7

When the test has stopped, the display continues to show the voltage

present on the test leads. Pressing either test voltage sor tbutton will

then display the test voltage immediately before the end of the test.

Test start / stop button

A test will only start if this button is pressed, held and then released as

soon as the red high voltage warning indicator LED lights. The LCD and

red LED high voltage warning indicators flash when the test starts.

A test will not start if the button is released before the red LED shows, or

pressed continuously for longer than 5 seconds. This is a safety feature to

prevent a test being started inadvertently.

The presence of a voltage greater than 50 V on the test leads is indicated

with flashing high voltage warning indicators. Testing is disabled if the

external voltage exceeds 80 V.

Testing will stop if the test start / stop button is pressed again, the

preset test time is reached, or, if the unit is not in burn mode, insulation

breakdown is detected.

When a test has finished, the instrument will discharge the load, which

may take some time. The operator must always check the load has been

discharged before touching the test leads.

Ω/I button

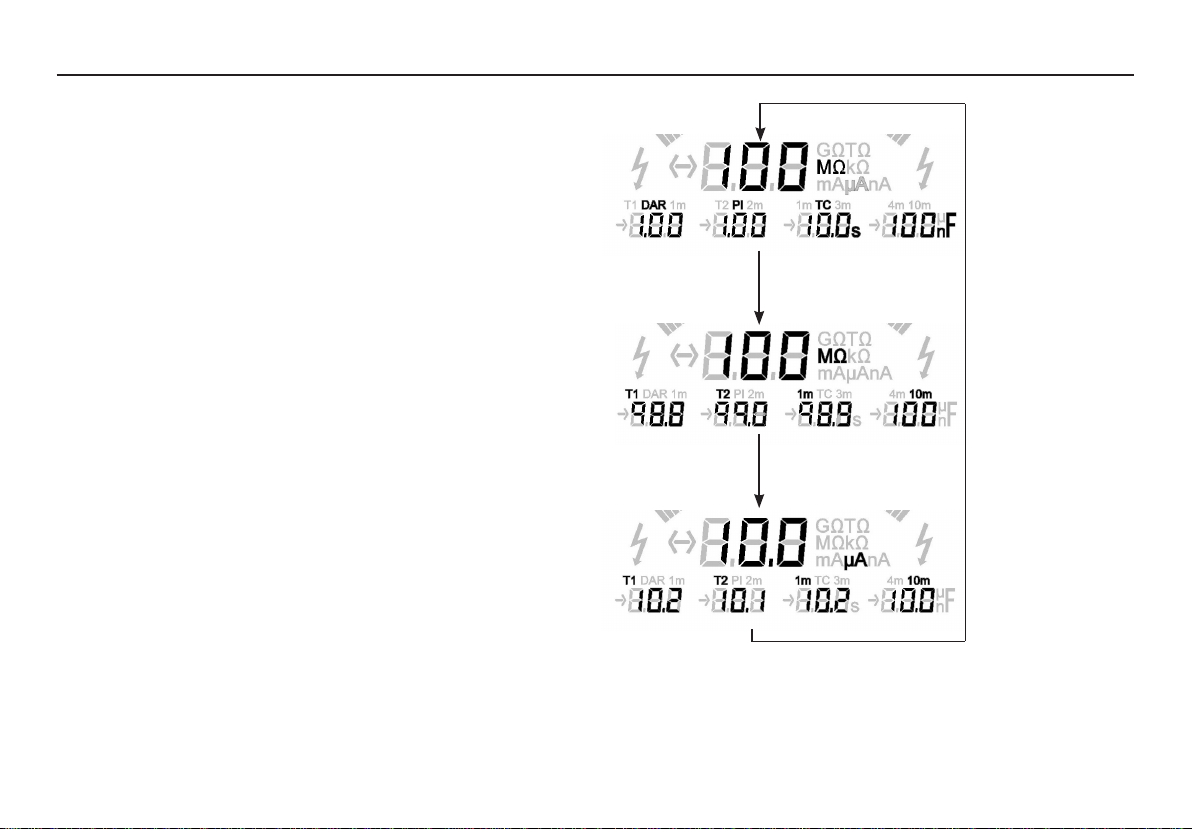

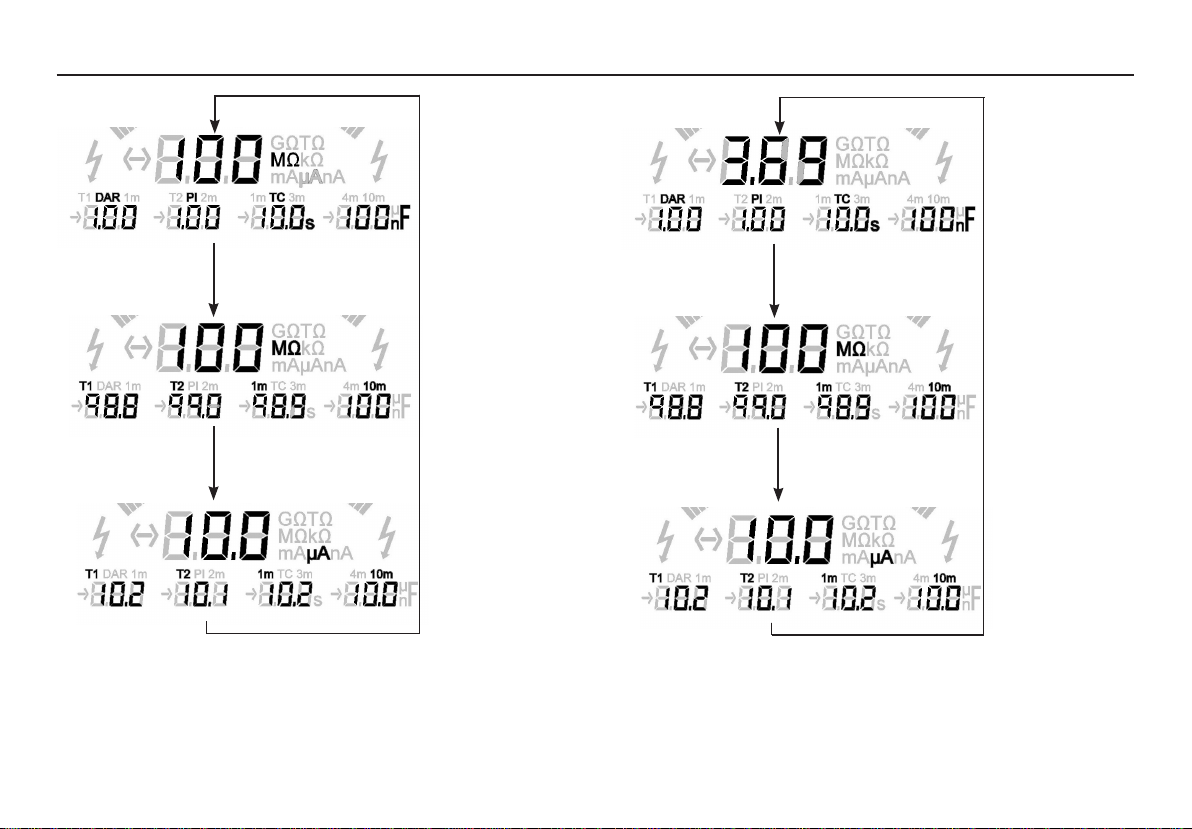

Pressing this button toggles the digital and secondary displays. The details

available when scrolling the secondary display will depend upon the test

mode selected, whether timers T1 and T2 have been set, and the duration

of the test. The digital display toggles between insulation resistance and

current.

Power On/Off button

The instrument will only turn on if this button is pressed, held and then

released when the display responds. The instrument will not turn on if

the button is released before the display responds, or if the button is held

down for too long. This is a safety feature to prevent the instrument being

inadvertently turned on.

The instrument is turned off either by pressing the button again, or if the

instrument is running on the battery, by timing out after 10 minutes of

inactivity.

Upon switching the instrument on the display will first show ‘Ini’ while it

undergoes a self-checking routine. When Ini disappears, the instrument is

ready for use.

Test voltage sand tbuttons

Using these buttons one of six test voltages can be selected: 250 V, 500 V,

1 kV, 2.5 kV, 5 kV, and 10 kV. The selected voltage is shown on the display.

A non standard voltage between 50 V and 10 kV can be selected by holding

down the ‘Fn’ function button whilst operating the buttons. The selectable

voltage is adjustable in 10 V steps between 50 V and 1 kV, and adjustable in

25 V steps between 1 kV and 10 kV. An auto repeat facility is enabled when

the button is held down, allowing faster travel through the range.

If there is an external voltage greater than 50 V on the test leads, the high

voltage warning indicators are flashed, and the display shows this voltage

instead. The instrument will not perform a test if this voltage is greater than

80 V.

During a test the display shows the actual voltage on the test leads. If the

test voltage is changed during a test, the new test voltage will be displayed

briefly.