Fluke 713 User manual

Other Fluke Test Equipment manuals

Fluke

Fluke 9011 User manual

Fluke

Fluke 5080A User manual

Fluke

Fluke TL1000-KIT Original instructions

Fluke

Fluke VisiFault Visual Fault Locator User manual

Fluke

Fluke 1587 FC User manual

Fluke

Fluke 714 User manual

Fluke

Fluke T5-600 Operating and installation instructions

Fluke

Fluke T+ User manual

Fluke

Fluke 5520A Service Manual

Fluke

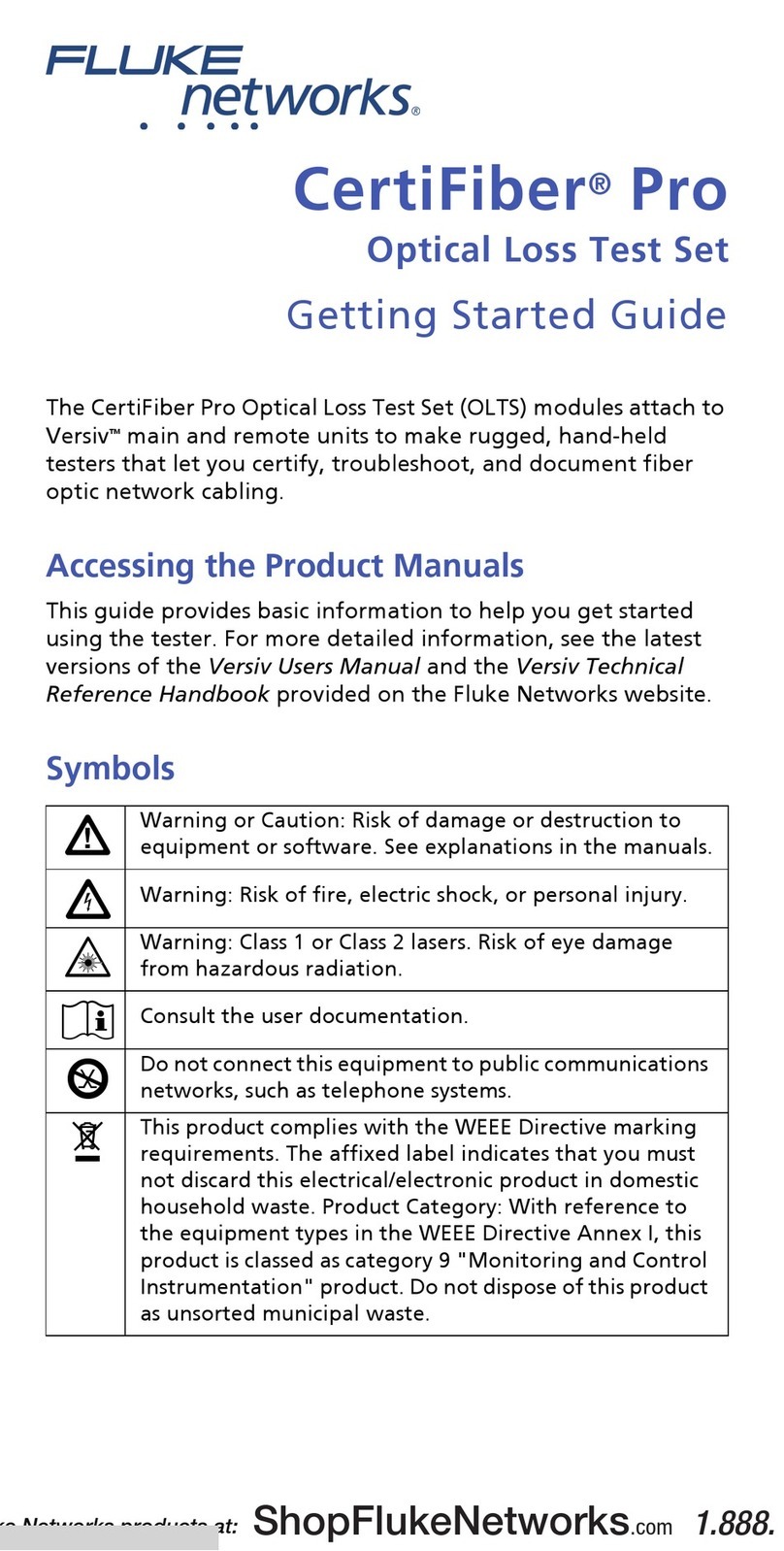

Fluke CertiFiber Pro User manual

Fluke

Fluke 1AC II VoltAlert User manual

Fluke

Fluke FIBER QUICKMAP User manual

Fluke

Fluke ScopeMeter 192B Manual

Fluke

Fluke T6-1000 Operating and installation instructions

Fluke

Fluke 714 User manual

Fluke

Fluke 635 QuickBERT-T1 Configuration guide

Fluke

Fluke 1625-2 User manual

Fluke

Fluke FIBER QUICKMAP User manual

Fluke

Fluke TS54 User manual

Fluke

Fluke 5700A Series II Service User manual

Popular Test Equipment manuals by other brands

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started

Agilent Technologies

Agilent Technologies N3280A user guide

Lifeloc

Lifeloc R.A.D.A.R. quick start guide

Mercury

Mercury TSL01 user manual

MAHA

MAHA MBT Series Original operating instructions