Fluke 515A User manual

Other Fluke Test Equipment manuals

Fluke

Fluke 990DSL User manual

Fluke

Fluke 80T-150U User manual

Fluke

Fluke 715 User manual

Fluke

Fluke TS22 User manual

Fluke

Fluke MP1 User manual

Fluke

Fluke 718-100G User manual

Fluke

Fluke FiberInspector Versiv Series Use and care manual

Fluke

Fluke A40B User manual

Fluke

Fluke 2000ACC User manual

Fluke

Fluke 154 User manual

Fluke

Fluke ScopeMeter 190-104 User manual

Fluke

Fluke P3830 User manual

Fluke

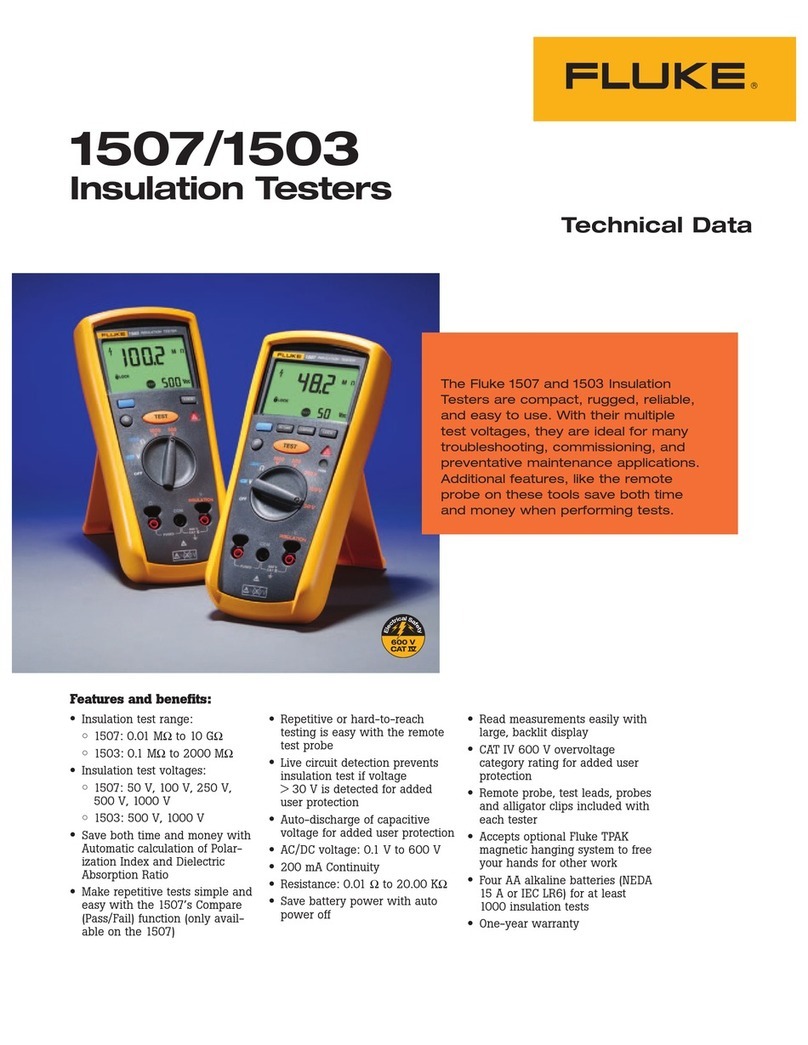

Fluke 1503 User manual

Fluke

Fluke 30800001 User manual

Fluke

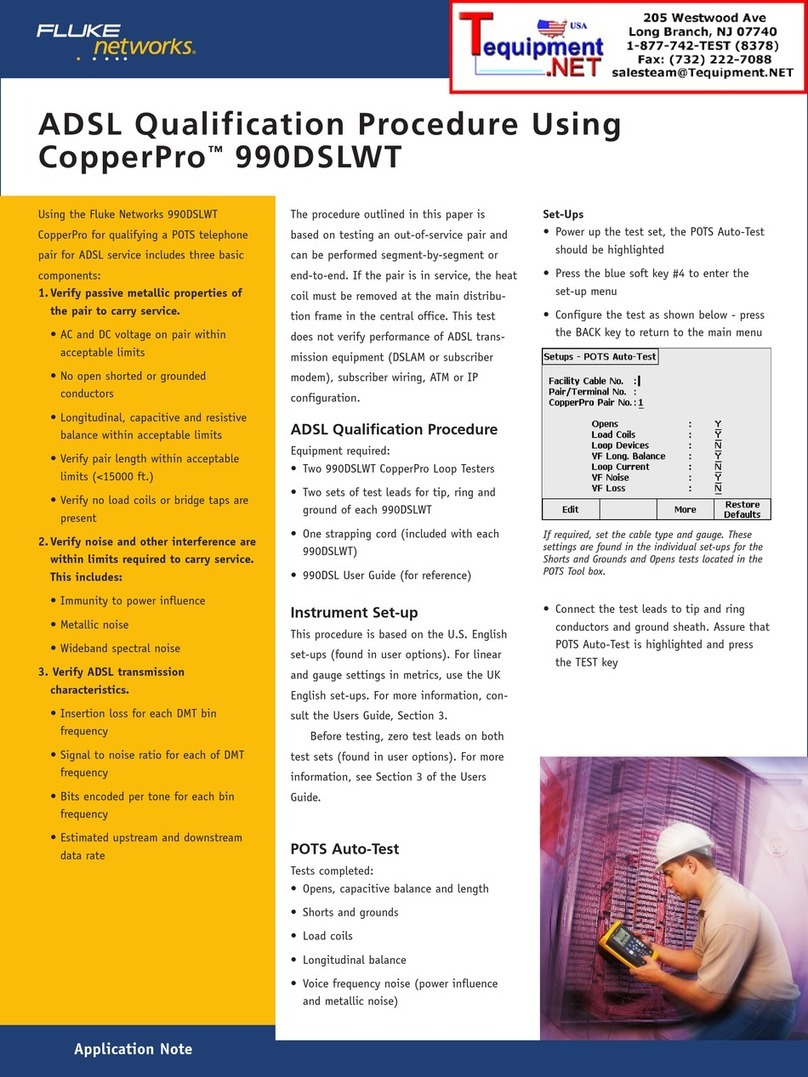

Fluke CopperPro 990DSLWT Reference guide

Fluke

Fluke AIRCHECK User manual

Fluke

Fluke T90 User manual

Fluke

Fluke 714 User manual

Fluke

Fluke P5515-V User manual

Fluke

Fluke OptiFiber Pro HDR User manual

Popular Test Equipment manuals by other brands

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started

Agilent Technologies

Agilent Technologies N3280A user guide

Lifeloc

Lifeloc R.A.D.A.R. quick start guide

Mercury

Mercury TSL01 user manual

MAHA

MAHA MBT Series Original operating instructions