Fike FIK-IR3-H2-HD User manual

Table of contents

Other Fike Security Sensor manuals

Fike

Fike 323-0001 User manual

Fike

Fike FIK-IR3-AS25 User manual

Fike

Fike 60-1039 User manual

Fike

Fike CEREX User manual

Fike

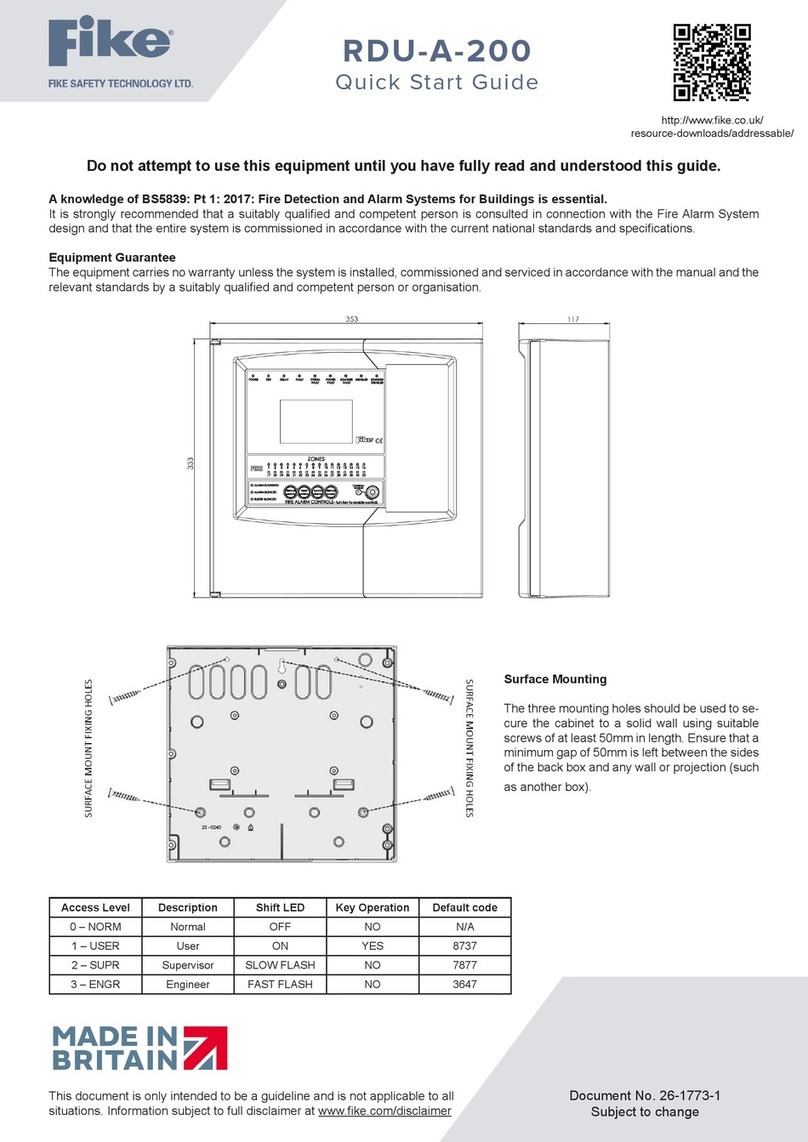

Fike RDU-A-200 User manual

Fike

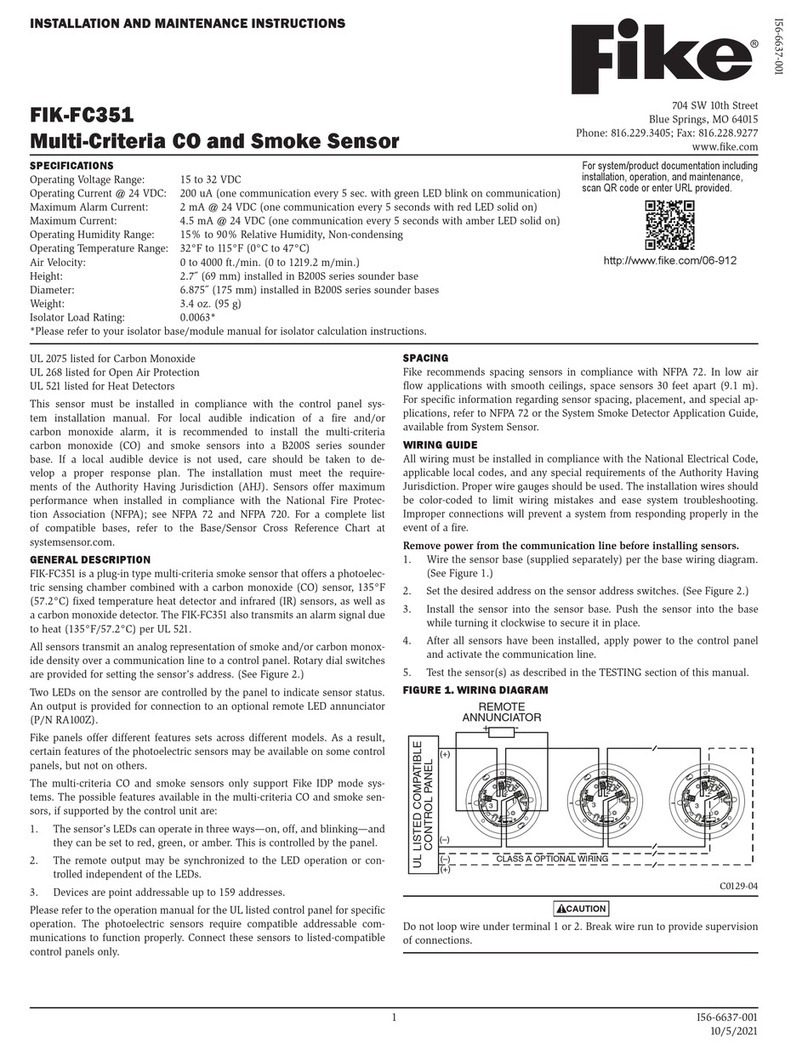

Fike FIK-FC351 User manual

Fike

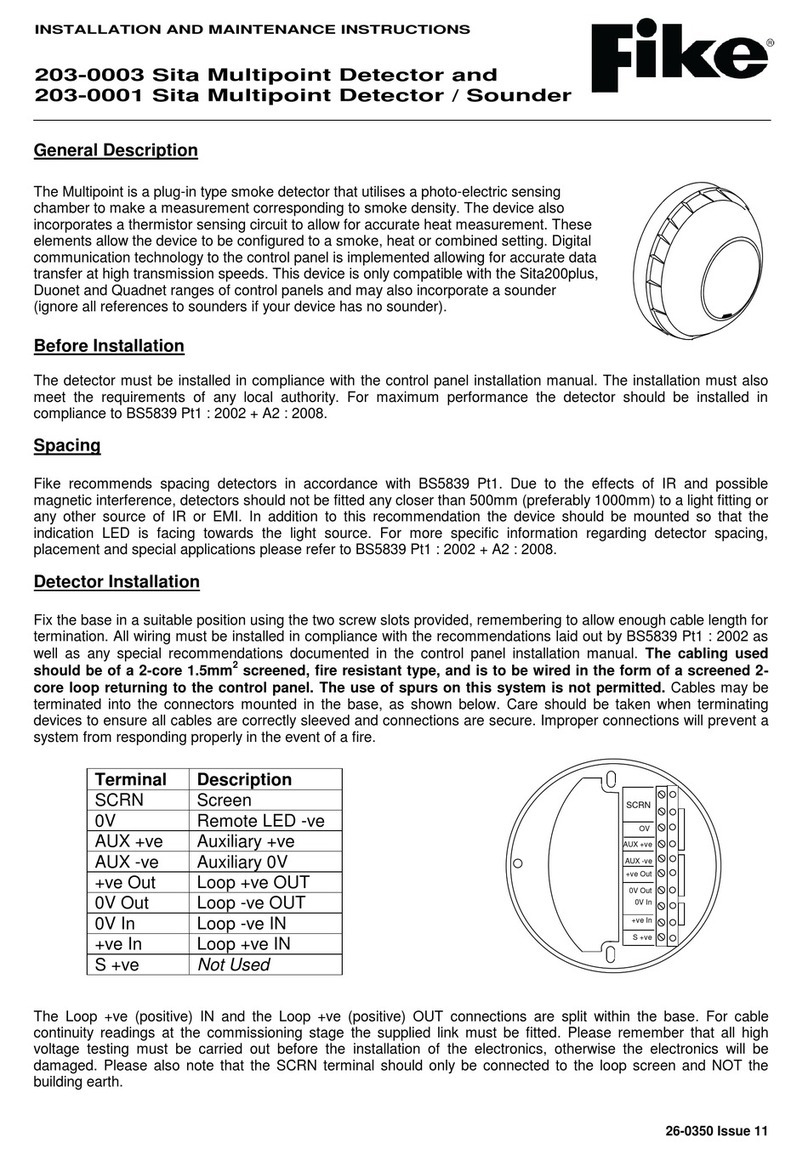

Fike Sita User manual

Fike

Fike FIK-UV-IR-HD Series User manual

Fike

Fike Twinflex Multipoint 202-0003 User manual

Fike

Fike FIK-W-PULL-DA User manual

Fike

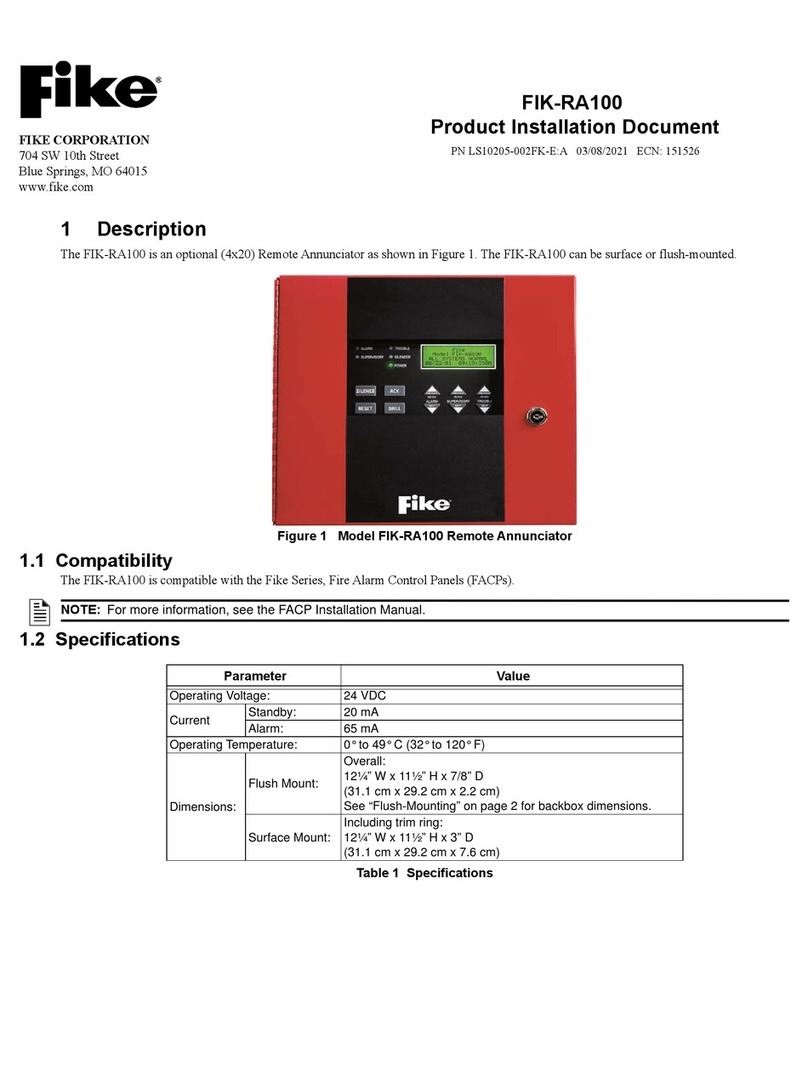

Fike FIK-RA100 Technical manual

Fike

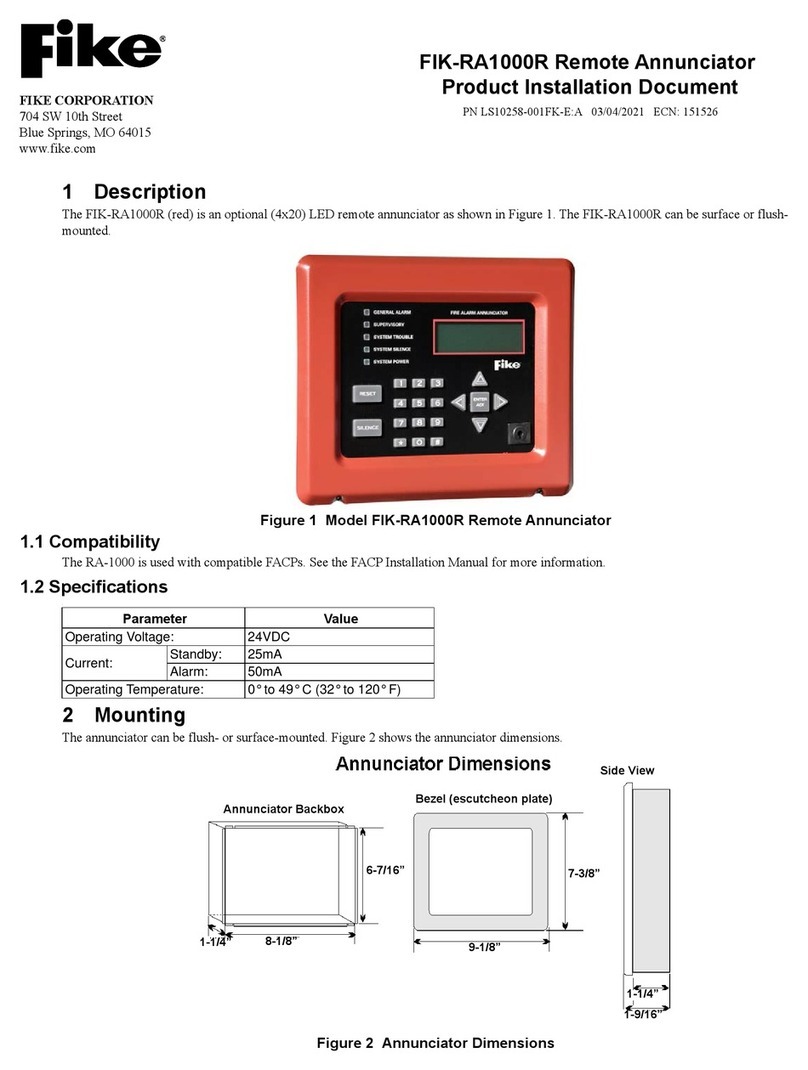

Fike FIK-RA1000R Technical manual

Fike

Fike FIK-W-PHOTO User manual

Fike

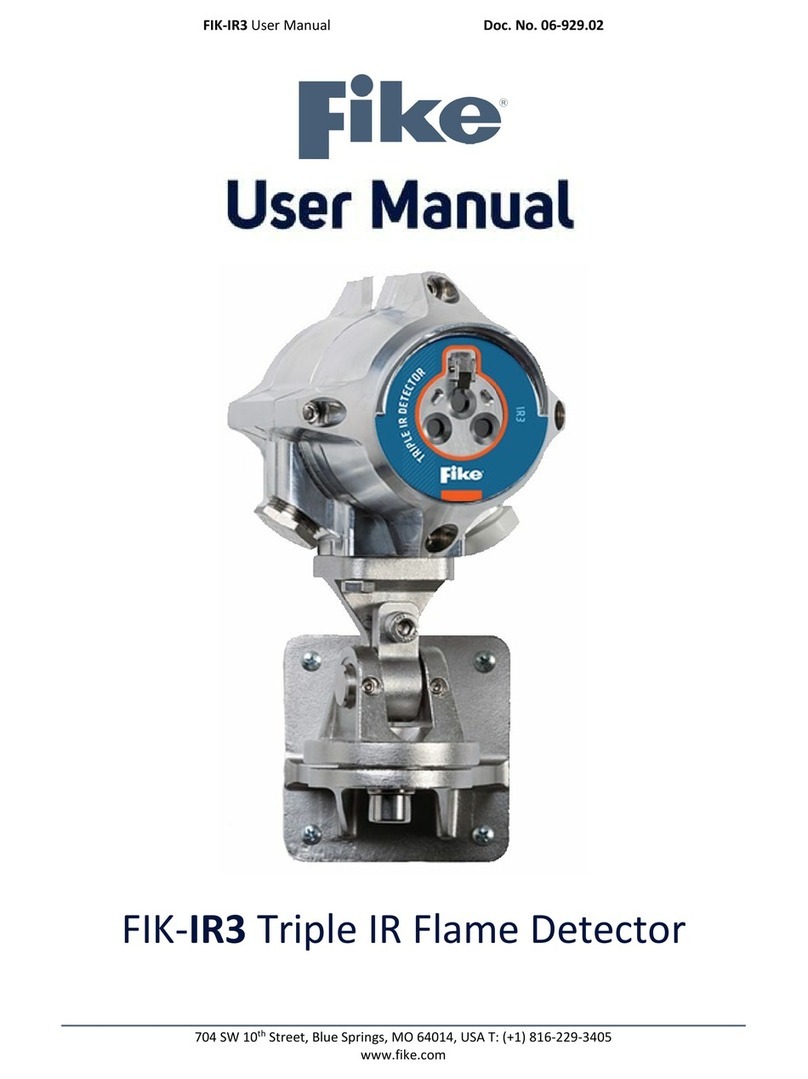

Fike FIK-IR3 User manual

Fike

Fike VESDA LaserCOMPACT VLC-500 User manual

Fike

Fike OCELUS Series User manual

Fike

Fike FIK-IR3-H2 User manual

Fike

Fike 204-0003 Twinflex Multipoint ASD User manual

Fike

Fike FIK-2351 User manual

Fike

Fike FIK-IR3-HD User manual

Popular Security Sensor manuals by other brands

SofTA

SofTA 1300 ELSD Installation and operation guide

Kilsen

Kilsen SK08A Installation sheet

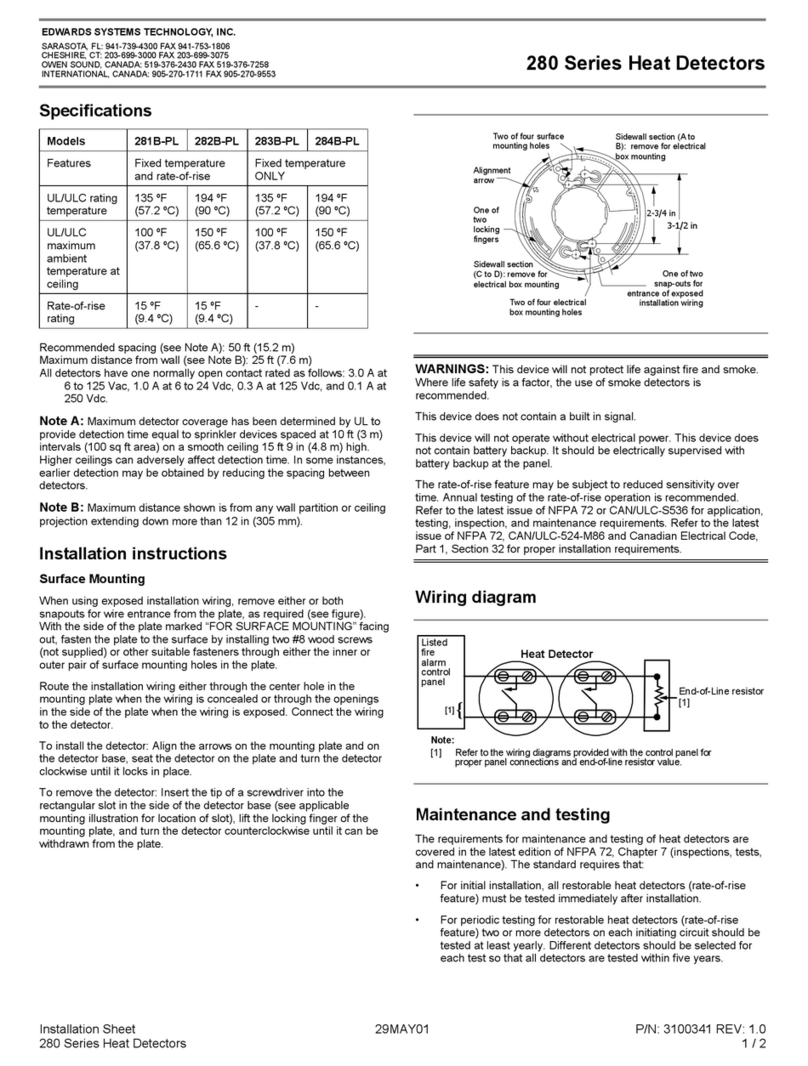

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY 280 Series Installation sheet

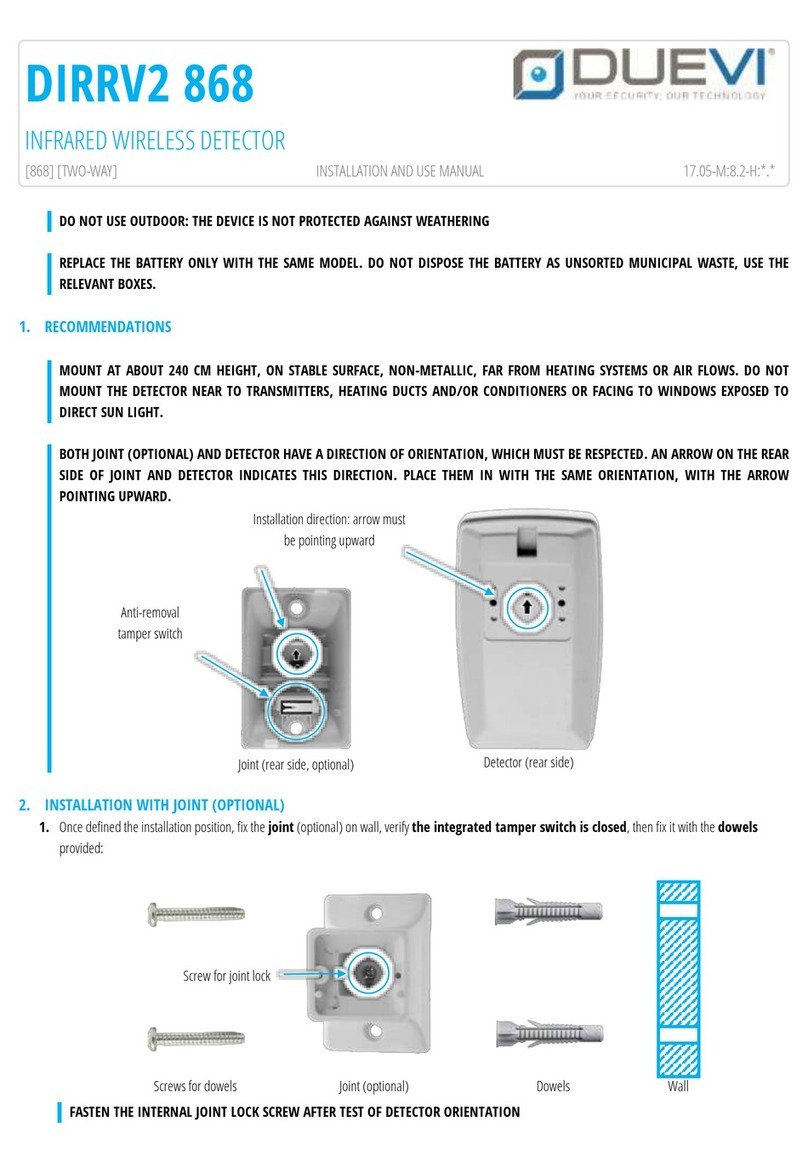

Duevi

Duevi DIRRV2 868 Installation and use manual

Optex

Optex MX-40QZ installation instructions

Honeywell

Honeywell Miller MightyLite Series User instruction manual supplement

Sentera Controls

Sentera Controls RCMFH-3 Mounting and operating instructions

Pulsar

Pulsar ADS MINI operating instructions

Emerson

Emerson Rosemount 389 quick start guide

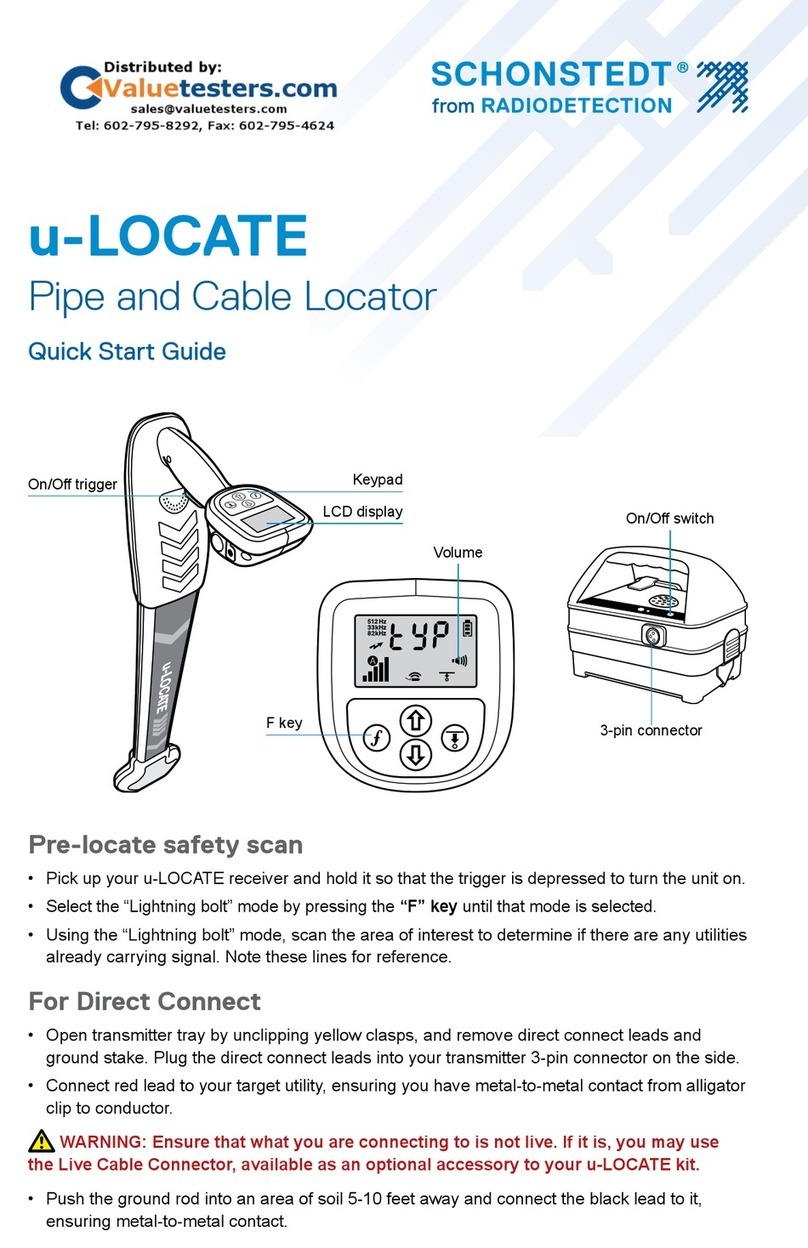

Radiodetection

Radiodetection Schonstedt u-LOCATE quick start guide

Eaton

Eaton xComfort CBMA-02/01 Instruction leaflet

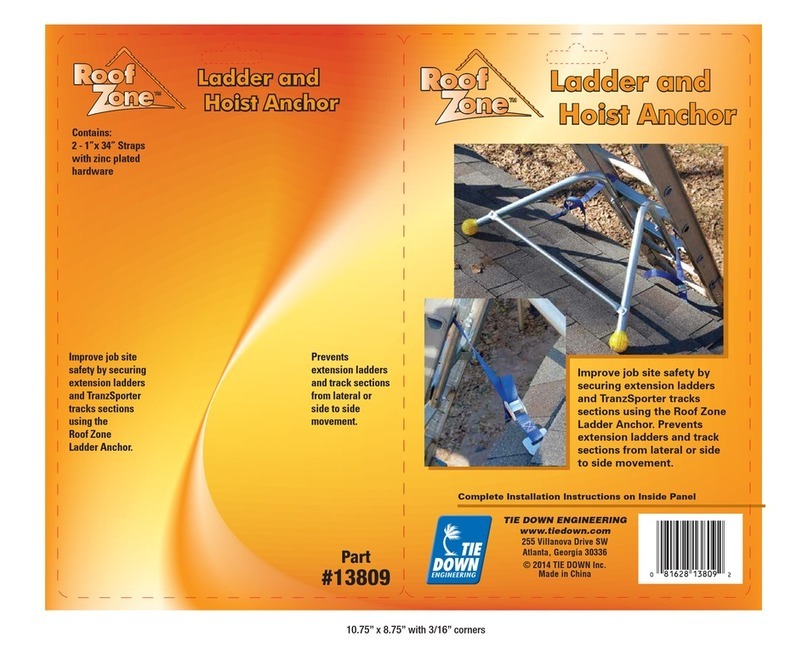

Tie Down Engineering

Tie Down Engineering Roof Zone 13809 installation instructions