Forest SDA46GBARFP User manual

Making British gardens great

Thank you for purchasing your garden bar from Forest Garden. Simply follow these step-by-step instructions and

our top tips, and you’ll be enjoying your garden bar for many years to come. If you have any questions or need

advice, our friendly team is here to help.

ISSUE: 0122

SHIPLAP GARDEN BAR

INSTRUCTIONS (6x4)

Missing something or need more information?

Call our aftersales team on

0333 321 3142

Visit our website for spare instructions and

more information

www.forestgarden.co.uk

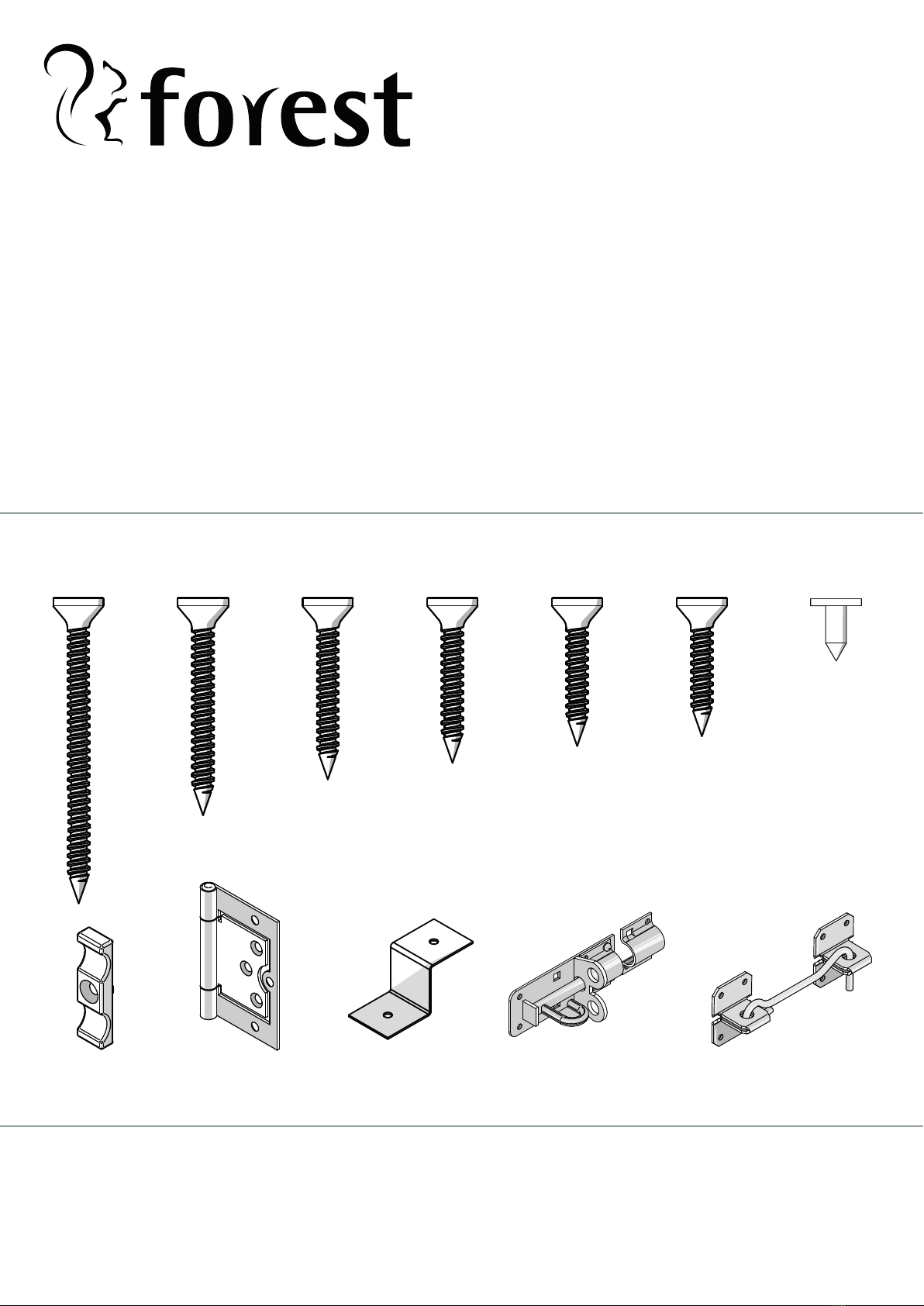

FIXING PACK CONTAINS:

4x50mm Screws

QTY: 58

5x70mm Screws

QTY: 12

4x40mm Screws

QTY: 12

3.5x30mm Screws

QTY: 109

3.5x25mm Screws

QTY: 112

Felt Tacks

QTY: 124

Flush Hinges

QTY: 10

Padbolt

QTY: 1

Turn Buttons

QTY: 4

6x120mm Screws

QTY: 3

Z-Brackets(28mm)

QTY: 14

Hook & Eye

QTY: 2

FIXING PACK CODE: SDA46GBARFP

Forest Garden, Oak Drive, Hartlebury Trading Estate, Hartlebury, Worcestershire, DY10 4JB

EU Authorised Representative: Authorised Representative Service, 77 Camden Street Lower Dublin, D02 XE80, Ireland

2

HEALTH & SAFETY

We strongly recommend that PPE

(Personal Protective Equipment) is

used throughout your build to ensure

you are protected from any potential

health and safety risks. Do not

exempt yourself from wearing PPE.

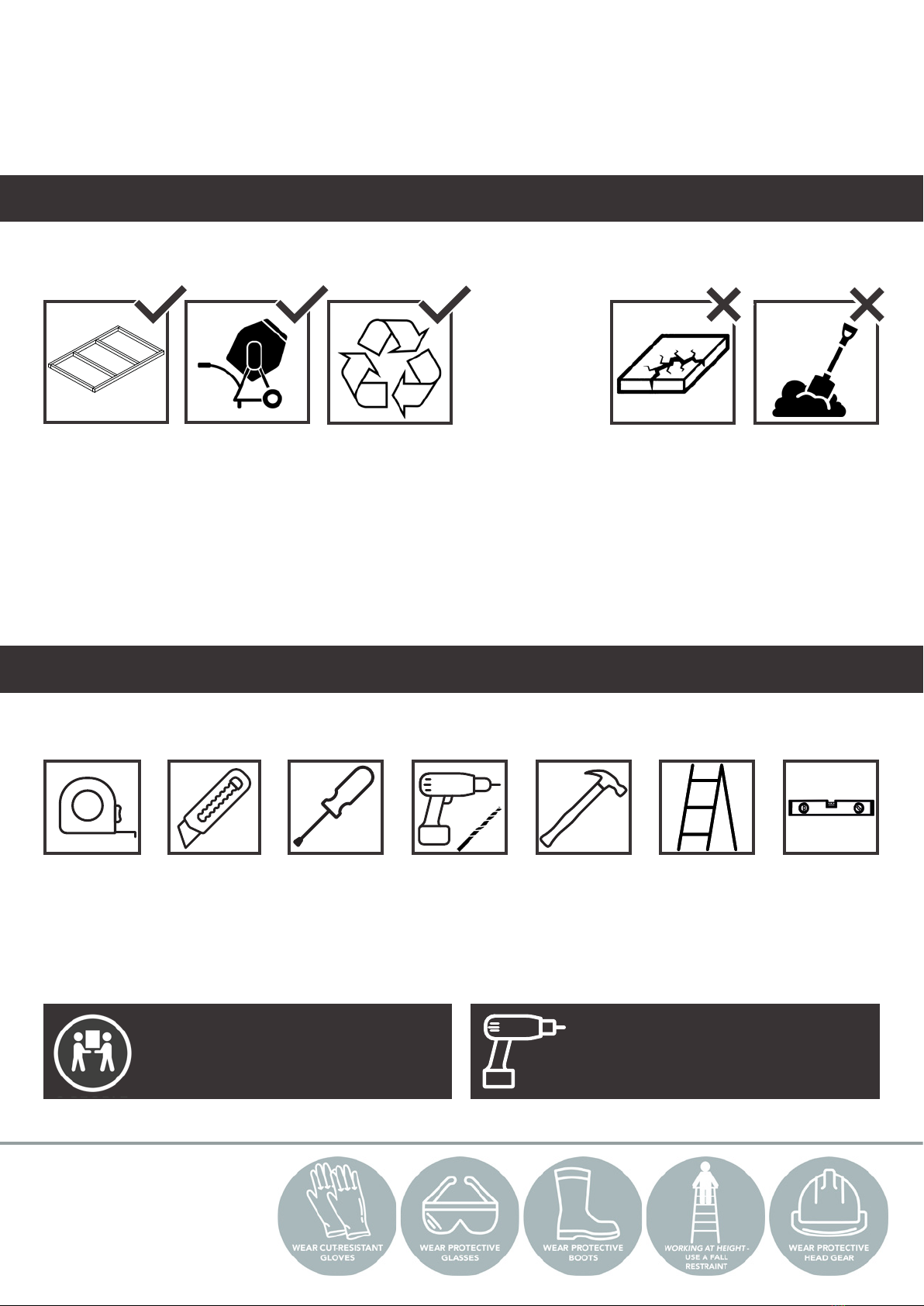

BEFORE YOU START

Please read through these instructions to familiarise yourself with your garden bar. We

recommend that you check all the components using the lists found on the front and back pages

before you start to build.

It is vital that you build your new garden bar on a solid, level base. Timber or plastic bases are

ideal, as are concrete slabs or solid concrete.

We recommend using the following tools (not supplied):

If you have an existing base and think it is suitable for your new garden bar to be sited on, it is

important that you check it is level and doesn’t deviate by any more than 15mm from edge to

edge. If this is not the case, the building will twist causing gaps to appear in the sections and

causing the roof, doors and windows to misalign.

There is more information on base preparation on our website www.forestgarden.co.uk

Assembly is relatively straightforward if you follow these step-by-step instructions.

We recommend aligning components properly before securing them together and pre-drilling

screw holes to avoid splitting the timber.

BASE PREPARATION

TOOLS NEEDED

Timber Base

Self-constructed/

Buy pre-made

Tape

Measure

Sharp Knife Pozidrive

Screwdriver

Drill &

2-3mm Drill

Bits

Hammer

Concrete

Concrete surface/

Concrete slabs

Pro Shed Base

Interlocking

eco-friendly base

Soil

A base of soil or

grass only

Broken Slabs/Gaps

Uneven slab sizes

with no cement

REMINDER

Always pre-drill before

screwing.

IMPORTANT

Assembly requires 2+

adults.

Ladder Spirit Level

PLEASE KEEP PLASTIC BAGS AND SMALL PARTS AWAY FROM CHILDREN

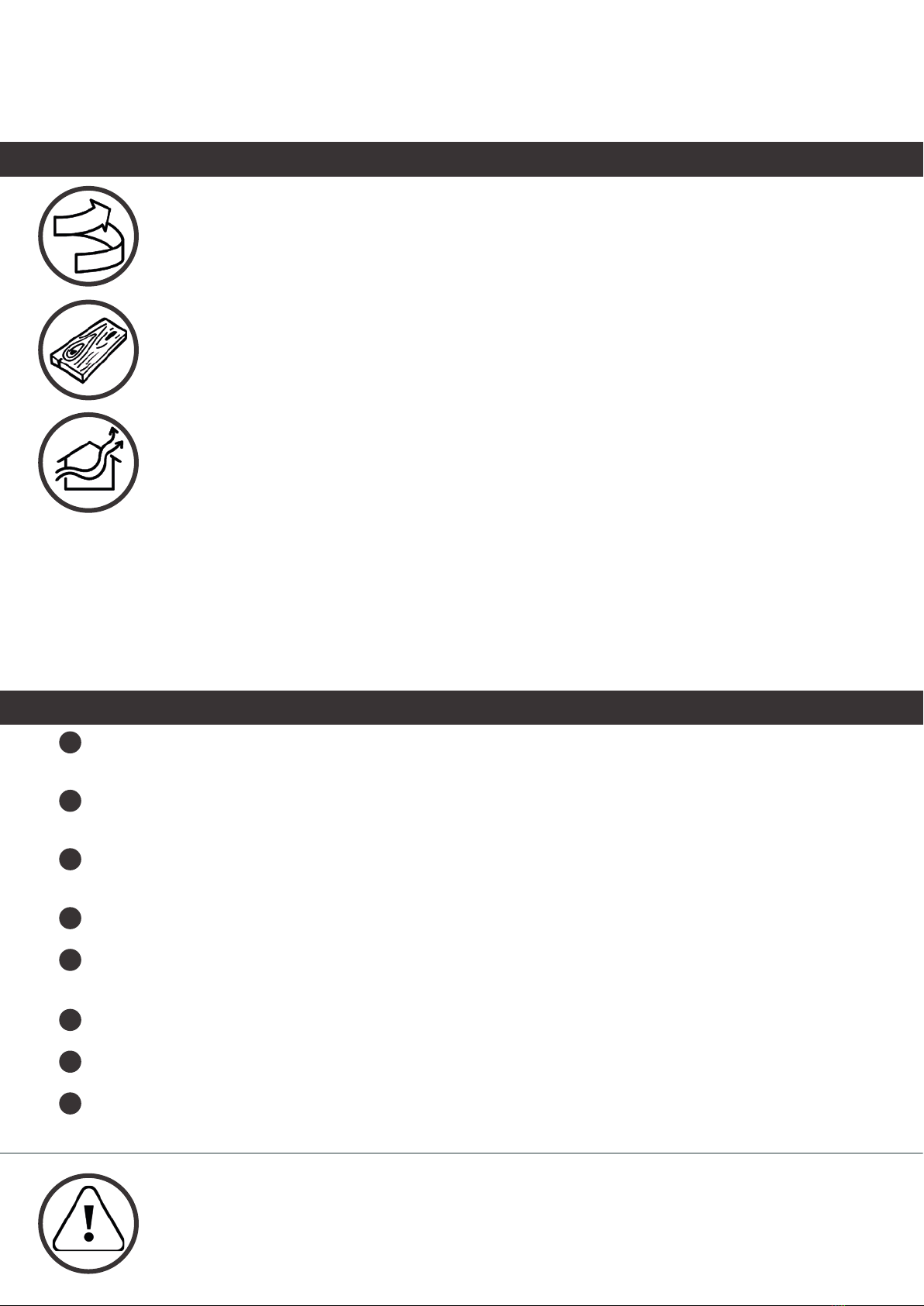

MOVEMENT, TWISTING & WARPING

Wood contains a natural level of moisture so decreasing humidity levels in the surrounding air may cause panels to change their

shape as the porous bres shrink. This can be exaggerated during prolonged periods of dry weather. Movement and gaps in

timber products are normal. In most cases, the wood will revert to its original form once the high temperatures subside and there

is more moisture content in the air. Similarly, in winter months, the opposite may occur with wood swelling.

CARE & ATTENTION

To help you get the most out of our products, it is useful to know a little more about the properties of timber, what

is normal and how your garden bar may behave as the seasons change. Wood is an extremely durable material for

construction but, as a natural product, when used outdoors it is susceptible to changes in the environment.

3

EXPANSION, CONTRACTION, SPLITS & CRACKS

All timber will expand and contract according to its environment. As a result of this expansion and contraction, it is very common

to see splits and cracks developing in the wood. Splits are common during the spring and summer months as the wood begins to

dry out. The outer surface dries rst and contracts over the still expanded core of the wood. The result is that splits and cracks

appear along the grain of wood. These splits are not a fault and do not affect the structural integrity of a product.

MOULD & BLUE STAIN

Mould is a surface-dwelling fungus that feeds on the nutrients and debris contained in the surface cells of timber. The most

common problems associated with mould are discoloured timber and an increase in permeability of the timber. Blue stain is part

of the same family but penetrates deeper into the surface layers of the timber. It stains the timber a dark blue, whereas mould is

usually black. These do not cause the timber to rot. Keep the building well ventilated to avoid mould.

POSITION YOUR GARDEN BAR IN THE BEST LOCATION IN YOUR GARDEN

Avoid areas where water pools and which are constantly wet. Position away from trees and cut back any overhanging foliage which can

cause moisture to be trapped against the walls and debris to collect on the roof.

1

RAISE YOUR GARDEN BAR OFF THE GROUND

Ideally, any concrete base should be the same footprint as the garden bar to allow surface water to run off without pooling. A timber base

can also be used. Raise your garden bar 50mm above ground level.

2

SEAL THE BEARERS

If using a wooden base, we recommend treating it with a treatment containing wax or oil. Also coat the bearers that come into contact

with the ground to prevent moisture rising.

3

USE AN END-GRAIN PROTECTOR

To protect the corners and panel joins, an end grain treatment can be applied.

4

SEAL THE PANELS & WINDOWS

Use a exible silicone sealant around windows to prevent water ingress. This can also be used where two sections of the garden bar join

together. Apply internally.

5

Treat your building annually. We advise the application of a high-quality preservative that contains a

mildewcide. For more information on the conditions of our guarantee see forestgarden.co.uk.

CONSIDER ADDING GUTTERS

Adding guttering around the fascia of the garden bar will redirect rain water away from the garden bar’s foundation.

6

KEEP VENTILATED

Good airow around the perimeter of the garden bar and regular ventilation inside the garden bar will help prevent mould and mildew.

7

CONSIDER A WEATHERPROOFING STAIN OR CLEAR TREATMENT

We recommend painting your garden bar with a weatherproong treatment at least once a year. This will help maintain the wood, stabilise

timber movement and help prolong the life of your garden bar.

8

TREATED TIMBER CONTAINING A BIOCIDAL PRODUCT

CONTROL OF WOOD DESTROYING ORGANISMS

Active Ingredients - Propiconazole, Tebuconazole, IPBC, Permethrine, Benzyl-C12-16-Alkyldimethyl Chlorides. (Dip Treated)

Basic Copper Carbonate, DDA Carbonate, DDA Chloride. (Pressure Treated)

Wear gloves when handling. Avoid inhalation of sawdust. Do not use in contact with drinking water or food. Do not use for animal

bedding or in sh ponds. Dispose of treated wood responsibly.

THINGS THAT YOU MIGHT SEE IN YOUR PRODUCT

8 TOP TIPS TO ENSURE YOUR GARDEN BAR IS FULLY WATERPROOF

THE ROOF OF THIS BUILDING IS NOT A LOAD BEARING STRUCTURE

ADVICE ON FELT HANDLING & USAGE

Roong felt is exible at temperatures above 5°C. In cold temperatures, extra care must be taken when handling and installing to prevent

cracking and damage to the felt. The felt should not be rolled, folded or used in temperatures lower than 5° C. In cold temperatures, the felt

should be stored indoors above 10°C for 24 hours prior to use. Felt must be lifted, not dragged, and should be stored on its end on a dry

surface.

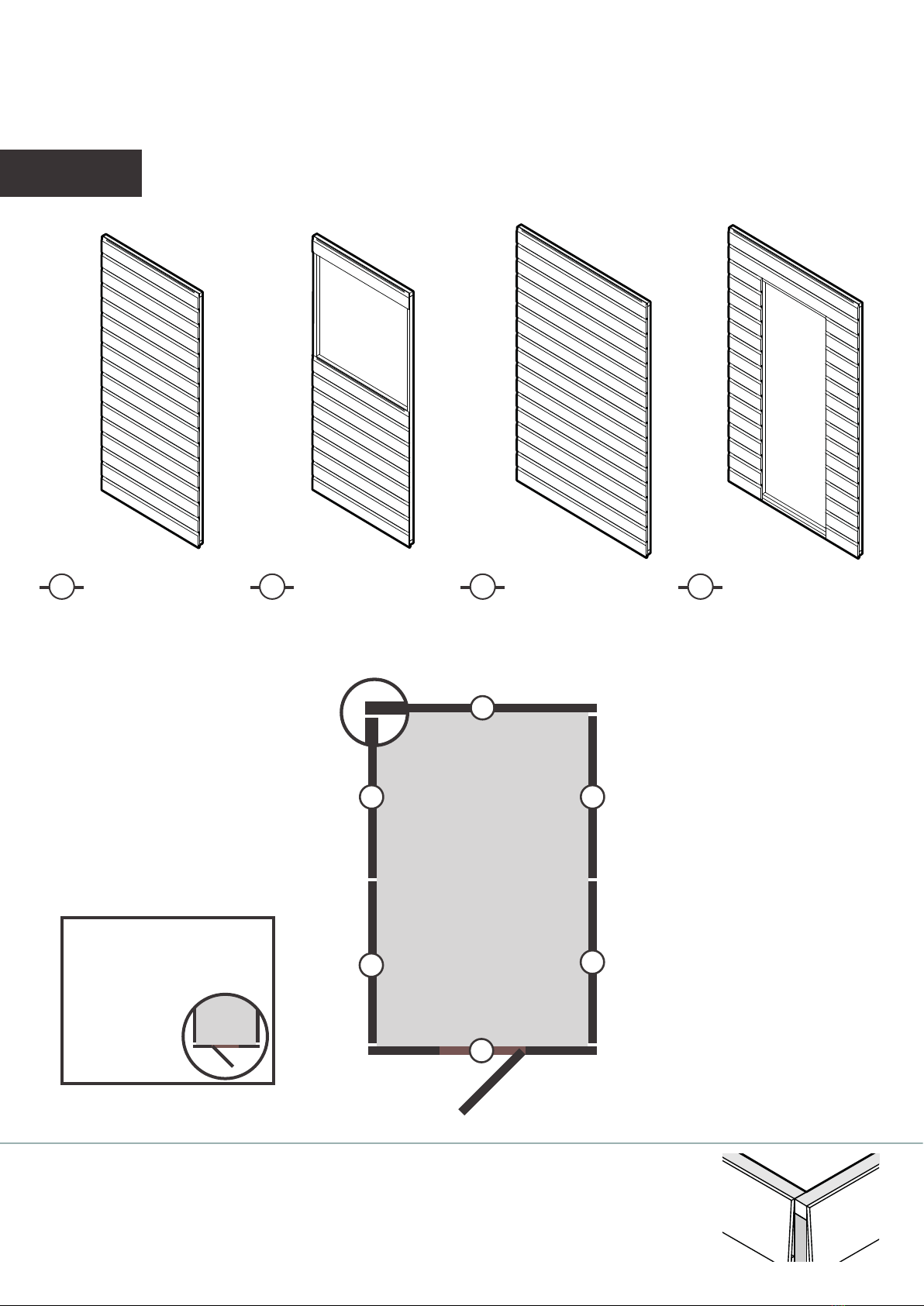

A3ft Panel (885 x 1945mm) C4ft Panel (1180 x 1945mm)

B3ft Panel (885 x 1945mm)

(Window)

KEY

PLEASE NOTE

The garden bar is made up of

multiple sections where same size

panels are interchangeable.

The door can be

hinged on either

side.

D4ft Panel (1180 x 1945mm)

(Door)

4

GARDEN BAR PANEL LAYOUT

Use the oor plan below, to identify the side panel positions before assemblying your garden bar.

Use the key and visuals below as a guide.

B

D

B

4’

6’ REVERSE APEX

C

A

A

Indicates the panel orientation

during construction.

PANEL POSITION

When assemblying your wall panels, ensure the timber framing on the panels are

ush at the corners. The space left next to the board is for the cover strip to sit into.

Ensure to apply the same panel position to all corners.

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

50MM

SCREWS 50MM

SCREWS 50MM

SCREWS

50MM

SCREWS 50MM

SCREWS

5

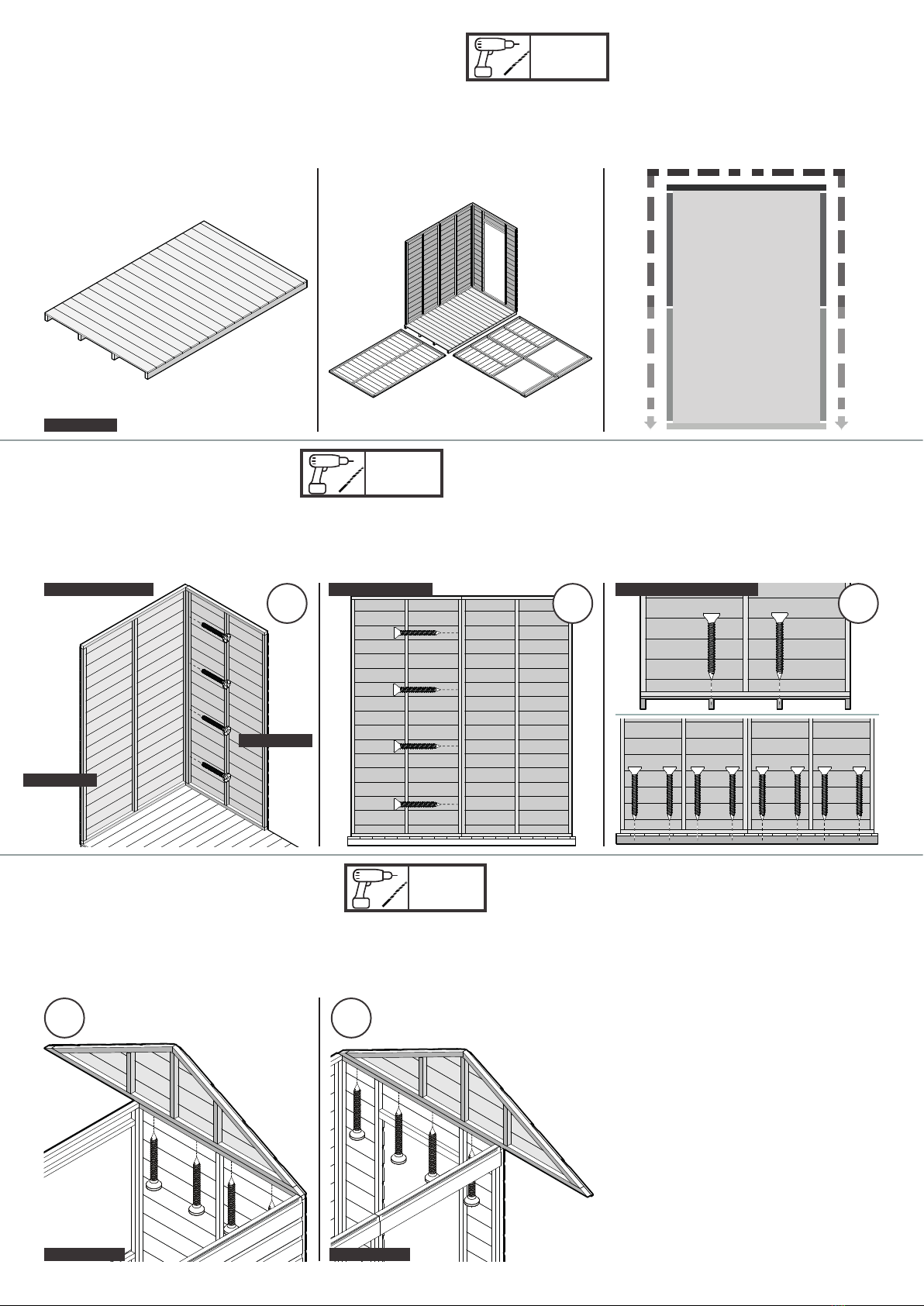

1a FLOOR & PANEL LAYOUT

1c APEX SECTIONS

1b SIDE PANELS

Position the Floor in your desired location. Lay out the panels around your garden bar

oor.

We recommend to start in a back corner,

then work from the back panels to the front

panels for assembly.

Attach the Apex Section by screwing to the

wall panels as shown below.

Repeat the process and attach the other

Apex Section by screwing to the wall panels as

shown below.

Start at a back corner. See the section layout

on page 4 to conrm position. Secure the

corner as shown below.

Repeat the process for the remaining panels

and secure the panels together. Ensure the

bottom board on the wall panel is up against

the oor’s outer edge.

Secure the panels into place by screwing into

the oor bearers beneath.

EG. INSIDE CORNER

SIDE PANEL

BACK PANEL

EG. BACK PANELS

APEX SECTION

EG. INTO FLOOR BEARERS

FLOOR

APEX SECTION

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

WALL

PANEL

FRAME

DOOR

WEATHER

STRIP

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

120MM

SCREWS

30MM

SCREWS 30MM

SCREWS

30MM

SCREWS

30MM

SCREWS

30MM

SCREWS

30MM

SCREWS

70MM

SCREWS

70MM

SCREWS

50MM

SCREWS 30MM

SCREWS 30MM

SCREWS

6

Secure the Door Weather

Strip to the side you want the

hinges, and ensure it’s ush to

the oor and against the face

of the wall panel framework.

Attach the Slamming Strip, to

the wall panel shown below.

This will be on the opposite

side you want the hinges.

PLEASE

NOTE

Screwing the

door weather

strip onto the

side panel

determines

the side of

your hinges.

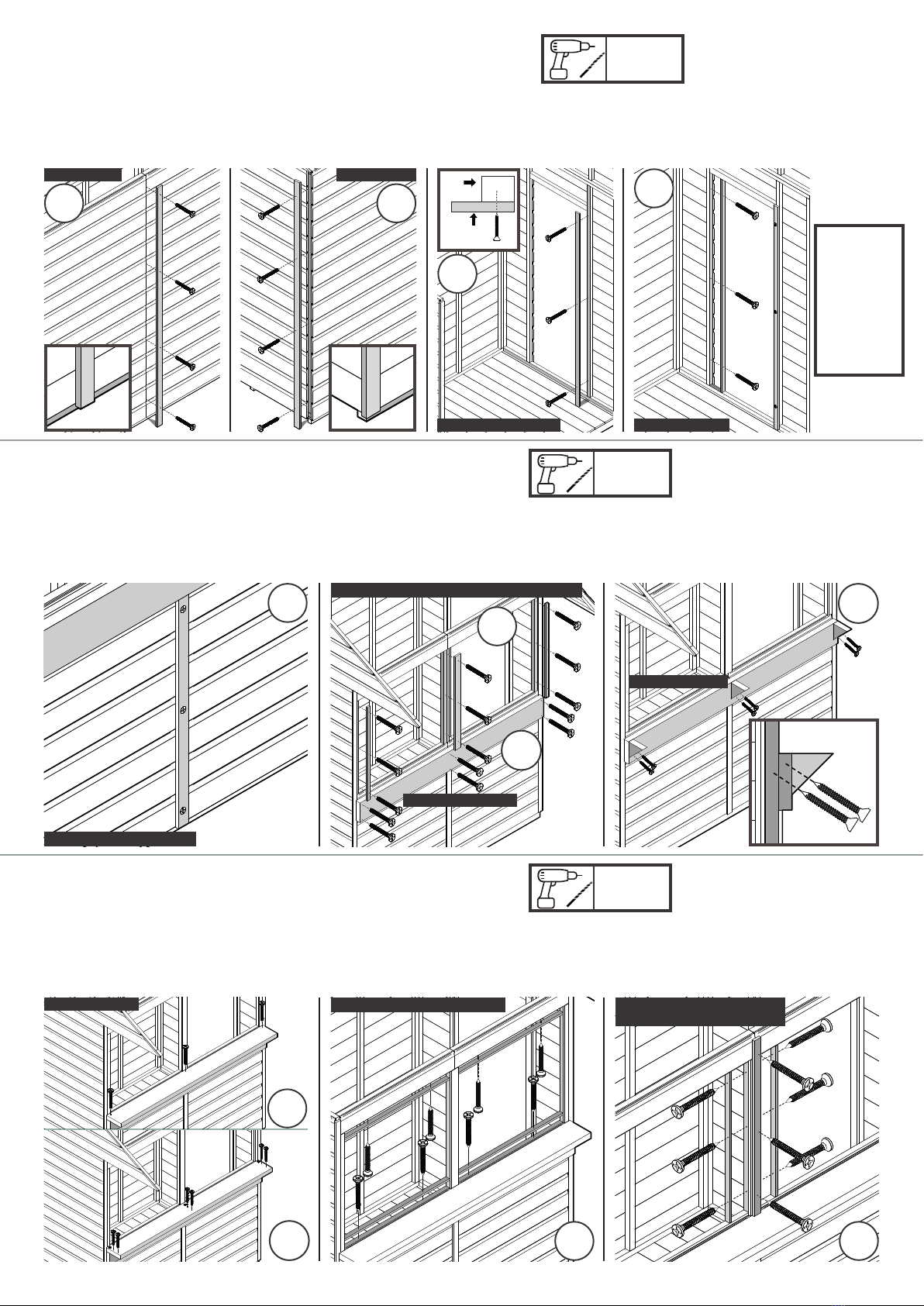

2COVER STRIPS & DOOR STRIPS

Attach the Cover Strip to the

adjoining panels. Ensure it is

ush to the bottom edge of

the panels as shown below.

COVER STRIPS COVER STRIPS

DOOR WEATHER STRIP

3b TABLE & WINDOW ASSEMBLY

3a TABLE & WINDOW ASSEMBLY

Attach the Top Table Piece. Secure to the

Table Back Piece at each end and in the centre.

Then use 50mm screws to secure to the angled

braces.

Attach the Top and Bottom Window Strips.

Repeat this process for the other window

opening. Ensure the strips are ush to the

window opening.

First attach the Smaller Cover Strip to the

adjoining window panels as shown below. You

will need this to position your bar table for the

correct height.

Attach the Window Cover Strips with 30mm

screws. Position and ensure your Table Back

Piece is ush end to end and sitting on the

Smaller Cover Strip underneath. Fix with

70mm screws.

Attach the Angled Braces to the Table Back

Piece. Angle the screws to secure the braces

into place. Ensure the end Angled Braces are

ush to the edge and the other is central.

SLAMMING STRIP

Attach the Cover Strips to the

corners. Ensure they are ush

to the bottom edge of the

panels as shown below.

COVER STRIP (40 x 12 x 828)

TABLE BACK PIECE

COVER STRIPS (28 x 12 x 791) & (56 x 12 x 791)

ANGLED BRACE

TABLE TOP PIECE

Secure the two Window Opening Side Strips

as shown below. Attach the middle Window

Cover Strip.

WINDOW STRIPS (28 x 12 x 829) WINDOW STRIPS (28 x 12 x 765)

COVER STRIP (40 x 12 x 890)

28mm

223mm

55mm

223mm

461mm

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW

25MM

SCREWS 25MM

SCREWS

25MM

SCREWS

30MM

SCREWS

30MM

SCREWS 30MM

SCREWS 30MM

SCREWS

7

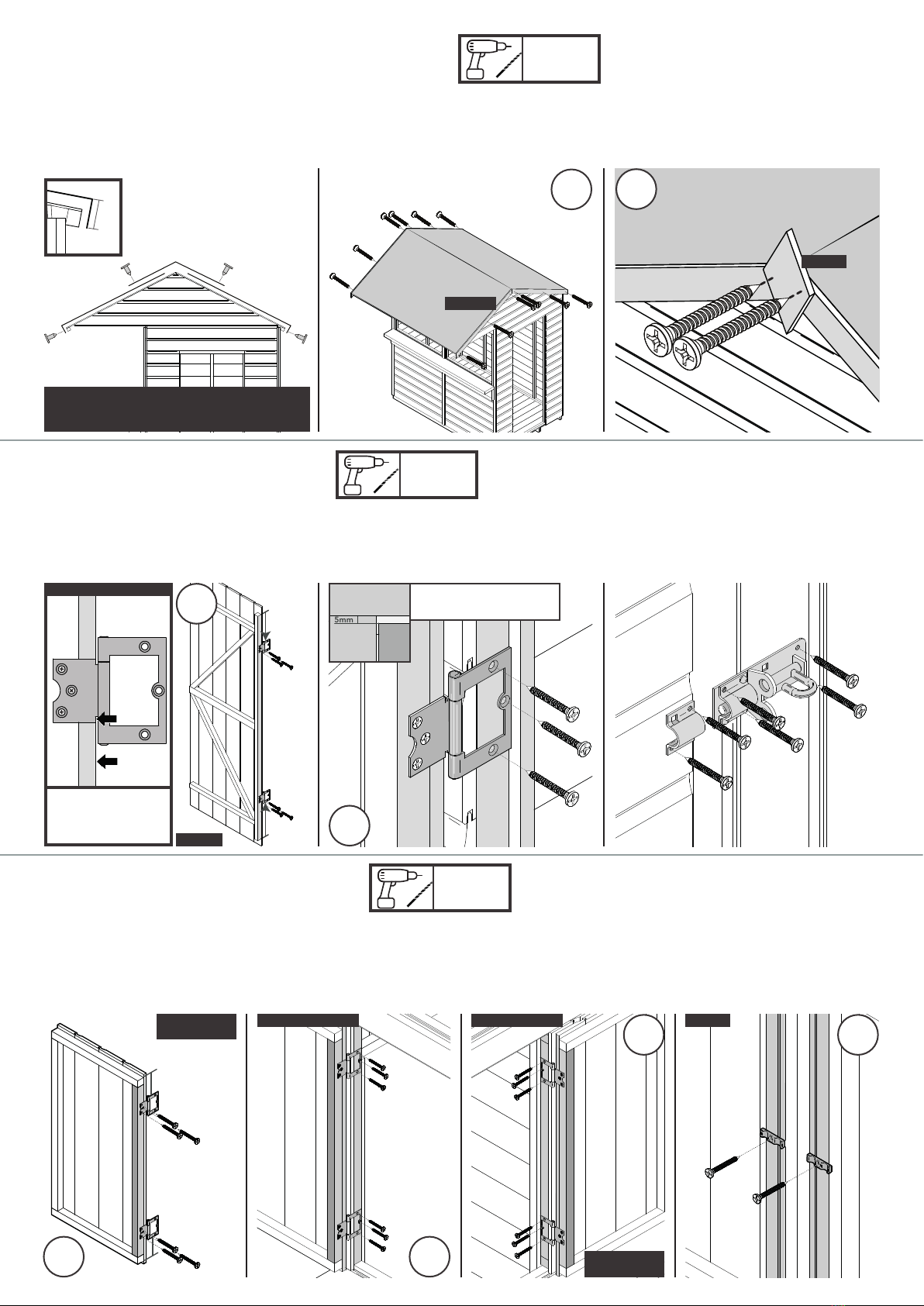

4a ROOF OVERHANG

4b ROOF STRUCTURE

Attach a Z-bracket to each end of the Beam

as shown below. Repeat the process for all

Beams. The Beam should be ush to the

Z-bracket.

Position 3 x Beams to the Apex Sections, in

the overhang section using the measurements

below as a guide.

Secure the Beams to the Apex Sections from

underneath into the attached Z-Brackets.

Position the Beams on your roof and use

the measurement provided before securing in

place. Ensure you are measuring in between

the Beams as shown below.

Screw the Z-brackets to the Apex Sections to

secure the Beams as shown below.

Position the OSB sheet for the overhang.

Ensure the OSB is ush and ts in between the

Apex Sections as shown below. Secure the

OSB sheet to the Apex Sections.

Z-BRACKET

4c OSB ROOF SHEETS

Secure the OSB sheet to the Beams. Mark

out where the beams are positioned before

pre-drilling.

Attach a Roof Strip to your OSB Roof Sheet.

Ensure the Roof Strip is ush to the edge of

the sheet. Repeat for the other OSB Roof

Sheet.

Screw the OSB Roof Sheets into position

as shown below into the Apex Sections, wall

panels and Beams beneath.

BEAM

BEAM

OSB OVERHANG SHEET

(636 x 1826)

OSB ROOF SHEET

(1105 x 1858)

ROOF STRIP (28 x 28 x 1858)

BEAM

175mm

175mm 5mm

Allow a 5mm gap at the

top when tting the door.

DOOR FACE

NOTCH IN

LINE WITH

DOOR FACE

DOOR

Make sure the outer

face of the notch on

the hinge is in line

with the door face.

HINGE POSITION

100mm

100mm

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW

50mm

40MM

SCREWS

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW.

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW

25MM

SCREWS

25MM

SCREWS

25MM

SCREWS

25MM

SCREWS 25MM

SCREWS

25MM

SCREWS 25MM

SCREWS

8

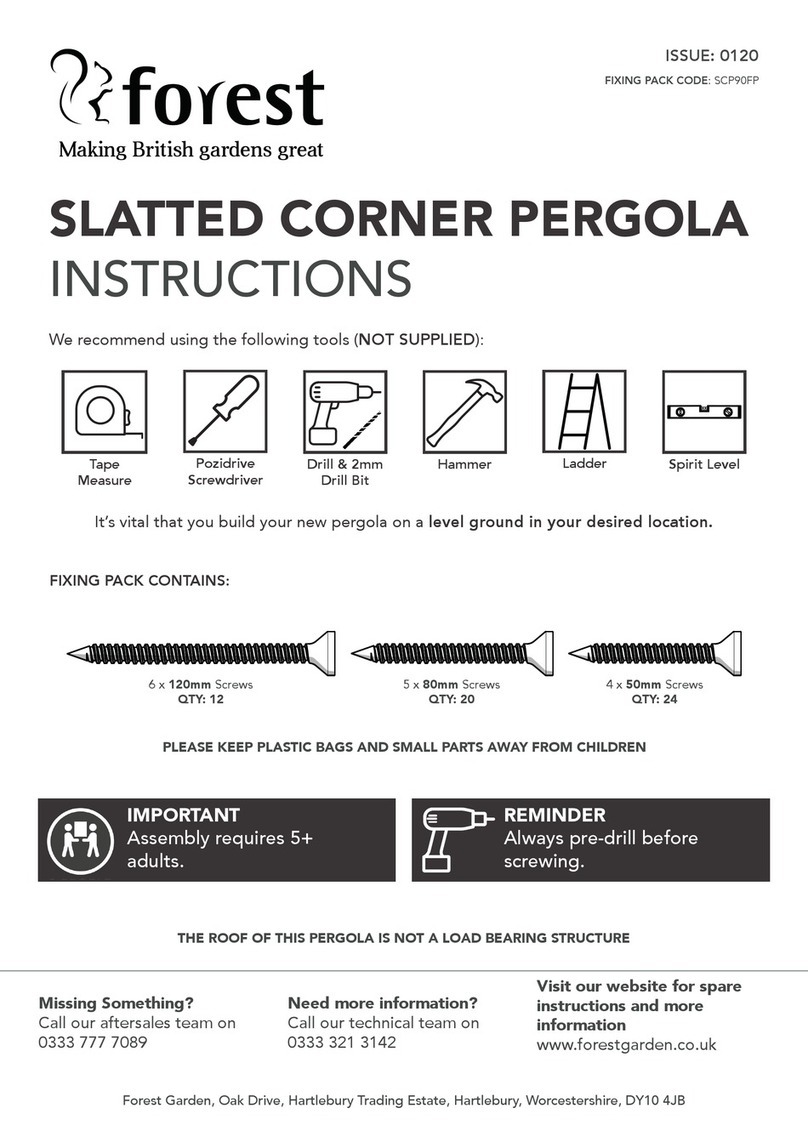

4d FELT, FASCIAS & FINIALS

5a DOOR FIXINGS

Measure out 3 equal lengths and overlap

on the top, around the edges and fold the

corners; tack to keep secure. Ensure there is

a 50mm overhang, working from the bottom

to the top.

Secure the Fascias as shown below. Ensure to

screw the Fascias into the framework behind.

Secure the Finials as shown below. Ensure to

screw the Finials into the Fascias behind.

Attach 2 x hinges to the door frame using the

measurements provided. Please take note of

the hinge position shown below.

Place the Door into the opening, ensuring it

is level. Make sure the hinges are up against

the Door Weather Strip face. Secure the hinges

in place.

Fix the Padbolt as shown below. Ensure

the screws for the lock go into the Door’s

framework behind. Attach the receiver to the

panel’s framework.

5b SHUTTER FIXINGS

Attach 2 x hinges onto the Outside Shutter frame with the

measurements provided. Please take note of the hinge position shown

above. Secure the shutter to the window opening as shown below.

Ensure the shutter is positioned centrally. Repeat this process for the

other Outside Shutter.

Attach 2 x hinges onto the Inside

Shutter frame (with the lip) with the

measurements provided. Secure

the Inside Shutter to the Outside

Shutter. Ensure the shutter is

positioned centrally.

Position centrally and attach

the turn buttons, onto the Inside

Shutter frame. Ensure when the

buttons turn, they catch the side

window strips to hold the shutters

in place.

TOP TIP: Use a measuring tape to measure out

3 equal lengths & cut with a sharp knife. Hammer the

tacks into the felt. Add the tacks at 150mm intervals.

FASCIAS

FINIAL

DOOR

INSIDE SHUTTER INSIDE

SDP63GBARIS

WITH LIP

SDP63GBAROS

WITHOUT LIP

OUTSIDE SHUTTER

PRE-DRILL WITH

2-3MM BIT

FOR ALL STEPS

BELOW

25MM

SCREWS 25MM

SCREWS

Label Part Code

Description No.

AMSBFL46

Floor (1180x1826mm) 1

BSDM885TPP

Section A - 3ft Panel (885x1945mm) 2

CSDPGB885WP

Section B - 3ft Window Panel (885x1945mm) 2

DSDM1180TPP

Section C - 4ft Panel (1180x1945mm) 1

ESDM1180TDP

Section D - 4ft Door Panel (1180x1945mm) 1

FSDAMPEA6

6ft Apex Section (474x1828mm) 2

G40121925PDT

Cover Strip (40x12x1925mm) 5

H38121710PDT Door Weather Strip (38x12x1710mm) 1

I28121637PDT

Slamming Strip (28x12x1637mm) 1

J40120828PDT

Small Cover Strip (40x12x828mm) 1

K28120791PDT

Window Cover Strip (28x12x791mm) 2

L56120791PDT

Window Cover Strip (56x12x791mm) 1

M165401794PDT

Table Top & Back Pieces (165x40x1794mm) 2

N120400120PAI45DT

Angled Brace (120x40x120mm) 3

O28120829PDT

Window Opening Top & Bottom Strip (28x12x829mm) 4

P28120765PDT

Window Opening Side Strip (28x12x765mm) 2

Q40120890PDT

Window Cover Strip (40x12x890mm) 1

R45281770 Beam (45x28x1770mm) 7

SOSB18266368

OSB Overhang Sheet - (636x1826x8mm) 1

TOSB185811058

OSB Roof Sheet - (1105x1858x8mm) 2

U28281858 Roof Strip (28x28x1858mm) 2

V59121145PAII63DT

Fascia (59x12x1145mm) 4

WFIN20010512DTR

Finial (105x12x200mm) 2

XMSDDR

Door (582x1692mm) 1

YSDP63GBAROS

Outside Shutter Door - Without Lip (410x780mm) 2

ZSDP63GBARIS Inside Shutter Door - With Lip (410x780mm) 2

AA 1

6' x 4' Reverse Apex Garden Bar (SDA46GBAR)

Felt - Please contact our aftersales team with your product code if you are missing your felt.

9

Use the labelled components on the next page to help identify the part code and description.

5c SHUTTER & DOOR FIXINGS

Screw your hook to the Inside Shutter and

secure your receiver to the panel into the

framework behind. Repeat the process for

both sides.

Line up the hook and eye and mark the

edges with a pencil for guidance. Ensure the

hook and eye are level and secured to the

framework behind.

CHECK YOU HAVE ALL YOUR PARTS PRIOR TO ASSEMBLY.

(The parts do not have codes on them. They are listed below should you need to order one.)

Timber is a natural material of which will shrink and swell as a result of varying moisture content.

Assembly of damaged parts may be deemed to be acceptance and this may affect the remedies you are entitled to. If the product is not constructed

in accordance with the instructions, or is altered in anyway (e.g. painted), the manufacturer cannot be held liable for any resulting damage.

The components provided may be heavy. Please lift with caution and with a minimum of 2 people.

Fix a Turn Button to the top and bottom

of the door panel. Ensure to screw into the

framework behind and once turned, the Door

is held in place.

10

H I J K L M N O P Q R

S T U V W X Y Z AA

A B C D E

F G

CHECK AND TIGHTEN ALL THE FIXINGS APPLIED TO THIS PRODUCT ON A REGULAR BASIS.

Table of contents

Other Forest Lawn And Garden Equipment manuals

Forest

Forest SCP90 User manual

Forest

Forest SBP43M User manual

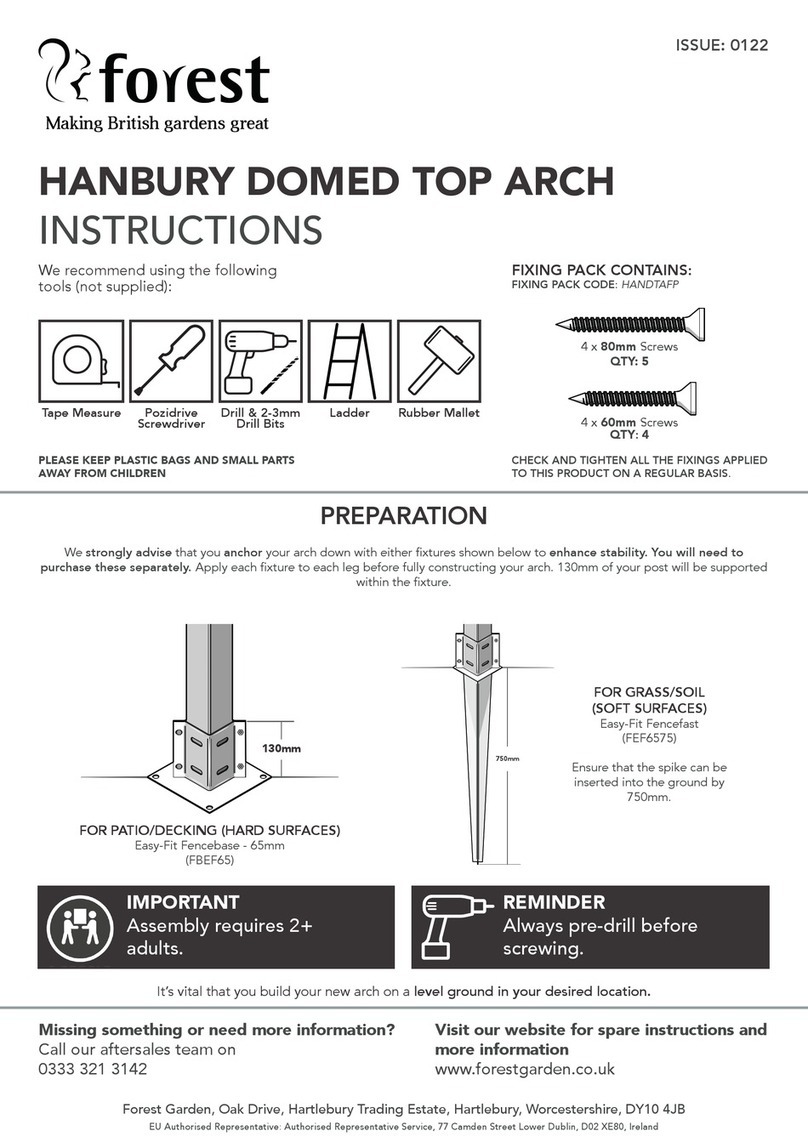

Forest

Forest HANBURY DOMED TOP ARCH User manual

Forest

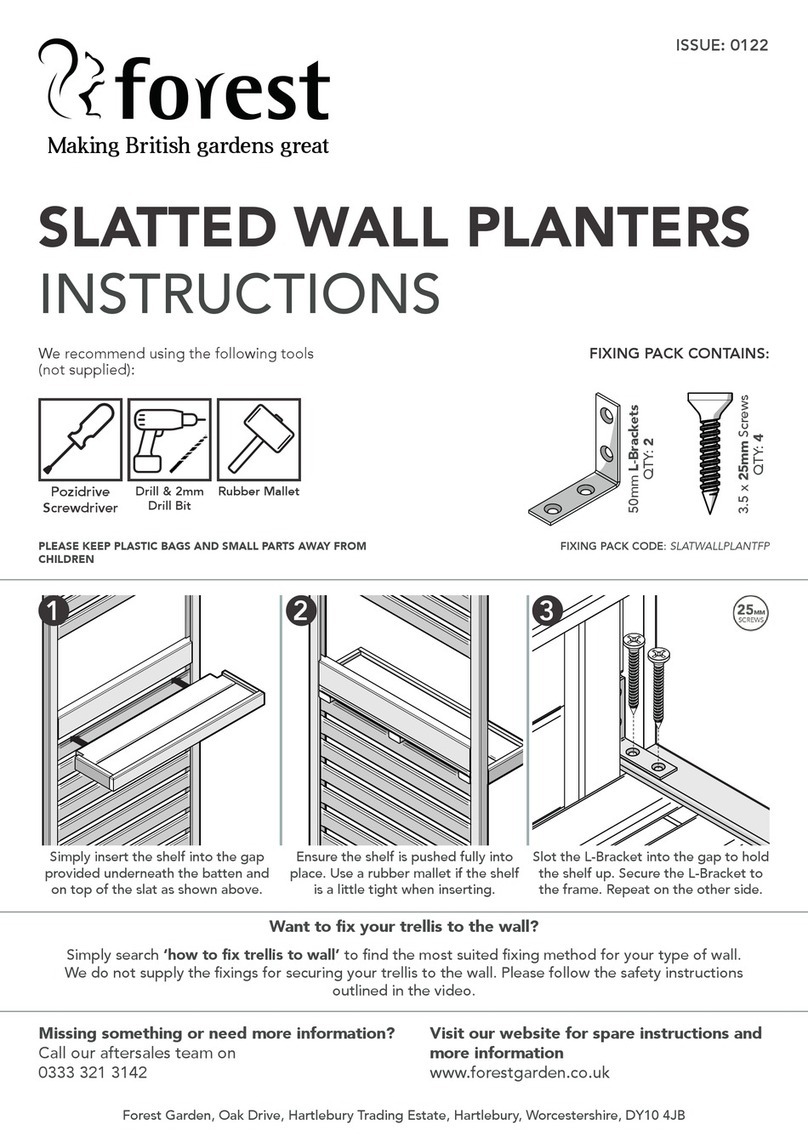

Forest SLATWALLPLANT1 User manual

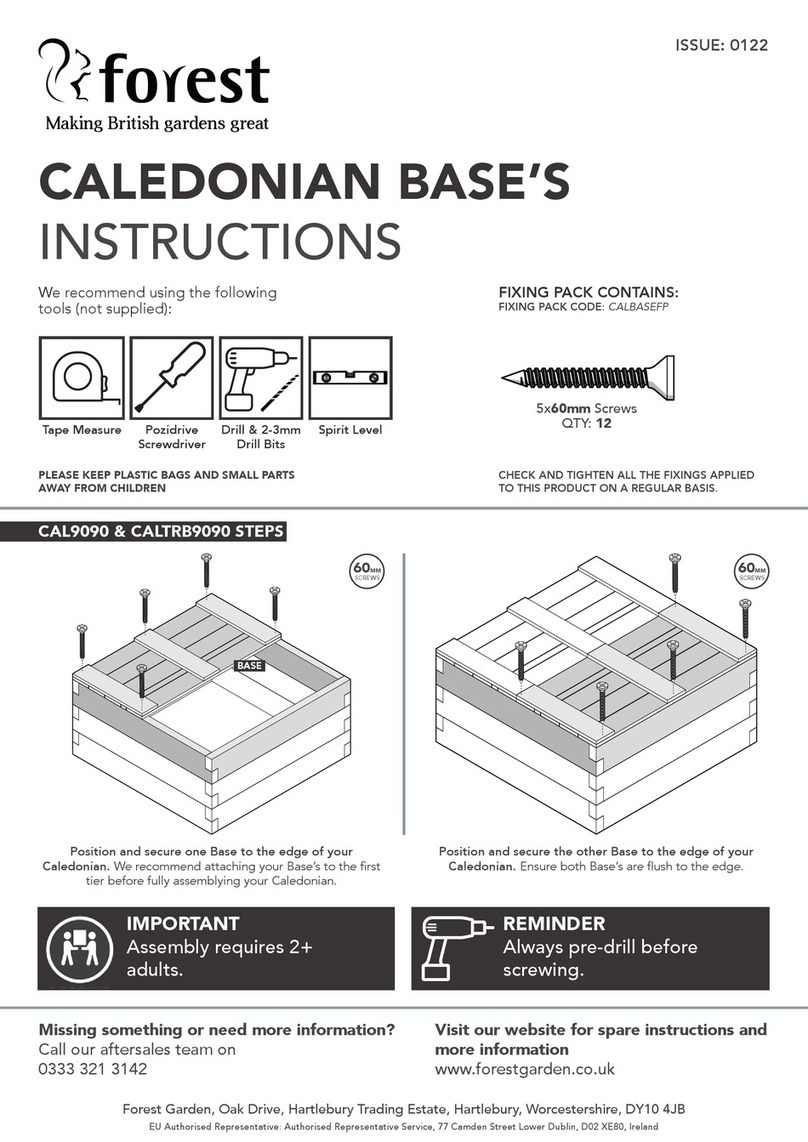

Forest

Forest CALEDONIAN CALBASEPK2 User manual

Forest

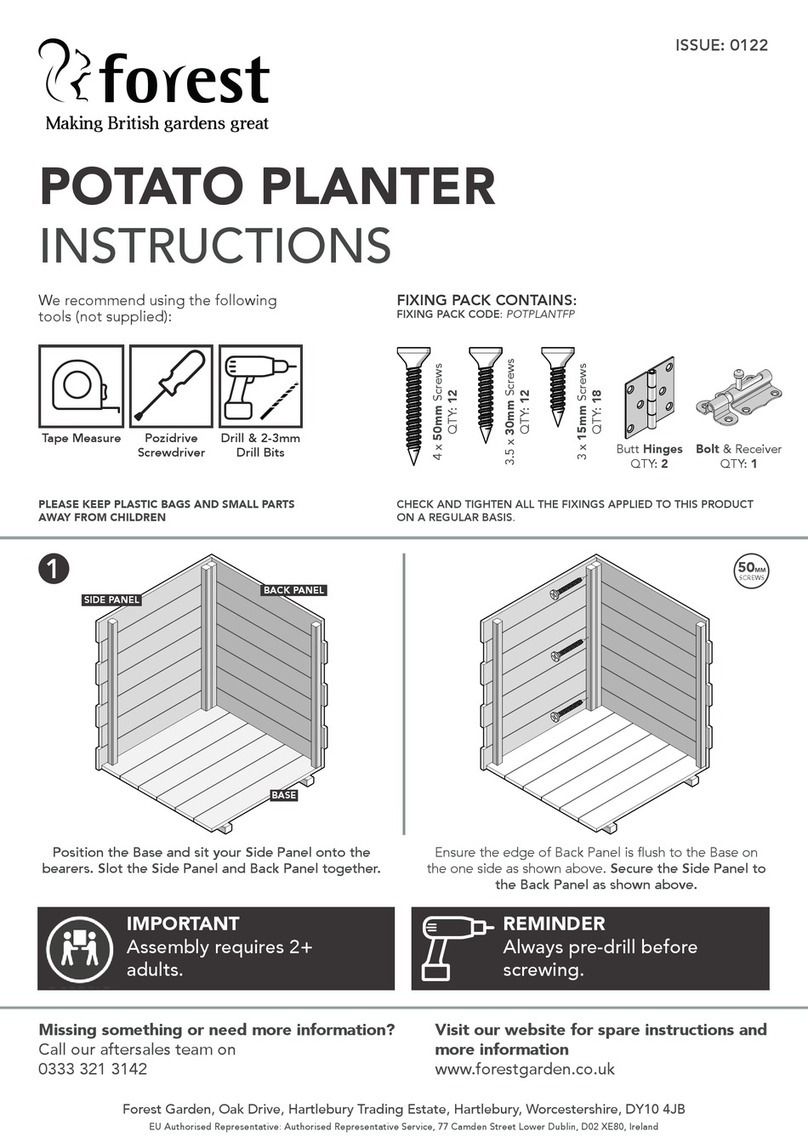

Forest POTATO PLANTER User manual

Forest

Forest 2.4M ULTIMA PERGOLA Manual

Forest

Forest OVERLAP APEX LOG STORE User manual