ADJUSTMENT AND

INSPECTION MR60 65/75/85

Doc. 10023982

Emesso Giugno 2011

Ver. AB

Pag. 3 di 16

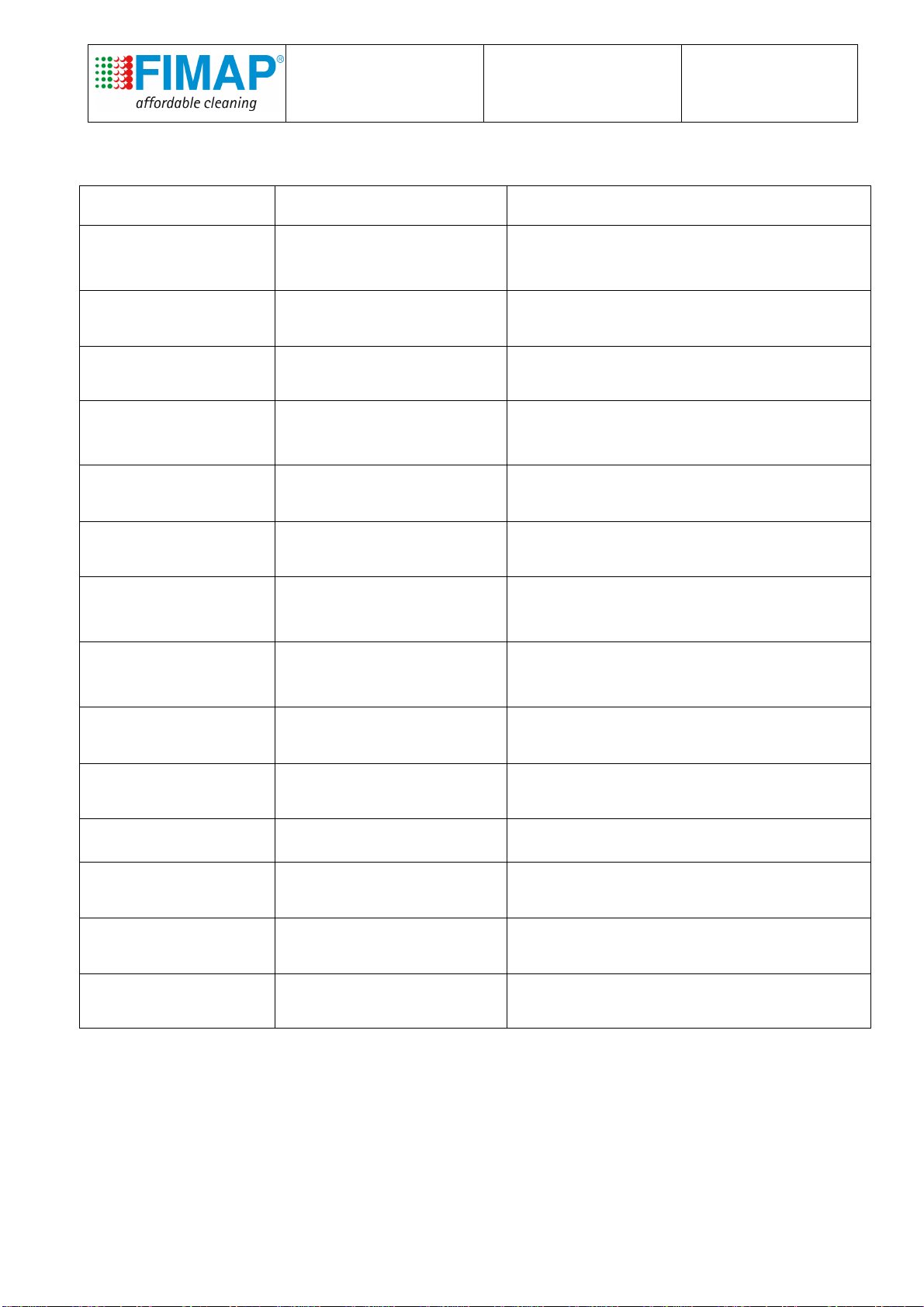

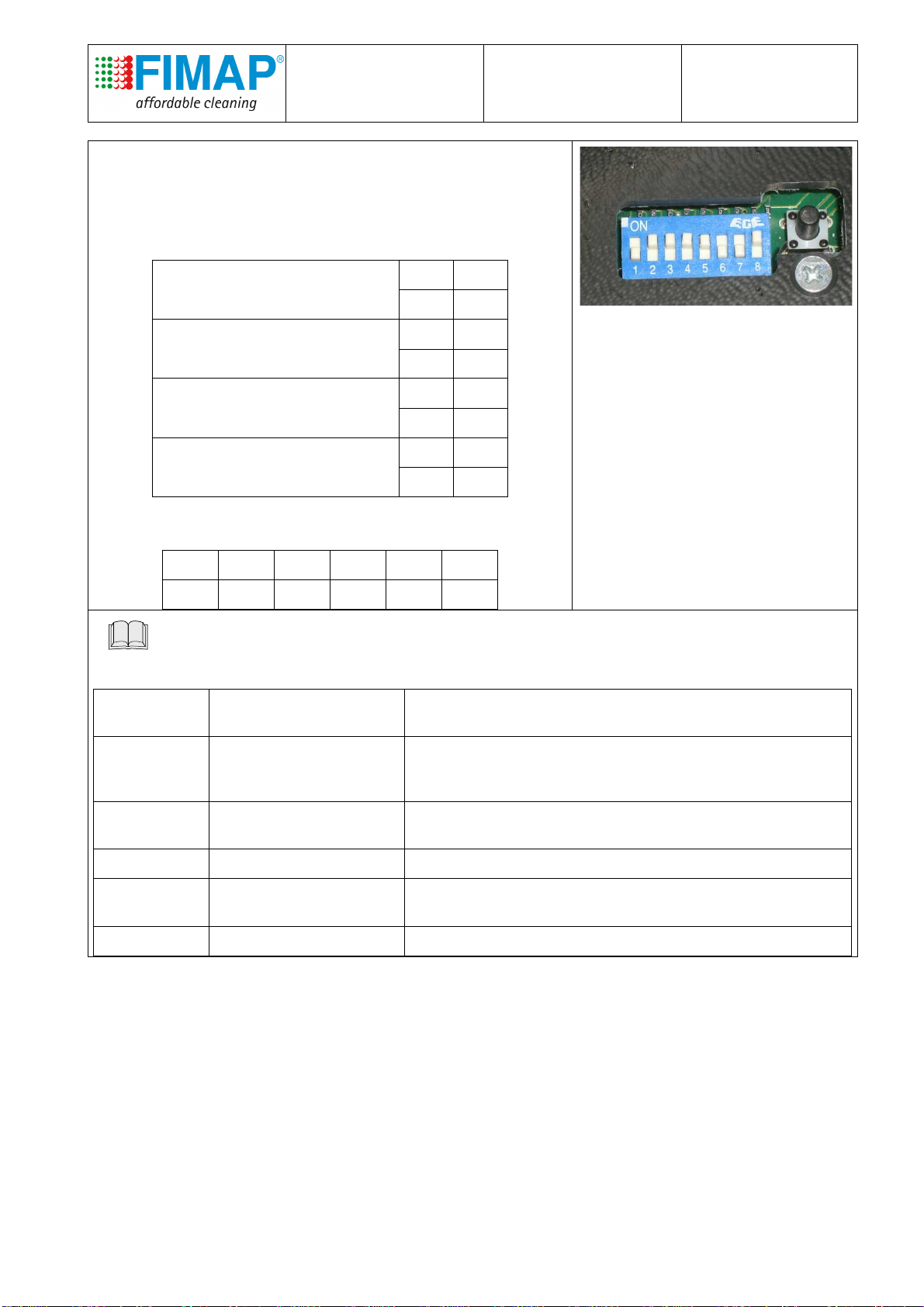

ALARM TABLE

Message Alarm What to do

ALARM A1

FW Switch ON Forward micro-switch on

in turning on.

Put the potentiometer in idle position and

check that the forward micro-switch is

open.

ALARM A2

BW Switch ON Backward micro-switch

on in turning on. Let the pedal stay in idle position and

open the backward micro-switch.

ALARM A3

Pot. FAULT Potentiometer error Check the potentiometer harness.

ALARM A4

Ref OUT Neutral Potentiometer not

correclty positioned

Put the potentiometer in the idle position

or if it already is in the right position,

adjust the potentiometer program.

ALARM A5

Over temperature Thermal protection Wait for 5 minutes and then check the

traction motor absorption rate.

ALARM A6

POWER STAGE Damaged power stage Replace the chopper card.

ALARM A7

OVERCURRENT Overcurrent Check the motor cables: If connections

are regular and repeat the alarm, replace

the chopper card.

ALARM A8 POWER

FUSE/RELAY Power fuse or internal

contactor damaged

Check the fuse on the + battery and

wiring, replace the chopper card if it

persists (General relay damaged).

ALARM A9

UNDERVOLTAGE Undervoltage Check the batteries for poor voltage.

ALARM A10

OVERVOLTAGE Overvoltage Battery voltage greater than 45V: check

battery status

Overload Current Current protection Check the motor current and possibly trim

the electronic current control

ALARM A12

DISABLE ON Disabling active Check the status of the disabled.

ALARM A13

KEY-OFF Turn off sequence active Check the wiring on the ignition power

key.

ALARM A14

EEPROM FAIL E²prom data reading

failed Check the settings: if the alarm is

repeated, replace the chopper card.