2

TECHNICAL DOCUMENTATION: EN

TABLE OF CONTETNS

1. IMPORTANT INFORMATION............................................................................................................................................ 3

2. GENERAL INFORMATION ................................................................................................................................................ 4

3. CONSTRUCTION............................................................................................................................................................... 4

4. TECHNICAL DATA SLIM N/W ........................................................................................................................................... 5

5. TECHNICAL DATA SLIM E ................................................................................................................................................ 6

6. DIMENSIONS INFORMATION .......................................................................................................................................... 7

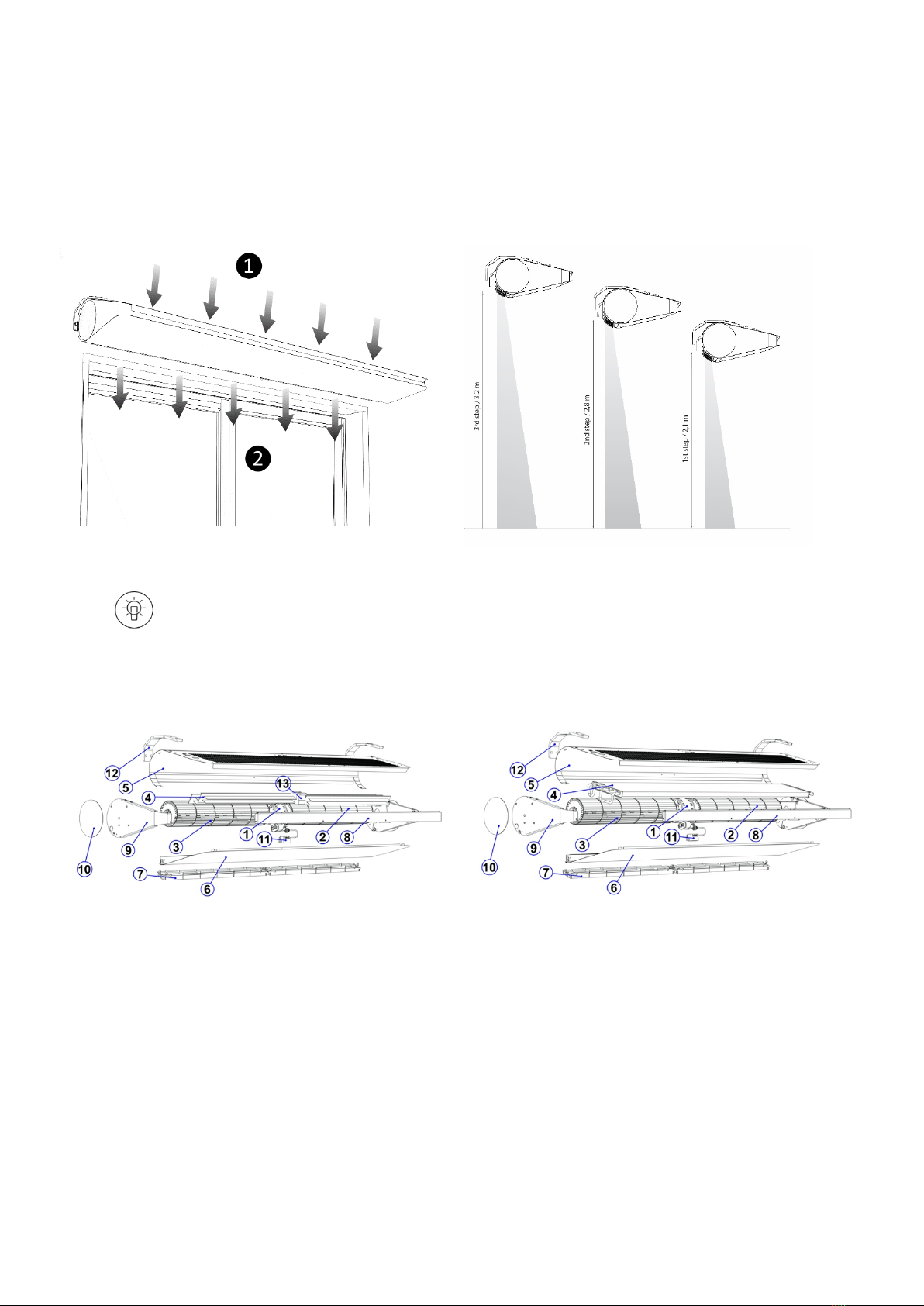

7. INSTALATION INFORMATION......................................................................................................................................... 7

8. MOUNTING - RECOMMENDED DISTANCES INFORMATION........................................................................................... 8

9. MOUNTING - CEILING MOUNTING INSTALLATION WITH THREADED RODS INFORMATION....................................... 8

10. MOUNTING WITH BRACKETS ....................................................................................................................................... 9

11. CONNECTION OF ELECTRICAL INSTALALTION .......................................................................................................... 10

12. BUILT-IN CONTROL...................................................................................................................................................... 11

13. BUILT-IN CONTROL – CONNECTION DIAGRAM SLIM E.............................................................................................. 12

14. BUILT-IN CONTROL – CONNECTION DIAGRAM SLIM W; SLIM N ............................................................................... 13

15. CONTROLS - OPTIONAL ELEMENTS............................................................................................................................ 14

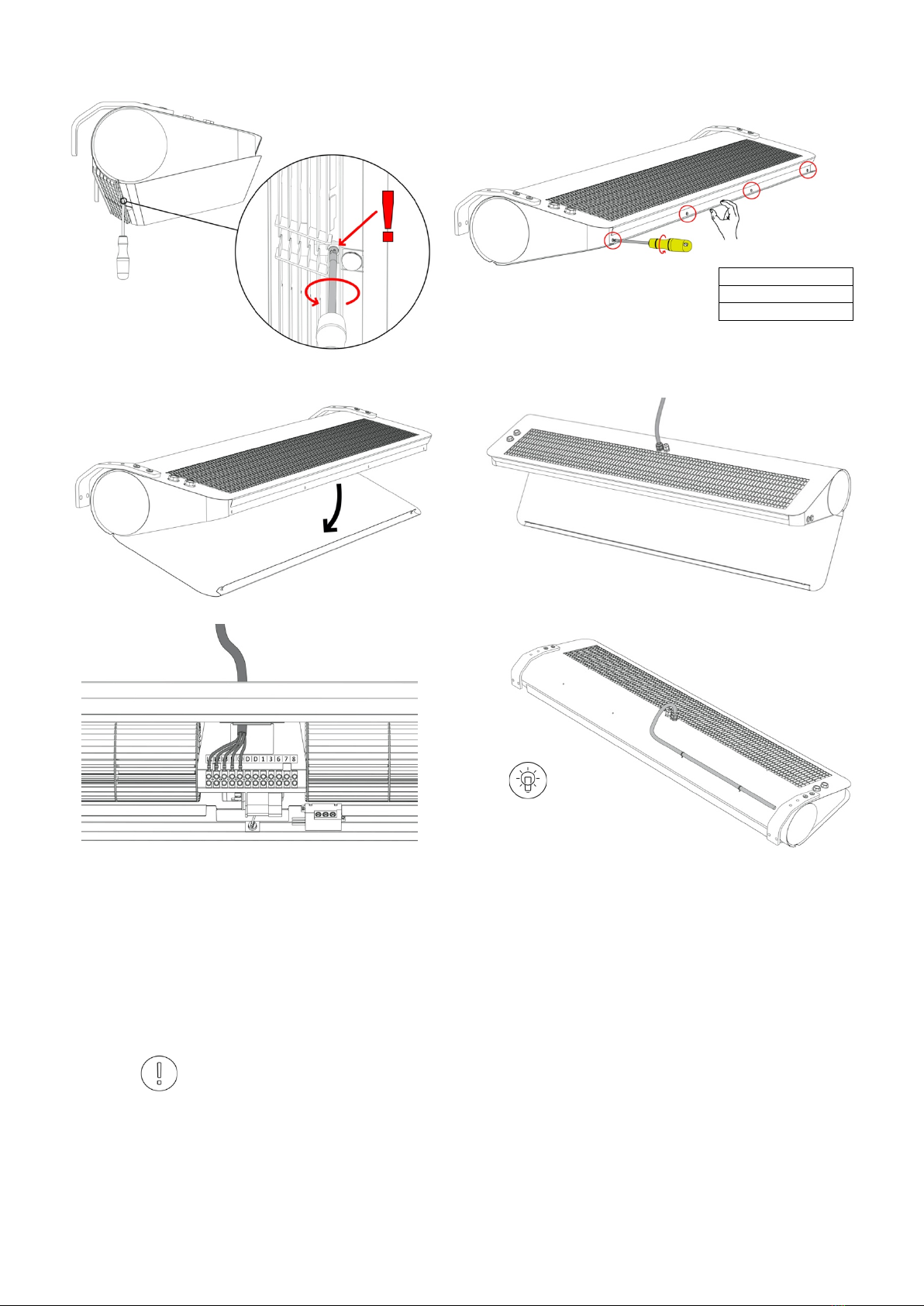

16. ADJUSTMENT OF OUTLET GRILLE .............................................................................................................................. 14

17. CONNECTION OF HYDRAULIC INSTALLATION........................................................................................................... 15

18. PARAMETERS OF THE HEATING MEDIUM .................................................................................................................. 15

19. FILTER INSTALLATION................................................................................................................................................. 16

20. OPERATON................................................................................................................................................................... 16

21. CLEANING AND MAINTENANCE ................................................................................................................................. 16

22. COMPLIANCE WITH WEEE 2009/19/EC....................................................................................................................... 17

23. CONFORMITY WITH WEEE DIRECTIVE 2012/19/UE ................................................................................................... 17

24. SERVICE AND WARRANTY TERMS .............................................................................................................................. 17

DOKUMENTACJA TECHNICZNA: PL

SPIS TREŚCI

1. WAŻNE INFORMACJE................................................................................................................................................19

2. INFORMACJE OGÓLNE..............................................................................................................................................20

3. BUDOWA ...................................................................................................................................................................20

4. DANE TECHNICZNE SLIM N/W...................................................................................................................................21

5. DANE TECHNICZNE SLIM E........................................................................................................................................22

6. WYMIARY...................................................................................................................................................................23

7. MONTAŻ....................................................................................................................................................................23

8. MONTAŻ–ZALECANE ODLEGŁOŚCI.........................................................................................................................24

9. MONTAŻZA POMOCĄSZPILEK GWINTOWANYCH..................................................................................................24

10. MONTAŻZA POMOCĄWSPORNIKÓW .....................................................................................................................25

11. PODŁĄCZENIE INSTALACJI ELEKTRYCZNEJ.............................................................................................................26

12. STEROWANIE WBUDOWANE ....................................................................................................................................27

13. STEROWANIE WBUDOWANE -SCHEMAT PODŁĄCZENIA SLIM E ............................................................................28

14. STEROWANIE WBUDOWANE -SCHEMAT PODŁĄCZENIA SLIM W; SLIM N..............................................................29

15. STEROWANIE-OPCJONALNE ELEMENTY ................................................................................................................30

16. REGULACJA KRATKI WYLOTOWEJ............................................................................................................................30

17. PODŁĄCZENIE INSTALACJI HYDRAULICZNEJ..........................................................................................................31

18. PARAMETRY CZYNNIKA GRZEWCZEGO...................................................................................................................31

19. MONTAŻFILTRA........................................................................................................................................................32

20. EKSPLOATACJA.........................................................................................................................................................32

21. CZYSZCZENIE IKONSERWACJA................................................................................................................................32

22. ZGODNOŚĆZDYREKTYWĄ2009/125/WE................................................................................................................33

23. ZGODNOŚĆ ZDYREKTYWĄWEEE 2012/19/UE ........................................................................................................33

24. KARTA GWARANCYJNA ............................................................................................................................................35