Fike Twinflex Multipoint 202-0003 User manual

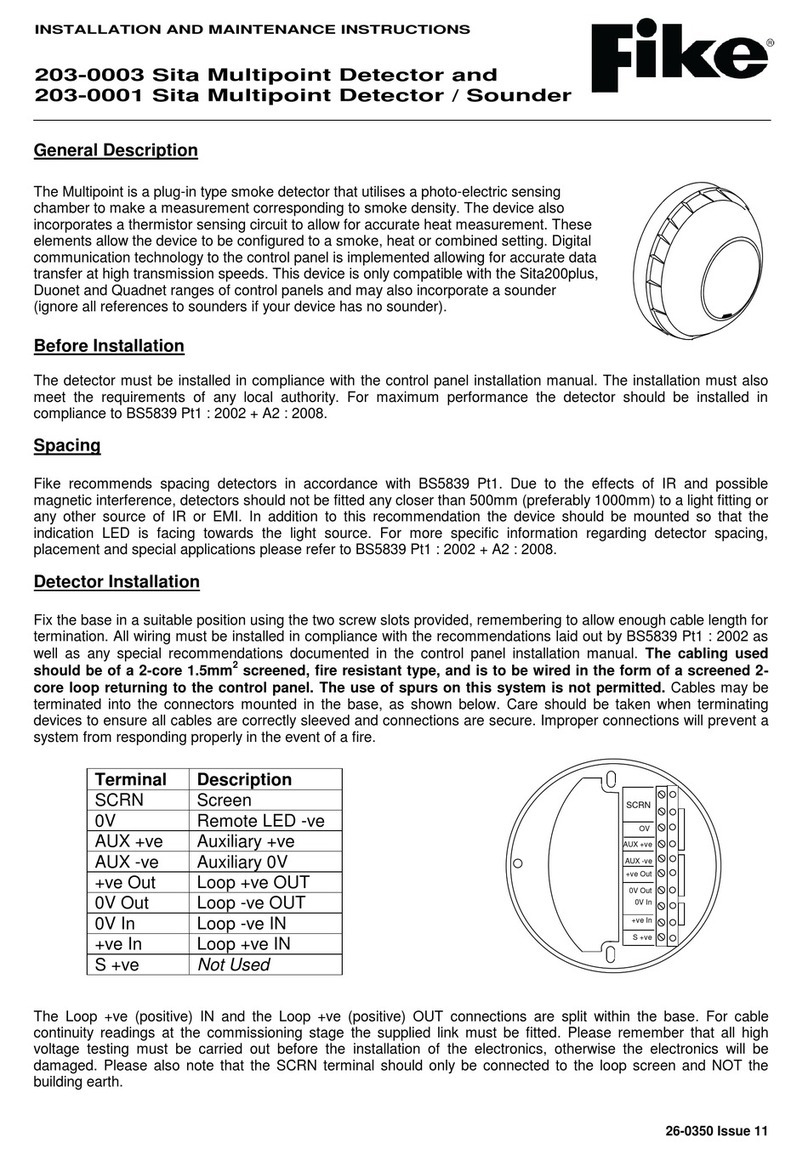

INSTALLATION AND MAINTENANCE INSTRUCTIONS

202-0003 Twinflex Multipoint Detector

202-0001 Twinflex Multipoint Detector

with Sounder

26-0027 Issue 12

General Description

The Multipoint is a plug-in type smoke detector that utilises a photo-electric sensing

chamber to make a measurement corresponding to smoke density. The device also

incorporates a thermistor sensing circuit to allow for accurate heat measurement. These

elements allow the device to be configured to a smoke, heat or combined setting. Digital

communication technology to the control panel is implemented allowing for accurate data

transfer at high transmission speeds. This device is only compatible with the Twinflex

control panels (and their associated detection and alarm equipment) and may also

incorporate a sounder (ignore all references to sounders if your device has no sounder).

Before Installation

The detector must be installed in compliance with the control panel installation manual. The installation must also

meet the requirements of any local authority. For maximum performance the detector should be installed in

compliance with BS5839 Pt1 : 2002 + A2 : 2008.

Spacing

Fike recommends spacing detectors in accordance with BS5839 Pt1. Due to the effects of IR and possible

magnetic interference, detectors should not be fitted any closer than 500mm (preferably 1000mm) to a light fitting or

any other source of IR or EMI. In addition to this recommendation the device should be mounted so that the

indication LED is facing towards the light fitting. For more specific information regarding detector spacing,

placement and special applications please refer to BS5839 Pt1 : 2002 + A2 : 2008.

Note: As with other optical detectors, this device should not be located where subjected to high levels or pulses of

light or infra red light, as this may cause false alarms or faults.

Detector Installation

All wiring must be installed in compliance with the recommendations laid out by BS5839 Pt1 : 2002 as well as any

special recommendations documented in the control panel installation manual. The cabling used should be of a 2-

core 1.5mm2screened, fire resistant type (e.g. MICC or FP200 equivalent), and is to be wired in the form of a

screened 2-core radial circuit (with no spurs) from the control panel, terminating at the last (“End of Line”) device.

Fix the detector base in a suitable position using the two screw slots provided, remembering to allow enough cable

length for termination. You may then terminate your cables directly into the terminal block according to the terminal

labels. It is important to maintain the screen continuity in order to protect against data corruption from interference.

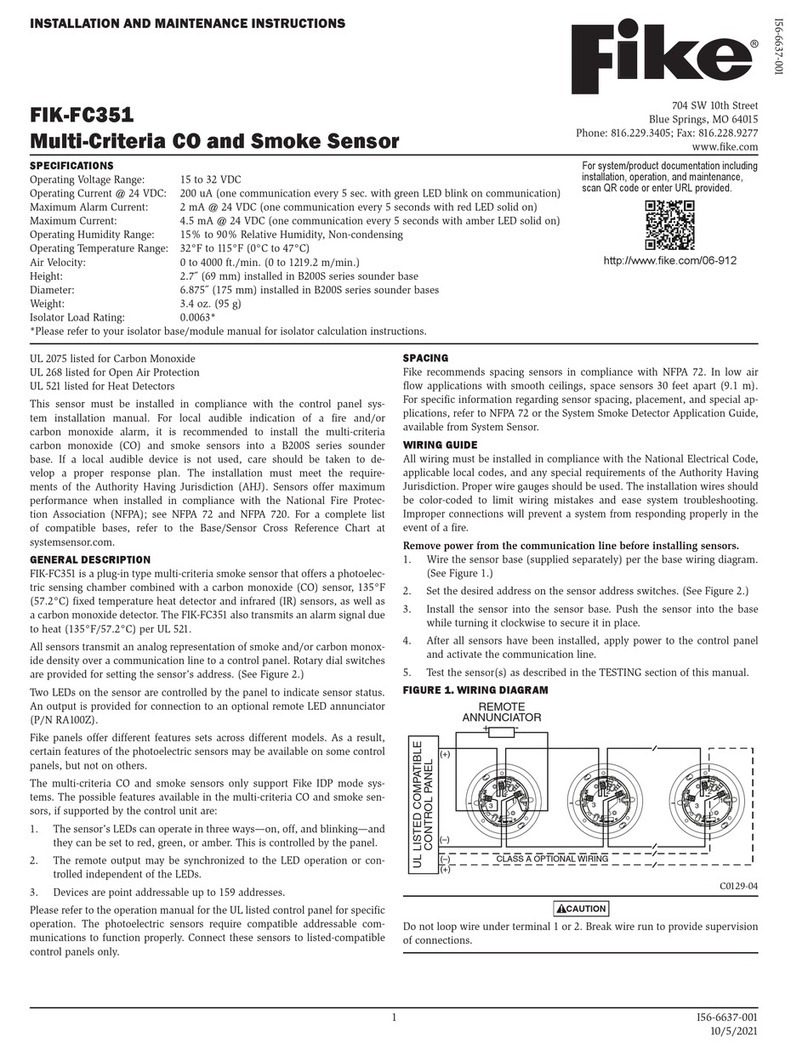

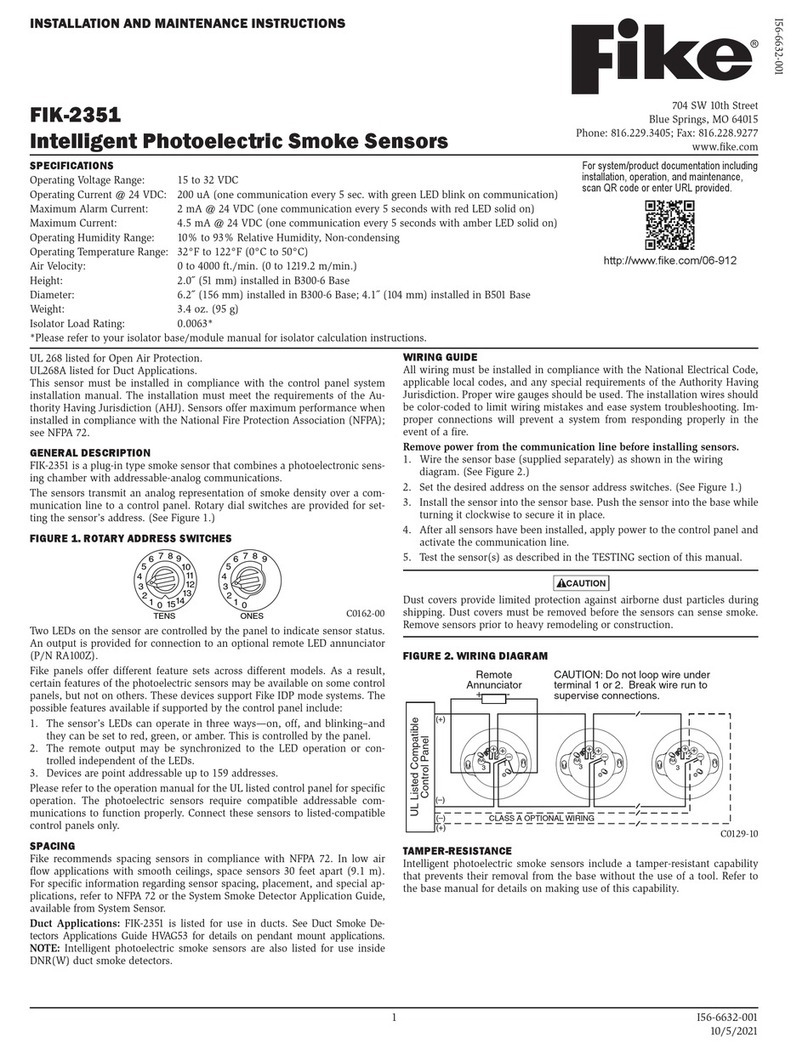

Connections

Terminal Description

SCRN Screen

0V Out Zone -ve out to next device

0V In Zone –ve in from panel

(or previous device)

– Remote LED Remote LED output -ve

+ Remote LED Remote LED output +ve

+ Line In Zone +ve in from panel

(or previous device)

+ Line Out Zone +ve out to next device

Note: The “+ Line Out” and “0V Out” terminals must

not be used on the last device in the zone.

0V In

0v Out

SCRN

+ Remote

LED

- Remote

LED

+ Line In

+ Line Out

Not connected

Not connected

26-0027 Issue 12

Twinflex Multipoint Detectors can be mixed on the same zone as other types of Twinflex device (eg. Twinflex

Callpoints). The above diagram shows how to make the zone positive, zone negative and screen connections

between the control panel and Twinflex Multipoint Detectors. Refer to the instruction leaflets supplied with other

Twinflex devices for their equivalent wiring/terminal labelling details.

Please note that the SCRN terminal on the detector bases should only be connected to the zone cable screen and

NOT to the building earth. The cable screen is connected to earth at the panel end only, via the zone “SCRN”

terminal (or EARTH terminal on the Twinflex V3 2/4/8 Zone panels). It is important to maintain the screen continuity

in order to protect against data corruption from interference.

Once all testing has been carried out on the cabling and ‘continuity & integrity’ has been proven, the Multipoint unit

may be assembled.

Program the onboard DIL switches as required before inserting the Electronics Module. Then locate the pins and

gently push home the module.

Remember that the device at the end of the line must have its EOL signal activated using the

relevant DIL switch. Do not use a resistor or capacitor (or another manufacturer’s End of Line

device) as the end of line, as this may prevent correct operation of the zone.

The Detector Head may then be offered up and twisted to locate until the catch operates. Remember not to force

this item. If the Electronics Module is correctly located then the Detector Head should locate with very little force.

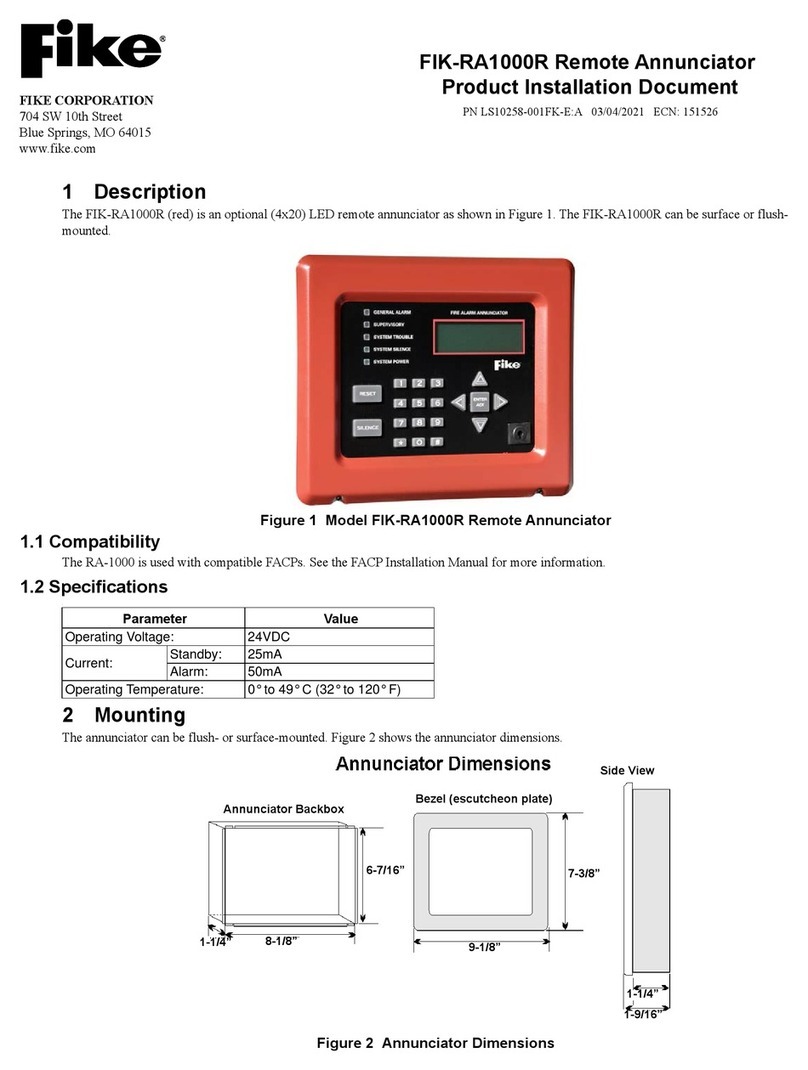

Tamper Resistance and Head Removal

The Multipoint detector incorporates a tamper resistant locking mechanism that

prevents its removal from the base without the use of a special tool. To remove the

device the tool should be offered up to the detector and turned anti-clockwise

allowing the detector to be removed from the base.

If required the Electronics Module may be removed by

inserting the Key into the triangular slot adjacent to the

LED and then pulling to ease the Module out. Do not

pull on the optical transmitter and receiver pair as you

may misalign them.

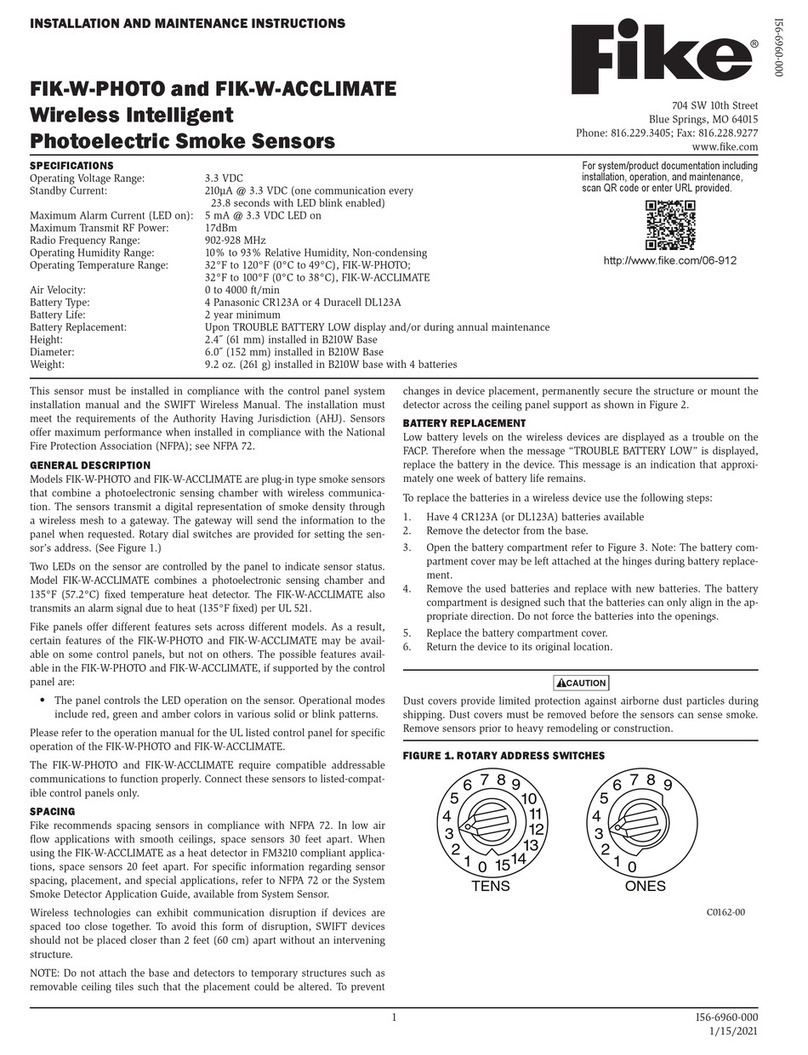

DIL Switch Settings

The detector DIL switches may be used to program the operation of

the Multipoint Detector. They may be altered when the device is

removed from the base.

If a heat detection mode is selected then use the ‘HEAT’ labels

supplied to label the base of the detector clearly.

The last device on the circuit must have the EOL signal enabled

(switch number 1 in the ‘ON’ position).

SWITCH OFF

SWITCH ON

1 2 3 4 5 6 7 8

O N

SCRN

ZONE -VE

ZONE +VE

+ Line In

+ Line Out

OV In

OV Out

SCRN

SCRN

+ Line In

+ Line Out

OV In

OV Out

SCRN

SCRN

TWINFLEX MULTIPOINT TWINFLEX MULTIPOINT

CONTROL PANEL

OPTICAL CHAMBER & HEAD

REMOVAL TOOL

ELECTRONICS MODULE &

REMOVAL KEY

26-0027 Issue 12

DIL SWITCH SETTINGS

1 2 3 4 5 6 7 8

EOL Signal Disabled (no end of line signal) OFF

Enabled ON

Detection Mode Disabled (no detection) OFF OFF OFF

Smoke 1 – Standard optical with high thermal

enhancement

ON OFF OFF

Smoke 2 – Standard optical with normal thermal

enhancement

OFF ON OFF

Smoke 3 – Low sensitivity optical with transient

rejection

ON ON OFF

Heat 1 – Rate of Rise 58

o

C, general use in normal,

stable environments

ON OFF ON

Heat 2 – Low fixed 58

o

C, Domestic kitchens etc OFF ON ON

Heat 3 – Hi Fixed 90

o

C, Commercial kitchens,

boiler rooms

ON ON ON

Smoke 2 / Heat 2 Combined OFF OFF ON

Logical Link * Logical link disabled OFF

Logical link enabled ON

Sound Pattern Disabled (no sound) OFF OFF

Sound 1 (Continuous tone at 970 Hz) ON OFF

Sound 2 (Alternating tone at 800/970 Hz) OFF ON

Sound 3 (Sweep up tone at 800 to 970 Hz) ON ON

Sounder vol Low OFF

High ON

* For use with Twinflex Checkpoint Plus Control panels only. The setting will be ignored on standard systems. With Logical Link enabled the

sounder in that device only will operate during the Alarm Confirmation period, and with the Logical Link disabled all the sounders in the same

zone as the device in alarm will operate during the Alarm Confirmation period.

Power Up

The Multipoint detector requires approximately one minute on power up to boot up its processor and settle down to

normal operation. Do not test the detector during this time. Ensure that the Detector Head is installed when the

system is powered up otherwise a fault condition will be present.

Head Contamination Warnings

If a smoke detector becomes dusty,its operation is affected, either making it more prone to false alarms, or in rare

cases reducing its sensitivity. The Multipoint LED will flash once approximately every 1.3 seconds. At the control

panel, the common ‘Fault’ LED will flash, the buzzer will sound and the relevant ‘Zone Fault’ LED will flash at

approximately twice the rate of the buzzer.

Replacing Contaminated Detector Head

The Detector Head contains the optical chamber. When an optical chamber becomes contaminated we recommend

replacing it with a new item. Cleaning an old chamber will not give satisfactory results. Firstly investigate the control

panel indications as above, then check the devices in the relevant zone to locate the Multipoint detector indicating

‘Fault’.

Remove the Detector Head with the Head Removal Tool and replace it with a new one. The fault indication should

clear in 30-45 seconds and return to normal.

Testing

We recommend the use of suitable smoke test equipment such as the ‘No Climb’ SOLO 300 tester or an equivalent

product. Due to the fact that the smoke detection modes are all ‘thermally enhanced’, it may be noticeable that on

test the devices respond more slowly than may be expected. This is perfectly normal and is due to the fact that

during test there is no additional heat present to cause the sensitivity to be enhanced.

Smoke mode 3 requires that the concentration of smoke is kept up for a longer period to trigger the device into

alarm, so patience is required. Small regular applications of test smoke are best in order to avoid drenching the

detector as this may result in sticky residues being left behind.

26-0027 Issue 12

Remote Indicator

The remote LED terminals (‘Remote LED + / -’) may be used to connect a separate

LED (Pt No. 600-0092). The LED functions are as follows:

•5ms every 5 seconds: End of Line

•5ms every 1.3 seconds: Fault

•350ms every 0.7 seconds: Fire detected by detector

•Continuous: Fire detected by detector and processed at panel

Note that the LED does not require a resistor.

Technical Data

Dimensions .................................................................105mm diameter x 62mm

Operating temperature .................................................................-10oC to +50oC

Voltage Ranges DC Output from Mains Powered Panel ...25.5 to 35V DC

DC Output from Battery Powered Panel..20 to 26V DC

Operating Current Quiescent ................................................114 uA (Typical)

End of line ON if applicable .....................50 uA (Typical)

(in addition to Quiescent)

Alarm Sounding – Sounder High.............8 mA (Typical)

Alarm Sounding – Sounder Low..............3.5 mA (Typical)

Alarm Sounding – Sounder Off ...............1.5 mA (Typical)

Alarm Activated .......................................48.5 mA (Typical)

(in addition to Alarm Sounding)

LED Operation Detector in Normal State. ........................Flash at 20 second intervals

Detector at EOL.......................................Flash at 5 second intervals

Detector in Fault. .....................................Flash at 1.3 second intervals

Detector Detecting Fire ...........................Flash at 0.7 second intervals

Detector in Fire (once processed at panel) Continuous

Loading Units V3 Panel: Pro Panel:

Max Loading Units per zone....................27 SLU ........ 160 DLU

Sounder High...........................................1.5 SLU ....... 8.0 DLU

Sounder Low ...........................................1.0 SLU ....... 3.5 DLU

No Sounder .............................................0.5 SLU ....... 1.5 DLU

Volume Level Sounder High...........................................89+ dB(A)

(@ 1m anechoic, Dual Tone) Sounder Low ...........................................65+ dB(A)

Flammability .................................................................UL94-V2

IP Rating .................................................................IP 21C

Part Codes No Sounder .............................................202 0003

With Sounder...........................................202 0001

0832

Fike Safety Technology Ltd,

31 Springvale Ind Est,

Cwmbran, UK. NP44 5BD

(Manufactured Date on Product Label)

0832-CPD-1572

0832-CPD-1573

EN54-3 Fire Alarm Device – Sounder

Type A – Indoor Use

EN54-5 Fire Alarm Device – Heat detector

EN54-7 Fire Alarm Device – Smoke detector

Sounder Technical Data: See 26-0747

Technical Support

Contact your supplier for technical support on this product.

Due to the complexity and inherent importance of a life risk type

system, training on this equipment is essential, and commissioning

should only be carried out by competent persons. Fike cannot

guarantee the operation of any equipment unless all documented

instructions are complied with, without variation. This unit complies

with the EMC directive.

Fike’s policy is one of continual improvement and the right to change

a specification at any time without notice is reserved. Whilst every

care has been taken to ensure that the contents of this document are

correct at time of publication, Fike shall be under no liability

whatsoever in respect of such contents. E&OE.

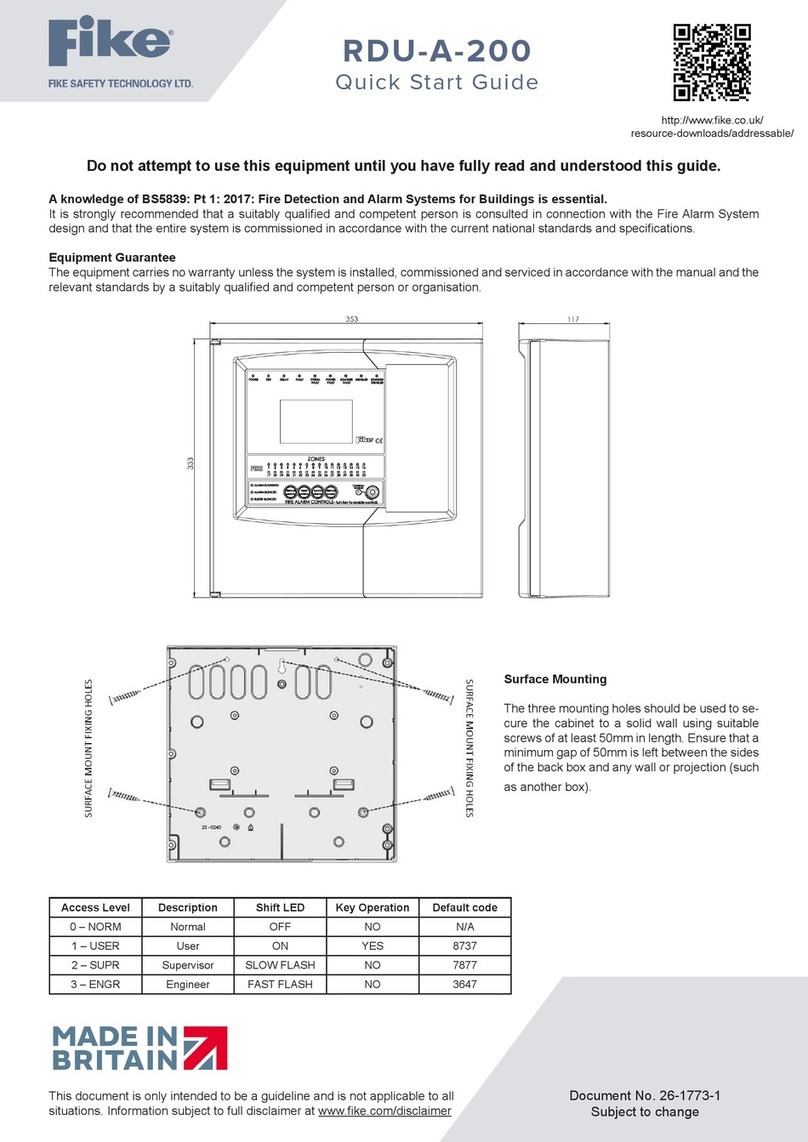

This manual suits for next models

1

Table of contents

Other Fike Security Sensor manuals

Fike

Fike FIK-IR3-HD User manual

Fike

Fike Sita User manual

Fike

Fike CEREX User manual

Fike

Fike FIK-IR3-H2-HD User manual

Fike

Fike 60-1039 User manual

Fike

Fike RDU-A-200 User manual

Fike

Fike OCELUS Series User manual

Fike

Fike 323-0001 User manual

Fike

Fike FIK-UV-IR-HD Series User manual

Fike

Fike FIK-IR3-H2 User manual

Fike

Fike FIK-IR3 User manual

Fike

Fike VESDA LaserCOMPACT VLC-500 User manual

Fike

Fike CIE-A-200 User manual

Fike

Fike FIK-W-PULL-DA User manual

Fike

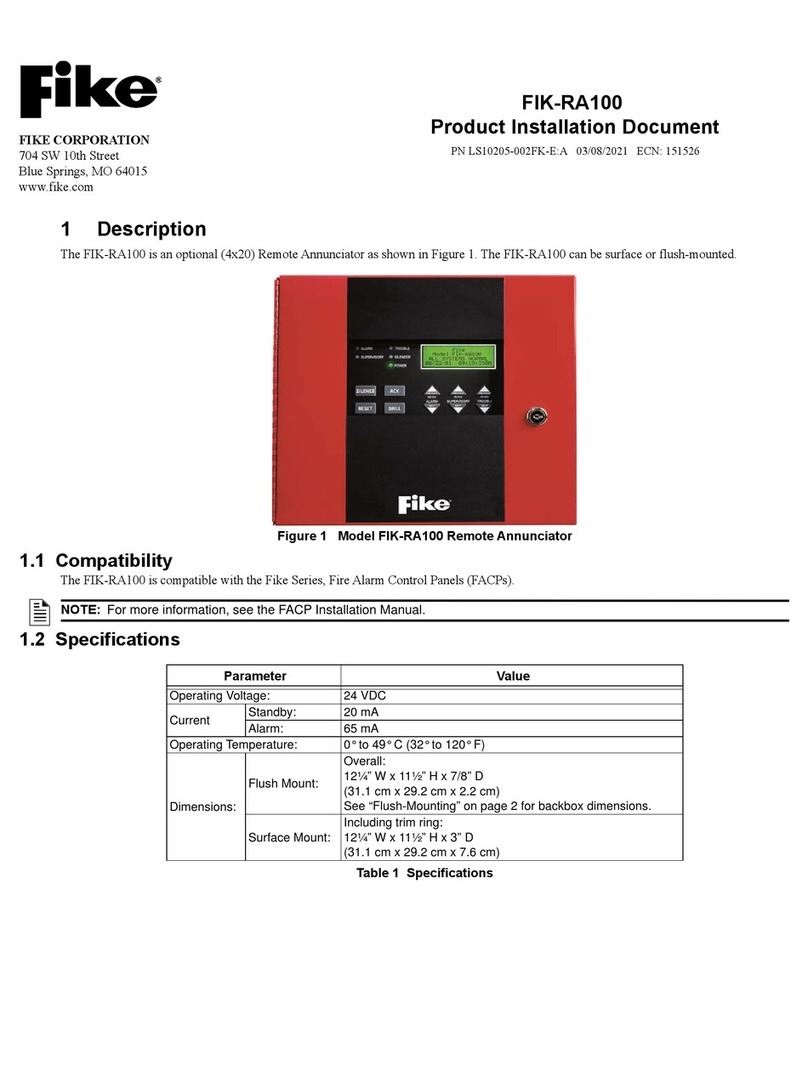

Fike FIK-RA100 Technical manual

Fike

Fike FIK-FC351 User manual

Fike

Fike FIK-RA1000R Technical manual

Fike

Fike 204-0003 Twinflex Multipoint ASD User manual

Fike

Fike FIK-W-PHOTO User manual

Fike

Fike FIK-2351 User manual