SMC Networks 4011 Series User manual

Other SMC Networks Controllers manuals

SMC Networks

SMC Networks C96 Series User manual

SMC Networks

SMC Networks LECP7-XB54 Series User manual

SMC Networks

SMC Networks ITV1000-CC Series User manual

SMC Networks

SMC Networks LECP2 Series User manual

SMC Networks

SMC Networks IR2000-A Series User manual

SMC Networks

SMC Networks PSE303-LBC User manual

SMC Networks

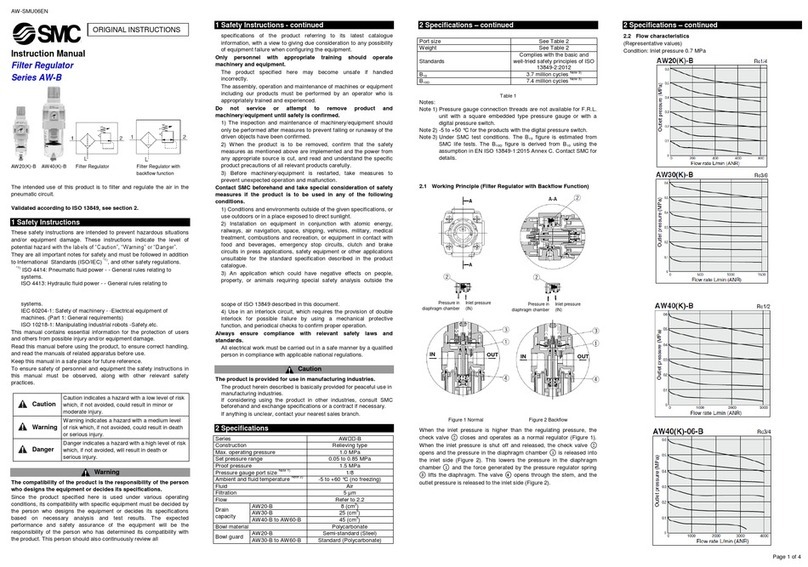

SMC Networks AW20-B User manual

SMC Networks

SMC Networks LEJ Series User manual

SMC Networks

SMC Networks VCHR30 Series Manual

SMC Networks

SMC Networks PFCA7 Series User manual

SMC Networks

SMC Networks VBA40A User manual

SMC Networks

SMC Networks VBA10A-02-X3239 User manual

SMC Networks

SMC Networks LEG Series User manual

SMC Networks

SMC Networks THERMO-CON HEC001 Series Use and care manual

SMC Networks

SMC Networks EQFS Series User manual

SMC Networks

SMC Networks ITV1000-52 Series User manual

SMC Networks

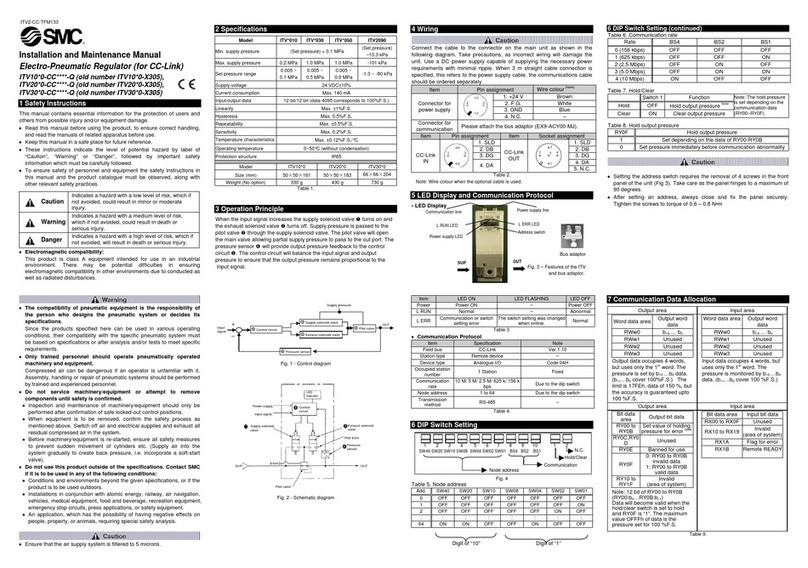

SMC Networks ITV10*0-CC****-Q Series Manual

SMC Networks

SMC Networks JXCD1 User manual

SMC Networks

SMC Networks ASD F-A Series User manual

SMC Networks

SMC Networks ITV1000 series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions