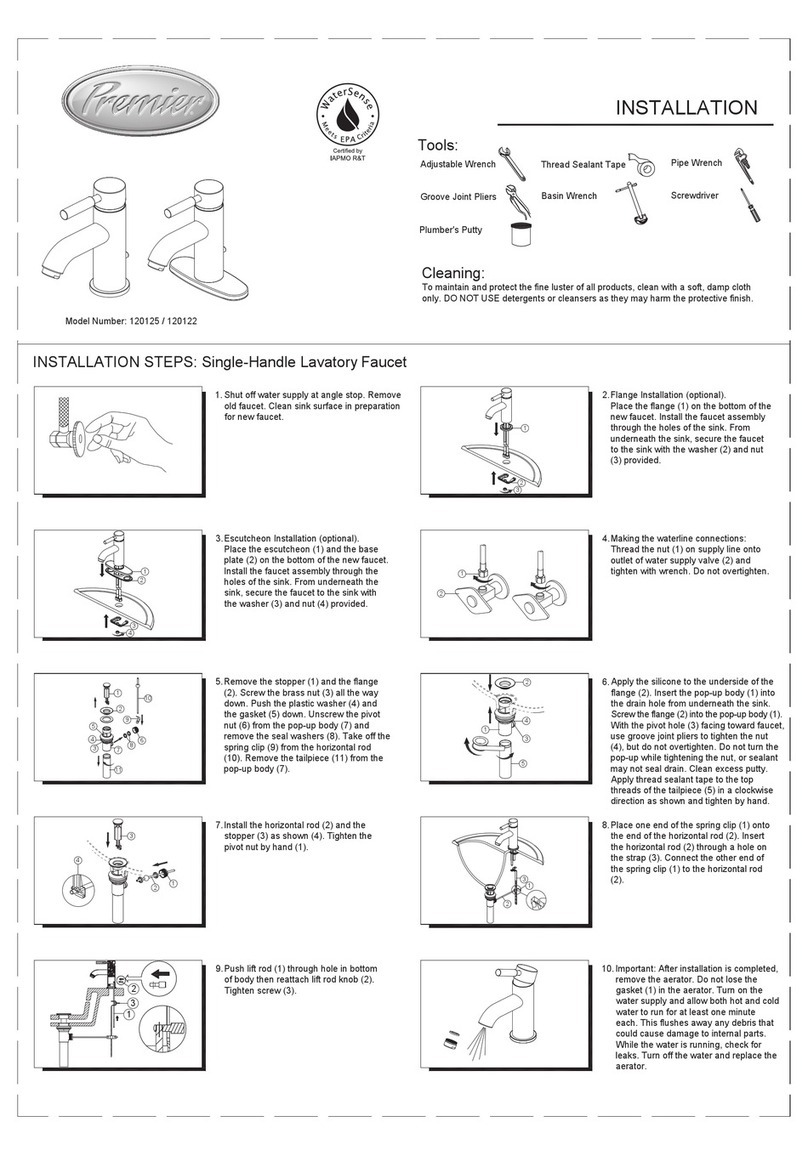

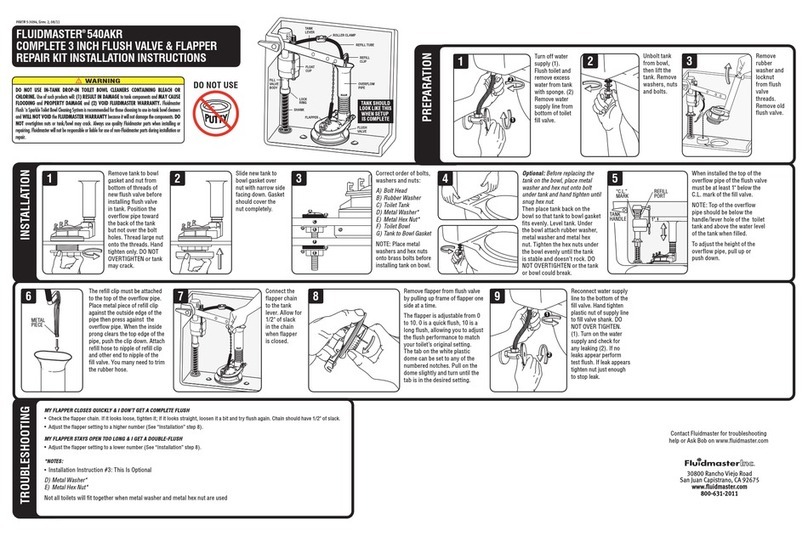

INSTALLATION

TROUBLESHOOTING

STEP 9: AT TACH /

RE-SECURE LID

TURN

COUNTER-

CLOCKWISE

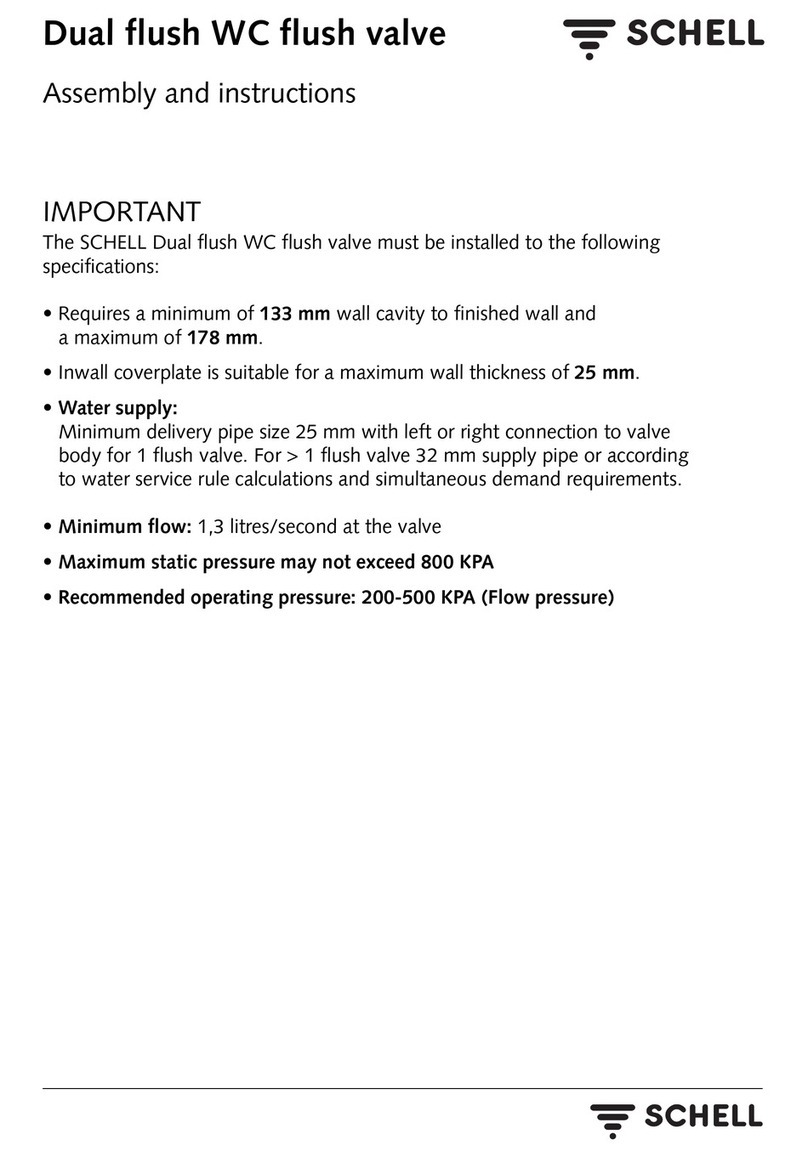

STEP 6: WATER SUPPLY CONNECTION

& FINE-TUNE TANK WATER LEVEL

A: Turn on water & flush

water supply line.

B: Turn off water & connect

water supply line to cistern

with approved fittings.

Hand-tighten only.

DO NOT OVERTIGHTEN.

C: Turn on water & check

for leaks.

D. FLUSH THE CISTERN TO CHECK THE TANK WATER LEVEL

After the water stops filling the tank, the water level should be at

water line “WL” mark (255mm) to ensure a proper flush.

WL

255mm

Tank Water Level

Adjustment Screw

+

–

STEP 7: ATTACH LINK

(IF REQUIRED)

A: Secure link into position.

B: Set seat onto link to mark desired

seat end point & cut point.

C: If cut required, cutting line guides

reference on back of link as needed.

Mini Hack Saw

Seat End

Point

Cut Point

23mm

IF THE INLET VALVE:

• DOES NOT TURN ON

• WON’T TURN OFF

• WON’T REFILL TANK

REMOVE CAP AND CHECK FOR DEBRIS

A: Turn off water supply.

B: Flush cistern.

C: With right hand push float up, grip and hold

shaft under float.

D: With left hand twist cap and lever arm coun-

terclockwise to unlock cap. Let cap hang on

float cup.

E: Hold empty cup upside down over un-

capped valve to prevent splashing.

F: Turn water supply on and off a few times.

G: Turn water supply off.

H: Replace valve cap.

• Place cap assembly on top of gray valve body

by aligning cap arm and adjustment rod.

• Press down on top cap while rotating top & arm

clockwise to locked position.

See Our Troubleshooting

HOW-TO VIDEO

http://bit.ly/2yAdZn7

VIDEO

*Always use genuine Fluidmaster parts when installing or repairing. Fluidmaster will not be

responsible or liable for use of non-Fluidmaster parts during installation or repair.

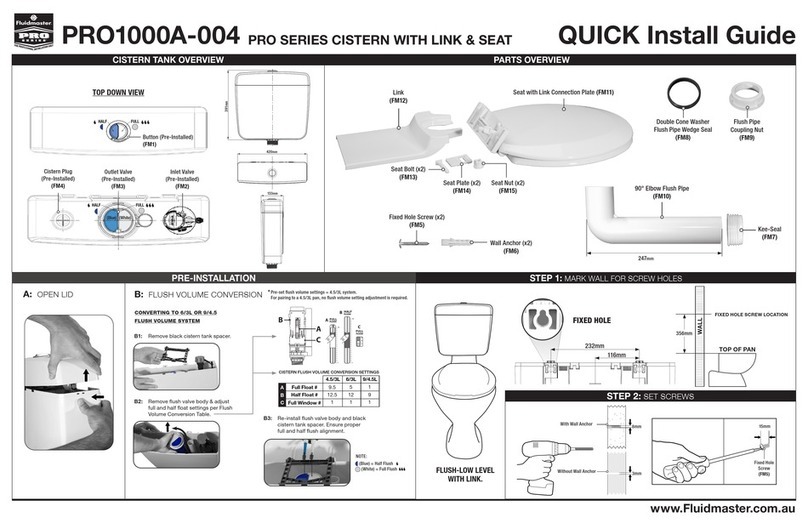

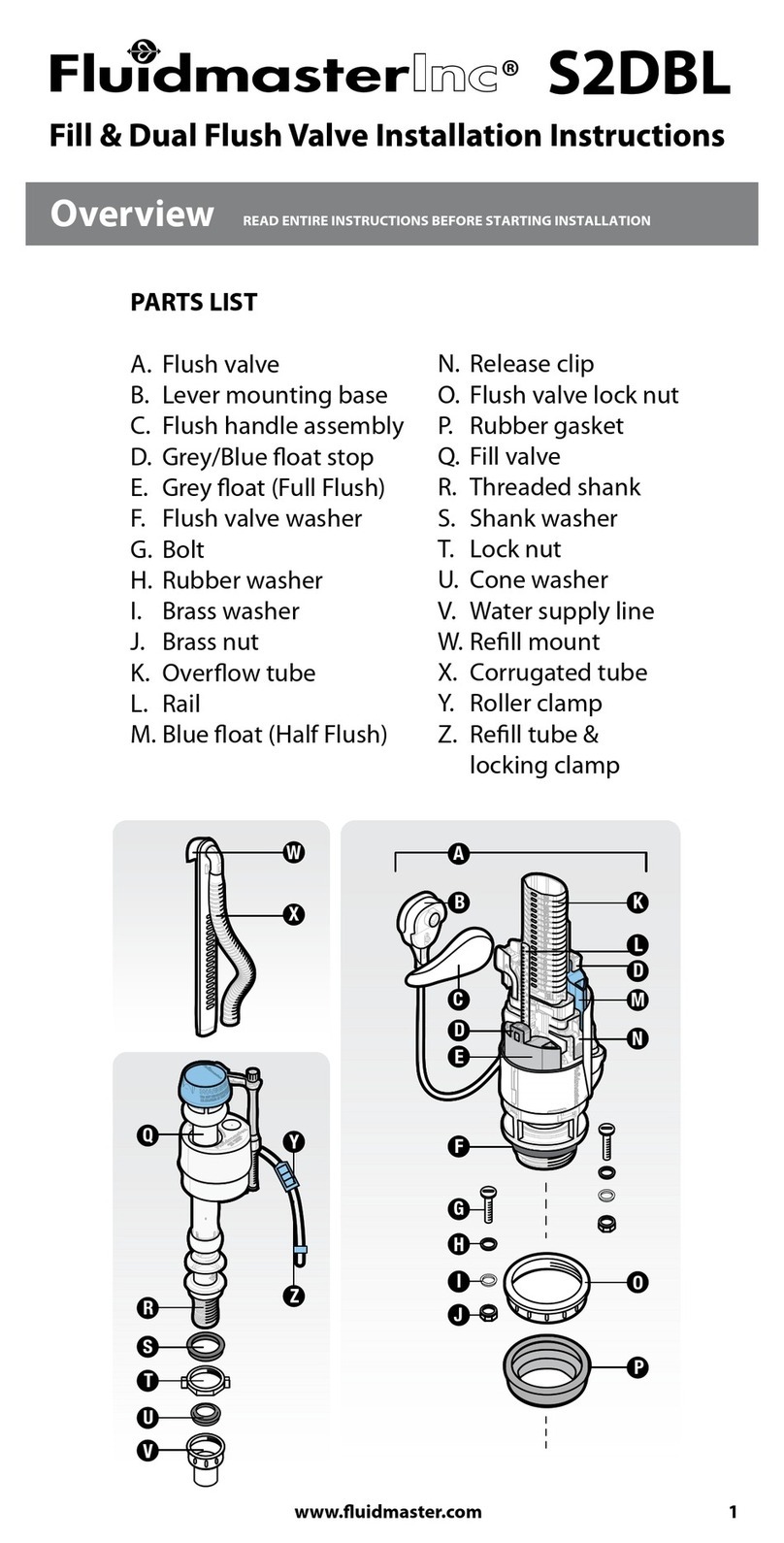

STEP 3: INSTALL FLUSH PIPES

A: Trim / Cut Flush Pipes as needed

per install type.

B: Lubricate kee-seal with soap and water.

Insert flush pipes and connect to pan.

C: Fit Flush pipe coupling nut and double cone washer wedge seal onto

flush pipe. Hand-tighten Flush pipe coupling nut and secure flush

pipe to outlet valve shank.

DO NOT OVERTIGTHEN

90° Elbow

Flush Pipe

(FM10)

90° Elbow

Flush Pipe

(FM10)

90° Elbow

Flush Pipe

(FM10)

Pan Entry

Flush Pipe

(FM9)

Pan Entry Flush Pipe

(FM9)

Cut this

side only

Cut length

Kee-Seal

(FM8)

Kee-Seal

(FM8)

Flush Pipe

Coupling Nut

(FM13)

Double Cone Washer

Flush Pipe Wedge Seal

(FM12)

68mm 27mm

215mm12 0 mm

After cut

Note: C1 Install type (with link) shown. For install

types C2 or C3, no cutting required on 90° elbow

(FM10) or Mid/High (FM11) Flush Pipes.

335mm

Cut this

side only

Pan Entry

Flush Pipe

(FM9)

Fluidmaster Australia Holdings Pty Ltd

5B/100 New Street

Ringwood, Victoria 3134

Australia

Phone: +61 (03) 8870 2555 | Toll Free: 1 800 931 166

IN NEW ZEALAND Call 09 415 5585

Email: salesau@fluidmaster.com

Website: www.Fluidmaster.com.au

WARRANTY

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled

to a replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or

damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure.

To present claims under this warranty, please contact your place of purchase or contact Fluidmaster Australia

Holdings Pty Ltd. NOTE: Original proof of purchase required.

Warranty excludes incorrect installation. Installation shall be in accordance with AS/NZS 3500.1 and AS/NZS

3500.2 (Install with licensed plumber; any installation processed without licensed plumber will void warranty)

10 Year Parts Replacement / 1 Year Parts & Labor Warranty.

Only clean with soap and warm water to maintain quality finish. Do not use harsh chemical cleaners.

DO NOT USE IN-CISTERN DROP-IN TOILET BOWL CLEANERS CONTAINING BLEACH OR

CHLORINE. Use of such products will: (1) RESULT IN DAMAGE to Cistern components and

MAY CAUSE FLOODING and PROPERTY DAMAGE and (2) VOID FLUIDMASTER WARRANTY.

DO NOT overtighten nuts or cistern/bowl may crack. Always use quality Fluidmaster

parts when installing or repairing. Fluidmaster will not be responsible or liable for use of

non-Fluidmaster parts during installation or repair.

WARNING

20-0006-1 Grev. 2, 10/19 (Sheet 1)

ADDITIONAL QUESTIONS?

For installation assistance, contact our

technical services department.

EMAIL, or CALLour toll-free number.

INSTALLATION

STEP 5: CISTERN ALIGNMENT

A: Slightly move cistern tank left to right as

needed on wall fixing bracket to ensure proper

cistern tank and flush pipe alignment with pan.

BACK OF CISTERN TANK

Connection Point

Connection Point

AGAINST WALL

11mm

11mm

(ONLY APPLICABLE FOR FIXING BRACKET INSTALL METHOD)

MONACO™UNIVERSAL CISTERN with LINK & SEAT

1000A-002 QUICK Install Guide

Install with Confidence

STEP 8: INSTALL SEAT

A: Insert Seat Bolt Plates

in Connection plate

(follow arrow guides).

For Link Application

Insert link to seat

connection plate. Set

seat bolts into pan

holes and hand-tighten

seat bolt nuts.

For Non-Link Application

Set seat bolts into

pan holes and hand-

tighten seat bolt nuts.

20mm

Seat Bolt

(FM16)

Seat Plate

(FM18)

STEP 4: HANG CISTERN TANK

FIXED HOLE

Connection Point

Connection

Point

BACK OF CISTERN TANK

AGAINST WALL

FIXING BRACKET

99mm

RIGHT

www.Fluidmaster.com.au