Net

Type

Steel

I

Stainless

steel

smallest

curve

capacity

minute

.

input

I

outpu

t

weight

mm

I

in

.

mm

I

in

.

mm

I

in

.

QSz

636 I I

2

I

5

/64

1,6 1

(16

I 20

I

0,8

QSz

736

(42

V)

2.

Construction

The

sheet

metal

shear

QSz

636

is

an

electric

tool

of

Class

II

and

is

in

accordance

with

the

VDE

regulations

0740.

The

protective

insulation

is

additional

to

the

normal

insulation

and

p

ro

tects

the

operator

against

electric

accidents

which

may

be

caused

by

de-

fects

in

the

normal

insulation

.

The

pole

housing

is

insulat

ed

by

the

motor

housing

made

of

shockproof

Polyamide

and

the

elec-

tric

parts

of

the

armature

are

protected

by

a

separating

insula-

tion

against

the

drive

shaft.

The

machine

is

supplied

with

a

two-

core

cable

without

earth

wire

and

must

not

be

earthed.

The

high

voltage

test

is

made

with

·

the

pre

sc

ribed

test

voltage

of 4000

Volts.

The

machine

is

radio-suppressed

according

to

radio

inter-

ference

degree

N.

Type

QSz

736

(42

V)

is

of

the

same

design

but

without

double

insulation.

This

type

must

also

be

connected

with

a

two-core

cable

without

earth

wire.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

3.

Connection

and

Operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safety

sockets.

Switch

must

be

in

the

"Off"

position

when

connecting

.

The

machine

performs

quick

and

clean

c

uts

when

blades

are

in-

serted

a~d

adj

usted

in

accordance

with

the

instru

ctions.

Stops

or

jams

only

occur

when

shear

is

worked

in

the

wrong

position

BE

195

/e

X 8.69

Printed

in

German

y

m/

min

I

Ft

/

min

Watts

Watts

kg

I

lbs

I I I

I

3 I 9,8 1700 280 150 2,3 I 5

and

will

be

eliminated

as

soon

as

the

shear

is

brought

by

the

right

to

uch

in

the

right

position.

Use

no

force!

If

necessary

switch

off

motor

a

nd

restart

cutting

opera

tion.

4.

Maintenance

and

Lubrication

Before

carryi

ng

out

any

maintenance

work

always

remember

to

pull

out

the

plug

.

Every

100

duty

hours

the

tool

should

be

.

cleaned

thoro

ughly

in

order

to

guarantee

the

safet

y

given

by

the

protec

tiv

e

insulation.

For

thi

s

purpose

carbon

holders

and

insul

ated

par

ts

must

be

cleaned

of

carbon

and

grinding

dust.

This

is

done

by

means

of

a

brush

or

by

blowing

o

ut

the

t

ool

with

dry

pne

um

atic

air

or

a

hand

blower.

For

checking

the

carbon

brushes

the

carbon

holde

rs

(10)

can

be

taken

out

after

unscre

w

ing

the

screws

(12).

Make

sure

that

the

carbon

brus

h

es

are

refitt

ed

in t

heir

original

place

a

nd

that

th

ey

mo

ve

easily

in

their

holder.

They

should

be

replaced

at

the

latest

when

they

have

worn

down

to

7

mm

(1

/

4"

).

Please,

onl

y

.

use

original

Fein

carbon

br

u

she

s

(Order

Reference

EZ 11-62).

After

fit

ting

,

new

brush

es,

run

tool

unloaded

for

abo

ut

15

minu-

tes

to

allow

brush

es

to

bed

in

.

One

pair

of

spare

carbon

brushes

will

be

found

in

the

motor

housing;

please,

do

not

forget

to

reorder

them

in

time.

In

order

to

prevent

accidents

check

cable

at

regula

r

intervals.

To

re

place

the

cable

unscre

w

th

e

screws

(22)

and

(2

3)

and

re

-

mo

ve

the

cover

(21)

.

Clamp

off

cab

le

from

switch

(14),

unscrew

screws

(20)

at

cabl

e

clamping

bridge

(1

9)

and

ta

ke

out

cab

le.

Use

Universal

Grease

type

Sst

1

instead

of

other

types

of

grease!

I