10

BLS 1.6 X

EN

Handling.

To pro ong the service ife of the b ades

smear cutting paste/oi a ong the sheet

meta cutting ine (for stee p ate) or

petro eum (for a uminium sheet).

Switching O /OFF (1).

■First check that the cab e and p ug are

not damaged.

Switching the power too ON:

■S ide switch (1) forwards (I).

Switching the power too OFF:

■S ide switch (1) backwards (0).

On y approach the work-piece with the

power too once the machine has been

switched on and the fu speed has been

reached.

Guide the power too at an ang e of 90° to

the sheet meta surface.

Sharp cutters produce an exce ent cut

and exert ess strain on the power too .

Reverse the b ades in good time, or

rep ace them.

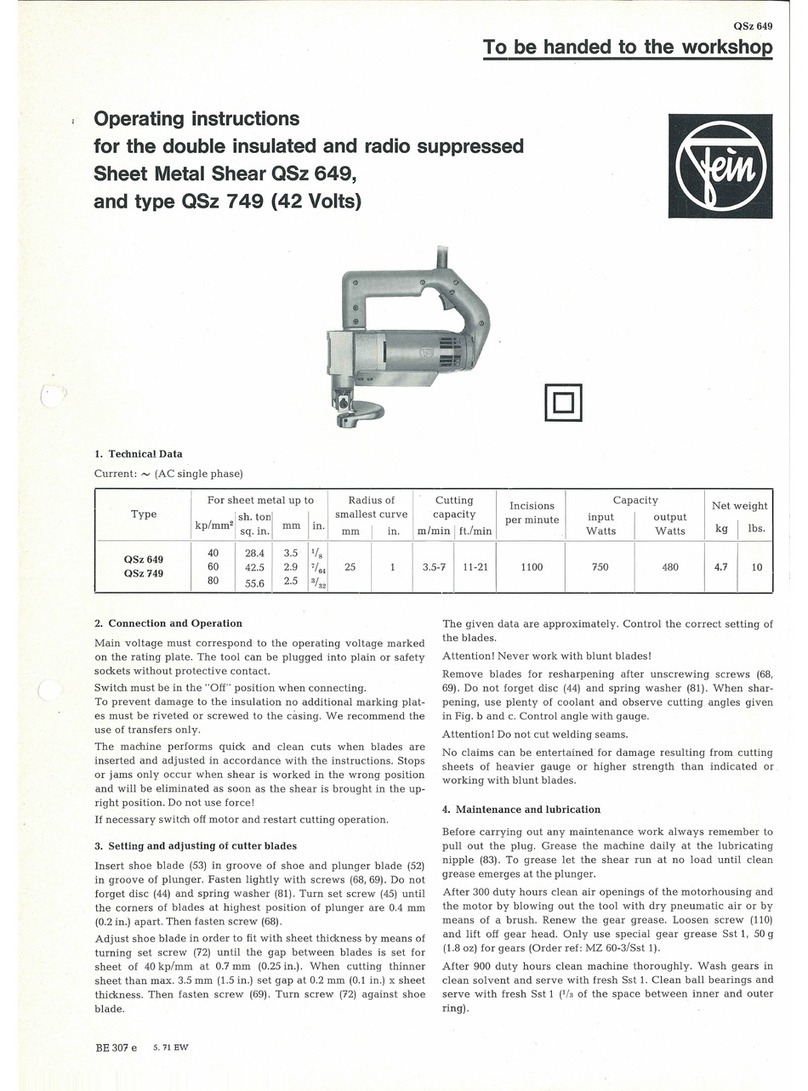

Setting the cutting width (6).

Risk of injury

by s itching the tool ON unintentionally.

Before adjusting, pull out the mains plug.

For a c ean cut without any burrs set the

cutting width (6a) between the fixed

b ades and p unger b ades.

Setting values for cutting width (6a)

When the power too is de ivered, the

cutting width (6a) is set at 0.2 mm and

corresponds with a sheet meta thickness

of approx. 1.0 mm. When working on

thinner or thicker sheet meta the fo ow-

ing va ues produce an optimum cutting

qua ity:

For a c ean cut without any burrs set the

cutting width (6a) between the fixed

b ades and p unger b ades.

■Unscrew the fixing screw for the fixed

b ade (6b).

■Unscrew the adjusting screw (6c) and

push back the fixed b ade.

■S ight y tighten the fixing screw (6b)

and set the cutting width (6a) using the

adjusting screw (6c) and a fee er gauge.

■Tighten the fixing screw for the fixed

b ade (6b).

■Check the cutting width (6a) using a

fee er gauge.

Reset the cutting width when a higher

feeding force is required because the cut-

ting width adjustment is too narrow, or

when excessive burr formation occurs

because the cutting width is too wide.

Reversing the blades (7).

Risk of injury

by s itching the tool ON unintentionally.

Before changing the tool, pull out the mains

plug.

Each b ade has four cutting edges. If the

cutters are b unt, turn the b ade through

90° or change it.

A ways change the p unger b ades and

fixed b ades as a pair.

■Unscrew the fixing screws (7d) and

remove.

■Reverse or change the b ades.

■Set the cutting width.

!

Thickness of

sheet metal Cutting

width (6a)

0.3 –0.6 mm 0.1 mm

0.8 –1.2 mm 0.2 mm

1.3 –1.6 mm 0.3 mm

!

3 41 01 042 06 3 - Buch Seite 10 Mittwoch, 23. April 2003 8:27 08