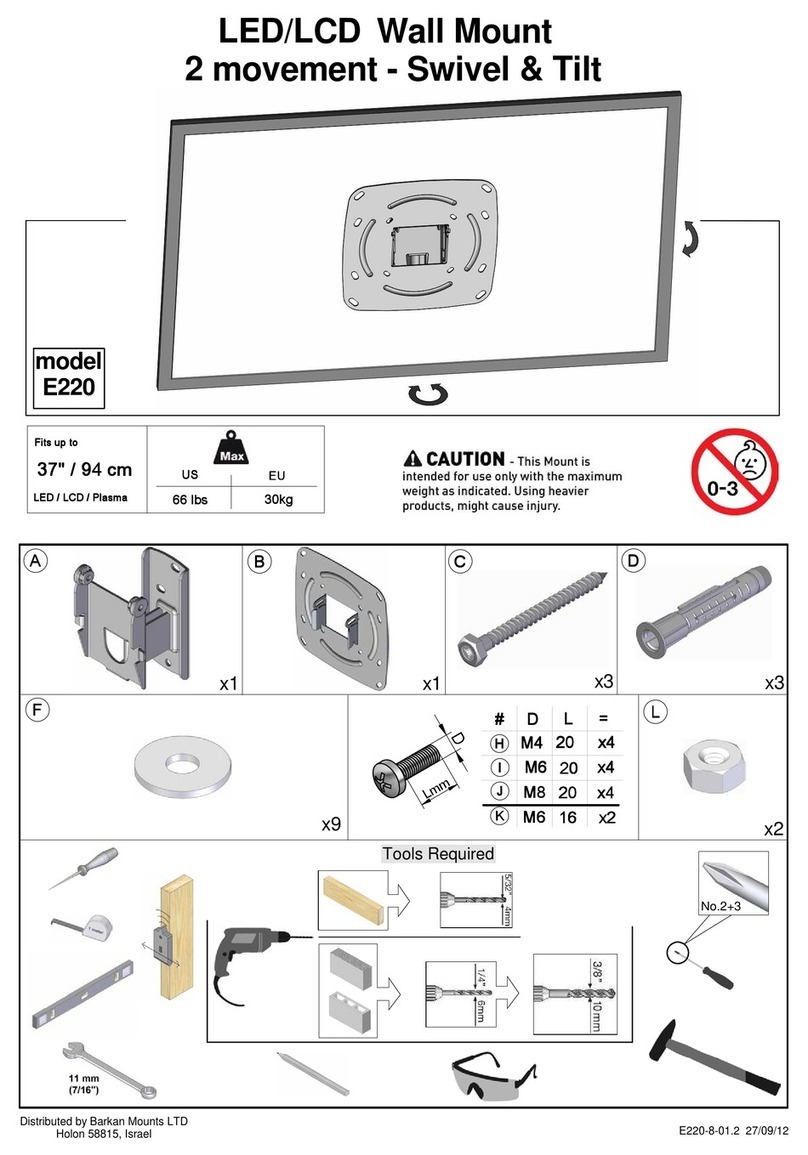

M6

M4 M8

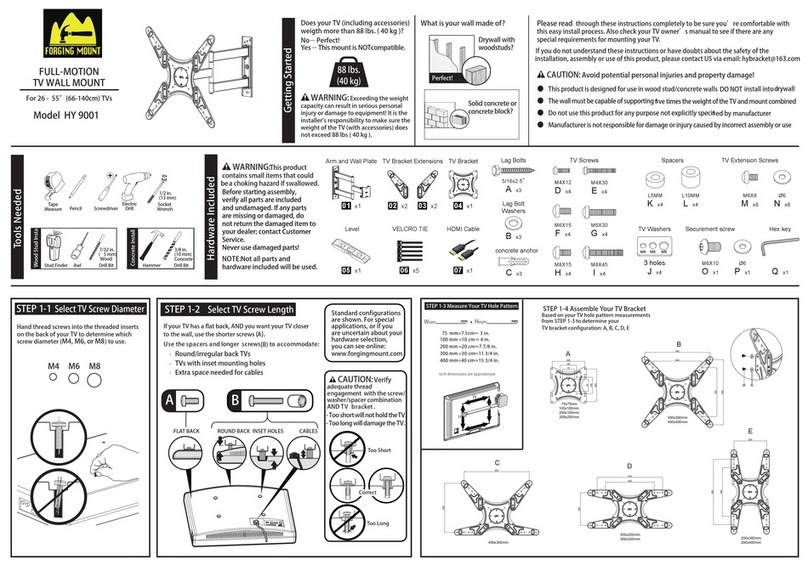

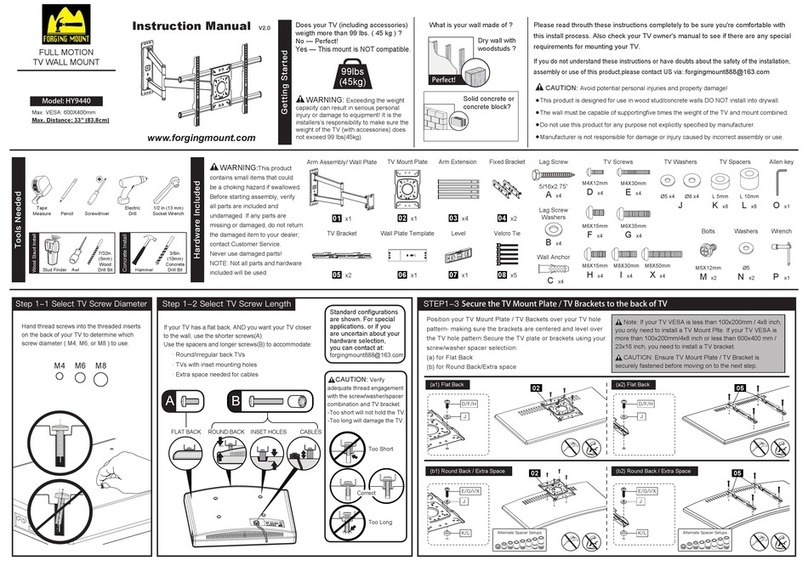

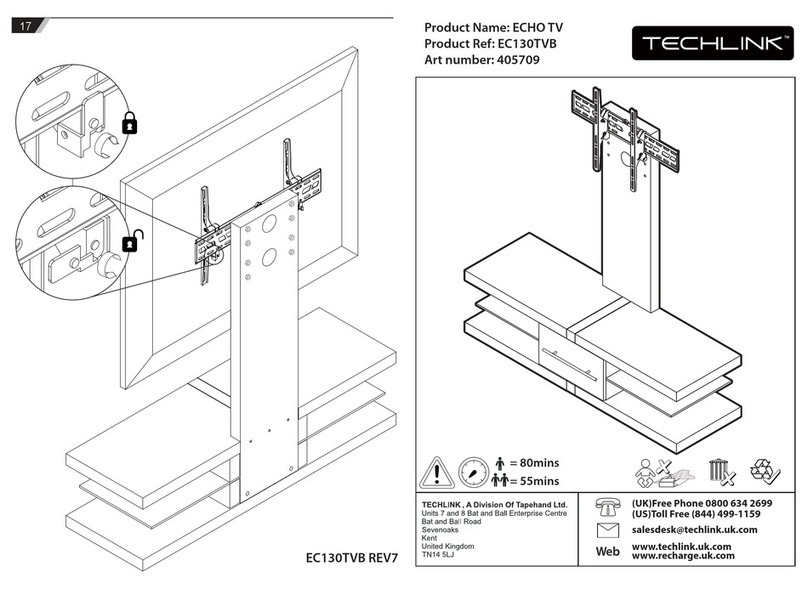

STEP 1-1

Select TV Screw Diameter

STEP 1-2

Select TV Screw Length

FLAT BACK ROUND BACK CABLESINSET HOLES

AB

Too Short

Too Long

Correct

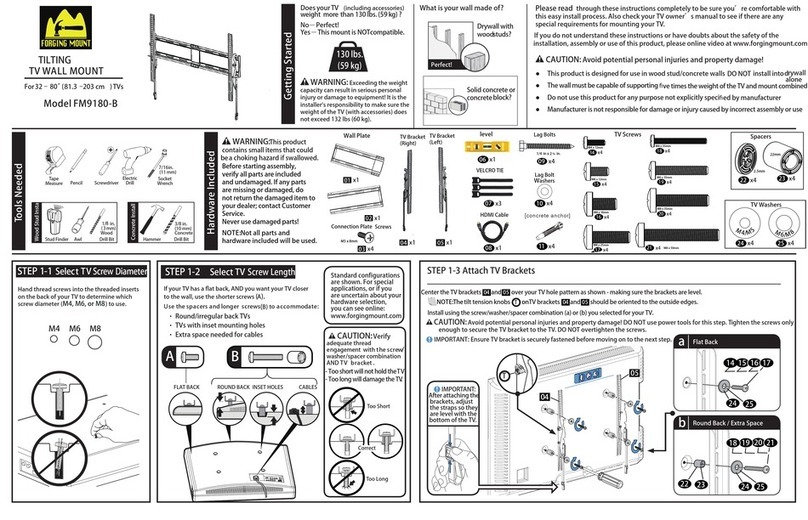

150 lbs.

(68 kg)

Does your TV (including accessories)

weigth more than 150 lbs. ( 68 kg )?

—

Perfect!

Y

—

This mount is NOT compatible.

If your TV has a flat back, AND you want your TV closer

to the wall, use the shorter screws (A).

Use the spacers and longer s crews

(B) to accommodate:

·Round/irregular back TVs

·TVs with inset mounting holes

·Extra space needed for cables CAUTION Verify

adequate thread

engagement with the screw/

washer/spacer combination

AND TV bracket .

- Too sho will not hold the TV.

- Too long will damage the TV.

Standard configurations

are shown. For special

applications, or if you

are uncertain about your

hardware selection,

you can see online:

www.forgingmount.com

Hand thread screws into the threaded inserts

on the back of your TV to determine which

screw diameter (M4, M6, or M8) to use.

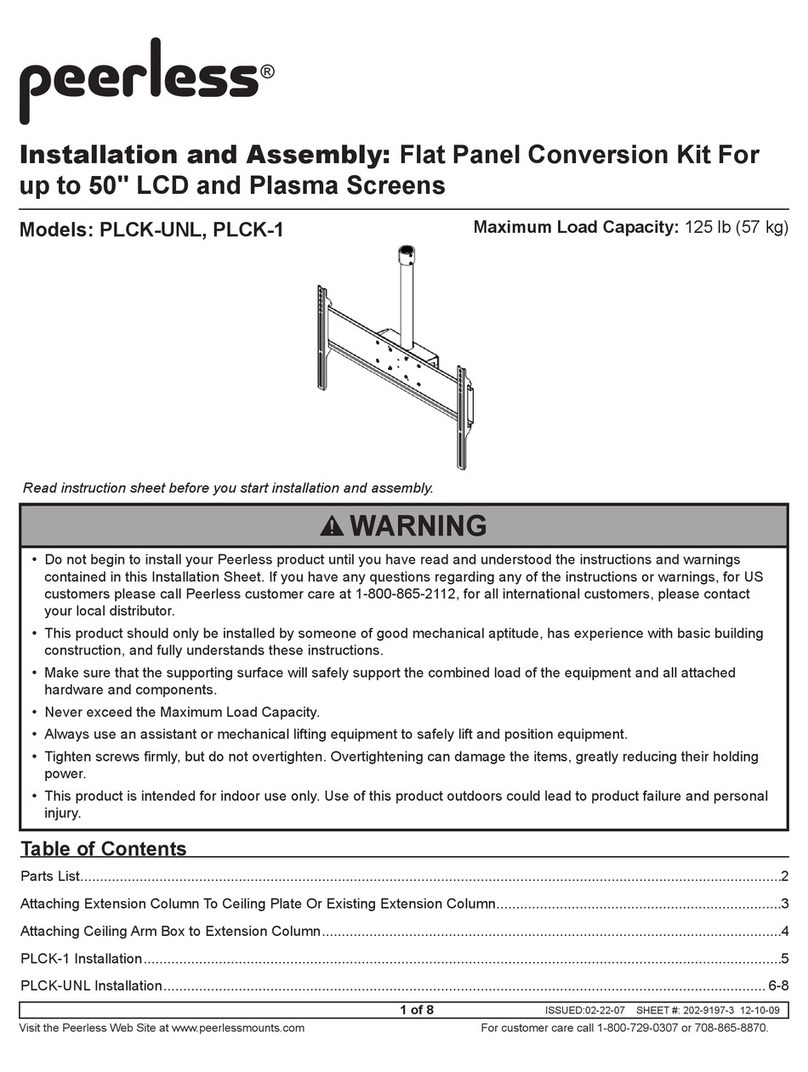

WARNING Exceeding the weight

capacity can result in serious personal

injury or damage to equipment! It is the

installer's responsibility to make sure the

weight of the TV (with accessories) does

not exceed 150 lbs ( 68 kg ).

Drywall with

woo studs?

Perfect!

What is your wall made of?

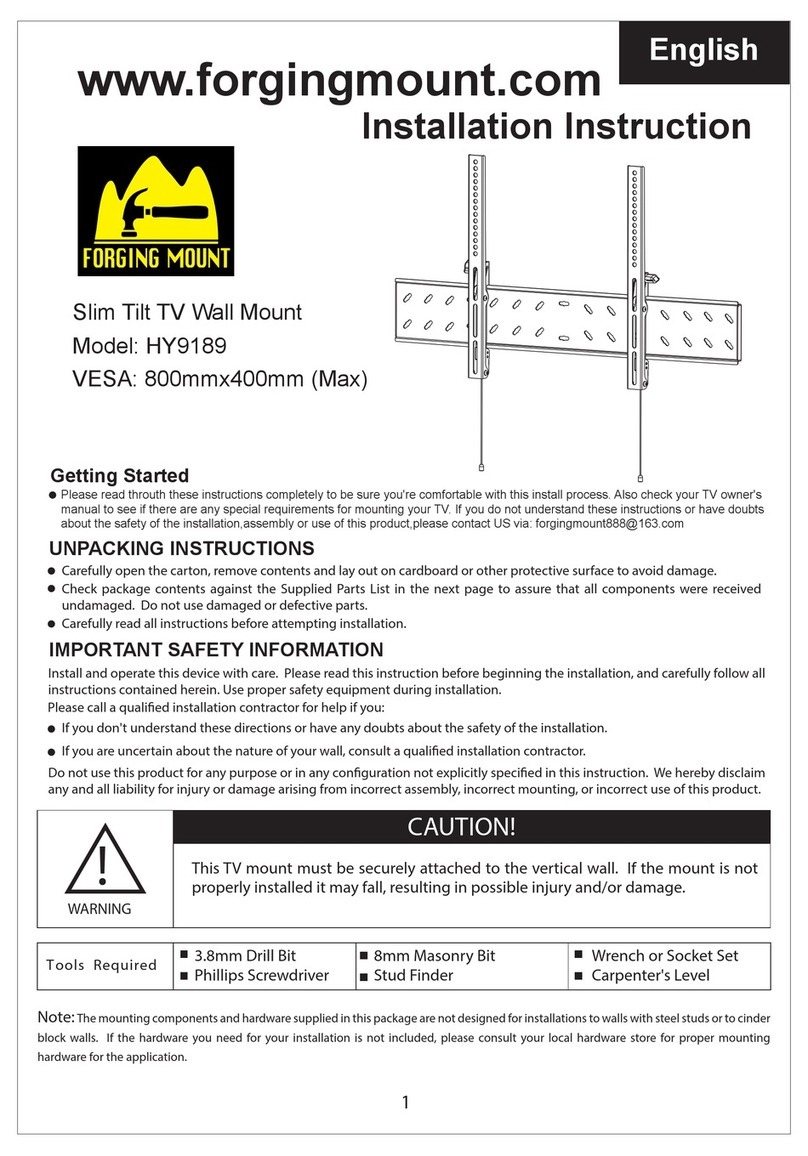

Please read through these instructions completely to be sure you’re comfortable with

this easy install process. Also check your TV owner’s manual to see if there are any

special requirements for mounting your TV.

If you do not understand these instructions or have doubts about the safety of the

installation, assembly or use of this product, please contact US via:

[email protected] CAUTION:

Avoid potential personal injuries and property damage!

●This product is designed for use in wood stud/concrete walls DO NOT install into

drywall

●The wall must be capable of supporting ve times the weight of the TV and mount combined

●Do not use this product for any purpose not explicitly speci ed by manufacturer

●Manufacturer is not responsible for damage or injury caused by incorrect assembly or use

Solid concrete or

conc et block?

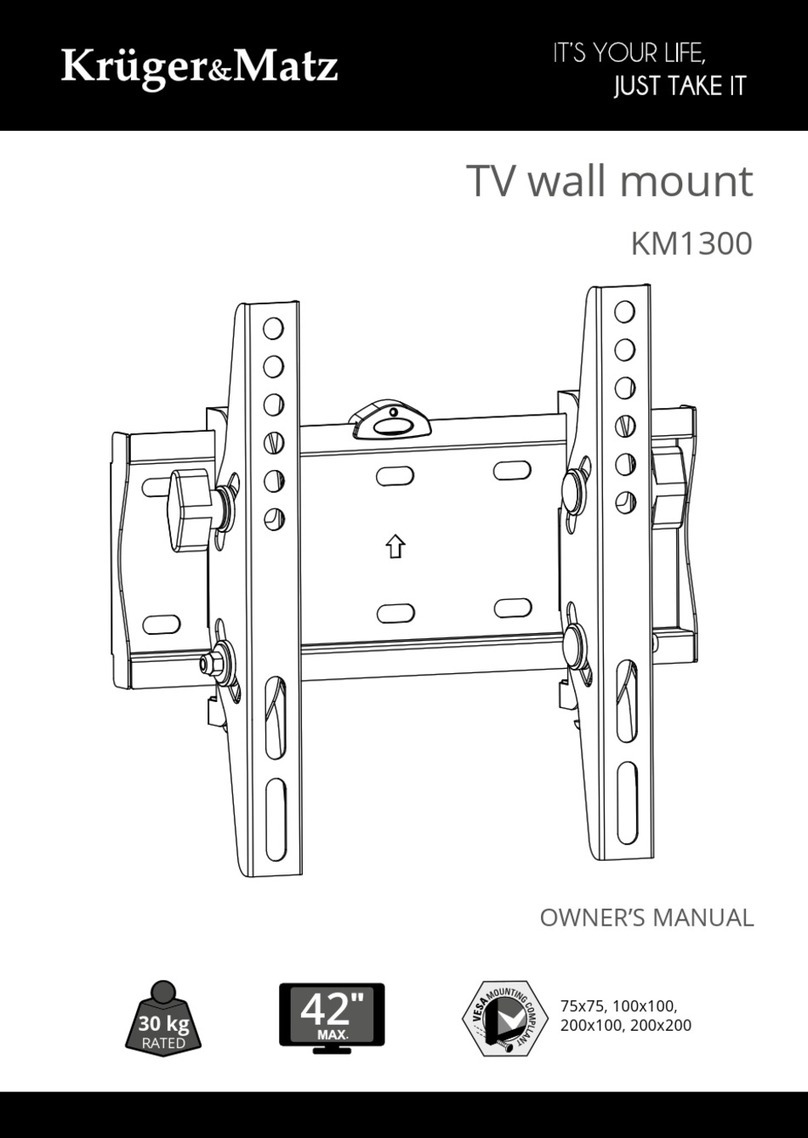

Tools Needed

Hardware Included

WARNING: This product

contains small items that could

bea choking hazard if swallowed.

Before starting assembly,

verify all parts are included

and undamaged. If any parts

are missing or damaged, do

not return the damaged item to

your dealer; contact Customer

Service.

Never use damaged parts!

NOTE: Not all parts and

hardware included will be used.

Concrete Install

Hammer Drill Bit

3/8 in.

(10 mm)

Concrete

Wood Stud Install

AwlStud Finder

5/32 in.

( 4 mm)

Wood

Drill Bit

Pencil Screwdriver

Tape

Measure Electric

Drill

1/2 in.

(13 mm)

Socket

Wrench

fi

fi

No

es

Getting Started

:

d

er

rt

:

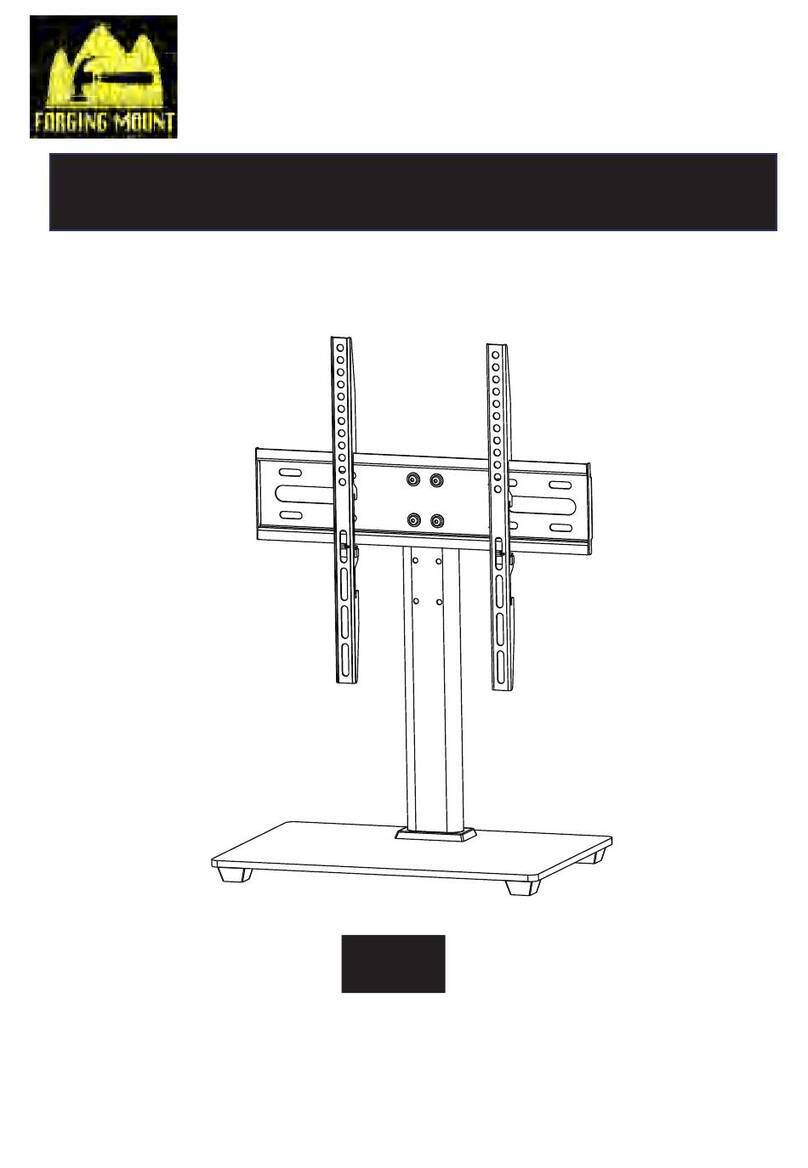

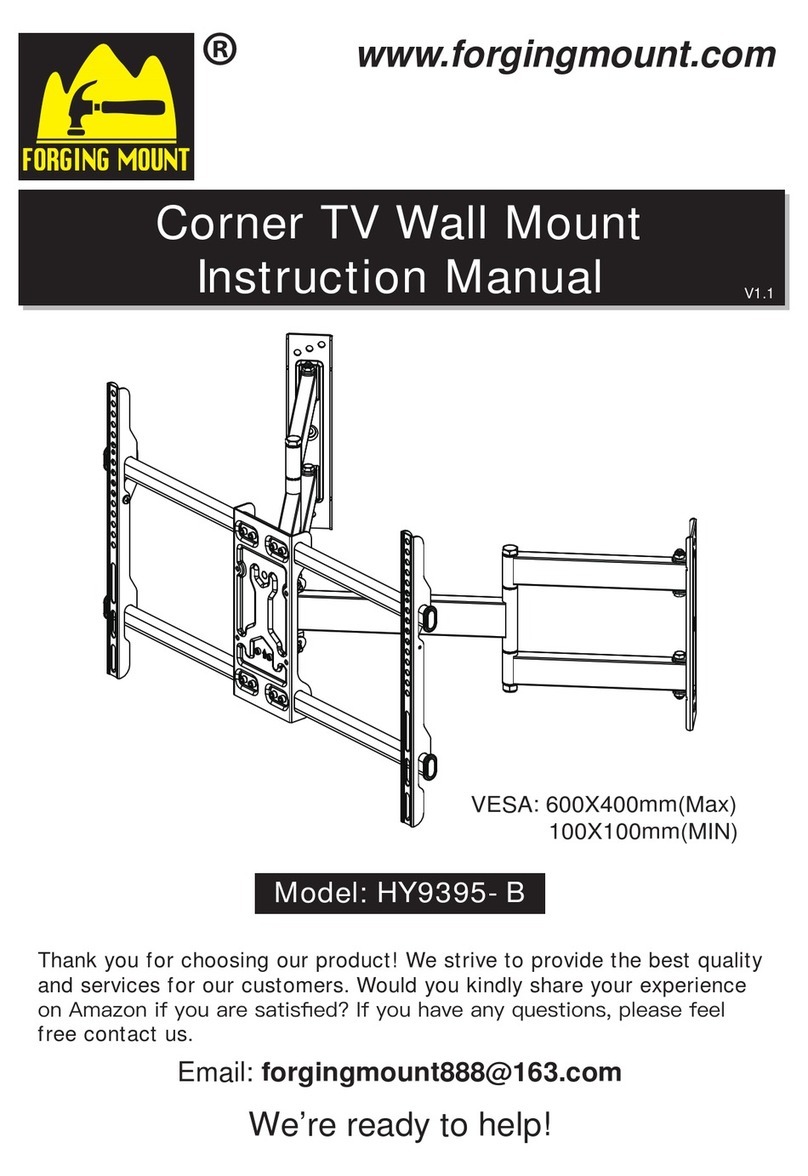

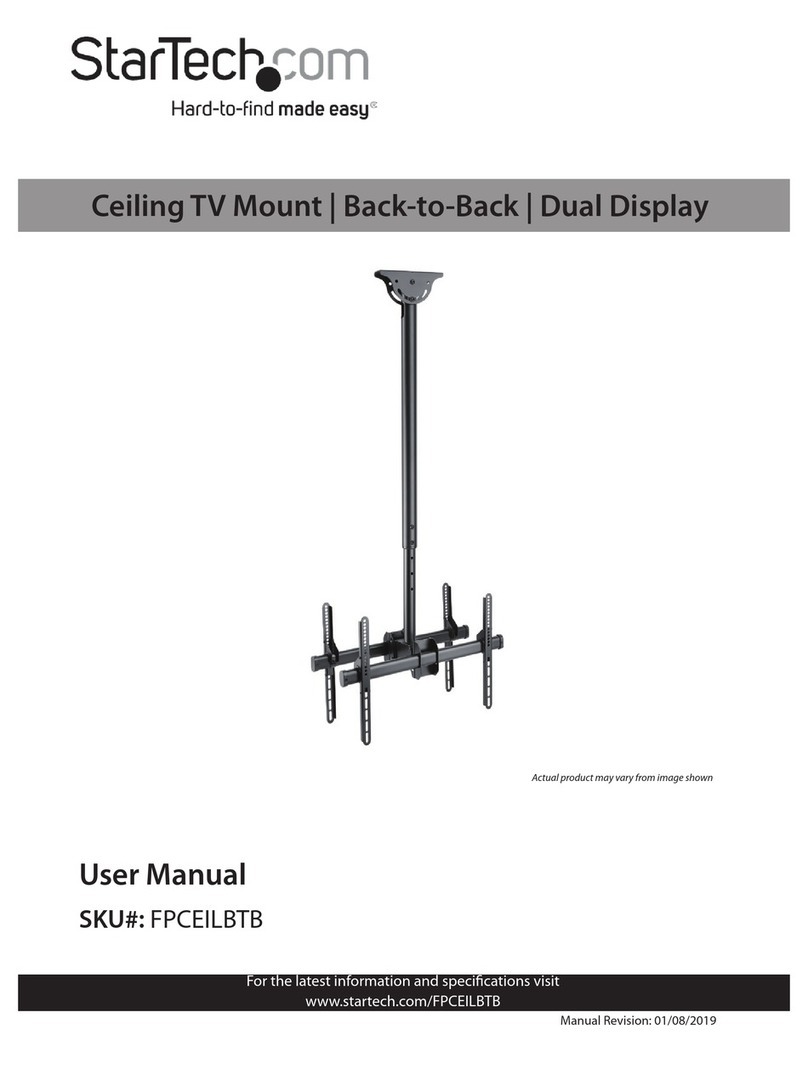

LONG ARM

TV WALL MOUNT

Model HY9393-B

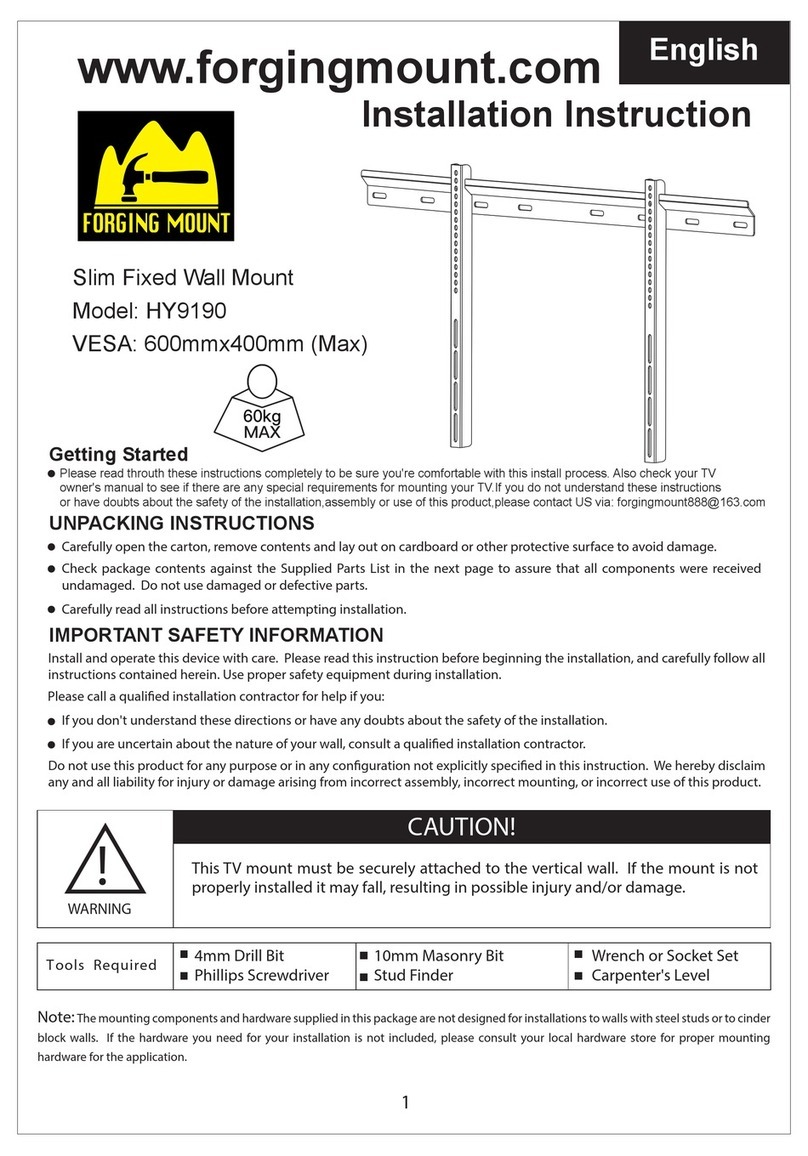

Specification Sheet

Installation Instruction

Supplied Parts List

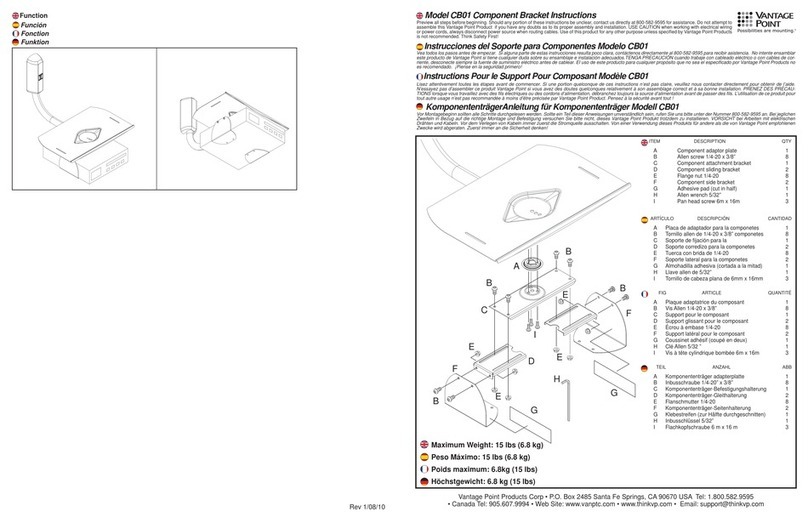

(4)M8 Washer-F

(4)M6x35 Bolt-K

(8)5mm M6/M8

Spacer-B (6)Lag Bolt Washer-X

(1)Left Monitor Bracket

(4)M4x12 Bolt-G

(4)M8x20 Bolt-L

(4)20mm M6/M8

Spacer-C

(6)M8x90mm Lag Bolt-Y

(1)Right Monitor Bracket

(4)M4x30 Bolt-H

(4)M8x35 Bolt-M

(4)M4 Washer-D

(6)M10x80mm

Concrete Anchor-Z

(1)Allen Key

(4)M6 Washer-E

(4)M6x20 Bolt-J

(4)M4 Spacer-A (4)M8x45 Bolt-N

(1)Wall Plate

(2)Plastic Knob

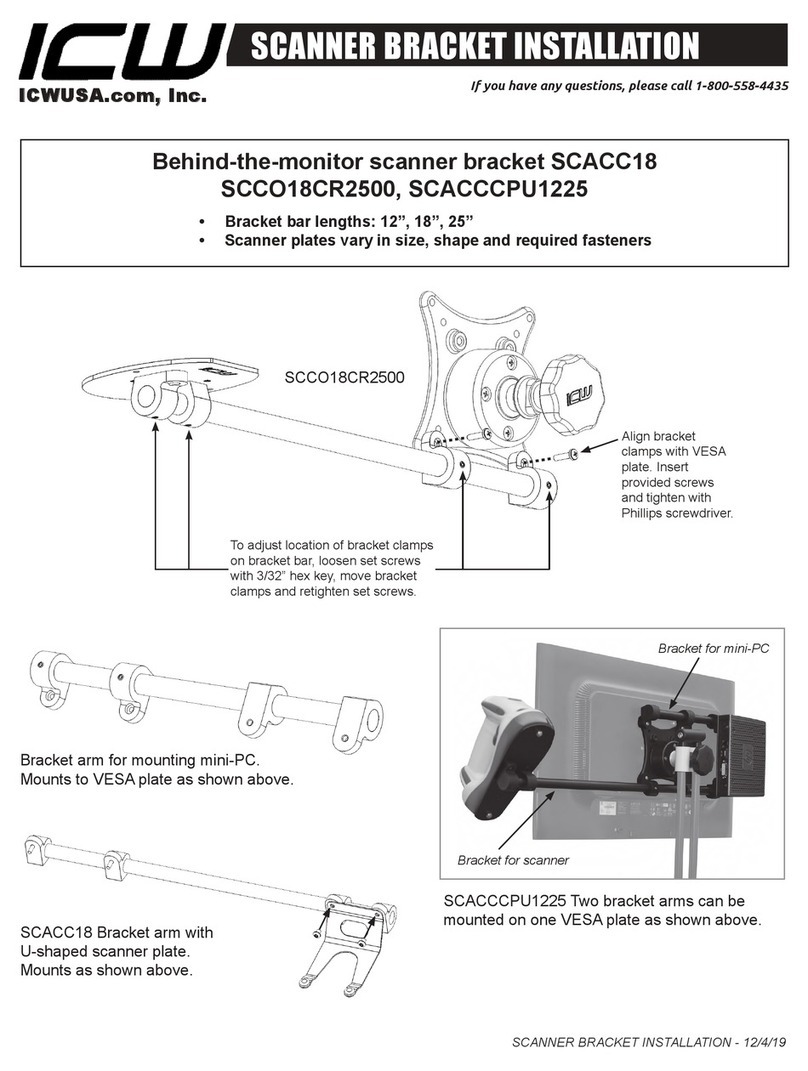

Pls install the Plastic Knob on the Monitor

Bracket as left diagram before do the next step.

Pls note the two knobs should be installed in

the opposite way on the two monitor brackets.

(1)bubble Level-I

(3)VELCRO TIE

(1)HDMI Cable