2

PROFI DYNAMIC XXL

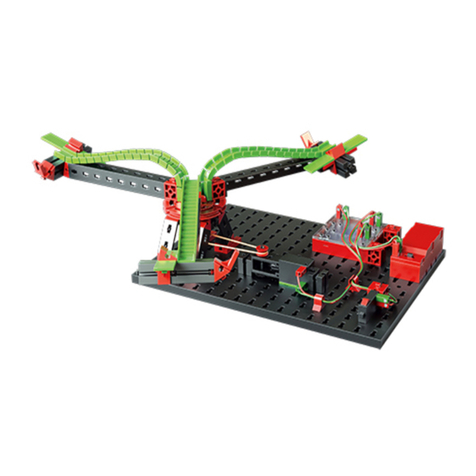

■The new Dynamic XXL obstacle course construction set is guaranteed to be even faster, higher and more action-packed than ever. At

just under one meter high with a track up to 5.60 meters long, plenty of new functions, new components and switches, this construction

set guarantees unlimited hours of entertainment. You can build new, fast courses thanks to the new flex tubes. The balls race across a

mechanical teeter-totter into different track circuits. They then speed through a loop on their way down before going over the quarter pipe,

through the spring loop and other obstacles. New: even more interaction is possible thanks to the ability to influence the ball’s route. A

mechanical switch can be used to adjust the course of the flex-rails, and an additional switch with switch lever determines the direction of

the course. The balls can also be stopped at a stopping point and then released. The balls are then brought back up to the top by the chain

lift which is operated by an XS motor. Three different ball obstacle courses can be built, providing a wide variety of construction alternatives.

Expanding the construction set with the PLUS set: the Bluetooth Control Set and Motor Set XS (up to two) make it possible to control

obstacles such as the switches or stopping point using a Bluetooth controller or smartphone/tablet.

Includes XS motor, 2x Rainbow LEDs, 2x flex tubes 360, 7x 90° curves, 5x 180° curves, 7x high-speed flex-rails, 8x flex-rails 90, 16x flex-rails

180, 8x balls, 2x cross-overs, 2x rotary funnels, 9V battery tray (battery not included). Ideal additions: all construction sets from the Dynamic

Line, Motor Set XS, Bluetooth Control Set, Sound+Lights, LED Set, Accu Set or Power Set.

What does dynamics mean?

■We encounter dynamics everywhere in our daily life and perhaps

no longer even recognize it because we are so used to it! We speak of

dynamics everywhere anything moves.

We experience this in the morning when we get up. We move from our

bed to the bathroom or the breakfast table. We drive or walk to school

or to work. We experience the effects of dynamics in nearly all hobby

sports or see them when we simply watch other people move.

Fun with Physics

Dynamics provides us with awesome experiences and fun, such as riding your bike, skiing, skateboarding, playing ball or riding a roller

coaster. Dynamics therefore enriches our lives, as expressed in the motto - Fun with Physics!

Try to think where you encounter dynamics in your everyday life!

• Riding in a car

• running, jogging, jumping

• ...