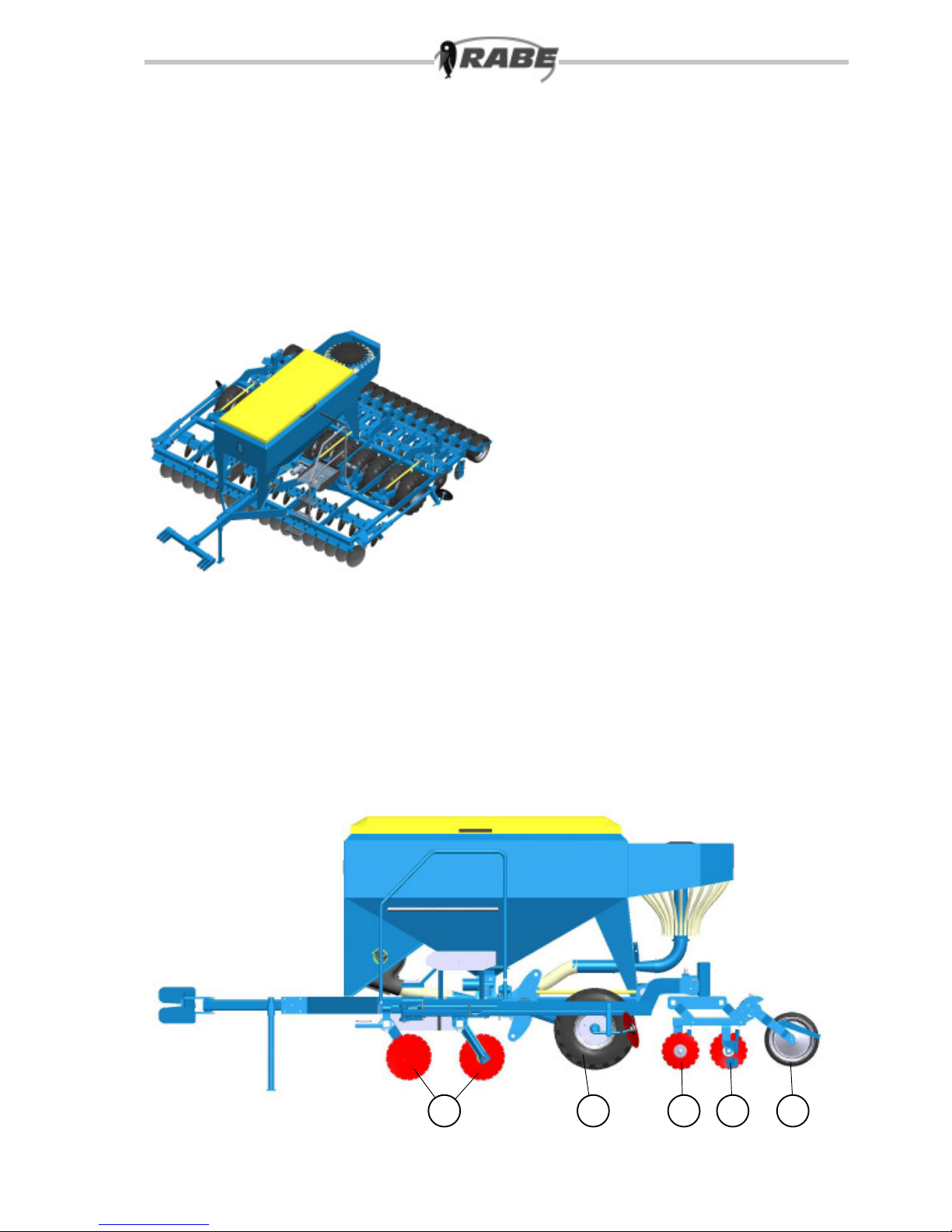

8

We reserve the right to make technical changes.

Safety precautions

Do not allow anyone to stand between the tractor and the imple-

ment during coupling or uncoupling, even if this is to allow opera-

tion of the external hydraulic controls. Danger of injury!

Always set the tractor’s hydraulic control mechanism to “attitude

control” before coupling or uncoupling.

Check the tractor and implement before each startup to ensure

that they are in perfect working order for driving and operation.

Observe the maximum axle loads (with full hopper) and maximum

permitted total weight.

Ensure that all safety devices are present and fitted before the

machine is transported.

Clear the working and turning area of bystanders before mano-

euvring or operating the implement. (This also applies to the lane

markers.)

DO NOT stand or ride on the implement or remain within its tur-

ning circle or operating area.

Before leaving the tractor unattended, and also before carrying

out adjustments, lower the implement, switch off the engine and

remove the ignition key.

Note that there is a danger of crushing and cutting injuries occur-

ring in the area of the three-point attachment and the hydraulic

lifting and folding mechanism, and during lane marker operation.

Beware of after-running coulters and rollers when the implement

is lifted at the end of a fast run; do not approach until the coulters

and/or rollers have come to a complete stop.

Handle hydraulic components and conduits with care, as they

become hot during operation.

If the blower begins to rattle or vibrate, shut down the hydraulic

system immediately and check the blade wheel of the blower for

correct dynamic balancing.

Note that incorrect balancing is dangerous, and can result in irre-

parable damage to the blower. Before carrying out maintenance

or adjustment work on the dosing devices – or driving on public

roads – switch off the electronic system (position “0”) and discon-

nect the system from the power supply (by pulling out the plug-in

connection for the power supply/implement cable loom).

Disable the tractor’s hydraulic control system to prevent accidental

operation while the implement is being towed along public roads.

Always lower the implement at both front and back BEFORE car-

rying out adjustment or any other work.

When filling with treated seed and cleaning the machine with com-

pressed air, note that seed dressing agent is a toxic irritant. Keep

sensitive body parts well protected (e.g. goggles, face mask and

gloves).

Before operating for the first time – or after a long period out of

use – check all screws and bolts for tightness, make sure that all

bearings are sufficiently greased, examine the hydraulic system

for leaks and check tyre pressures.

- Maximum length of combination (tractor + implement) 18 m

- Maximum width 3 m

- Maximum height 4 m

- Maximum total weight of combination 16t, of which 20% on front

axle.

The operating pressure of the hydraulic system must not exceed

200 bar.

The machine identification plate (8.1) contains certification details,

and must not be altered or made illegible.

8.1