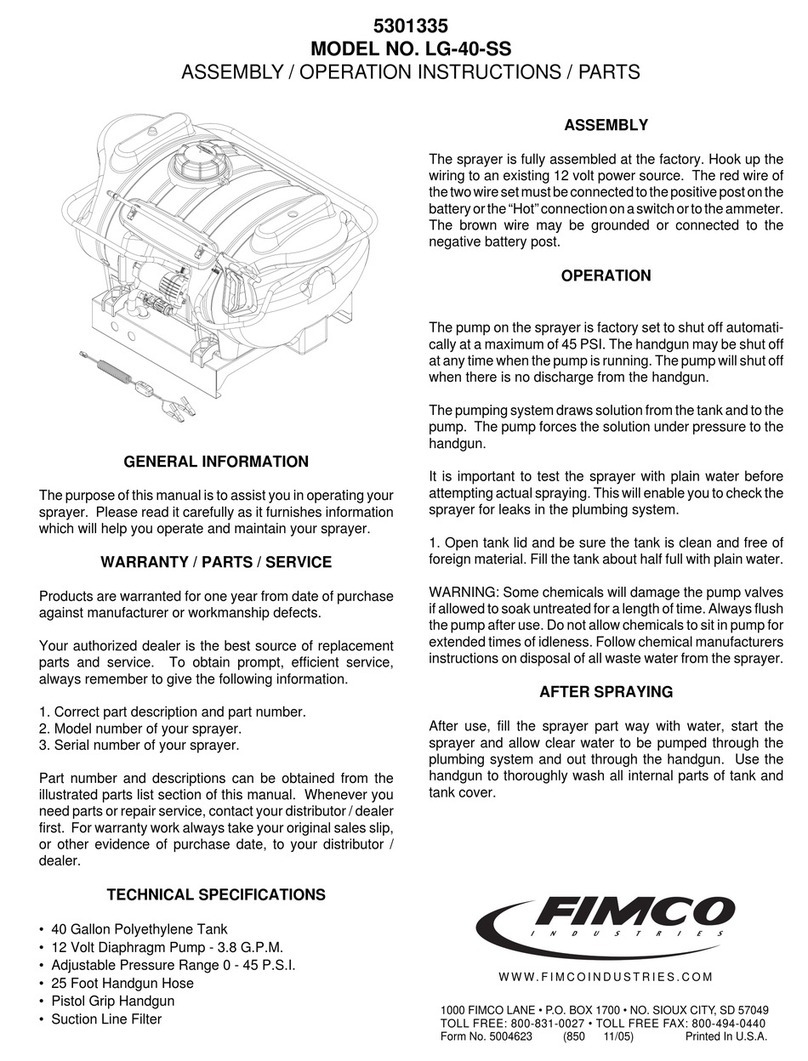

Time Required in seconds to travel a distance of:

200 Ft.

(Miles per Hour)

100 Ft.

2.0

3.0

1.0

5.0

6.0

7.0

9.0

8.0

10.0

4.0

157.6

6.8 14

68 sec.

17

8.5

9.7

11

14

34

23

34

17

19

23

27

136 sec.

68

45

Speed in M.P.H.

Speed Chart

300 Ft.

23

20

51

34

41

29

26

68

102

205 sec.

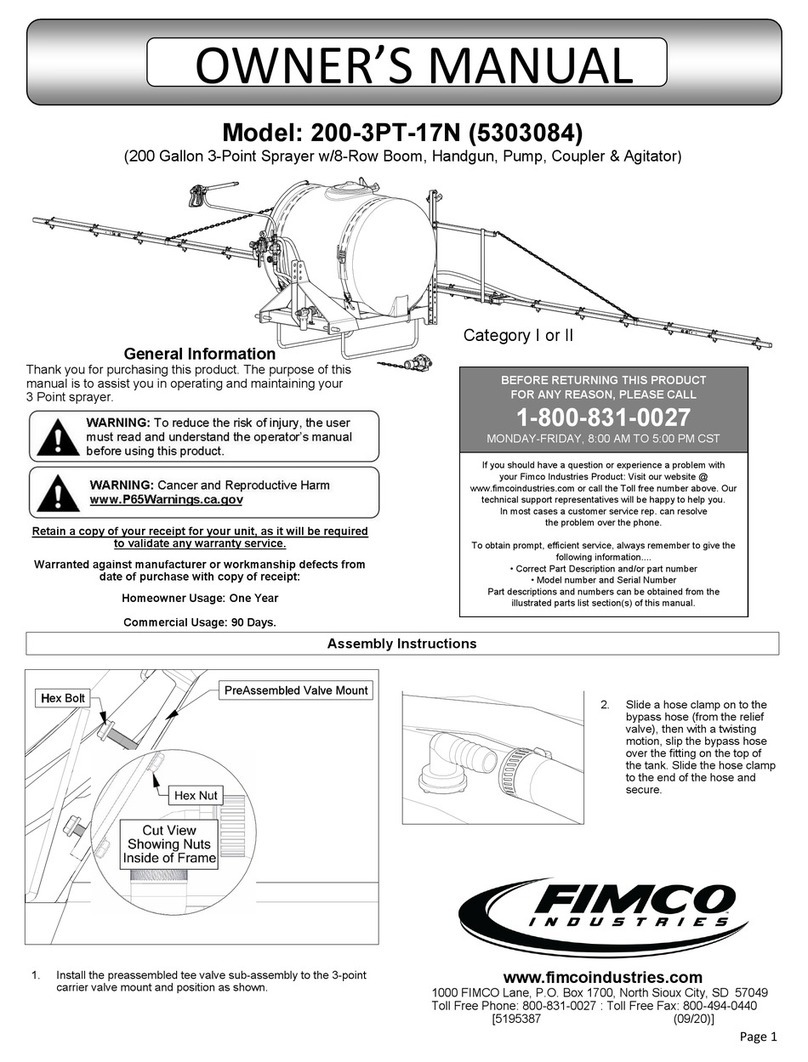

Gallons Per 1000 Sq. Ft. - Based on Water

MPH

Pressure

Pressure

AIXR11002VP

Number

AIXR11002VP

Number

Tip

Tip

18"

Height

Spray

18"

Height

Spray

.27.34

.45

.680.2040

Gallons Per Acre - Based on Water

(GPM)

Capacity

(GPM)

Capacity

0.2040

30

20

15

(psi)

0.17

0.14

0.12

30

20

15

(psi)

0.17

0.14

0.12

29.859.6

MPH

.58

.48

.41

2

50.4

41.6

35.6

MPH

1

MPH

25.2

20.8

17.8

2

.23

.19

.16

MPH

5

11.9

10.1

8.3

7.1

MPH

5

14.919.8

.29

.24

.20

MPHMPH

.39

.32

.27

34

12.6

10.4

MPHMPH

16.8

13.8

11.8

3

8.9

4

7.4

9.9

8.4

6.9

5.9

MPH

6

6.3

5.2

4.5

8

Tip Chart

Page 2

Operation

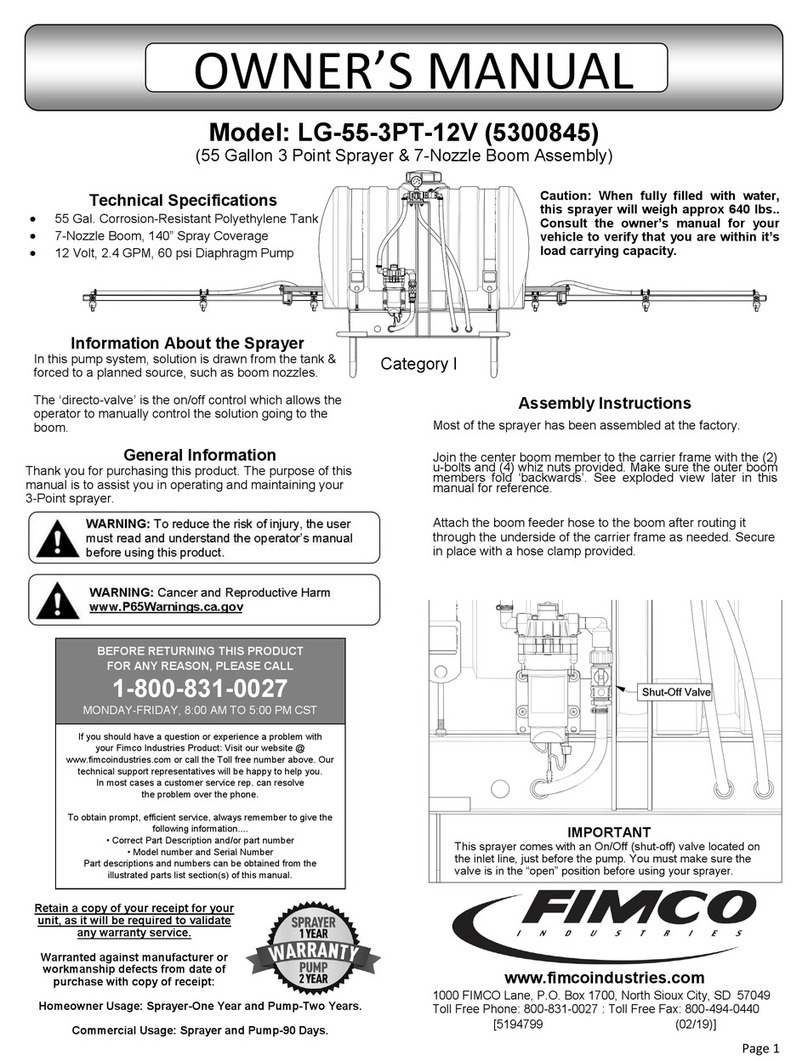

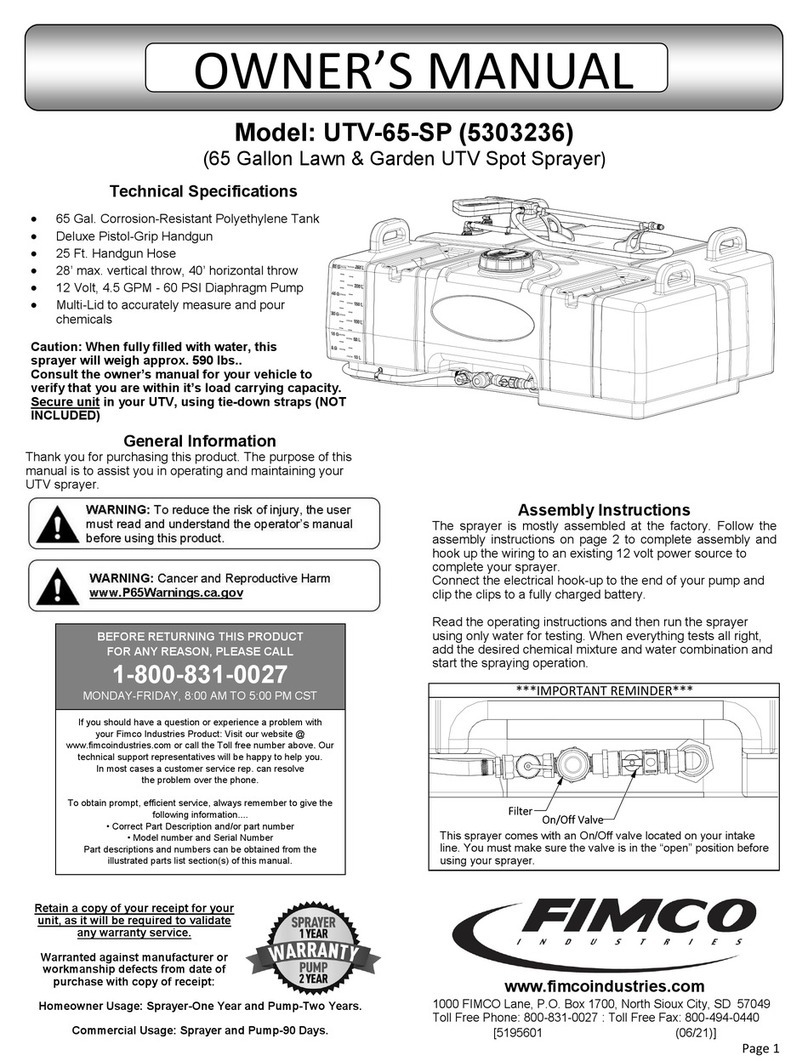

Your sprayer is equipped with one ON/OFF switches. This is on

the wire assembly that you hook up to your battery. The "-" is

the "ON" position and the "o" is the "OFF" position for the switch.

In addition to the ON/OFF switch, the pump is equipped with an

electronic pressure switch that is factory pre-set for it to shut off

at 45 p.s.i.. This switch assembly is the 'square box' on the head

portion of the pump.

Always fill the tank with a desired amount of water first, and then

add the chemical slowly, mixing as you pour the chemical into

the tank. You may use the handgun to spray into the solution in

order to mix the chemical and water.

Initially begin spraying by opening the handgun. This will enable

the air in the line to be purged through the handgun tip, while

building pressure.

The pumping system draws solution from the tank, through the

strainer/filter, and to the pump. The pump forces the solution

under pressure to the handgun and/or boom nozzles.

Open the handgun by squeezing the handle lever.

•

Rotating the adjustable nozzle tip on the handgun will

•

change the tip pattern from a straight stream to a cone

pattern (finer mist).

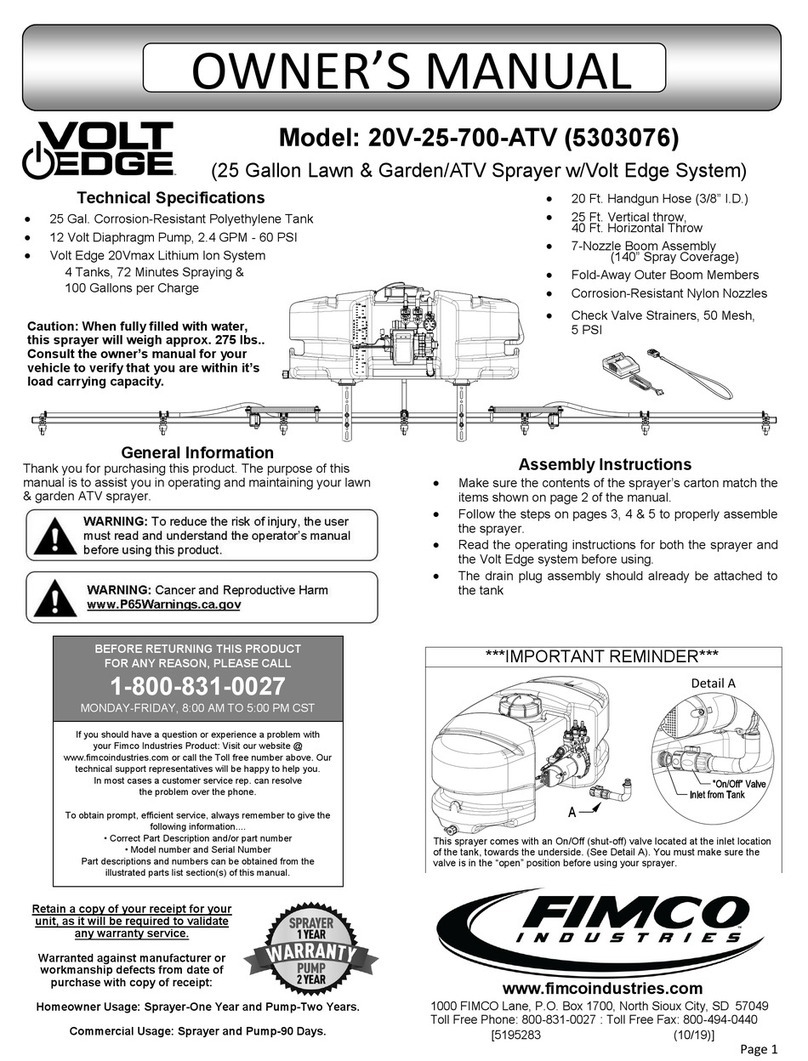

1. Install the Quick Release Brackets to the tank as shown in

the exploded view drawing.

2. Place the tank, with the brackets attached, on your ATV

carrier rack. Attach using ratchet straps.

3. Slide the boom mounting brackets into the Quick Release

Brackets. Use Cam handles on Quick Release Brackets to

secure the boom mounting brackets.

4. Attach the nozzle harness assembly to the boom. Each

nozzle body has a brass nut which holds it to the steel boom

member. Make sure these are tightened securly.

5. Attach the boom assembly to the boom mounting brackets at

desired height. Be sure to center boom assembly.

6. Thread the pressure gauge into the manifold assembly. Use

teflon tape or thread sealant to insure no leaks.

7. Remove the drain plug assembly and handgun clips from the

parts bag. Attach them to the tank as shown in the exploded

view drawing.

8. Connect the wiring harness to the rear of the pump. Clip the

alligator clip ends to a fully charged 12 Volt battery. Red wire to

the 'Hot' connection, and black wire to the 'Ground'.

Assembly

Testing the Sprayer

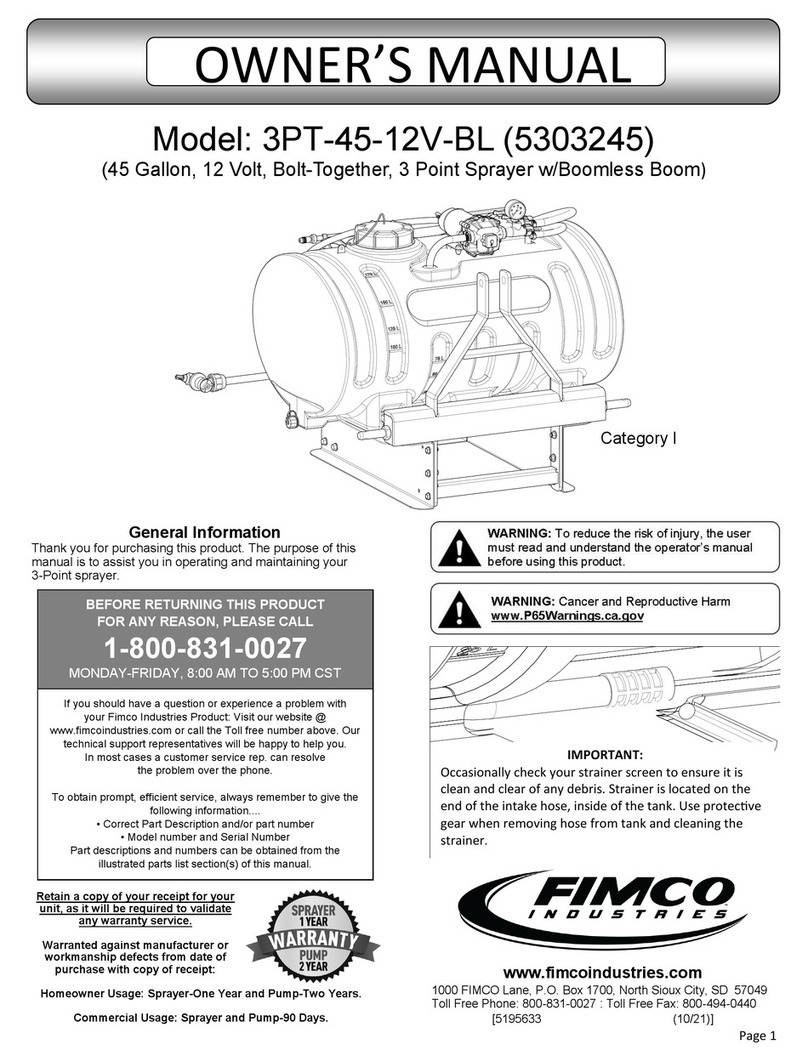

NOTE:

It is VERY important for you to test your sprayer with plain

water before actual spraying is attempted. This will enable

you to check the sprayer for leaks, without the possibility of

losing any expensive chemicals.

Add water to the tank & drive to the starting place for spraying.

When you are ready to spray, turn the boom valve to the "on"

position. This will start solution spraying from the tips of the boom.

The pressure will decrease slightly when the boom is spraying.

Adjust the pressure by turning the "ON/OFF" valve lever on the

pressure adjust valve.

Read the operating instructions and Initially begin spraying by

closing the 'pressure adjust' valve (this is the ON/OFF valve

located at the end of your manifold assembly) and opening the

boom line valve (this is the 'middle' valve on the manifold). This

will enable the air in the line to be eliminated (purged) through all

the tips, while building pressure. When everything tests correctly

(no leaks, & good pressure), add the desired chemicals to the

mixture and water combination and start your spraying operation.

Adjust the pressure and spray as you did in the testing procedure.

Conditions of weather and terrain must be considered when

setting the sprayer. Do not spray on windy days. Protective

clothing must be worn in some cases.

Be sure to read the chemical label(s) correctly!

Calibration

Chemical labels may show application rates in gallons per acre,

gallons per 1000 square feet, or gallons per 100 square feet. You

will note that the tip chart shows all 3 of these rating systems.

Once you know how much you are going to spray, then determine

(from the tip chart) the spraying pressure (PSI), and the spraying

speed (MPH).

Determining the proper speed of the pulling vehicle can be done

by marking off 100, 200, & 300 feet. The speed chart indicates

the number of seconds it takes to travel the distances. Set the

throttle and with a running start, travel the distances. Adjust the

throttle until you travel the distances in the number of seconds

indicated by the speed chart. Once you have reached the throttle

setting needed, mark the throttle location so you can stop and go

again, returning to the same speed.

Add water and proper amount of chemical to the tank and drive to

the starting place for spraying.