This sensor must be installed in compliance with the control panel system

installation manual and the SWIFT Wireless Manual. The installation must

meet the requirements of the Authority Having Jurisdiction (AHJ). Sensors

offer maximum performance when installed in compliance with the National

Fire Protection Association (NFPA); see NFPA 72.

GENERAL DESCRIPTION

Models FIK-W-PHOTO and FIK-W-ACCLIMATE are plug-in type smoke sensors

that combine a photoelectronic sensing chamber with wireless communica-

tion. The sensors transmit a digital representation of smoke density through

a wireless mesh to a gateway. The gateway will send the information to the

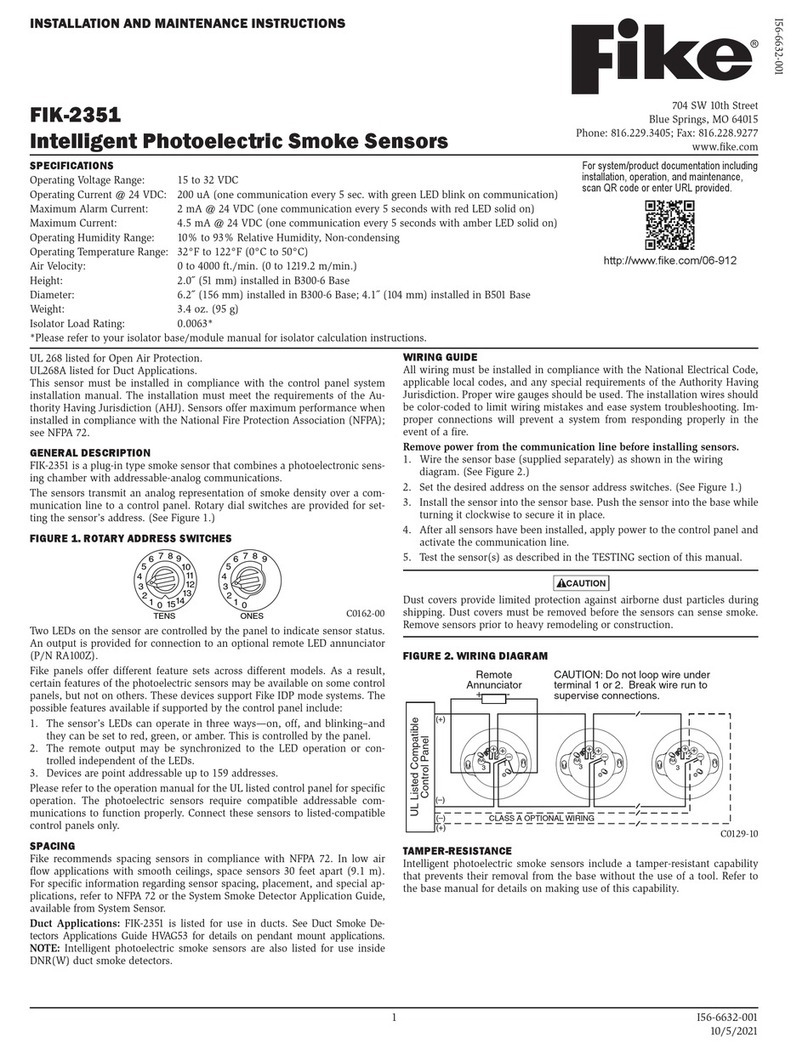

panel when requested. Rotary dial switches are provided for setting the sen-

sor’s address. (See Figure 1.)

Two LEDs on the sensor are controlled by the panel to indicate sensor status.

Model FIK-W-ACCLIMATE combines a photoelectronic sensing chamber and

135°F (57.2°C) fixed temperature heat detector. The FIK-W-ACCLIMATE also

transmits an alarm signal due to heat (135°F fixed) per UL 521.

Fike panels offer different features sets across different models. As a result,

certain features of the FIK-W-PHOTO and FIK-W-ACCLIMATE may be avail-

able on some control panels, but not on others. The possible features avail-

able in the FIK-W-PHOTO and FIK-W-ACCLIMATE, if supported by the control

panel are:

• The panel controls the LED operation on the sensor. Operational modes

include red, green and amber colors in various solid or blink patterns.

Please refer to the operation manual for the UL listed control panel for specific

operation of the FIK-W-PHOTO and FIK-W-ACCLIMATE.

The FIK-W-PHOTO and FIK-W-ACCLIMATE require compatible addressable

communications to function properly. Connect these sensors to listed-compat-

ible control panels only.

SPACING

Fike recommends spacing sensors in compliance with NFPA 72. In low air

flow applications with smooth ceilings, space sensors 30 feet apart. When

using the FIK-W-ACCLIMATE as a heat detector in FM3210 compliant applica-

tions, space sensors 20 feet apart. For specific information regarding sensor

spacing, placement, and special applications, refer to NFPA 72 or the System

Smoke Detector Application Guide, available from System Sensor.

Wireless technologies can exhibit communication disruption if devices are

spaced too close together. To avoid this form of disruption, SWIFT devices

should not be placed closer than 2 feet (60 cm) apart without an intervening

structure.

NOTE: Do not attach the base and detectors to temporary structures such as

removable ceiling tiles such that the placement could be altered. To prevent

I56-6960-000

INSTALLATION AND MAINTENANCE INSTRUCTIONS

changes in device placement, permanently secure the structure or mount the

detector across the ceiling panel support as shown in Figure 2.

BATTERY REPLACEMENT

Low battery levels on the wireless devices are displayed as a trouble on the

FACP. Therefore when the message “TROUBLE BATTERY LOW” is displayed,

replace the battery in the device. This message is an indication that approxi-

mately one week of battery life remains.

To replace the batteries in a wireless device use the following steps:

1. Have 4 CR123A (or DL123A) batteries available

2. Remove the detector from the base.

3. Open the battery compartment refer to Figure 3. Note: The battery com-

partment cover may be left attached at the hinges during battery replace-

ment.

4. Remove the used batteries and replace with new batteries. The battery

compartment is designed such that the batteries can only align in the ap-

propriate direction. Do not force the batteries into the openings.

5. Replace the battery compartment cover.

6. Return the device to its original location.

Dust covers provide limited protection against airborne dust particles during

shipping. Dust covers must be removed before the sensors can sense smoke.

Remove sensors prior to heavy remodeling or construction.

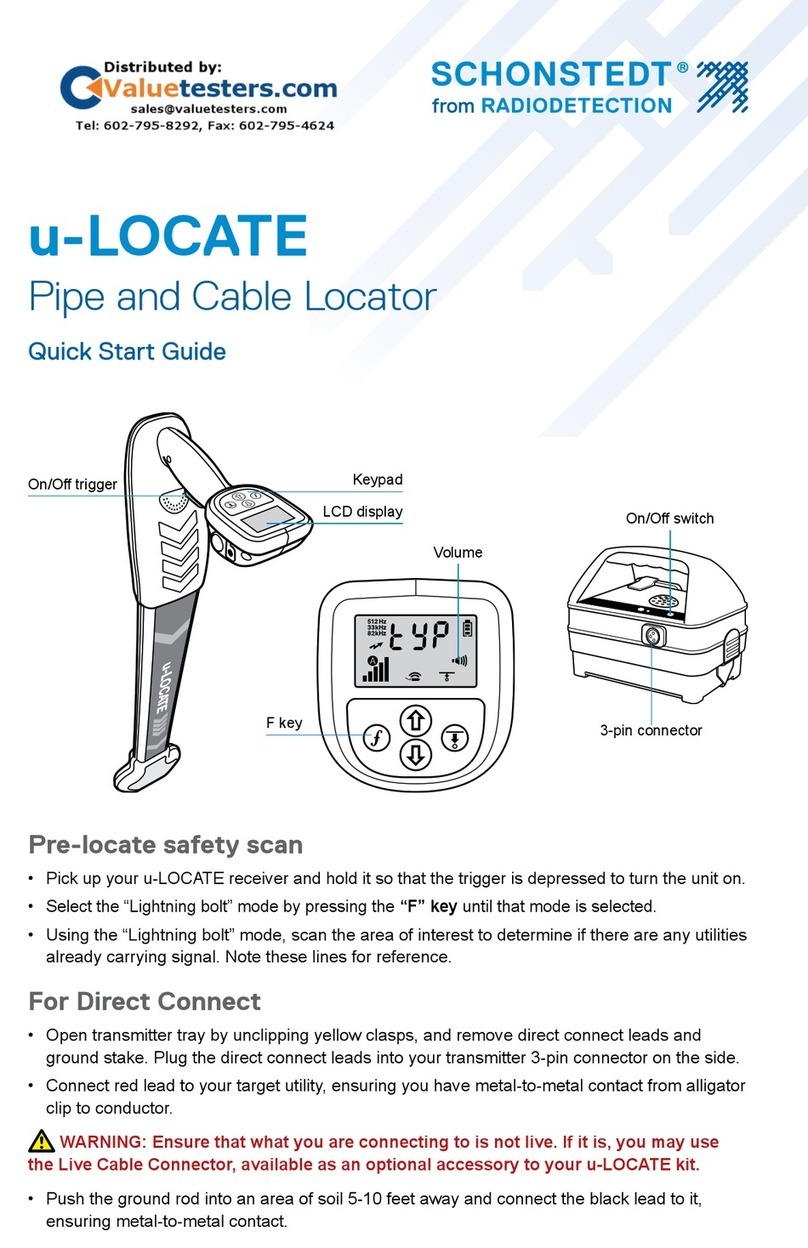

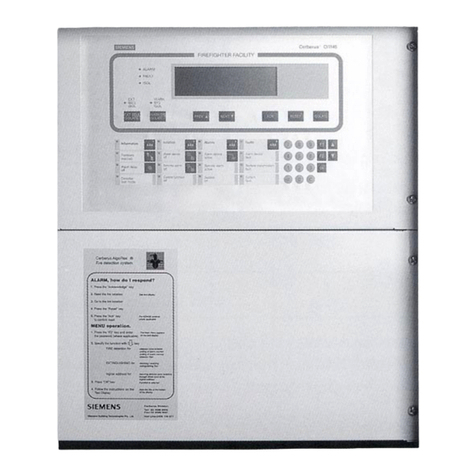

FIGURE 1. ROTARY ADDRESS SWITCHES

TENS ONES

9

10

11

12

13

14

15

8

7

6

5

4

3

210

9

8

7

6

5

4

3

210

C0162-00

SPECIFICATIONS

Operating Voltage Range: 3.3 VDC

Standby Current: 210µA @ 3.3 VDC (one communication every

23.8 seconds with LED blink enabled)

Maximum Alarm Current (LED on): 5 mA @ 3.3 VDC LED on

Maximum Transmit RF Power: 17dBm

Radio Frequency Range: 902-928 MHz

Operating Humidity Range: 10% to 93% Relative Humidity, Non-condensing

Operating Temperature Range: 32°F to 120°F (0°C to 49°C), FIK-W-PHOTO;

32°F to 100°F (0°C to 38°C), FIK-W-ACCLIMATE

Air Velocity: 0 to 4000 ft/min

Battery Type: 4 Panasonic CR123A or 4 Duracell DL123A

Battery Life: 2 year minimum

Battery Replacement: Upon TROUBLE BATTERY LOW display and/or during annual maintenance

Height: 2.4˝ (61 mm) installed in B210W Base

Diameter: 6.0˝ (152 mm) installed in B210W Base

Weight: 9.2 oz. (261 g) installed in B210W base with 4 batteries

R

704 SW 10th Street

Blue Springs, MO 64015

Phone: 816.229.3405; Fax: 816.228.9277

www.fike.com

FIK-W-PHOTO and FIK-W-ACCLIMATE

Wireless Intelligent

Photoelectric Smoke Sensors

http://www.fike.com/06-912

Fo

r system/product documentation including

installation, operation, and maintenance,

scan QR code or enter URL provided.

1 I56-6960-000

1/15/2021