SUMMARY

ON CONSIGNMENT OF THE MACHINE............................................................................................................................... 35

INTRODUCTORY COMMENT............................................................................................................................................... 35

TECHNICAL DATA............................................................................................................................................................... 35

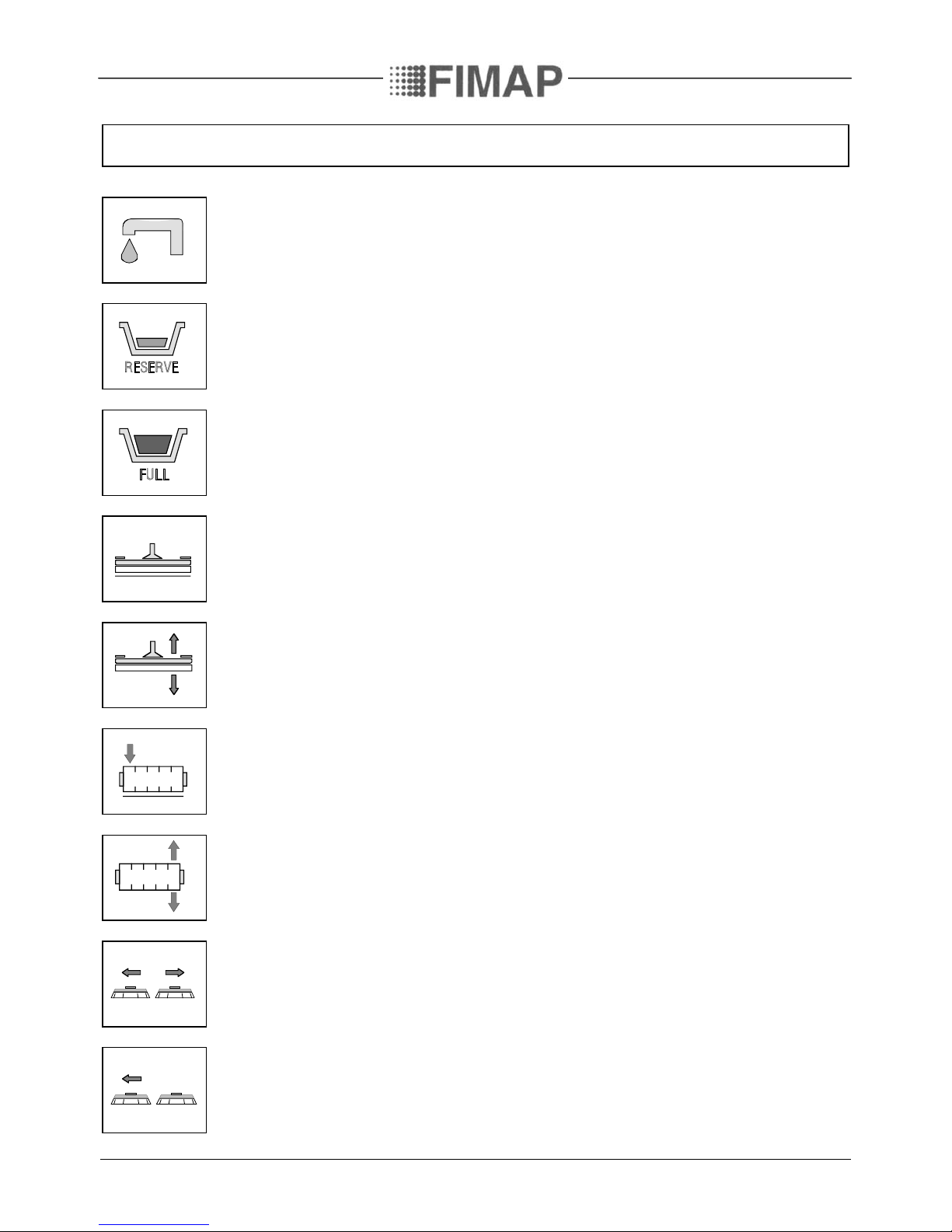

SYMBOLOGY USED ON THE MACHINE............................................................................................................................... 36

MACHINE PREPARATION...................................................................................................................................................39

1. HANDLING OF THE PACKED MACHINE......................................................................................................................................................... 39

2. HOW TO UNPACK THE MACHINE................................................................................................................................................................... 39

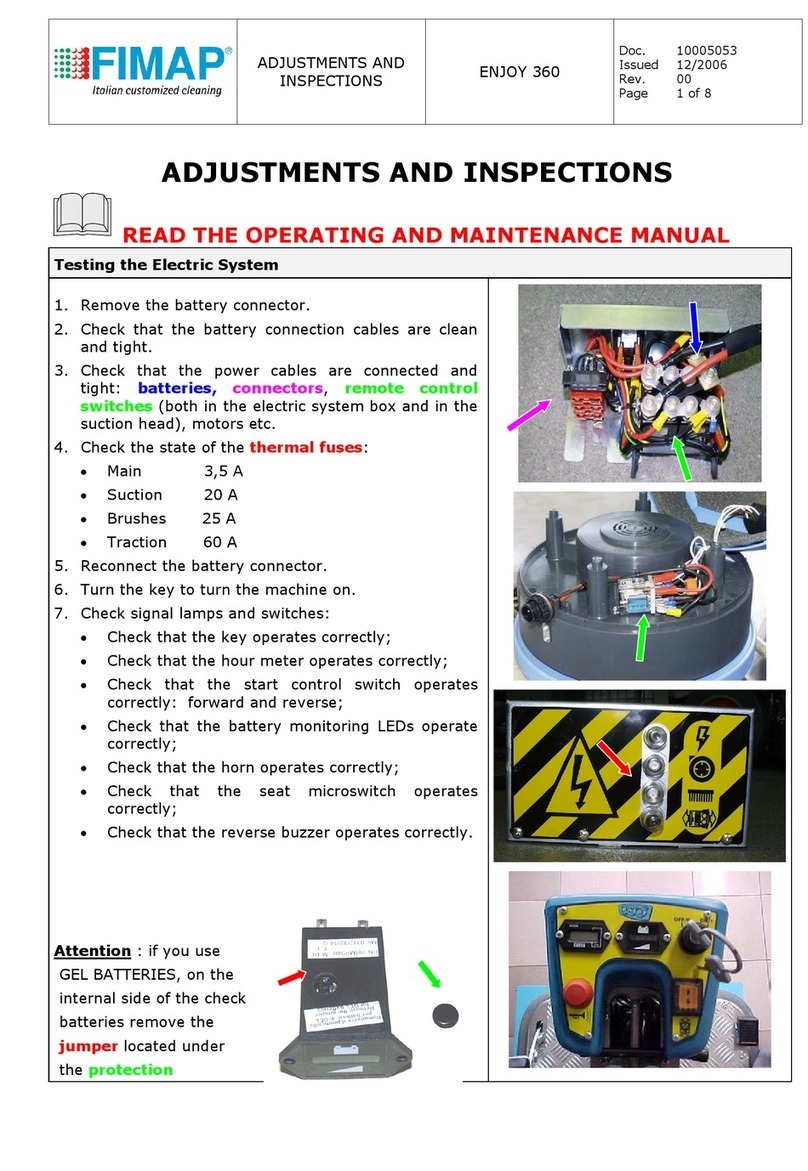

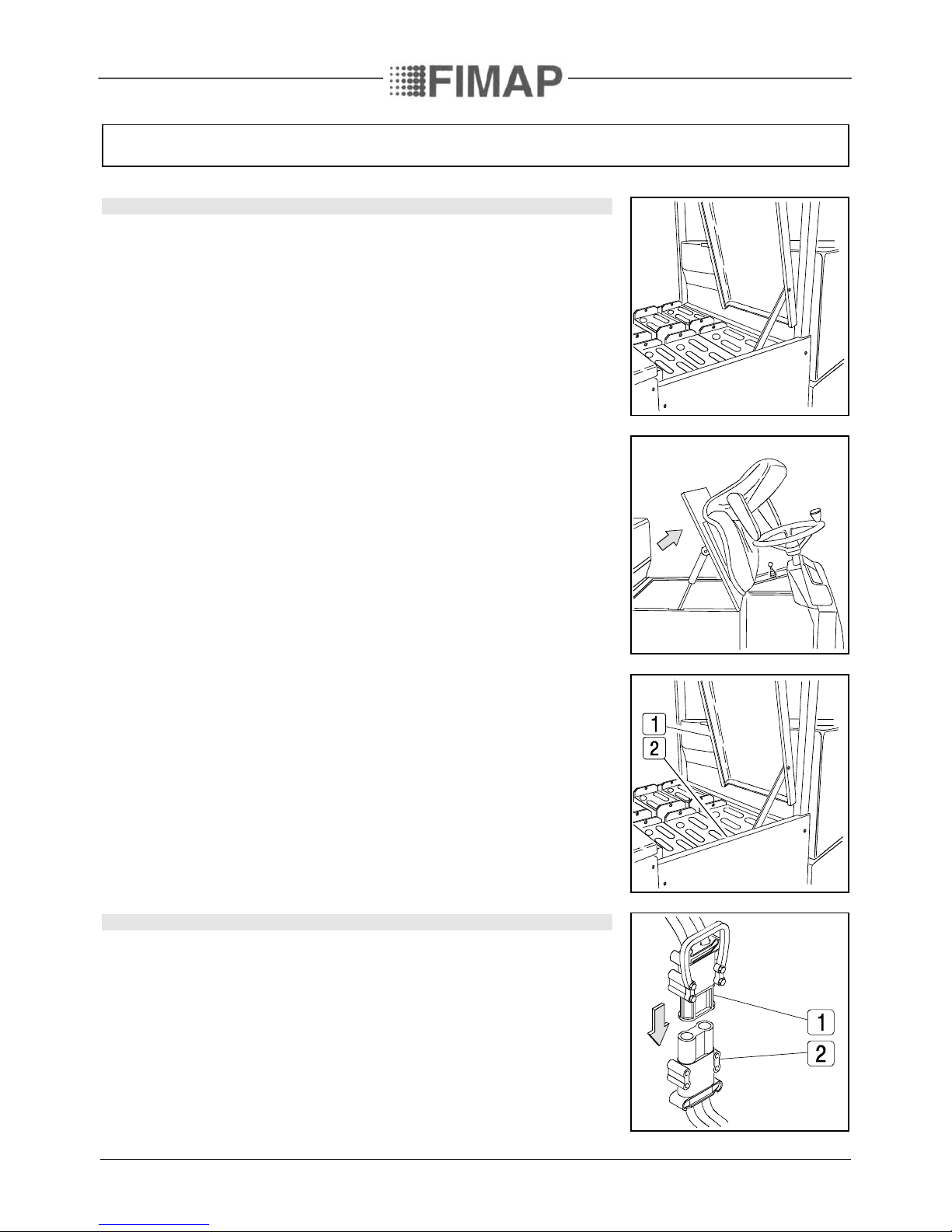

3. INSTALLATION OF THE BATTERIES INTO THE MACHINE.........................................................................................................................40

4. CONNECTION OF THE BATTERY CONNECTOR ............................................................................................................................................40

5. CONNECTION OF THE BATTERY CHARGER...................................................................................................................................................41

6. RECHARGE OF THE BATTERIES ......................................................................................................................................................................41

7. LEVEL INDICATOR FOR THE CHARGE OF THE BATTERIES........................................................................................................................41

8. SQUEEGEE ......................................................................................................................................................................................................... 42

9. ADJUSTMENT HEIGHT SQUEEGEE SUPPORT.............................................................................................................................................. 42

10. BRUSHES ASSEMBLY...................................................................................................................................................................................... 43

11. ASSEMBLY CYLINDRICAL BRUSH ................................................................................................................................................................. 44

12. ASSEMBLY SIDE BARS .................................................................................................................................................................................... 44

13. HOPPER............................................................................................................................................................................................................. 44

14. SOLUTION WATER .......................................................................................................................................................................................... 45

15. RECOVERY TANK............................................................................................................................................................................................. 45

GENERAL RULES OF SECURITY .........................................................................................................................................46

PERFORMANCE................................................................................................................................................................... 47

CHECK MOTORS..................................................................................................................................................................................................... 49

PRESSURE BRUSHES............................................................................................................................................................................................. 49

TRACTION ............................................................................................................................................................................................................... 50

SQUEEGEE AUTOMATIC - MANUAL.................................................................................................................................................................... 50

BASE CYLINDRICAL BRUSH (TUNNEL) AUTOMATIC - MANUAL.................................................................................................................... 50

BRAKES.....................................................................................................................................................................................................................51

HORN........................................................................................................................................................................................................................51

BLINKING AND WORKING LIGHTS......................................................................................................................................................................51

ON COMPLETION OF THE WORK ....................................................................................................................................... 52

DAILY MAINTENANCE........................................................................................................................................................ 54

CLEANING OF THE RECOVERY TANK................................................................................................................................................................. 54

CLEANING OF THE RECOVERY TANK FILTER................................................................................................................................................... 54

CLEANING OF THE SQUEEGEE............................................................................................................................................................................ 54

REPLACEMENT OF THE SQUEEGEE RUBBER....................................................................................................................................................55

DISASSEMBLY OF THE BRUSHES.........................................................................................................................................................................55

SOLUTION TANK AND FILTER CLEANING......................................................................................................................................................... 56

CLEANING OF THE HOPPER ................................................................................................................................................................................ 56

WEEKLY MAINTENANCE.................................................................................................................................................... 57

ADJUSTMENT SIDE BARS......................................................................................................................................................................................57

ADJUSTMENT SPLASH GUARD BRUSHES BASE ................................................................................................................................................57

ADJUSTMENT HEIGHT CYLINDRICAL BRUSH...................................................................................................................................................57

CLEANING OF THE SUCTION HOSE.................................................................................................................................................................... 58

CLEANING FILTER SUCTION MOTORS............................................................................................................................................................... 58

TROUBLE SHOOTING GUIDE.............................................................................................................................................. 59

INSUFFICIENT WATER ONTO THE BRUSHES ................................................................................................................................................... 59

THE SQUEEGEE DOES NOT DRY PERFECTLY.................................................................................................................................................... 59

THE SUCTION MOTOR DOES NOT FUNCTION ..................................................................................................................................................60

THE MACHINE DOES NOT START .......................................................................................................................................................................60

EXCESSIVE FOAM PRODUCTION ........................................................................................................................................................................60

THE MACHINE DOES NOT CLEAN SATISFACTORILY........................................................................................................................................61

CHOICE AND USE OF BRUSHES..........................................................................................................................................62

BATTERIES..........................................................................................................................................................................63

BATTERY TYPE ....................................................................................................................................................................................................... 63

MAINTENANCE OF THE BATTERY ...................................................................................................................................................................... 63

DISPOSAL OF BATTERIES..................................................................................................................................................................................... 63

34