Table of Contents

427-0075-01-12 Revision 140 October 2019 3

This document does not contain any export-controlled information.

PT-Series HD Camera Installation

1.1 Camera Overview ......................................................................................................................5

1.2 Installation Overview ..................................................................................................................5

1.2.1 Camera Connection Options ............................................................................................5

1.2.2 Serial Communications Overview ....................................................................................6

1.2.3 Supplied Components ......................................................................................................6

1.2.4 Required Components .....................................................................................................6

1.3 Location Considerations ............................................................................................................7

1.4 Bench Testing ............................................................................................................................7

1.5 Camera Mounting ......................................................................................................................7

1.5.1 Galvanic Isolation .............................................................................................................7

1.5.2 Earth Ground Connection .................................................................................................8

1.5.3 Installation of Camera and Galvanic Isolation Kit .............................................................9

1.6 Camera Connections ...............................................................................................................12

1.6.1 Remove the Back Cover ................................................................................................12

1.6.2 Connecting power ..........................................................................................................13

1.6.3 Video Connections .........................................................................................................14

1.6.4 Ethernet Connection .......................................................................................................14

1.6.5 Serial Connection ...........................................................................................................14

1.6.6 Serial Communications Settings - Hardware DIP Switches ...........................................15

1.6.7 Back Cover Gasket ........................................................................................................17

1.6.8 Cable Gland Sealing ......................................................................................................17

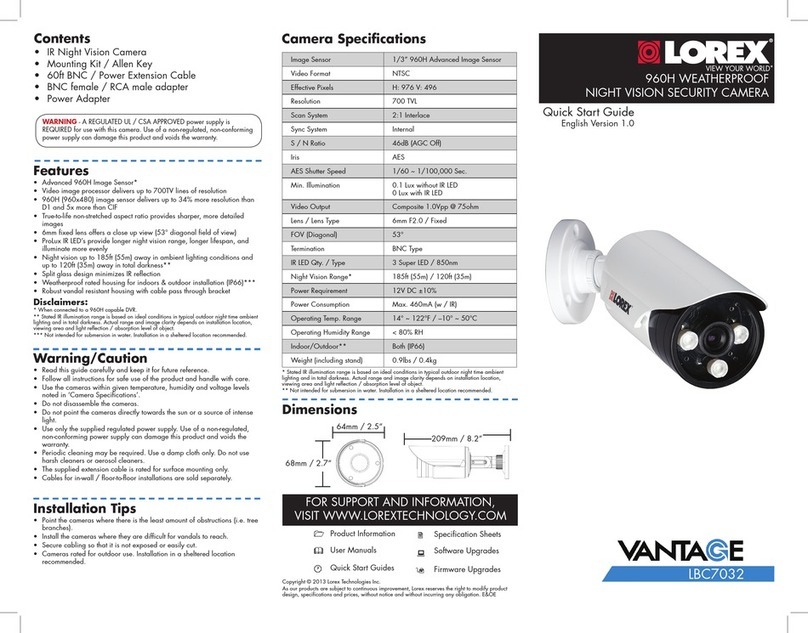

1.7 PT-Series HD Camera Specifications ......................................................................................19

Basic Operation and Configuration

2.1 IP Camera, ONVIF Profile S Compliant ...................................................................................21

2.1.1 Serial and/or IP Communications ...................................................................................21

2.1.2 Server Configuration ......................................................................................................21

2.2 Camera Bench Test .................................................................................................................21

2.2.1 Set IP Address using the FLIR Discovery Network Assistant (DNA) .............................22

2.3 Log into the Camera Web Page ...............................................................................................23

2.3.1 Live Video Page .............................................................................................................24

2.3.2 Camera Control and Status ............................................................................................25

2.3.3 Web Control Panel .........................................................................................................25

2.4 Camera Configuration ..............................................................................................................27

2.4.1 Expert and Admin Accounts ...........................................................................................28

2.4.2 Setup Menu ....................................................................................................................29

2.4.3 Maintenance Menu .........................................................................................................34

2.4.4 Files Menu ......................................................................................................................50

2.5 Thermal Imaging Overview ......................................................................................................52

2.6 Troubleshooting Tips ...............................................................................................................53

Serial Address: Decimal To Binary Conversion

3.1 Address Conversion Table .......................................................................................................56