Document No. 26-1773-1

Subject to change

Document No. 26-1773-1

Subject to change

Commissioning

The commissioning process regarding the loops and devices is covered in the Control Panel Engineering & Commissioning Manuals.

The repeater panel commissioning is only concerned with the functionality of the repeater panel itself.

Communications between the panel and repeater is via a multi-drop RS-485 Peripheral Bus.

2-core 1.5mm2 screened re resistant cable (i.e. FP200, Firetu, Firecell) cable should be used for communications to the repeater.

The maximum total cable length from the control panel to a repeater is 500 metres.

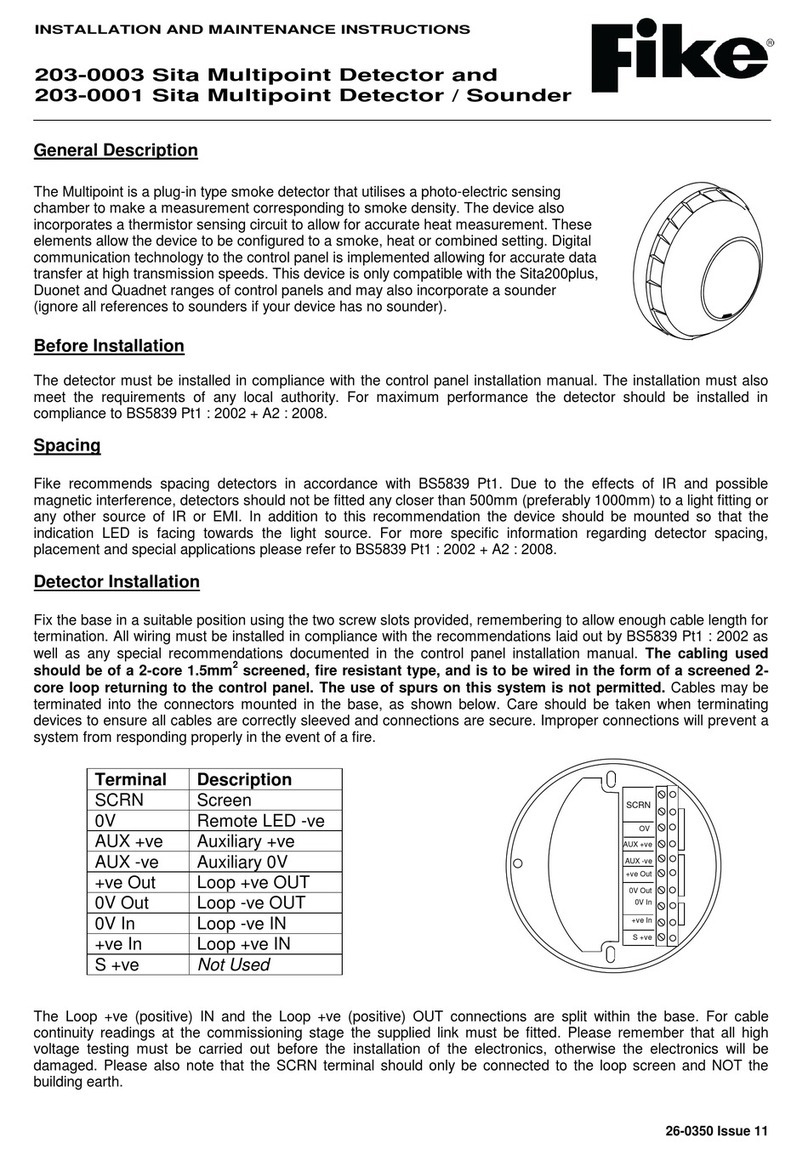

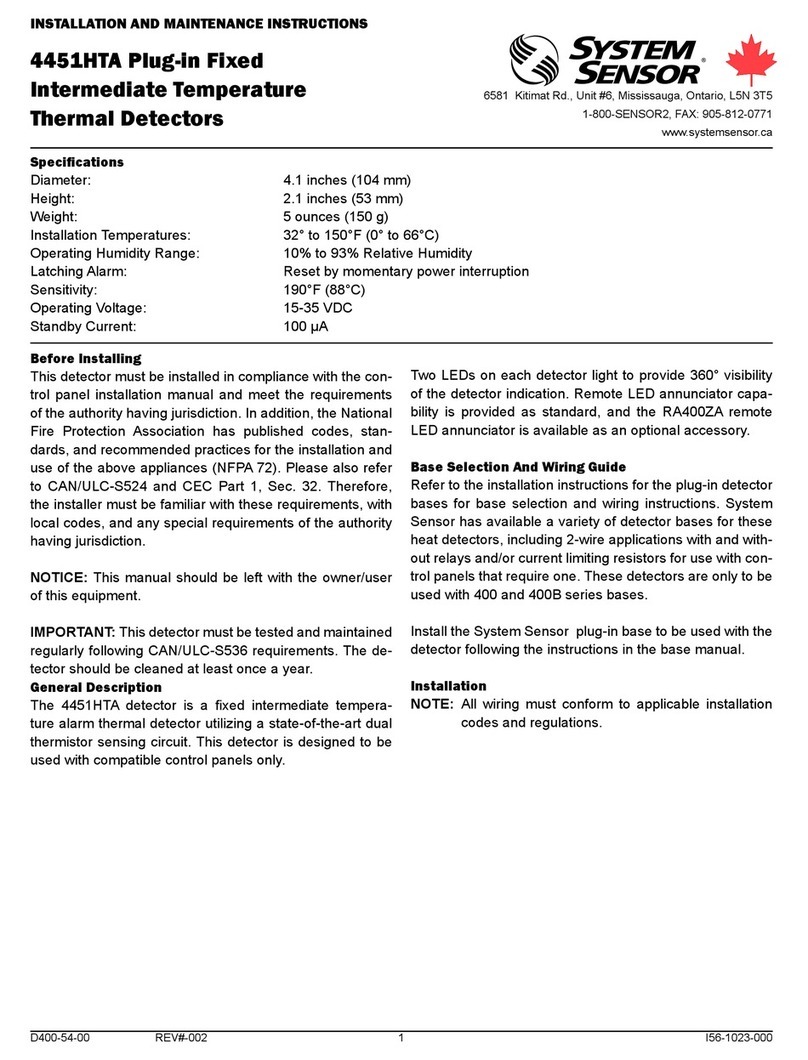

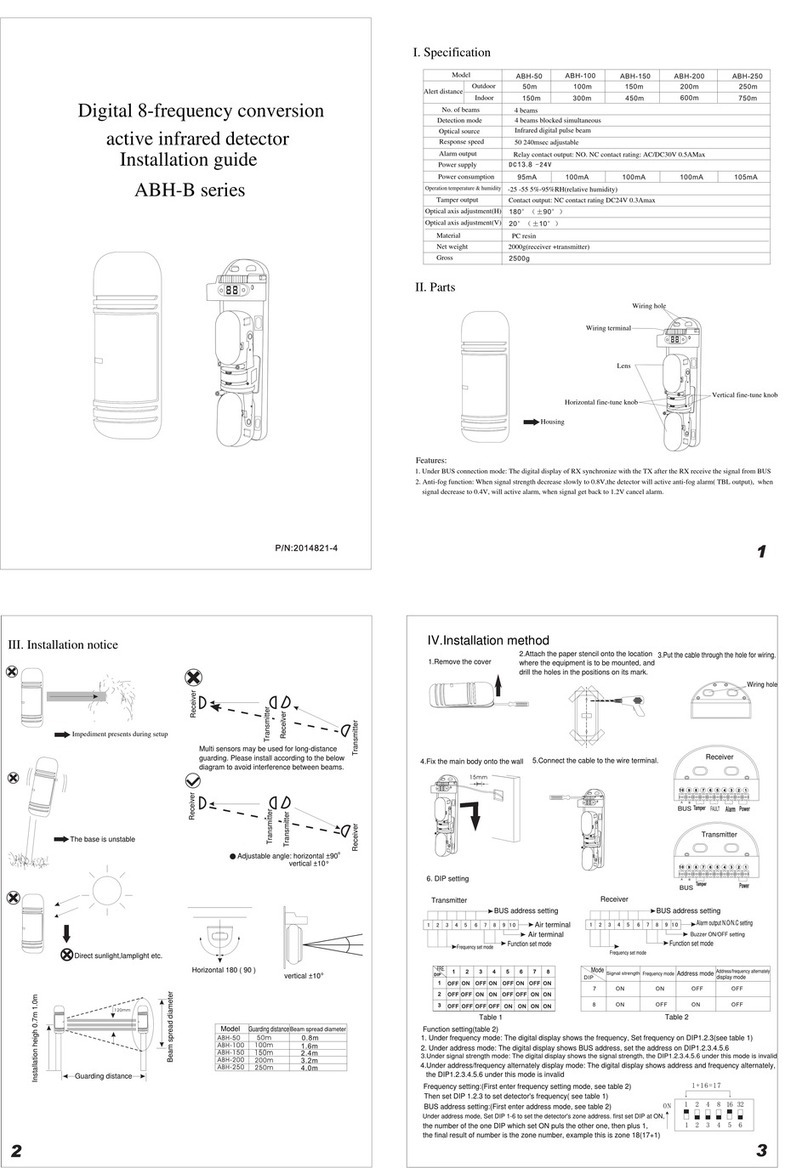

Up to 8 repeaters can be used but they must all be within the maximum 500 metres cable length and are wired + to +, - to -, the screen

must be connected to the control panel at one end only using the terminals provided. Terminate the unused end in a connector block

as shown below and so on up to the maximum of 8 repeaters.

The peripheral bus must be run from the panel to the rst repeater then the second repeater and so on; the peripheral bus must not

be spurred from one point.

The jumpers are tted to impedance match the cable with the driver ICs & prevent signal reections down the cable.

The commissioning engineer will require the peripheral bus continuity and insulation readings, along with correctly marked ‘as-wired’

drawings and completed conguration sheets in order to commission the repeater panel.

The system conguration must be downloaded into the repeater panel using the CIE-A-200 OSP programming software using a USB

lead to link to a computer. This procedure is exactly the same for the repeater panel as has been done on the main control panel.

However, the conguration must be the repeater panel conguration (including the panel type being repeater and the address being

the repeater address) and not the control panel conguration.

NOTE: It is imperative that the correct version of OSP is used to match your version of repeater panel. The use of an

incompatible version may result in incorrect operation of the repeater panel.

When the system conguration has been downloaded into the repeater panel, the commissioning engineer should verify that all the

re alarm system events are correctly reported on the repeater panel and the repeater panel controls operate correctly.

This will involve testing the system and therefore can be combined with the overall system commissioning process.

If the repeater panel has been tted as a system upgrade then a full system test should

be carried out to verify that all the re alarm system events are correctly reported on the

repeater panel and the repeater panel controls operate correctly.

SCRN SCRN

PB_1

--

++

PB_1

PANEL 1 PANEL 2

EOL

NOT EOL

RDU

EOL

END OF

LINE RDU

MOVE JUMPER