Fluke B Series User manual

Other Fluke Test Equipment manuals

Fluke

Fluke VisiFault Visual Fault Locator User manual

Fluke

Fluke 730G User manual

Fluke

Fluke 714B User manual

Fluke

Fluke T5-600 Operating and installation instructions

Fluke

Fluke T5-600 User manual

Fluke

Fluke Fiber OneShot PRO User manual

Fluke

Fluke 5730A User manual

Fluke

Fluke 1503 User manual

Fluke

Fluke 1AC II VoltAlert User manual

Fluke

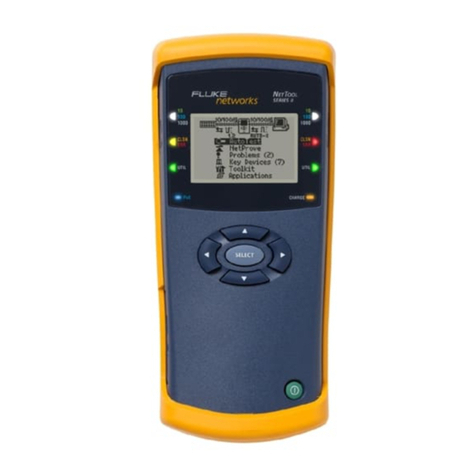

Fluke NetTool II Series User manual

Fluke

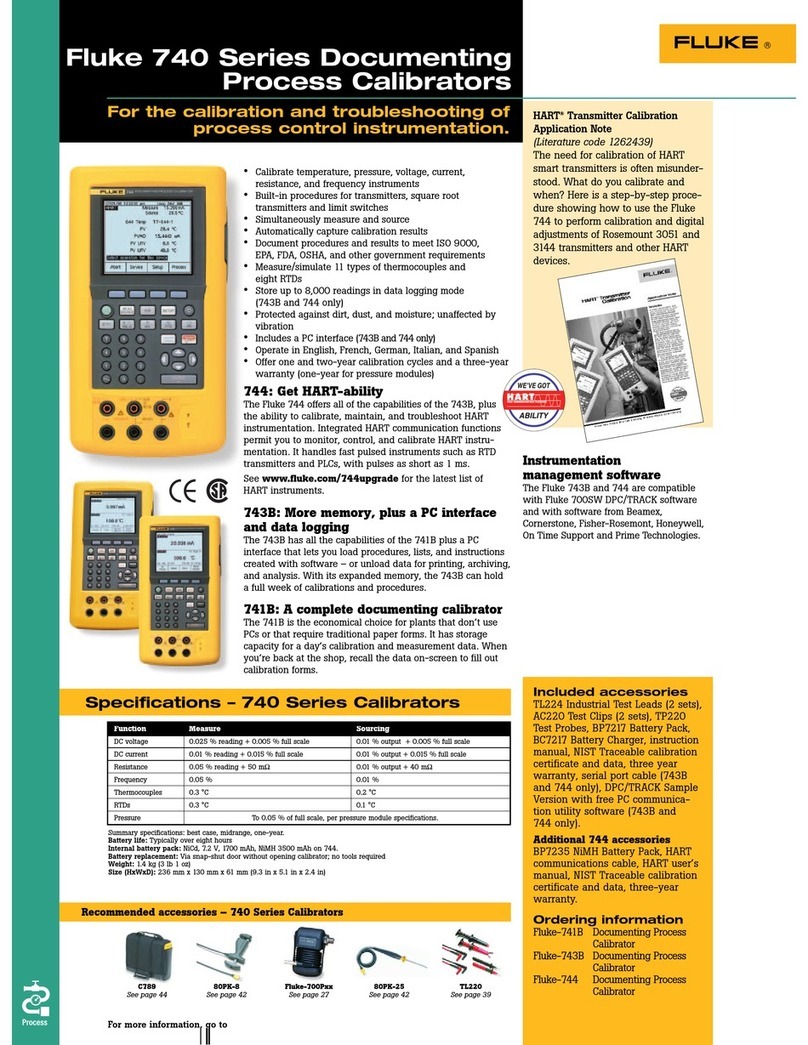

Fluke 741B User manual

Fluke

Fluke 5500A User manual

Fluke

Fluke 9640A Series User manual

Fluke

Fluke 725/FPC User manual

Fluke

Fluke 5623B User manual

Fluke

Fluke 4180 User manual

Fluke

Fluke 7526A-156 Use and care manual

Fluke

Fluke P3100 Series User manual

Fluke

Fluke TS54-A-09-TDR User manual

Fluke

Fluke FiberInspector Versiv Series Use and care manual

Popular Test Equipment manuals by other brands

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started

Agilent Technologies

Agilent Technologies N3280A user guide

Lifeloc

Lifeloc R.A.D.A.R. quick start guide

Mercury

Mercury TSL01 user manual

MAHA

MAHA MBT Series Original operating instructions