flamco Vacumat Eco Series User manual

TemplateA4_v20130506

Vacumat Eco®

NOR

ESP

POL HUN

ENG DEU NLD FRA ITA DAN

SWE FIN CES SLK

RUS TUR

www.amcogroup.com/manuals

TemplateA4_v20130506

2

BE Flamco Belux

Monnikenwerve 187 /1

B -8000 Brugge

+32 50 31 67 16 info@amco.be

CH Flamco AG

Fännring 1

6403 Küssnacht

+41 41 854 30 50 info@amco.ch

CZ Flamco CZ

Evropská 423/178

160 00 Praha 6

+420 602 200 569 info@amco.cz

DE FlamcoGmbH

Steinbrink3

42555Velbert

+49 2052 887 04 info@amco.de

DK Flamco

Tonsbakken16-18

DK-2740Skovlunde

+45 44 94 02 07 info@amco.dk

EE Flamco Baltic

Löötsa 4

114 15 Tallin

+372 56 88 38 38 info@amco.ee

FI FlamcoFinland

Ritakuja1

01740 Vantaa

+358 10 320 99 90 info@amco.

FR Flamcos.a.r.l.

BP 77173

95056CERGY-PONTOISEcedex

+33 1 34 21 91 91 info@amco.fr

HU FlamcoKft.

H-2040Budaörs,Gyáru.2

H-2058Budaörs,Pf.73

+36 23 88 09 81 info@amco.hu

NL FlamcoB.V.

Postbus502

3750 GM Bunschoten

+31 33 299 75 00 support@amco.nl

PL FlamcoSp.zo.o.

ul.Akacjowa4

62-002SuchyLas

+48 616 5659 55 info@amco.pl

SE Flamco Sverige

Kungsgatan 14

54131Skövde

+46 500 42 89 95 vvs@amco.se

UAE FlamcoMiddleEast

P.O.Box262636

JebelAli,Dubai

+971 4 881 95 40 info@amco-gulf.com

UK FlamcoLimited

WashwayLane-StHelens

MerseysideWA106PB

+44 1744 74 47 44 info@amco.co.uk

TemplateA4_v20130506

3

Vacumat Eco

ENG Installationandoperatinginstructions

Translation of the original operating instructions ____________________________________________________________________________________________ 5

DEU Montage-undBetriebsanleitung

Orginalbetriebsanleitung___________________________________________________________________________________________________________________________ 29

NLD Montageengebruikshandleiding

Vertalingvandeoorspronkelijkegebruiksaanwijzing_______________________________________________________________________________________ 53

FRA Installationetmoded’emploi

Traductiondelanoticed’utilisationoriginale_________________________________________________________________________________________________ 77

ESP Instruccionesdeinstalaciónyfuncionamiento

Traduccióndelasinstruccionesdefuncionamientooriginales__________________________________________________________________________ 101

ITA Istruzionid’installazioneed’impiego

Traduzionedelleistruzionioperativeoriginali ________________________________________________________________________________________________ 125

DAN Monterings-ogdriftsvejledning

Oversættelseafdenoriginalebetjeningsvejledning ________________________________________________________________________________________ 149

NOR Installasjons-ogbruksanvisning

Trykksikring,aktivavgassing,påfylling_________________________________________________________________________________________________________ 173

SWE Instruktionerförinstallationochdrift

Översättning av originalinstruktionerna ________________________________________________________________________________________________________ 197

FIN Asennus-jakäyttöohjeet

Alkuperäistenkäyttöohjeidenkäännös_________________________________________________________________________________________________________ 221

POL Instrukcjamontażuiobsługi

Tłumaczenieoryginalnejinstrukcjiobsługi ____________________________________________________________________________________________________ 245

HUN Telepítésiésüzemeltetésiútmutató

Azeredetiüzemeltetésiútmutatófordítása ___________________________________________________________________________________________________ 269

CES Návodkinstalaciaobsluze

Překladoriginálníchprovozníchpokynů_______________________________________________________________________________________________________ 293

SLK Návodnamontážaobsluhu

Prekladpôvodnéhonávodunaobsluhu _______________________________________________________________________________________________________ 317

RUS Инструкции по установке и эксплуатации

Перевод оригинального руководства по эксплуатации _______________________________________________________________________________ 341

TUR Montajvekullanmakılavuzu

Orijinalçalışmatalimatlarınınçevirisi ___________________________________________________________________________________________________________ 365

TemplateA4_v20130506

4

TemplateA4_v20130506

ENG

5

English (ENG) Instruction and installation manual

Content

1. Liability ................................................................................................................................................................................................................. 6

2. Warranty ............................................................................................................................................................................................................... 6

3. Copyright ............................................................................................................................................................................................................. 6

4. General safety instructions ................................................................................................................................................................................ 6

Purposeanduseofthismanual........................................................................................................................................................................... 6

Qualicationsrequired,assumptions.................................................................................................................................................................... 6

Staffqualication.................................................................................................................................................................................................. 7

Intendeduse......................................................................................................................................................................................................... 7

Incominggoods.................................................................................................................................................................................................... 7

Transportation,storageandunpacking................................................................................................................................................................ 7

Operations room ................................................................................................................................................................................................... 7

Noisereduction..................................................................................................................................................................................................... 8

Emergencystop/Emergency-off......................................................................................................................................................................... 8

Personalprotectiveequipment(PPE)................................................................................................................................................................... 8

Exceedingpermittedpressure/temperaturelevels............................................................................................................................................. 8

Systemwater........................................................................................................................................................................................................ 8

Safeguards............................................................................................................................................................................................................ 8

External forces ...................................................................................................................................................................................................... 9

Inspectionbeforecommissioningandre-inspection............................................................................................................................................ 9

Operating insurance inspections .......................................................................................................................................................................... 9

Electricalequipmentinspections,routineinspection........................................................................................................................................... 9

Maintenanceandrepairs....................................................................................................................................................................................... 9

Obviousmisuse..................................................................................................................................................................................................... 9

Residualhazards................................................................................................................................................................................................... 10

Warningsymbolsinthismanual........................................................................................................................................................................... 10

5. Product description ............................................................................................................................................................................................ 10

Additionaldocumentation..................................................................................................................................................................................... 10

Plantlayout........................................................................................................................................................................................................... 10

Components/equipment..................................................................................................................................................................................... 11

Modeofoperation................................................................................................................................................................................................. 12

Marking ................................................................................................................................................................................................................. 14

6. Assembly .............................................................................................................................................................................................................. 16

Installing,leveling,bolting..................................................................................................................................................................................... 16

Connecting the pipework ...................................................................................................................................................................................... 16

Connectingtheelectricalsupply........................................................................................................................................................................... 16

7. Commissioning .................................................................................................................................................................................................... 16

Commissioning ..................................................................................................................................................................................................... 16

Settings / control actions ...................................................................................................................................................................................... 17

Recommissioning .................................................................................................................................................................................................. 17

Explanations relating to the SPC m1 control menu .............................................................................................................................................. 17

8. Maintenance ........................................................................................................................................................................................................ 19

Malfunction list / error messages .......................................................................................................................................................................... 19

Appendix 1. Technical data, general specications ................................................................................................................................................. 21

Ambientconditions....................................................................................................................................................................................................... 21

Installation examples ..................................................................................................................................................................................................... 21

Example of a unit / pipeline integration ......................................................................................................................................................................... 22

Minimumdistances:clearanceforserviceandrepair................................................................................................................................................... 22

Appendix 2. Technical Data, specications .............................................................................................................................................................. 23

Appendix 3. Menu structure of the SPC m1 - diagram ............................................................................................................................................ 24

Appendix 4. Terminal diagram .................................................................................................................................................................................... 25

Appendix 5. Optional accessories and their integration .......................................................................................................................................... 26

Appendix 6. Declaration of Conformity ..................................................................................................................................................................... 27

TemplateA4_v20130506

6

1. Liability

Alltechnicalinformation,dataandinstructionscontainedintheseoperatinginstructionsforpracticaloperationsandthosetobe

performedarecorrectatthetimeofgoingtopress.Thisinformationistheresultofourcurrentndingsandexperiencetothebestof

ourknowledge.WereservetherighttomaketechnicalchangessubjecttothefuturedevelopmentoftheFlamcoproductreferredto

inthispublication.Hencenorightsmaybederivedfromtechnicaldata,descriptionsandillustrations.Technicalpictures,drawings

andgraphsdonotnecessarilycorrespondtotheactualassembliesorpartsasdelivered.Drawingsandpicturesarenottoscaleand

containsymbolsforsimplication.

2. Warranty

WarrantyspecicationscanbefoundinourGeneralTermsandConditionsanddonotformpartofthismanual.

3. Copyright

Thismanualmustbeusedcondentially.Itmaybecirculatedamongauthorisedpersonnelonly.Itmustnotbegiventothirdparties.

Alldocumentationisprotectedbycopyright.Distributionorotherformsofreproductionofdocuments,evenextracts,exploitation

ornoticationofthecontentshereofisnotpermitted,wherenototherwisespecied.Infringementsareliabletoprosecutionand

paymentofcompensation.Wereservetherighttoexerciseallintellectualpropertyrights.

4. General safety instructions

Disregardorlackofattentiontotheinformationandmeasuresinthismanualmayposeahazardtopeople,animals,theenvironment

andtangibleassets.Failuretoobservethesafetyregulationsandtheneglectofothersafetymeasuresmayleadtothelossofliability

fordamagesintheeventofdamageorloss.

Denitions

• Operator:Anaturalpersonorlegalentitywhoistheowneroftheproductandusestheaforementionedproduct,orisnominatedto

useit,underthetermsofacontractualagreement.

• Principle:Thelegallyandcommerciallyresponsiblepurchaserintheimplementationofconstructionprojects.Canbebothanatural

andalegalentity.

• Responsibleperson:Therepresentativeappointedtoactbytheprincipleoroperator.

• Qualiedperson:Anypersonwhoseprofessionaltraining,experienceandrecentprofessionalactivitygivesthemtherequisite

professionalknowledge.Thisimpliesthatsuchpeoplehaveknowledgederivedfromrelevantnationalandinternalsafety

regulations.

4.1 Purpose and use of this manual

Thefollowingpageslisttheinformation,specications,measuresandtechnicaldatathatallowtherelevantpersonneltousethis

productsafelyandfortheintendedpurpose.Responsiblepersonsorthoseengagedbythemcarryingouttherequiredservicesmust

readthismanualattentivelyandunderstandit.

Suchservicesinclude:

storage,transportation,installation,electricalinstallation,commissioningandre-starting,operation,maintenance,inspection,repair

anddismantling.

Wheretheproductistobeusedinplants/facilitieswhichdonotcomplywithharmonisedEuropeanregulationsandrelevant

technicalrulesandguidelinesofprofessionalassociationsforthiseldofapplication,thepresentdocumentispurelyforinformative

andreferencepurposes.

Asthisunitmaybesubjecttounlimitedinspectionatalltimes,thismanualmustbekeptintheimmediatevicinityoftheinstalledunit,

atleastwithintheconnesoftheoperationsroom.

4.2 Qualications required, assumptions

Allpersonnelmusthavetherelevantqualicationstocarryouttherequiredservices,andbephysicallyandpsychologicallycapable.

Theareaofresponsibility,competenceandsupervisionofpersonnelisthedutyoftheOperator.

TemplateA4_v20130506

ENG

7

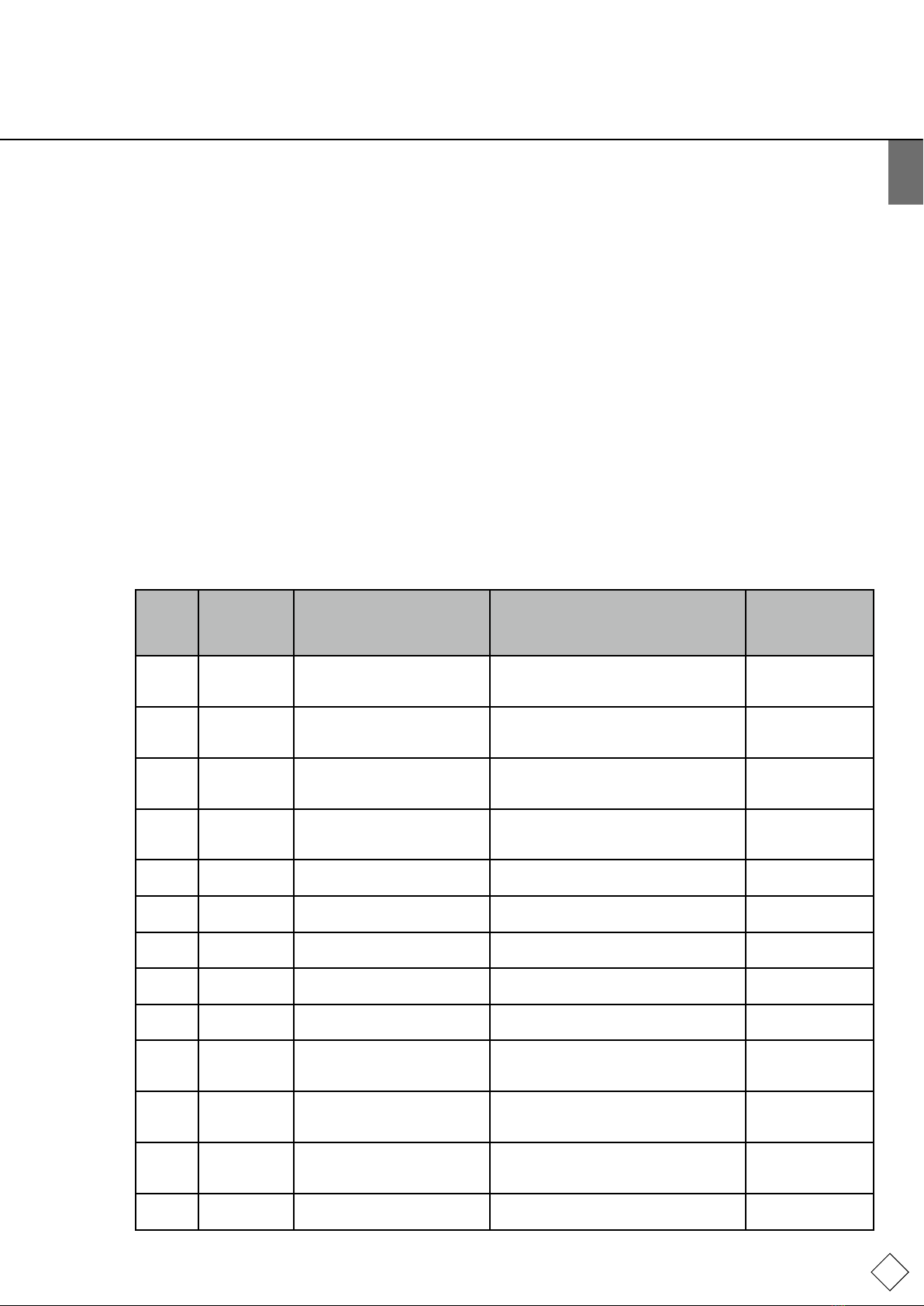

Required service Professional group Relevant qualications

Storage,transportation Logistics,transport,warehousing Transportandwarehousingspecialist

Installation,dismantling,repair,maintenance.

Re-commissioning after installation of extra

componentsormodication.Inspection.

Installationandbuildingservices HVACspecialist.

People with operations room

clearancewithknowledgegleaned

fromthisguide.

Firstcommissioningofconguredcontrolunit

(generic),re-commissioningafterpowercut,operation

(workontheterminalandSPCcontrolunit)

Electrical Installation Electrical engineering Specialist in electrical engineering /

installation

Initialandre-inspectionofelectricalsystems Qualiedperson(QP)with

certicationinElectricalEngineering

Inspectionbeforecommissioningandre-inspectionof

pressureequipment

Installationandbuildingservices

engineeringperformedinthe

contextoftechnicalinspection.

QualiedPerson(QP)

4.3 Staff qualication

OperatinginstructionsaretransferredbyFlamcorepresentativesorothersassignedbythemduringdeliverynegotiationsoron

demand.

Trainingfortherequiredservices,installation,dismantling,commissioning,operation,inspection,maintenanceandrepairarepartof

thetraining/furthereducationforserviceengineersoftheFlamcobranchofcesornamedservicecontractors.

Suchtrainingcoversinformationabouton-siterequirementsratherthanperformance.

On-siteservicesincludetransportation,thepreparationofanoperationsroomwiththerequisitefoundationengineeringto

accommodatethesystem,andtherequisitehydraulicandelectricalconnections,theelectricalinstallationforthepowersourceofthe

degassingequipmentandinstallationofthesignalleadsfortheITequipment.

4.4 Intended use

Degassingandtopping-upclosedwaterheatingandcoolingwatersystemsinwhichtemperature-affectedchangestothevolumeof

theprocesswater(heatcarrier)occur.

ThewaterheatingsystemsaresubjecttoEN12828withamaximumoperatingtemperatureof105°C.

Theuseofthedegassingsysteminsimilarplants(e.g.heattransfersystemsforprocessindustryortechnologicallyconditionedheat)

mayrequirespecialmeasures.

4.5 Incoming goods

Theitemsdeliveredmustbecomparedagainsttheitemslistedontheshippingnoteandinspectedforconformity.Unpacking,

installationandcommissioningmaybestartedonlyoncetheproducthasbeencheckedtoconformwiththeintendeduseas

statedintheorderprocessandcontract.Inparticular,exceedingthepermissibleoperatingordesignparametersmayleadto

malfunctioning,componentdamageandpersonalinjury.

Ifnotinlinewithconformityorifthedeliveryisincorrectinanotherway,theproductmustnotbeused.

4.6 Transportation, storage, unpacking

Theequipmentisdeliveredinpackingunitsincompliancewiththecontractualspecications,orrequirementsforspecic

transportmethodsandclimatezones.TheymeettherequirementsoftheFlamcoSTAGGmbHpackagingguidelinesasaminimum.

Inaccordancewiththeseguidelines,thedegassingsystemsaresuppliedstoredonspecialpallets.Thesepalletsaresuitablefor

transportationwithsuitablefork-lifttrucks.Theforksmustbesettothewidestpossibleouterdimensionsinordertopreventthe

loadfromtipping.Thegoodsdeliveredmustbemovedinthelowestpossiblesettingoftheliftingequipmentandperpendicularto

theforks.

Ifthepackagesaresuitableforliftinggear,theyaremarkedattheappropriateliftingpoints.

Importantnote:Transportthepackedgoodsascloseaspossibletotheenvisagedset-uplocationandmakesurethereisa

horizontal,solidsurfaceonwhichthegoodscanstand.

Caution:Useanapproachthatpreventsuncontrolledfalling,slidingortippingover.Thegoodsmayalsobewarehousedintheir

packaging.Stackingoftheequipmentistobeavoided.Useonlypermittedliftinggearandsafetools,andweartherequiredpersonal

protectiveequipment.

4.7 Operations room

RoomwhichmeetsthetermsoftheapplicableEuropeanregulations,Europeanandharmonisedstandardsandapplicabletechnical

regulationsandtheguidelinesofprofessionalassociationsfortheeldconcerned.WheretheuseofVacumatEcoisconcerned,

theseroomsgenerallyhaveequipmentforheatgenerationanddistribution,watertreatmentandtop-up,powersupplyand

distribution,andmeasurement,controlandinformationtechnology.

Accessforunqualiedanduntrainedpersonsmustberestrictedorforbidden.

TemplateA4_v20130506

8

Theset-uplocationofthedegassingequipmentmustguaranteethattheoperation,servicing,testing,maintenance,assemblyand

disassemblycanbeperformedregularly,withoutobstructionandsafely.Thesurfaceformingtheinstallationareafortheequipment

mustensurestabilityandsupport.Bearinmindthatthemaximumpossibleforcescomprisethedeadweightincludingthewaterll.

Ifstabilitycannotbeguaranteed,thereisadangerthattheunitwilltipover,ormoveunderloadand,asaconsequence,causeinjury

topersonsandmalfunctions.

Theambientatmospheremustbefreeofelectrically-conductivegases,highconcentrationsofdustandaggressivevapours.

Thereistheriskofexplosionifanycombustiblegasesarepresent.

Dependingontheprocess,thewatertemperaturecanriseto90°Contheunit;incaseofimproperoperation,itcanexceed90°C.

Thereisthusadangerofinjurytopersonsthroughburnsand/orscalding.

Floodedequipmentmustnotbeoperated.Ifelectricalequipmentshortcircuits,personsorotherbeingsinthewaterwillbe

electrocuted.Furthermore,thereisadangerofmalfunctionandpartialorirreparabledamagetoindividualcomponentsdueto

watersaturationandcorrosion.

4.8 Noise reduction

Ensurethatthenoiseemissionsintheinstallationareminimisedbyusingstate-of-the-arttechnology(e.g.bymeansofsound-

absorbentpipettings).

4.9 EMERGENCY-STOP / EMERGENCY-OFF

TheEmergencyStopfunctionrequiredunderthetermsofEuropeanDirective2006/42/ECisprovidedbytherespectivemainswitch

onthecontrolunit.

IffurthersafetychainswithEmergencyShut-Downdevicesarerequiredbythecongurationornatureofoperationsoftheheat

generator,thesearetobeinstalledonsite.

4.10 Personal protective equipment (PPE)

PPEmustbeusedwhencarryingoutpotentiallydangerousworkandotheractivities(e.g.welding),inordertopreventorminimise

theriskofpersonalinjuryifothermeasurescannotbetaken.Thesemustcomplywiththerequirementsspeciedbythemain

contractororoperatoroftheoperationsroomorthesiteinquestion.

Ifnorequirementsarespecied,tooperatetheautomatnoPPEisrequired.Minimumrequirementsarewell-ttingclothingand

sturdy,closedandslip-prooffootwear.

Otherservicesrequiretheprotectiveclothingandequipmentnecessaryfortheactivityinquestion(e.g.transportandassembly:

rugged,close-ttingworkclothing,footprotectors[safetyshoeswithtoecaps],headprotection[safetyhelmet],handprotectors

[protectivegloves];maintenance,repairandoverhaul:rugged,close-ttingworkclothing,footprotectors,handprotectors,eye/face

protector[safetygoggles]).

4.11 Exceeding permitted pressure / temperature levels

Theobjectofthedegassingsystemistoensurethattheequipmentcannotexceedthepermissibleoperatingoverpressureor

permissiblemediumtemperature(heatingmedium).Excesspressureandtemperaturemayleadtocomponentoverload,irreparable

damagetocomponents,lossoffunctionand,asaresult,toseverepersonalinjuryanddamagetoproperty.Regularchecks/

inspectionsofthesesafeguardsmustbecarriedout.

4.12 System water

Non-ammabletypesofwaterwithoutsolidsorbrouscomponentsthatdonotpresentadangertooperationalreadinesswiththeir

constituents,andwillnotdamagewater-conductingcomponentsofthedegassingequipment(e.g.pressurisedcomponents,pumps

andmotorpositionvalves)orhaveundueinuenceonitsworking.Componentsconductingprocesswaterarepipelines,hosestothe

vessel,deviceandsystemconnections,andtheircasings,sensors,pumpsandvessels.Operationwithimpropermediacanleadto

impairedfunction,damagetocomponentsand,asaconsequence,toseriouspersonalinjuryanddamage.

TheoperatingmediummustmeettherequirementsofVDI2035!Desalinatedwatermusthaveaconductivitybetween10and100µs/

cmwithapHvaluethatdoesnotexceedtheallowablelimitsaccordingtoVDI2035dependingonthematerialused.

4.13 Safeguards

Theequipmentsuppliedisequippedwiththerequiredsafetydevices.Totesttheireffectivenessorrestoretheset-upconditions,

theequipmentmustrstbetakenoutofservice.Takingthesystemoutofserviceimpliesthatpowershouldbecutandhydraulic

connectionsblocked,topreventaccidentalorunintentionalre-connection.

4.13.1 Mechanical hazards

Thefan-wheelcasingonthepumpprotectsoperatorsfrompersonalinjuryfrommovingparts.Beforecommissioning,checkthatitis

tforpurposeandxedinplace.

4.13.2 Electrical hazards

Theprotectionclassoftheelectricallyoperatedcomponentspreventsinjurytopersonsthroughpotentiallyfatalelectrocution.

TheprotectionclassisatleastIP42(4:Protectedagainstaccesswithawire;2:Protectionagainstdrippingwaterifthecasingis

angledupto15°.)Thecontrolunitcover,thecoverofthepumpfeed,themotorballvalveconnection,thethreadedcableglandsand

thevalveconnectorplugsmustbeinspectedforeffectivenesspriortocommissioning.Checkthatthegroundconnectionsaretight.

Theinstalledpressuresensors,thepressureswitchandthetemperaturesensorareoperatedwithprotectivelowvoltage.

AvoidweldingworkonadditionalequipmentthatiselectricallyconnectedtotheVacumatEco.Strayweldingcurrentsoranimproper

earthconnectioncouldleadtothedangerofreandthedestructionofpartsoftheunit(e.g.thecontrolunit).

TemplateA4_v20130506

ENG

9

4.14 External forces

Avoidanyadditionalforces(e.g.:forcescausedbyheatexpansion,owoscillationsordeadweightsontheowandreturnlines).

Theycanleadtocracksandbreaksinthewater-bearingpipework,toalossofstability,andalsotofailure–associatedwithserious

personalinjuryanddamagetoproperty.

4.15 Inspection before commissioning and re-inspection

ThesechecksguaranteeoperationalsafetyanditscontinuedpresenceinlinewithapplicableEuropeanregulations,Europeanand

harmonizedstandardsandpertinenttechnicalrulesandguidelinesoftheprofessionalassociationsforthiseldofapplication.

Therequiredinspectionsmustbearrangedbytheowneroroperator;aninspectionandmaintenancelogbookforschedulingand

traceabilityofmeasurestakenmustbekept.

4.16 Operating insurance inspections (under the German implementation of Council Directive 89/665/EEC)

Pressure equipment, vessels (§14; 15)

Category [see

appendix II

of Directive

97/23/EC,

diagram 2)

Vessel nomi-

nal capacity

/ nominal

pressure

Inspection

prior to

commis-

sioning

[§14]

inspector

Re-inspection [§15 (5)]

Timeframe, maximum period [a] / inspector

External inspection Internal inspection Strength inspection

Art.3,

para.3

5 litres /

PN10

Qualied

Person

(QP)

Maximumperiodnotdened.Themaximumintervalmustbeestablishedbythe

Operatoronthebasisofinformationprovidedbythemanufacturercoupledwithpractical

experienceandchamberload.TheinspectionmaybecarriedoutbyaQualiedperson.

4.17 Electrical equipment inspections, routine inspection

Withoutprejudicetotheconsiderationsoftheinsurer/Operator,itisrecommendedthattheelectricalequipmentrelatingtothe

externalpressurecontrolunitbeinspecteddemonstrablytogetherwiththeheating/coolingunitnotlessthanevery18months(see

alsoDINEN60204-1(2007)).

4.18 Maintenance and repairs

Thedegassingequipmentmustbedisabledandpreventedfrombeingunintentionallyenableduntiltheinspectioniscompleted.To

stopelectricalequipment(controlunit,pump,motorballvalve,peripheralequipment),isolatethepowersupplytothecontrolunit.

Notethatthesafetycircuitsanddatatransmissionsmadewhileshuttingdowncouldtriggersafetychainsorgenerateincorrectdata.

Note: Even if the control unit is switched off, a 230V signal / voltage may be present across terminals 12,13,14, 16 and 17!

Existinginstructionsfortheheatingorcoolingunitasawholemustbeobserved.Inordertoshutdownhydrauliccomponents,the

relevantsectionsmustbeblockedusingthecapvalvesandballvalvescontainedinthescopeofdeliveryoftheVacumatEco.

Thepressurecanberelievedusingtheunit'sllanddrainvalve.

Caution:Themaximumsystemwatertemperatureinconductingcomponents(vessel,pumps,casings,hoses,pipelines,peripheral

equipment)mayreach90°Cand,inthecaseofimproperoperation,mayexceedthat.Thispresentsadangerofburnsand/or

scalding.

Themaximumpressureofsystemwaterinconductingcomponentsmaybeequaltothemaximumsetpressureforthesystem's

applicablesafetyvalve.TheVacumatEco300uptosize900hasamaximumpositiveworkingpressureof10bar.Useofeye/face

protectorsisrequirediftheeyesorfacecouldbeinjuredbyyingpartsorsprayinguids.

Unauthorisedmodicationsto,andtheuseofnon-approvedcomponentsorreplacementpartsisprohibited.Thiscanresultin

seriousinjurytopersonsandendangeroperationalsafety.Theywillalsorenderanyclaimfordamagesagainstproductliabilityvoid.

TherecommendedapproachistocallinFlamcocustomerservicetoperformmaintenanceandrepairs.

4.19 Obvious misuse

• Operationatincorrectvoltageandfrequency.

• FeedingindrinkingwatersystemsandoperationwithmediumthatdoesnotcorrespondtoVDI2035.

• Operatingthesystemwithdeionizedwater.

• Operatingthesystemwithammable,toxicorexplosivemeans.

• Operationwiththewrongsystempressureandtoohighortoolowasystemtemperature.

• Mobileapplication.

TemplateA4_v20130506

10

4.20 Residual hazards

Fire:professionalreprotectionmustbeensuredonsite.

4.21 Warning symbols in this manual

Warningagainsthazardouselectriccurrent.

Disregardingthiscouldputlivesatrisk,causeresortriggeraccidents,leadtocomponentoverloadanddamage,orprevent

functionality.

Warningagainsttheimplicationsoferrorsandincorrectset-upconditions.

Failuretoobservecanleadtoseriouspersonalinjury,componentoverloadanddamage,orfunctionalimpairments.

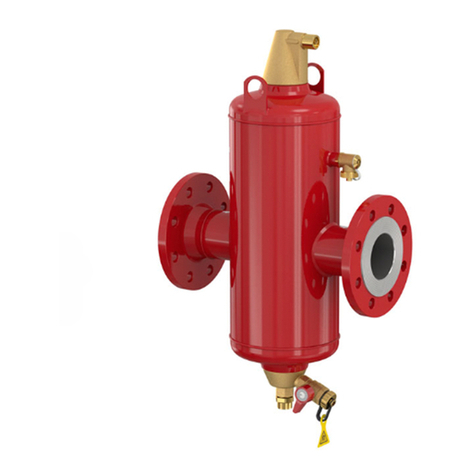

5. Product description

Thecontentsofthismanualconsistofthespecicationsforastandardequipmentlevel.Whereappropriate,thisincludesinformation

onoptionsorothercongurations.Ifoptionalextrasaresupplied,furtherdocumentationisprovidedinadditiontothismanual.

5.1 Additional Documentation

VacumatEco-circuitdiagramSPCm1

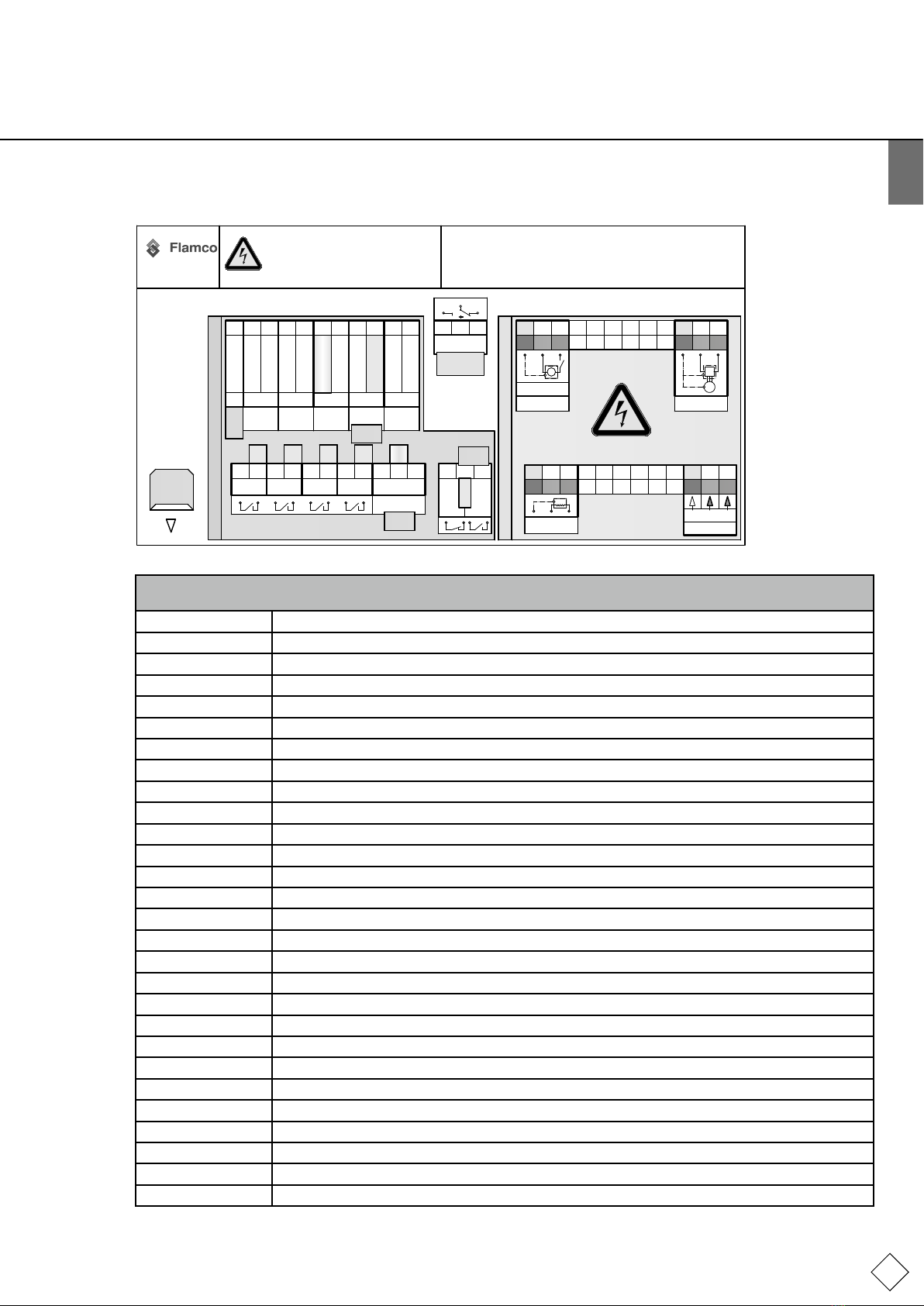

5.2 Plant layout

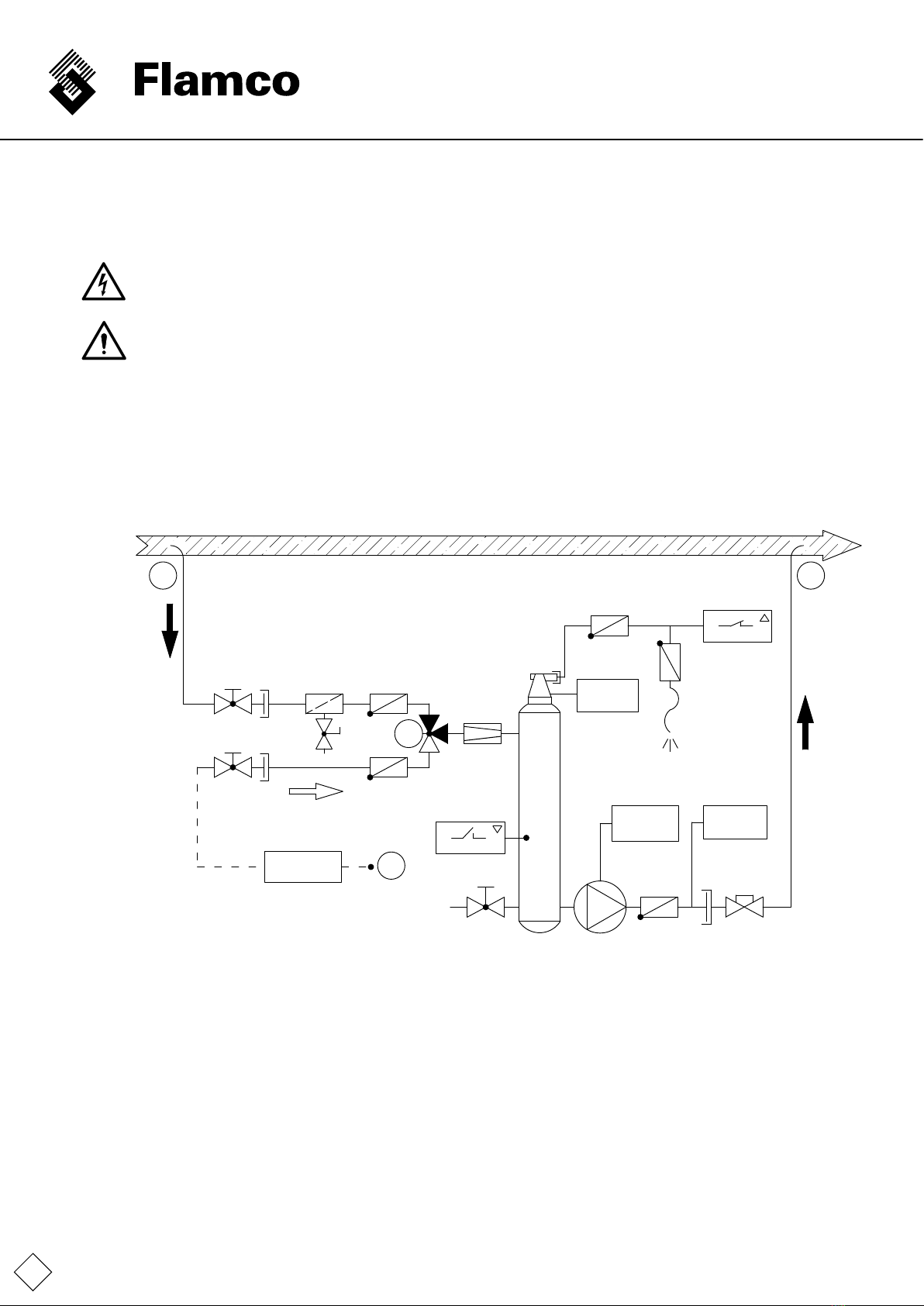

Systemdiagram:

Pvac

P

L

1

1

2

2

45

5

6 7 8

9

10

12

T

11 13

14

15

18

19

20 22

21

M

Psys

NFE x.x

A B

C2

3

16

A Supply to Vacumat Eco with gas-rich medium

B Return from Vacumat Eco to system circulation with degassed medium

C Top-up connection point (NFEx.2-variable,optionalwiring)

1 Ball valve

2 Flatsealingthreadedconnectiononnon-returnvalve

3 Fillinganddrainvalve

4 Dirttrap(0.5mm)

5 Check valve

6 3-wayswitchmotorballvalve

7 Volumeowlimiter

8 Degassing vessel

9 Temperature contact sensor

10 Filling level limit switch

11 Drainvalve(withcap)

12 Pumpwithfrequencyconverter

13 Check valve

14 Systempressuresensor

15 Cap valve

16 Special check valve

17 Sensor insulation

18 PressureSensor-degassingvessel

19 Automaticde-aerator

20 Aerationpreventer(checkvalve)

21 Vent line

22 Pressure switch

TemplateA4_v20130506

ENG

11

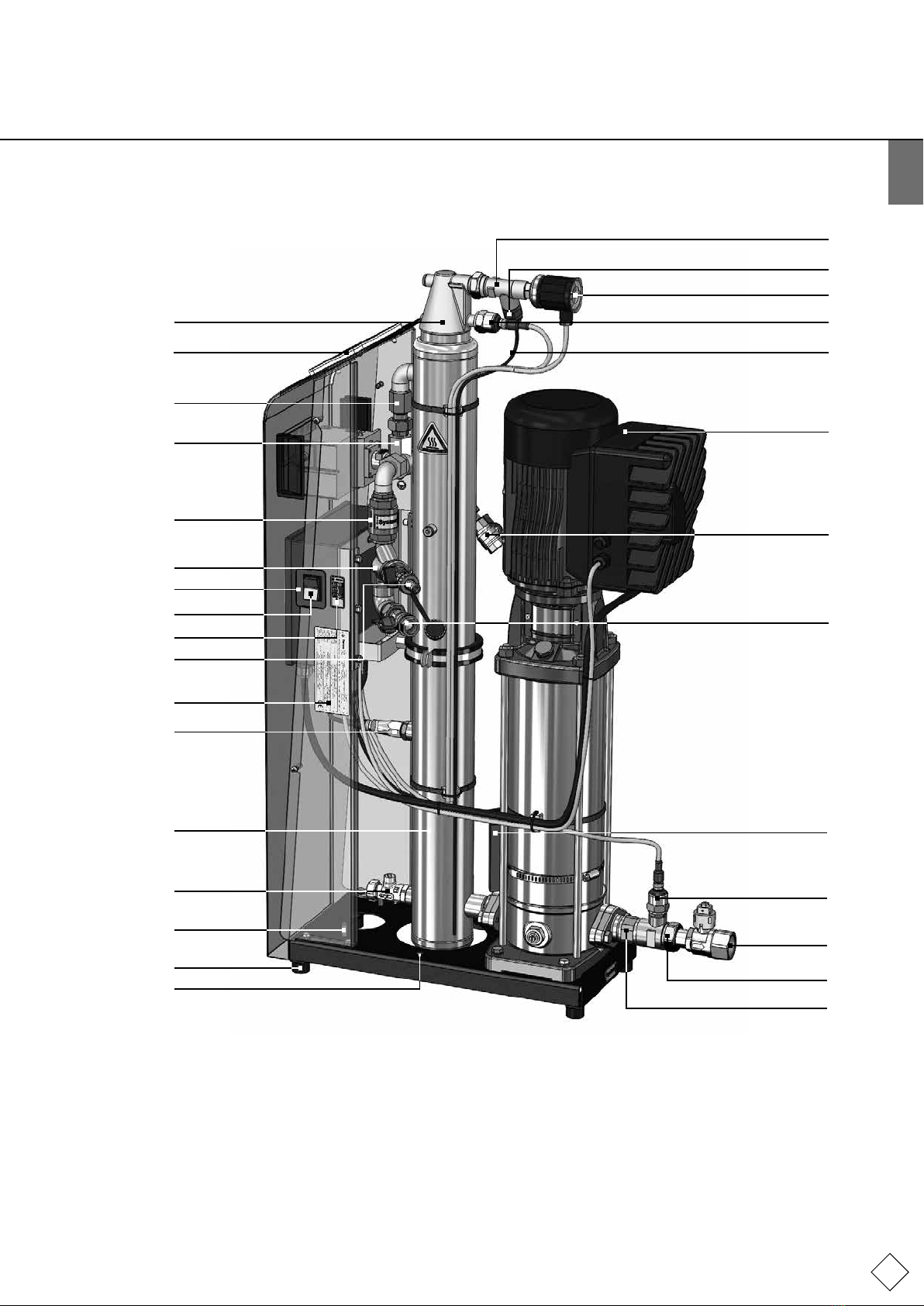

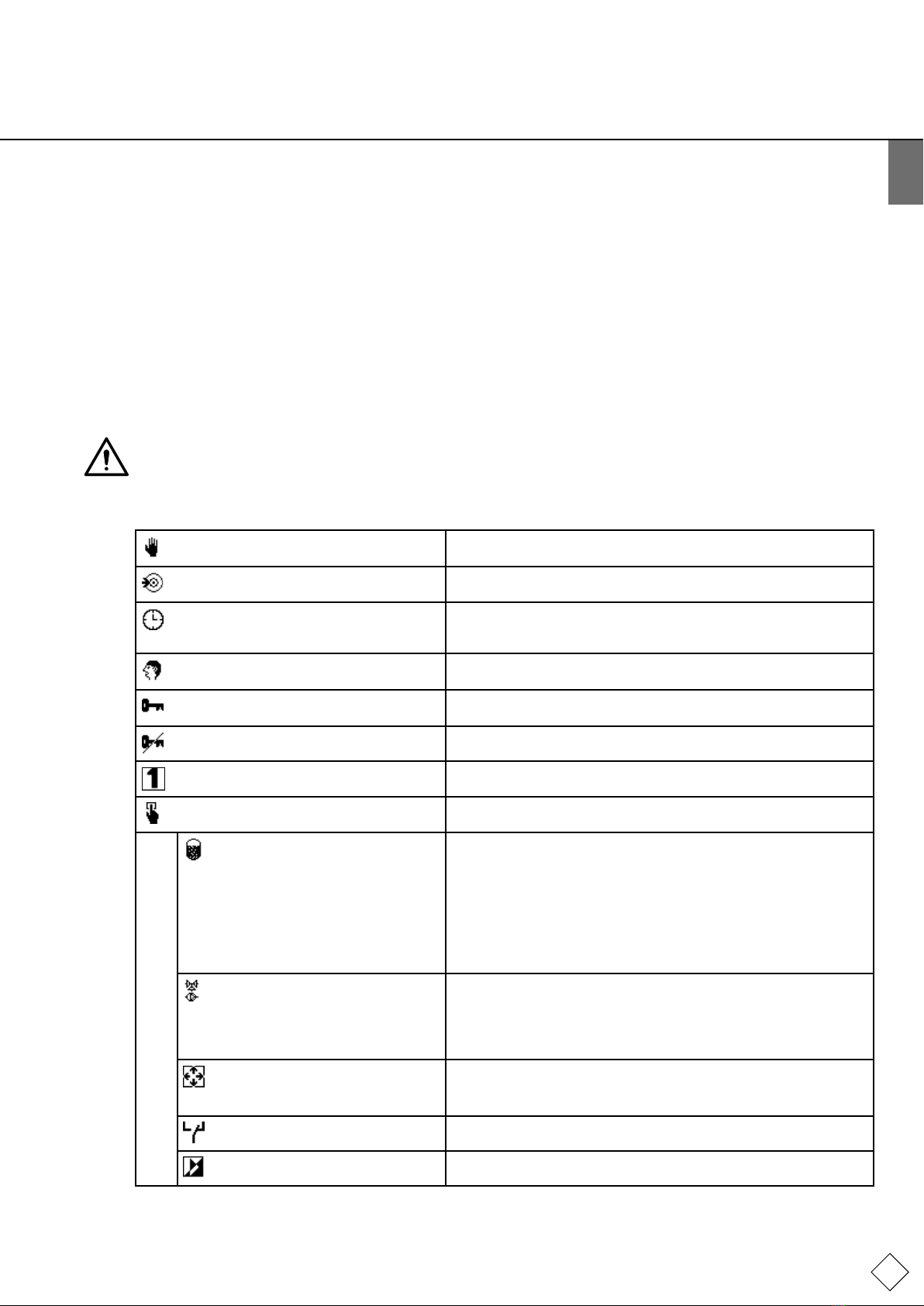

5.3 Components / equipment

22

18

21

12

1,C

1,A

9,17

14

B

2

13

16

20

19

27

7

6

5

4

28

23

24

3

25

10

8

11

26

30

29

23 Control unit ON/OFF switch

24 Servicelabelwithservicecontacts

25 Planttypeplate

26 Groundconnectionforapplyingtheexternalequipotentialbonding(protectiveearthconductor)

27 Operator terminal

28 Controlunit(SPCm1)

29 2xmountinghole(toensurestabilityagainsttipping)

30 Rubberbuffers(forsoundinsulation;insulationagainststructure-bornesoundpropagation)

TemplateA4_v20130506

12

5.4 Mode of operation

TheVacumatEcoworksasanactivedegassingdevicewithautomatictop-up

5.4.1 Basic principle of degassing in the Vacumat Eco

Degassingisperformedbyremovingsystemmediumfromthesystemcirculationthroughabypass.Thisisconveyedthroughthe

systemconnection(A)andthefollowingvolumeowlimiter(7)intothedegassingvessel(8).Duringpumpoperation,thedegassing

vessel(8)isplacedunderadenednegativepressure.Theabilityofairtodissolveinthesystemmediumisheavilyreducedbythe

loweredpressure,causingbubblestoform,accumulateandexpandandthisairtorise.

Theprocessisfacilitatedbytherotatingairseparatorprinciplewheretheairisseparatedanduniedbythetangentialinow,

intensiedtowardsthemiddleofthevessel(intheairheadofthedegassingvessel).Thisoptimisesdegassing.

Allfreegasesandaproportionofdissolvedgasesareremovedfromthesysteminanenergy-savingmannerwhichisconsidered

non-criticalintermsof:

• Corrosion.

• Heattransfertoheatingsurfaces.

• Flowbehaviourinthesystem.

Thisworks,amongotherreasons,becausethefrequency-controlledpumpwithadjustedspeedgentlyregulatesthevacuumtobe

builtuptoanenergeticallymeaningfullevel(temperature-controlled),thusavoidingpressuresurges.

Afterreducingthepumpspeed,thevesselisplacedundersystempressurebysubsequentmediumow,resultinginthe

dischargeoftheaircollectedabovewaterlevelviathede-aeratorunit(16,19-22).

TheVacumatEcoperformscheckdegassingcyclicallyinordertoautomaticallypausethedegassingwhenthepresetgascontent

levelisreached.Thisischeckedanddecidedatthede-aeratorunit.

Pressureswitch(22)detectswhetherairstillexistsatchargelevel,whichleadstopresetvacuumcontrolatthedegassingsystemby

(Reduceddegassing=MIN,Normaldegassing[default]=MED,andStrongdegassing=MAX).

Thequantityofmediumsuppliedtothevesselisreturnedtothecirculationlinesystemconnection (B)returnviaabypasslinewhile

thepumpisrunning.Cyclicaldegassingtakesplacein“Fullyautomatic”mode.Inthismode,thepumprunningtime(vacuum

build-up)alternateswiththeejectionoftheseparatedair(reducedpumpspeed).

AlthoughtheVacumatEcoworksveryquietly,fullyautomaticdegassingoperationmodecanbeinterruptedbyfreelyprogrammable

breaks(e.g.,atnight).Itisalsopossibletoswitchoffdegassing.Thesystemistheninstandbymode.Topping-upcanstillbedonein

thismodeasneeded.

5.4.2 Top-up

Bothpressure-controlledandlevel-controlledtopping-upcanbeperformed.

Topping-upoccurswhenthemotorballvalve(6)switches;mediumthenpassesintotheEcoVacumatthroughthetop-upopening(C)

andisfedtothesystembythepump.

Topping-upinterruptsbreaksandstandbyoperatingmode,orfollowscompletedcyclesofnormaldegassingorcheckdegassing.

Ifthetop-uprequirementisactive,itisprimarytoallotherprocessesbecausethepressuremustbemaintainedaboveallelse.

5.4.3 Pressure-controlled top-up

Equivalenttofactorysettingtotop-uppressureholdingsystemswith(passive)diaphragmpressureexpansionvessels.

Thetop-upswitch-onandswitch-offpressurescanbeeditedinthepressurescreen.

5.4.4 Level-controlled or externally-controlled top-up (for active pressure maintenance)

Theoperatorhastheoptiontousethelevel-controlledtop-upforpressuremaintenanceusinganautomaticpressureholdingdevice.

(Seeterminaldiagram/electricalconnection)Topping-upoccurshereforaslongastheexternaltop-uprequestispresentand

VacumatEcovolumeortime-monitoringallowsit.

5.4.5 Top-up OFF

Top-upcanalsobedisabledviasoftwareintheStartmenu.

TemplateA4_v20130506

ENG

13

5.4.6 Operating mode - fully automatic

Oncethesystemhasbeenfullysetup(Startmenucompleted)andcommissioned,andthecontrolunithasbeenswitchedon,a

delayrstoccurs;thenthetemperatureinthemachineisinitiallyadjustedforapresetperiodbeforeitismeasured.Basedonthe

temperatureandthepresetcheckdegassingmode,theprocessinthevesselisregulatedsothat,afteracertaintime,itispossible

todetermineatthepressureswitchwhetherundissolvedairstillexistsinthemediumatthelevelpredenedbythedegassingmode.

Ifthisisnotthecase,noairisdischargedincheckdegassinganddegassingisinterrupted;then,afterreadjustingthetemperature,

thegasloadistestedagainandtheprocessisrepeated.

However,ifairisdischargedfromthevesselinthecheckdegassingdischargephase,checkdegassingisfollowedbynormal

degassing;alowernegativepressureisbuiltupthanincheckdegassingandthemediumisundersaturatedwithrespecttothe

existinggascharges.Thisisrepeatedcyclicallyuntileithercheckdegassingispending,orthesystemswitchestoadegassing

waitbecausenoairisdischargedattheendofthedischargephaseduringnormaldegassing.Thesystemthencontinueswiththe

temperatureadjustmentsandcheckdegassingafteraspeciedintervaltime.

t

n

Zyklenablauf Vacumat ECO 20150417

5.4.7 Standby operating mode

Topping-uponlyoccursinthismodeduring"virtuallypermanentpauses"innormaldegassing,andthusinterruptsthepauses.

Checkdegassingisnotperformed.

Inaddition,thestandbysettingcanalsobeinducedbybridgingcontact39and40(takespriorityoverthesoftwaresetting).

Thiscanbeusedto,forexample,switchoffdegassingremotelyoralsotointerruptdegassingwhenthecirculationpumpsare

switchedofftopreventinefcientdegassing.ItisnotnecessarytowaituntiltheVacumatEcodetectsthisproblem(withadelay)

aftercheckdegassingorbecausenogasisdischargedduringnormaldegassing.

5.4.8 Break times / exclusion times with blocking intervals

Breaktimesfordegassingcanbedenedsothatatime-limitedstandbymodeisimplementedautomaticallyatcertaintimesofday.

Upto8blockingintervalscanbeimplementedperdayforthesebreakswhicharereferredtoasexclusiontimesinthisdocument.

5.4.9 Vacuum test

Requiresthesupplyconnectiontobeshutoffwhenthevesselisfull(comingfromthesystemreturn).Whendoingso,thepump

generatesavacuumafteracoupleofseconds;thevacuummustremainstableforaspeciedperiodoftimeinordertoverifythe

pump’sperformanceandensurethevesselisleak-tight.Thistestistypicallyneedstobeperformedpriortocommissioningand

aftermaintenance.

Generate vacuum Discharge

Decision:

Normal degassing or

interruption

Generate vacuum Discharge

Adjust

temperature

Switch-on

delay

Control unit ON

* Pump runs at a low speed level in order to achieve discharge pressure in the vessel.

** Pump runs at a higher speed level in order to build up the target vacuum in the vessel.

*** Pump runs at a high speed in order to build up a stronger vacuum in the vessel and degas effectively.

Pump OFF

Pump ON*

Pump ON**

Pump ON***

Pause

normal degassing

Cycle

Normal degassing

Cycle

Check degassing

TemplateA4_v20130506

14

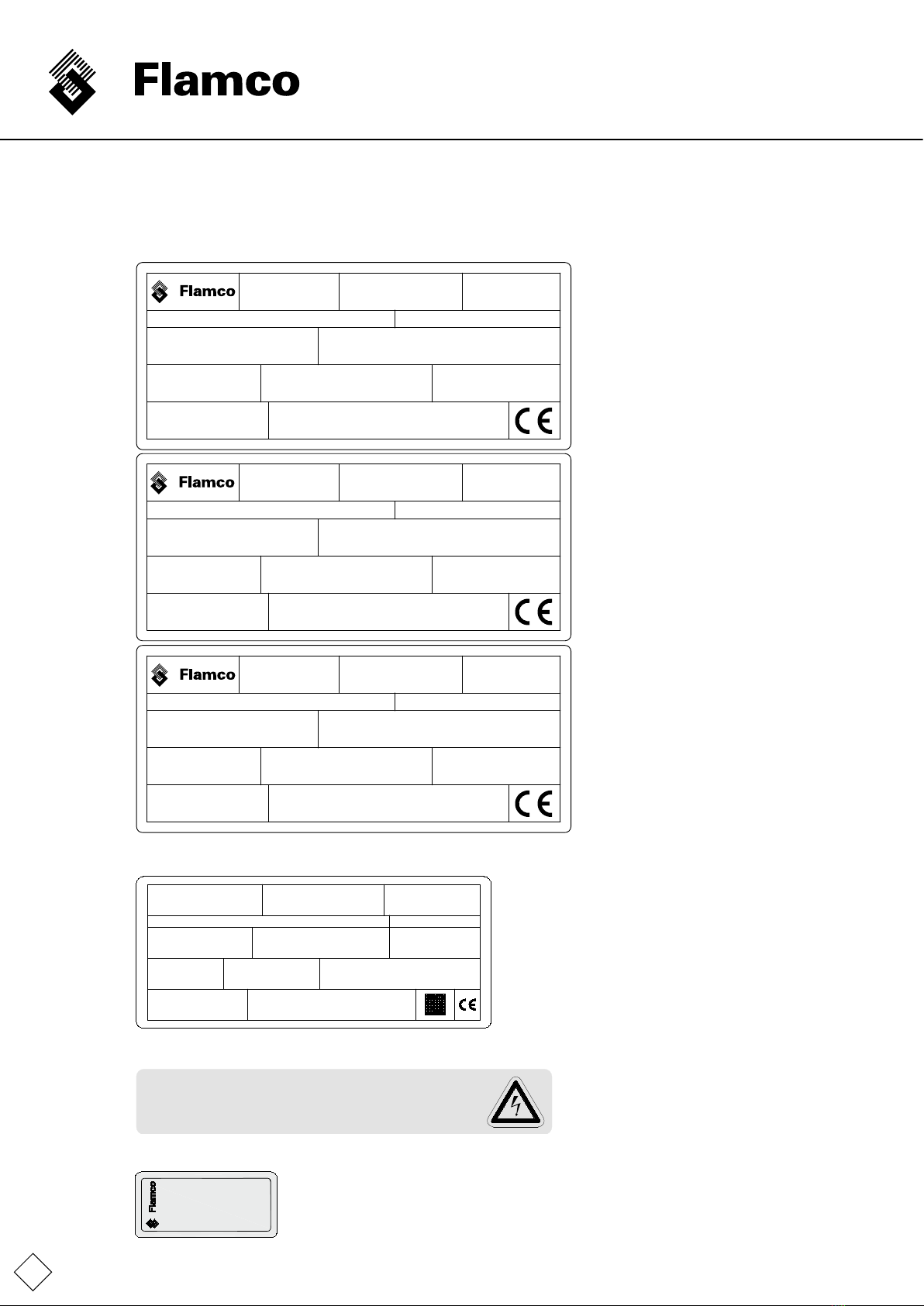

5.5 Marking

(withexamplesandplaceholdersforvariableinformation)

5.5.1 Type plates

Flamco STAG GmbH; Berliner Chaussee 29; 39307 Genthin; Germany

Typ:

Type:

Type:

Type:

Serien-Nr.:

Serial-No.:

N° de Série:

Volgnummer:

Nennspannung:

Nominal voltage:

Tension nominale:

Nominale spanning:

Vacumat Eco 900

1x 230 V 50/60 Hz

Zulässige Medientemperatur min. / max.:

Permissible media temperature min. / max.:

Température de média mini. / maxi. admissible:

Toegestane temperatuur media:

3 / 90 °C

Nennstrom:

Nominal current:

Courant nominal:

Nominale stroom:

6,8 A

Zulässiger Betriebsüberdruck:

Permissible working overpressure:

Surpression de service admissible:

Toelaatbare werkdruk:

-1/+10 bar

Herstellungsjahr:

Year of manufacture:

Année de fabrication:

Jaar van vervaardiging:

20xx

Nennleistung:

Nominal power:

Puissance assignée:

Nominaal vermogen:

1,1 kW

Zulässige Umgebungstemperatur min. / max.:

Permissible ambient temperature min. / max.:

Température de ambiante mini. / maxi. admissible:

Toelaatbare omgevingstemperatuur min. / max.:

3 / 45 °C

Schutzart:

Protection:

Protection:

Bescherming:

IP 42

Flamco STAG GmbH; Berliner Chaussee 29; 39307 Genthin; Germany

Typ:

Type:

Type:

Type:

Serien-Nr.:

Serial-No.:

N° de Série:

Volgnummer:

Nennspannung:

Nominal voltage:

Tension nominale:

Nominale spanning:

Vacumat Eco 600

1x 230 V 50/60 Hz

Zulässige Medientemperatur min. / max.:

Permissible media temperature min. / max.:

Température de média mini. / maxi. admissible:

Toegestane temperatuur media:

3 / 90 °C

Nennstrom:

Nominal current:

Courant nominal:

Nominale stroom:

5,18 A

Zulässiger Betriebsüberdruck:

Permissible working overpressure:

Surpression de service admissible:

Toelaatbare werkdruk:

-1/+10 bar

Herstellungsjahr:

Year of manufacture:

Année de fabrication:

Jaar van vervaardiging:

20xx

Nennleistung:

Nominal power:

Puissance assignée:

Nominaal vermogen:

1,1 kW

Zulässige Umgebungstemperatur min. / max.:

Permissible ambient temperature min. / max.:

Température de ambiante mini. / maxi. admissible:

Toelaatbare omgevingstemperatuur min. / max.:

3 / 45 °C

Schutzart:

Protection:

Protection:

Bescherming:

IP 42

Flamco STAG GmbH; Berliner Chaussee 29; 39307 Genthin; Germany

Typ:

Type:

Type:

Type:

Serien-Nr.:

Serial-No.:

N° de Série:

Volgnummer:

Nennspannung:

Nominal voltage:

Tension nominale:

Nominale spanning:

Vacumat Eco 300

1x 230 V 50/60 Hz

Zulässige Medientemperatur min. / max.:

Permissible media temperature min. / max.:

Température de média mini. / maxi. admissible:

Toegestane temperatuur media:

3 / 90 °C

Nennstrom:

Nominal current:

Courant nominal:

Nominale stroom:

2,85 A

Zulässiger Betriebsüberdruck:

Permissible working overpressure:

Surpression de service admissible:

Toelaatbare werkdruk:

-1/+10 bar

Herstellungsjahr:

Year of manufacture:

Année de fabrication:

Jaar van vervaardiging:

20xx

Nennleistung:

Nominal power:

Puissance assignée:

Nominaal vermogen:

0,4 kW

Zulässige Umgebungstemperatur min. / max.:

Permissible ambient temperature min. / max.:

Température de ambiante mini. / maxi. admissible:

Toelaatbare omgevingstemperatuur min. / max.:

3 / 45 °C

Schutzart:

Protection:

Protection:

Bescherming:

IP 42

5.5.2 SPC m1 control unit type plate

Herstellungsjahr

Année de fabrication

:

:

:

Year of manufacture

20XX

Tension assignée d'emploi

Bemessungsbetriebsspannung

Rated operational voltage

:

:

:

Phasenzahl

Nombre de phase

Number of phases

1

:

:

:

Frequenz

Fréquence

Frequency

:

:

:

Volllaststrom

Courant de coupure

:

:

:

Bemessungskurzschluss-Strom

Mesure de la courant de court-circuit

:

:

:

Dokumentationsnummer

Numeró de dessin :

:

:

Schutzart

Protection

Degree of protection IP54

:

:

:

Flamco STAG GmbH; Berliner Chaussee 29;

39307 Genthin; Germany

Cut-off current 16A

Rated short-circuit current 16A

Drawing number 952-19.13.27-1

Typ :

Type:

:Type Serial-No.

Serien-Nr.

N° de série

:

:

:

Classe de protection

Protection class

I

Schutzklasse

:

:

:

SPC m1/1.2 - lw

50/60Hz

±1%

230V

±10%

5.5.3 Electrical safety

high voltage! Opening by qualified personnel only.

gefährliche Spannung! Nur vom Fachpersonal zu öffnen.

Disconnect the unit from the power supply before opening it.

Vor dem Öffnen des Gerätes spannungsfrei schalten.

Attention,

Achtung,

5.5.4 Service numbers

Service Germany

+49 0 2052 887 969

+49 0 2052 887 69

Fax.:

Tel.:

Service Nederland

+31 0 33 299 7500

+31 0 33 298 6445

Tel.:

Fax.:

()

)(

)

)(

(

TemplateA4_v20130506

ENG

15

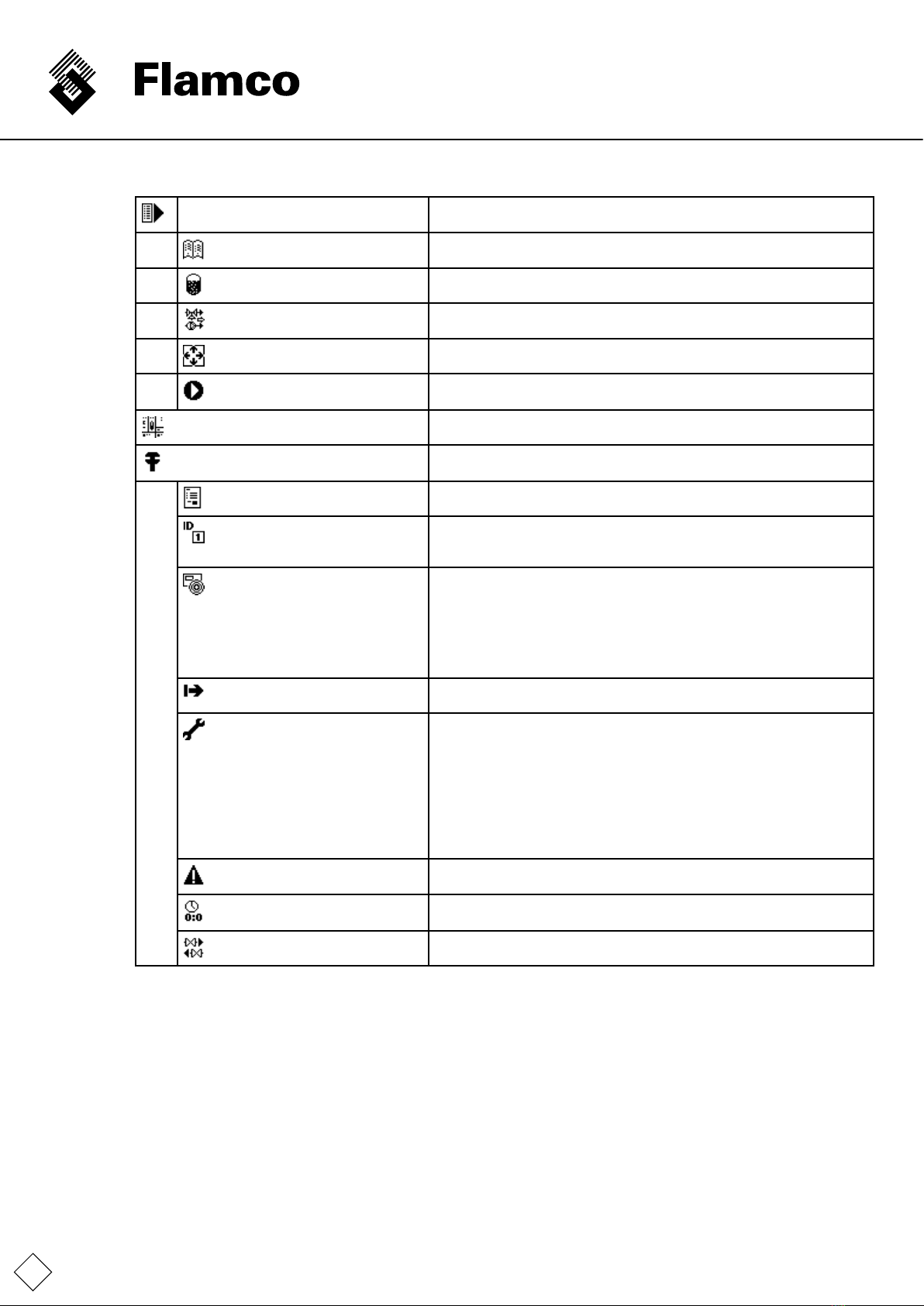

5.5.5 Label from the terminal board cover (inside)

31 32 33 34 35 36 37

1 3 6 7 8 9 10 11

+24V

counter

signal -

analog IN

sensor

SPC m1/V1.0

45 46 48 49 51 52

N

16 17 22 23 25 26

N L

~

N L

signal in

mains supply

230V 50/60Hz

44 47 50

PE

15 21 24

PEPE

extra - low voltage

Terminal

42 43

N L

41

PE

19 20

1812 13 14

38 39 40

fault

NCNO

2 4 5

27 28 29 30

+24V / signal +

Read the manual !

Bedienanweisung lesen !

+24V / signal +

signal -

GND

INPUT

FC OUT

OUT +

OUT -

4 - 20 mA

refill IN 230V FU/ FC

level

switch

pressure

switch refill release

FC

5A

5A 30

250 VDC

VAC

ohmic load

Störung FU

Standby

GND

sensorsensor

ATTENTION:

Even if unit is isolated from

power supply, terminals 12,

13, 14, 16 and 17 may carry

230V voltage!

ACHTUNG:

Trotz Netztrennung kann, an

den Klemmen: 12, 13, 14, 16

und 17 eine Spannung von

230V anliegen !

FC

M

fault FC

system

temperature

pwm

pressure

vessel

pressure

analog

out

0 - 10 V

OUT

analog

out

motor ball valve

high voltage (230V 50/60Hz)

option

L

RS232

option

11.06.2015

option

option

GND

GND

GND

GND

GNDA

AGND

Klemmenplan Vacumat ECO 20150708

Explanation of the abbreviations on the label on the terminal board cover.

Note:Theswitchsettingsshownrepresentthecurrent-free,non-switchedstate.

FU/FC Frequencyconverter

rellIN230V Top-up signal input 230V

extra-low voltage Protective low voltage

fault Fault,commonfaultoutput

MMotor(pumpmotor)

high voltage Voltage as per markings

L Phase

N Neutral wire

PE Protectiveearth(PE)conductor

mainssupply Powerfeed

NO normallyopen(volt-freeinopenposition)

NC normallyclosed(volt-freeinclosedposition)

pwm Inputforwatermeterwithpulseoutput(option)

sensor Sensor

systempressure Systempressuresensorinput

vessel pressure Vessel pressure sensor input

temperature Temperature sensor input

FC out FC out

ohmicload Ohmicload,resistance

motorballvalve Motorballvalve

level switch Levelswitch/oatswitch/dryrunprotection

pressure switch Pressureswitchcontrolleddegassing

rell Top-up

release FC release FC

standby standby

mainssupply Mainsfeed

GND/AGND/GNDA Mass(A=analogue,onlyconnectedasperterminaldiagram)

out analogue out analogue

TemplateA4_v20130506

16

6. Assembly

6.1 Installing, levelling, bolting - Ensure stability!

Setuptheunitonaatandstable(concrete)surfacenearthewellintheoperating/boilerroom.

Ensure that a oor drain is available for the unit.

Usebothframeholesonthebaseplate(Ø12)tosecuretheVacumatEcoagainsttipping.Usesufcientlylong(stainless)

steelscrewsØ10(withplugsandpossiblyplasticwashers)forthisinordertoanchortheminthegroundinsuchawaythattipping

canbeprevented,butsothatthescrewdoesnottransmitstructure-bornenoise.(Donottightenthescrewtootightly.)

Notetherequiredminimumdistancestowalls,maintenanceareasandassemblyareas(seeAppendix1)

6.2 Connecting the pipework

Note:Onlyworkingtemperaturesofbetween3and90°Carepermissible.Bearthisinmindwhenselectingtheplaceofinstallation.

Makesurethatthisconnectionismadesolelywiththeheatgeneratorandthattherearenoexternalhydraulicpressureinuences

presentatthepointofentrainment(e.g.hydraulicbalancers,distributors).

PipelinediametersmustbeatleastsizeDN32ontheunit'spressureports.

Ifthepipeworklengthismorethan10metresfromthepressureportstothereturnpipe,theconnectionpipesmustbeatleast

DN40.TheinletconnectionsfromthesystemandtoppingupmustbeatleastDN20.AtleastDN25mustbeusedforpipelines

longerthan10m.Thebranchpipeconnectionlengthstothesystemmustnotexceed20m.

Usesealantsandfeedlinesappropriatetotheinstallation;however,pleaseobserveatleastthemaximumpermittedvolumetricow,

pressureandtemperaturevaluesforthepipeworkinquestion.

Make sure that all connections to the unit are installed so that they are without tension at the joints!

Reinforced hoses must not be subjected to tension, twisting or kinking, etc. If a reinforced hose is used on the inlet to the

unit it must be designed to be vacuum-tight!

6.3 Connecting the electrical supply

ThepowersupplyconnectionmustbecreatedbythecustomerbetweenthemainssupplyandtheSPCm1.

Themainssupply,earthingsystemandcableprotectionmustbeprovidedincompliancewiththerequirementsoftheresponsible

powersupplycompany(PSC)andtheapplicablestandards.Therequiredinformationcanbefoundonthetypeplateofthecontrol

unitandtheterminalplan(labelling;Appendix4).

ThemainsconnectiontobeprovidedviaasuitableCEEplug/socketcombinationwithload-switchingabilityorotherpermissible

mainswitch.

Thiselectricalinstallationworkmustbeperformedbyaqualiedelectricallyskilledpersonnel.

Note:installequipotentialbondingbetweentheearthconnectionandequipotentialbondingconductor.Theminimumdiameter,

qualityandtypeofthepowercablesmustcomplywiththerulesandregulationsapplicableattheinstallationlocationforthis

application.Electricalpowercablesshouldbeguidedalongcableguttersatalltimes.

Thenishedsystemallowstheusertoprogramthecongurationandsystem-dependentparametersintothecontrolunit.

For more detailed instructions regarding the top up function check additional instructions at www.amcogroup.com.

7. Commissioning

7.1 Commissioning

Keepacommissioninglog!

Checkthattheinstallationandassemblyactionsarecomplete(e.g.powersupplyavailableatthemainsdistributionboard,

functioningoractivatedfusesandprotectiveconductorconnections,equipmentisfreefromleaksandthestablesetupoftheunit).

1. Afterthecapvalveandtheballvalveontheunithavebeenopened,thepumpautomaticallyde-aerated,thevessellledwith

systemmedium,theaircompletelydischargedfromthevesselviathede-aeratorunitandthesystemimpermeabilityischecked,

thecontrolunitcanbeswitchedon.Firstthecontrolunithardwarestatusandthenthesoftwarestatusaredisplayed.

2. NowstartworkingthroughtheStartmenu.Youmayneedtobeloggedonwiththeappropriateaccesscodeforanydelegated

responsibilities.Iftheresponsibilitiesaredelegatedtothecustomer/operatororpresetexworks(asinmostcases),youwillnot

needaspecialaccesscodetoworkthroughtheStartmenu.

3. AfterconrmingthelastmenuitemintheStartmenu:"START",thesystemstartsfullyautomaticoperation.

TemplateA4_v20130506

ENG

17

7.2 Settings / control actions

IndividualcontrolactionscanbeperformedbytappingthesensorsurfacesmarkedwithLEDsorwithngermovementsonthe

sensorwheel.WhenyouhaveworkedthroughtheSTARTmenuandthesystemhasstartedup,thesystem'sstatuscanbeprecisely

monitoredusingvariousoperationalindicators(1to3)includingstatisticalanalysisofthesystemvalues.Thebasicmenustructure

canbefoundinAppendix3ofthisdocument.

ItispossibletochangetheexistingsettingsviatheCONFIGURATIONafter"START".Asthechangetothetop-upcontroltypeis

abasiccongurationandpossiblyalsodenedbytheequipmentlevel,thisisonlypossibleviatheSTARTmenu.Tothisend,the

systemisstoppedwhenthe"ResetStartmenu"itemisselectedinCONFIGURATION,andanewversionoftheSTARTmenuis

workedthroughbasedonappropriateprompts.(Forthispurposeitmaybenecessarytorepeatthepressuresettingsastheymay

havebeenresettothefactorysettings.)

7.3 Recommissioning

Recommissioning(e.g.,afterextendedperiodsofinactivity/shutdownandmaintenance)assumesthatthesystemisfreefromleaks

andcorrectlyconnectedelectrically.Afterextendeddowntimesitisadvisabletoperformmaintenancebeforerecommissioning.

7.3.1 Visual check of the temperature contact sensor - check assembly

FortheVacumatEcotofunctioncorrectly,itisessentialthatthetemperaturesensor(Pos.9inthesystemdiagram)hasareliable,

xedcontactwiththepumpbodythroughthetensioningstrapthatattachesittothepumpbody.Itisalsoveryimportantthat

thetemperaturecontactsensorissufcientlyshieldedagainstambienttemperatureswiththesensorinsulation(pos17).

Thismustalwaysbecheckedduringcommissioning,systeminspection,servicingormaintenance!

7.4 Explanations relating to the SPC m1 control menu

Explanations relating to the SPC m1

control menu Testing data points

alsoincludesavacuumtest.

Menu item 2: Data transfer makesitpossibletoperformsoftwareupdatesfortheSDcardviathe

extensionmoduleortoreaddata.

Menu item 3: Date / time mustbeusedtosetthecorrecttimeonthecontrolunit.(Thesystem

clockisbatterybufferedandlastsforabout10yearswithoutamains

connection.)

Menu item 4: Language canbeselectedtochoosealanguageforcommunicatingwiththecontrol

unitfromuptotwentydifferentlanguages.

Menu item 5: Log in supportstheentryofaccesscodesinorderforservicestafftocarryout

settings,includingsettinginternalFlamcoparameters.

Menu item 6: Logout supportsloggingoutafterusingaccesscodes.

Menu item 7: Inaccessibleforthecustomer/operator.

Menu item 8: Conguration allowsuserstosetorchangethedifferentdefaultsthatarerelevantfor

operatingthesystem.

Degassing modes 8-1:

Default → Fully automatic

Optional → Standby

Blocking times

Check degassing

(settingup)(softwaredefault)Onlytop-upispossiblehere!

fordegassing.Nighttimebreakscanbesetup,forexample.

Checkdegassingtype.Checkforgasresidualsolutioncontent:

8ml/lofair=MAX

12ml/lofair=MED

15ml/lofair=MIN

Top-up 8-2:

Top-up capacity 8-2-1-3:

Parameter list 8-2-2:

Preconfiguration50L(whenpulsewatermeterandmakeupare

configuraredbytheSalesEngineerorserviceDepartment).

Accept/edittop-updefaults.

Pressure 8-3:

Pressure settings 8-3-1: Default →Editfactorysettings.*

Error messages 8-5: Default →16grouperrormessagesnotoncontact.

Reset Start menu 8-6: →Activateeditingmode!

TemplateA4_v20130506

18

Menu item 9: Start-up menu Onlyavailableaslongasithasnotyetbeenfullyprocessed,forexample,

afterinitialcommissioningorresettingtheStartmenuinthe"Conguration".

Read the instruction manual 9-1:. →Readandacknowledge.

Degassing modes 9-4: →Choosebetweenfullyautomaticandstandby.

Control type 9-5: →pressure-controlled,externally-controlledortop-upOFF

seealsoTop-upsection.

Pressure settings 9-6: →Editpressuresinthediagram.

START 9-7: →TriggersystemSTART;jumptooperatingdisplay1.

(Thecommissioningtimeisalsologged.)

Menu item 10: Operating menu 3screens-seeAppendix3-Menustructureoverview.

Menu item 11: Service Menuitemforreadinginformationaboutthecontrolunitandtheoperation

alreadyperformedandfaults.

Order number 11-1 →Ordernumber/Date/Time/Inputcodelevel.

System info 11-2: →11-2-1SystemID/type

→11-2-2Degassingmode

→11-2-3Controltype

Version information 11-3: →11-3-1Controlunitsoftware/hardware

→11-3-2Terminalsoftware/hardware

→11-3-3Database

→11-3-4Bootloader

→11-3-5 Language file

→11-3-6VersionofanymodulesfittedinSLOT1

→11-3-7VersionofanymodulesfittedinSLOT2

Commissioning 11-4: Datecommissioning/time/codelevelduringcommissioning.

Maintenance 11-5:

11-5-1 Due date or comment

about the performed

maintenance 1

11-5-2 Due date or comment

about the performed

maintenance 2

11-5-3 Reset treatment

Recurringdevicetest(1year).

Recurringelectricaltest(1.5years).

Resetprocessingcapacitydate/time/codelevel.

History 11-6: →Faultcode/Fault/Date/Timeofoccurrence(upto100faultscanbe

traced).

Operating times 11-7: →Motorpump/motorballvalve/pressureswitch/degassingtotalsince

commissioning.

Top-up 11-8: →Top-upamount/top-uptime/top-uplist/processing.

* Flamco will not accept any liability for the consequences of incorrect parameterisation.

It may sometimes be necessary to rst edit a pressure value other than the intended one so that the actual value to be

changed receives enough space so that no implausibilities arise that could prevent system operation.

TemplateA4_v20130506

ENG

19

8. Maintenance

ThecomponentsoftheVacumatEcoarelargelymaintenance-free.

Nevertheless,itisrecommendedtoperformanannualvisualcheckofthesystem(includingforleaks).Inaddition,thedirttraptobe

providedbythecustomerintheinowlinemustbecleanedatleastonceayear,evenifautomaticdetectiondoesnotrequirethis.

Cleaningmayalsobedoneatmorefrequentintervals(dependingonhowdirtythesystemwateris).

Shouldavisualcheckofthesystemnecessitatefurthermaintenance,thismayalsoonlybedonebyqualiedpersonnel.

The temperature contact sensor must be visually inspected (Check assembly) at least during maintenance!

(alreadydescribedinCommissioning)

Itisalsorecommendedtoperformthevacuumtestaftermaintenance.

ThemenuitemServiceintheServicemenucanbeusedtoreadoffthenextservicedate.ThisshouldbeanaidfortheOperator.

Thenextservicedate(inbrackets)issavedhere.Ifthesystemclockiscorrectlyset,theOperatorwillbeinformedaboutreaching

thedateviaamessage.

365daysformaintenance1and548days(1.5years)formaintenance2areprovidedaftercommissioning.

TheVacumatEcocontinuestoworkwhenagrouperrormessageistriggered.

“Servicedone”shouldonlybeconrmedbyauthorisedstaff.Thecontrolunitthendeterminesthenextservicedateitself.

Maintenance 1standsformaintenancedevice.

Maintenance 2standsfortheperiodicinspectionofelectricalequipment.

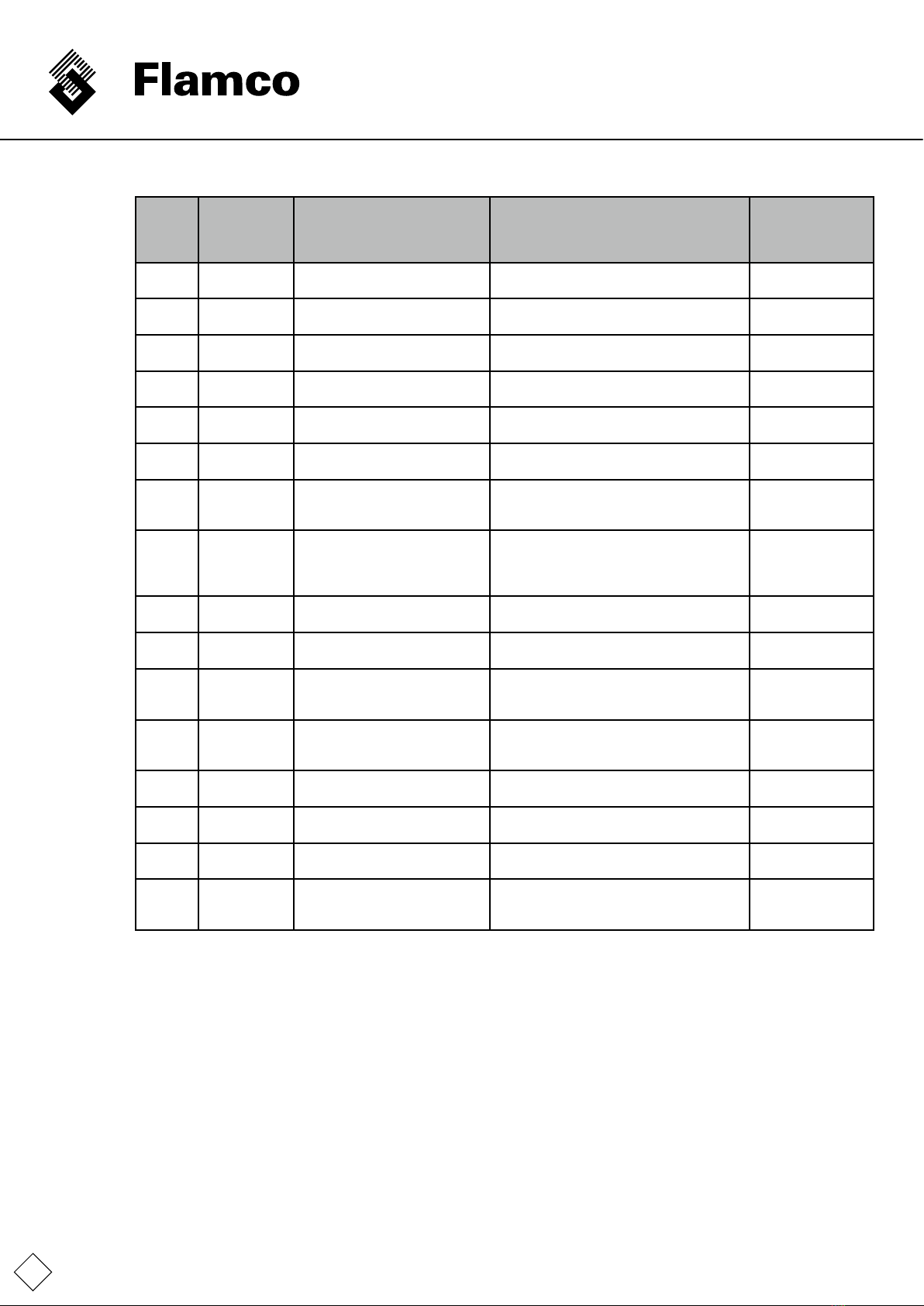

8.1 Malfunction list / error messages

Error

no. Error

message Error / Name Effect / Action holding /

subject to

mandatory

acknowledgement

2PS 20mA ↑Pressure sensor overcurrent /

sensor fault

Systeminforcedrest;motor,motorball

valveimmediatelyOff/Reducepressurein

system/changesensor.

NO

3PS 4mA ↓Pressuresensorcablebreak/

sensor fault

Systeminforcedidlemode;motor,motor

ballvalveimmediatelyOff/Repaircable/

changesensor.

NO

4VS 20mA ↑Vacuum sensor overcurrent /

sensor fault

Systeminforcedidlemode;motor,motor

ballvalveimmediatelyOff/Reduce

pressure/changesensor.

NO

5VS 4mA ↓Vacuumsensorcablebreak/

sensor fault

Systeminforcedidlemode;motor,motor

ballvalveimmediatelyOff/Repaircable/

changesensor.

NO

6↓↓ Temp Temperature sensor short circuit

/ sensor fault

Faultshutdown/Checkcableand

clamping/changesensor.

NO

7↑↑ Temp Temperaturesensorcablebreak

/ sensor fault

Faultshutdown/repaircable/change

sensor.

NO

8↓ Pressure Lower alarm limit pressure

undershot(Pamin)

Faultshutdown/Leadpressureinthe

workingpressurerange.

NO

9↑ Pressure Upperalarmlimitpressure

exceeded(Pamax)

Faultshutdown/Leadpressureinthe

workingpressurerange.

NO

12 ↓ Temp Temperaturerangeundershot Faultshutdown/guidetemperatureto

operatingtemperaturerange.

NO

13 ↑ Temp Temperaturerangeexceeded Faultshutdown/guidetemperatureto

operatingtemperaturerange.

Faultshutdown.

NO

14 TC / FC motor TC / FC message motor pump Systeminforcedidlemode;motor,motor

ballvalveimmediatelyOff/switchoff,5

minbreak,switchon.

YES

15 Dryrunning Filling level limit in the vessel

permanentlyundershot

Systeminforcedidlemode;motor,motor

ballvalveimmediatelyOff/expandsupply

line,excludepressureportcontraction.

YES

22 Top-up

volume ↓

IWZ(pulsewatermeter)delivers

nowateraftertop-uprequest

Top-upoff/Ensuresupply. YES

TemplateA4_v20130506

20

Error

no. Error

message Error / Name Effect / Action holding/

subject to

mandatory

acknowledgement

23 Top-up

inadmissible

Top-upwithoutrequest(IWZ

deliverssignalswithoutsupply)

Top-upoff/checkmotorballvalveforleaks

fortop-up.

YES

24 Top-up interval

↓

minimumtop-upcycleinterval

undershot

Top-upof/correctdefaultsifnecessary;

excludepipeburst.

YES

25 Top-up

number↑

maximumnumberofcycles

withinatimewindowexceeded

Top-upof/correctdefaultsifnecessary;

excludepipeburst.

YES

26 Top-up

volume ↑

Maximumvolumeexceededina

top-upcycle(withIWZ)

Top-upof/correctdefaultsifnecessary;

excludepipeburst.

YES

27 Top-up time ↑Maximumtimefortop-upcycle

exceeded(withoutIWZ)

Top-upof/correctdefaultsifnecessary;

excludepipeburst.

YES

31 v 3 ↑Watertreatmentmodule

processingamountexceeded

Top-upoff/correctdefaultsifnecessary;

replacetreatmentmodule.

YES

35 Temp

controller

Pressurecontrollerfaulty Faultshutdown-targetpressureinvessel

notreached/contactservice.

Possibilityofacontaminatedlter.

YES

37 P output Dischargepressurenotreached

withinthe"maximumduration

for waiting for ejection pressure

cycleendtobereached"

Faultshutdown-targetpressureinvessel

notreached/contactservice.

Possibilityofacontaminatedlter.

YES

39 Pa max ↑Pamaxexceeded Faultshutdown/Reducepressuretowithin

theworkingpressurerange.

YES

41 Adjustpsys Adjustsystempressurefault Motorshutdown/Ensureinletpressurefrom

thesystem.

YES

42 No

characteristic

curve

Novaliddegassingcharacteristic

curve

Novaliddegassingcharacteristiccurve. YES

55 v 1 ↑Watertreatmentmodule

processing amount warning

threshold1

No/Preparemodulereplacement.

(consumptionat70%)

YES

56 Maintenance

1!

Nextmaintenancetype1is

pending

No/Performmaintenance1. YES

57 Maintenance

2!

Nextmaintenancetype2is

pending

No/Performmaintenance2. YES

60 Extension Lastexternalmoduleactionwith

errorsended

No/repeatactionifnecessary. YES

61 v 2 ↑Watertreatmentmodule

processing amount warning

threshold2

No/preparemodulereplacement

(consumptionat90%)performmodule

replacementimmediatelyifnecessary.

YES

If any errors other than those described occur and they cause permanent problems (not self-acknowledging), please contact

the service to solve the problem!

This manual suits for next models

3

Table of contents

Languages:

Other flamco Water Filtration System manuals

flamco

flamco FlexBalance EcoPlus C Series User manual

flamco

flamco Flamcovent Smart Owner's manual

flamco

flamco Clean Smart User guide

flamco

flamco Flamcovent Clean Smart User manual

flamco

flamco Flamcovent Clean Smart User guide

flamco

flamco Flamcovent Smart User guide

flamco

flamco Flamcovent Clean F User manual

flamco

flamco MeiFlow Shunt UD DN15 S Installation and maintenance instructions

flamco

flamco Clean User manual

flamco

flamco Clean User manual