SCRUBBING WITHOUT DRYING ....................................................................................................................... 24

DRYING................................................................................................................................................................ 25

SCRUBBING WITH DRYING ............................................................................................................................... 26

SMART DRYING MODE ...................................................................................................................................... 27

REVERSE FUNCTION......................................................................................................................................... 27

BUZZER ............................................................................................................................................................... 27

EXTRA BRUSH HEAD PRESSURE .................................................................................................................... 27

WORKING HEADLIGHTS.................................................................................................................................... 28

EMERGENCY BUTTON....................................................................................................................................... 28

BRAKING CONTROL........................................................................................................................................... 28

ALARM SCREEN ................................................................................................................................................. 29

HOUR METER ..................................................................................................................................................... 30

TUTORIAL............................................................................................................................................................ 30

BATTERY CHARGE LEVEL INDICATOR ............................................................................................................ 30

OVERFLOW DEVICE .......................................................................................................................................... 31

OPTIONAL FUNCTIONS ..........................................................................................................31

REAR VIDEO CAMERA....................................................................................................................................... 31

DETERGENT SOLUTION RECYCLING SYSTEM (FLR VERSIONS) ................................................................ 31

AUTOMATIC DETERGENT DOSING SYSTEM (FSS VERSIONS) .................................................................... 31

SIDE BRUSH ....................................................................................................................................................... 32

AUTOMATIC REQUEST FOR TECHNICAL ASSISTANCE (FFM VERSION) ..................................................... 32

LIQUID SUCTION WAND KIT.............................................................................................................................. 32

SPRAY GUN KIT .................................................................................................................................................. 33

AT THE END OF THE WORK...................................................................................................34

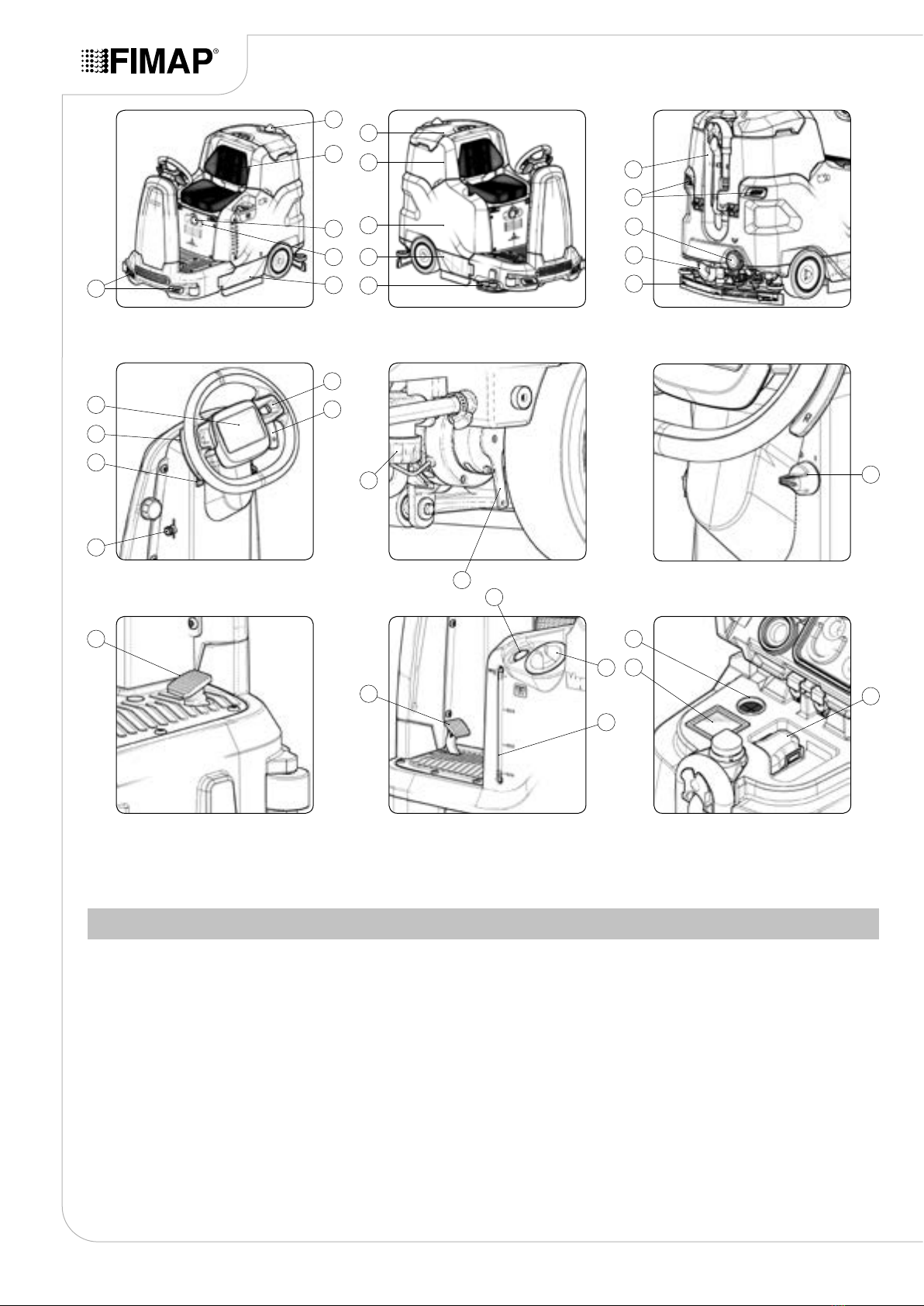

ROUTINE MAINTENANCE.......................................................................................................34

DRAINING THE RECOVERY TANK .................................................................................................................... 35

EMPTYING THE DEBRIS HOPPER (SWEEPING VERSION)............................................................................ 35

CLEANING THE SQUEEGEE BODY................................................................................................................... 35

CLEANING THE BRUSH HEAD BRUSHES (SCRUBBING VERSION).............................................................. 36

CLEANING THE BRUSH HEAD BRUSHES (SWEEPING VERSION)................................................................ 36

CLEANING THE LATERAL BRUSH (SCRUBBING VERSION)........................................................................... 36

CLEANING THE LATERAL BRUSH (SWEEPING VERSION)............................................................................. 36

CLEANING THE RECOVERY TANK FILTERS .................................................................................................... 37

CLEANING THE RECYCLE FILTER (FLR VERSIONS)...................................................................................... 37

EMPTYING THE SOLUTION TANK..................................................................................................................... 37

CLEANING THE WATER SYSTEM FILTER ........................................................................................................ 38

CLEANING THE VACUUM TUBE........................................................................................................................ 38

EXTRAORDINARY MAINTENANCE........................................................................................38

REPLACING THE SQUEEGEE BODY RUBBER BLADES................................................................................. 39

REPLACING THE BRUSH HEAD SPLASH GUARD........................................................................................... 39

REPLACING THE SIDE SQUEEGEE SPLASHGUARD RUBBER BLADES ...................................................... 39

FILLING BRAKING SYSTEM OIL BASIN ............................................................................................................ 39

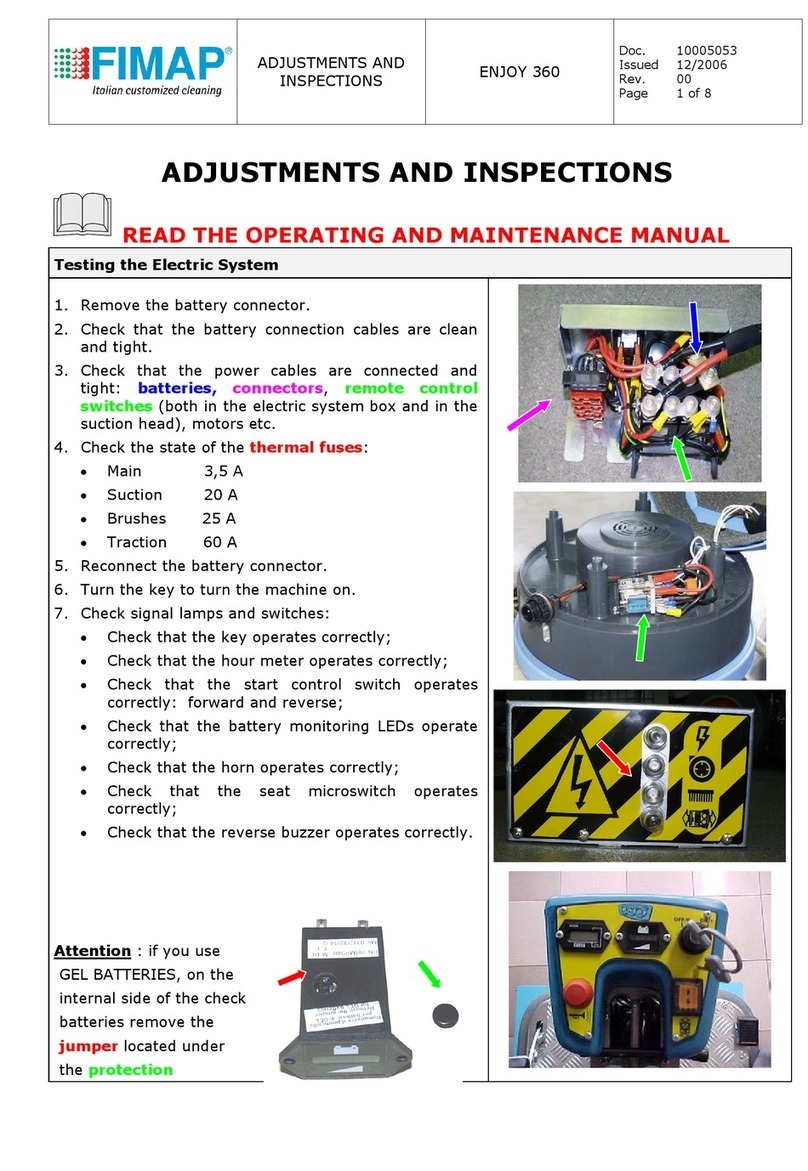

ADJUSTMENT INTERVENTIONS............................................................................................40

ADJUSTING THE SQUEEGEE BODY'S RUBBER BLADES .............................................................................. 40

ADJUSTING THE BRUSH HEAD BODY SIDE SPLASH GUARDS (SCRUBBING VERSION) .......................... 41

ADJUSTING THE SIDE BRUSH (SWEEPING VERSION).................................................................................. 42

DISPOSAL ................................................................................................................................42

TROUBLESHOOTING ..............................................................................................................43

EC DECLARATION OF CONFORMITY ...................................................................................45

4