Section 2

Operation

2-1. INTRODUCTION

2-2, This section describes how to set up and make

measurements with your Multimeter. Even though you

may have used amultimeter before, we recommend that

you read the entire section carefully so that you can use all

of the features of your Multimeter.

2-3. SETTING UP YOUR INSTRUMENT

2-4, Unpacking

2-5. Your Multimeter is shipped in aspecial protective

container that should prevent damage to the instrument

during shipping. Check the shipping order against the

contents of the container and report any damage or short

shipment to the place of purchase or the nearest Fluke

Technical Service Center. Alist of these service centers is

located in Section 5. The container should include the

following:

•The 8010A or 8012A Multimeter

•Two test leads (one red and one black)

•Line power cord

•The 8010A/8012A Instruction Manual

2-6. If reshipment of the instrument is necessary, please

use the original shipping container. If the original

container is not available, be sure that adequate

protection is provided to prevent damage during

shipment. We recommend that the instrument be

surrounded by at least three inches of shock-absorbing

material on all sides of the container.

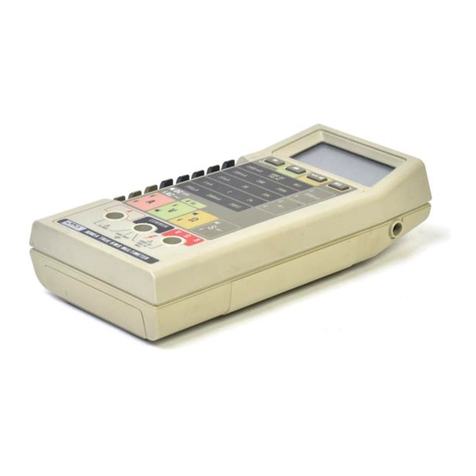

2-7. Remove the Multimeter from its container and

place it in aconvenient location. The carrying handle on

the meter can be used as aprop-stand or positioned out of

the way (behind the Multimeter). To position the handle,

pull outward on the hubs of the handle and rotate the

handle into position.

2-8, AC Line Voltage Requirements

2-9. AC line voltage requirements for your Multimeter

are listed on adecal attached to the bottom of the

instrument. Refer to Section 4 for the procedure to

change the ac line voltage setting. If your Multimeter has

the -01 Battery Option, refer to Section 6for information

on changing ac line voltages.

CAUTION

Do not connect the power cable to the

instrument before verifying that the intended

source matches the ac line configuration of

the instrument.

2-10. Fuse Replacement

2-11. There is one, user-replaceable fuse (FI) in your

Multimeter. The fuse (FI) and the fuse holder form an

integral part of the mA input connector and can be

removed with ordinary tools. The fuse rating is: 2A,

normal blow (recommended part AGX2).

2-12. Use the following procedure to replace the fuse,

FI:

1. Set the POWER switch to OFF.

2. Remove the input power cord from the

Multimeter.

WARNING

DO NOT REPLACE THE FUSE WITH THE

INSTRUMENT TURNED ON OR CONNECT-

ED TO LINE POWER.

3. Refer to Figure 2-1, item 5for the location of

the fuse holder.

2-1